-

Posts

108 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Ross Moffett

-

-

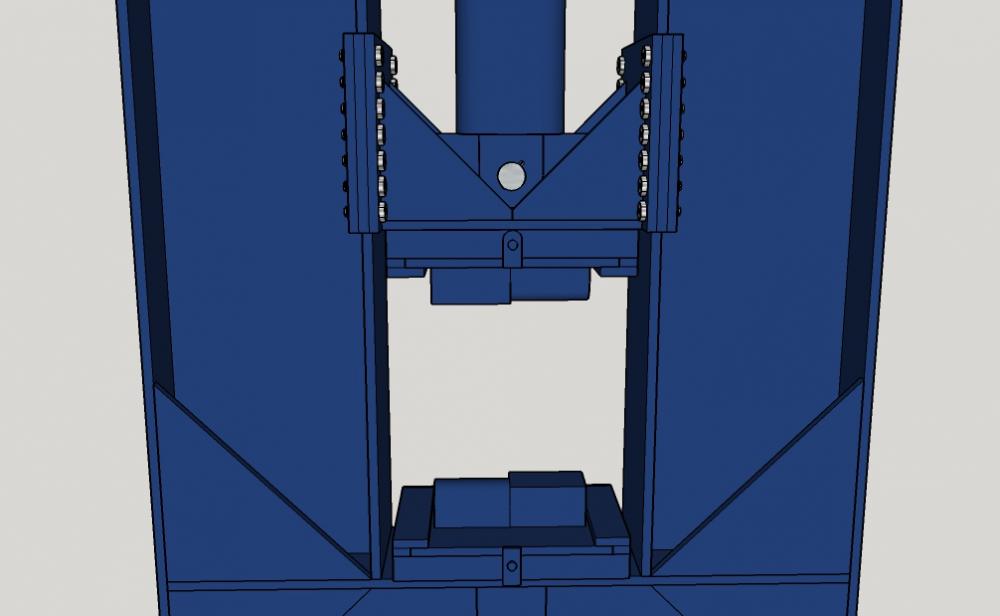

Thanks for the reply. I agree with you this guide system will definitely be stronger and work more smoothly. I'll post pics once I've changed the guides.

-

