-

Posts

108 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Ross Moffett

-

Flowlife: Got some good points there! VFD's are maybe an option but I haven't managed to find one that is above 7.5 KW (10HP) and that one's already R10 000 ($718), getting a 3 phase motor wouldn't be a problem, they are quite widely available secondhand. As for motor size for a 9 GPM pump, I'd need a 14.5 hp motor. I've tried looking for phase converter's here but with little to no success... Thanks for the input.

-

Flowlife: I could maybe counter that by getting a PTO pump? I don't have 3 phase and getting it would be extremely expensive...

-

Thanks for all the advice! Ross.

-

Hmm, 33 metric tons aka 36 imperial tons...? I guess I'd have to get a cylinder which can run on tractor hydraulic oil or is there no difference?

-

Kozzy: Yes, it does have rear hydraulics (a 2640 PSI, 9.2 GPM pump), so technically I could just hook the press up to the tractor but do you think the oil reservoir would be big enough? If I did use the tractor's pump I'd be getting around 33 tonnes and 1.3" sec with a 6" cylinder, correct me if I'm wrong? 1Forgeur: Thanks for the advice.

-

Hi Y'all What are your thoughts on running a forging press off of a tractor PTO (New Holland 8030)? Thanks in advance.

-

Pity indeed. Well I guess the search continues . I may still have it tested if it doesn't cost too much $$ of course.

-

I would buy new but the price of hydraulics here is quite expensive, it was about $400 for a new 5 inch bore cylinder. Thanks for the advice. Ross.

-

Well.... that could be a problem...

-

It's about 14cm from the middle of one fitting to the other. Thanks for the reply. Ross.

-

Okay, I tested the cylinder using a compressor but it only extended about 3 cm and it was super stiff, I couldn't push it back in or out by hand. I think maybe it not being used in about 10+ years has something to do with this? I'll take it somewhere to have it checked out and maybe have clevis rod ends attached. But by my estimate the stroke is around 10 cm + or -. Ross.

-

Thanks for all the replies everyone! Great advice Ian, I will soon have access to a compressor and I'll test the cylinder. Ross.

-

Hello from Seattle / Bellingham, WA

Ross Moffett replied to Scott98118's topic in Introduce Yourself

Welcome aboard Scott! Ross -

I'll try that. Some guys I've been chatting too (not on IFI) have expressed their doubt of the cylinder being telescoping but hey, only one way to find out! Any concerns or suggestions for the press design, structurally? Ross.

-

Thanks for the reply! I''ve been trying to keep all the calculations in mind and I'll probably go for a 19 or 28 gpm pump (2 stage) run by a petrol engine because I don't have suitable power to be able to run an electric motor, the engine won't be under powered. Ross.

-

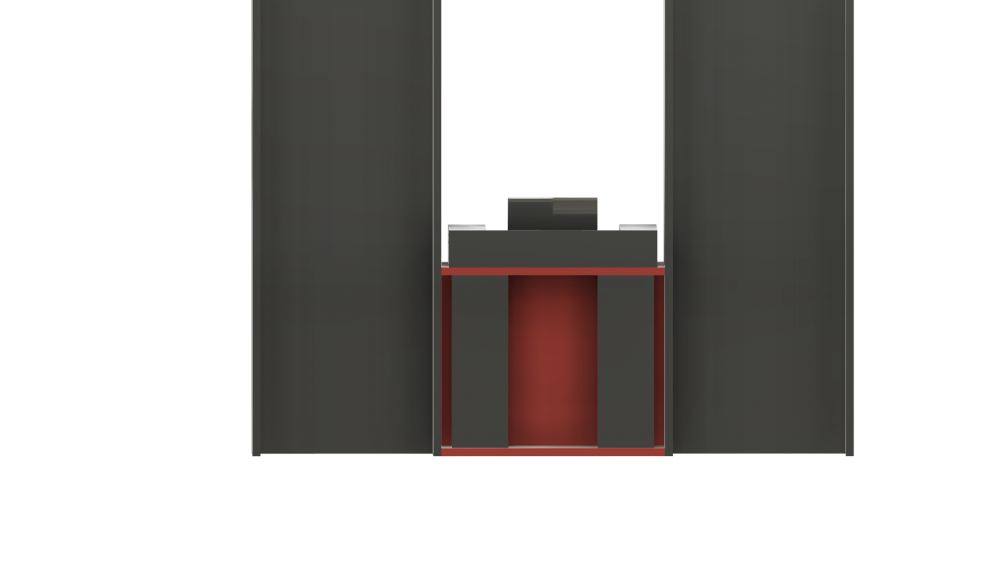

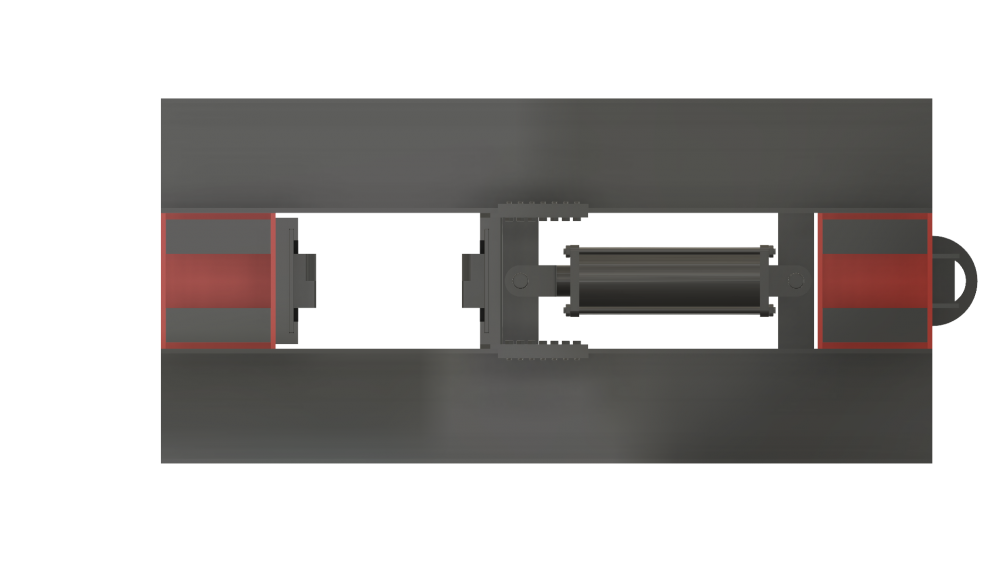

Update* My neighbor said I could take the cylinder and its free of charge! I've been working on a design and I just wanted to run it through for inspection! Note: This is a rough design and open to change/modification. Overall dimensions H 1304 mm (Cylinder included) W 863 mm Th 254 mm All input is appreciated! Ross

-

I was really hoping I'd be able to use it! I'll probably take it to some hydraulic experts and see if they can figure out its specs as it doesn't have any numbering or writing on it as far as I've seen anyways. My calculations say on a 8.2 in bore (I'm accounting for wall thickness) at 16 gpm I'll get 1.2 in per second. Good idea on having the non-ram side moveable! Ross.

-

Hi Y'all! Today I met one of my neighbors (I've recently moved) whose a retired electrical engineer. He was showing me his home built hydraulic log splitter and the some of the parts he'd gotten from an old punch press, long story short, he still had the cylinder from the punch press and he implied I could use it for building my forging press if I wanted to! So my question is if its suitable or not? I only got the rod and bore diameter's, rod is possibly 2 stage/telescoping? Bore size: 22 cm/ 8.66 in. Rod size (smaller): 7 cm/ 2.75 in. I'm estimating the stroke is around 8 inches, maybe less. Thanks in advance!

-

+1 for Damasteel, I haven't worked with the Austenitic "version" of it as I make knives and not jewelry, but definitely worth consideration. Ross.

-

Welcome aboard Charles. Where exactly are you in SA? Regards, Ross.

-

Jspool: Thanks will do. Regards.

-

Press Design - To have or not to have 45 degree joins?

Ross Moffett replied to Ross Moffett's topic in Presses

Thanks for all the replies and advice. I'm looking forward to starting this project. Ross. -

Press Design - To have or not to have 45 degree joins?

Ross Moffett replied to Ross Moffett's topic in Presses

BeaverNZ: Thanks. I think I will go the extra mile and box it in with stiffeners. Jspool: I'm aiming for around 30 tonnes. -

Press Design - To have or not to have 45 degree joins?

Ross Moffett replied to Ross Moffett's topic in Presses

Here's the updated design, I hope I did the correct modifications? Beaver NZ: How should I strengthen this design more? Ross. -

Press Design - To have or not to have 45 degree joins?

Ross Moffett replied to Ross Moffett's topic in Presses

Beaver NZ: Thank you for the reply sir. I will definitely change the frame then. Ross.

v5.thumb.png.23e77280d7ddbece7a945eb39aac7181.png)

v7.thumb.png.a586cec96ef60a12241fe6dc13b9f2ed.png)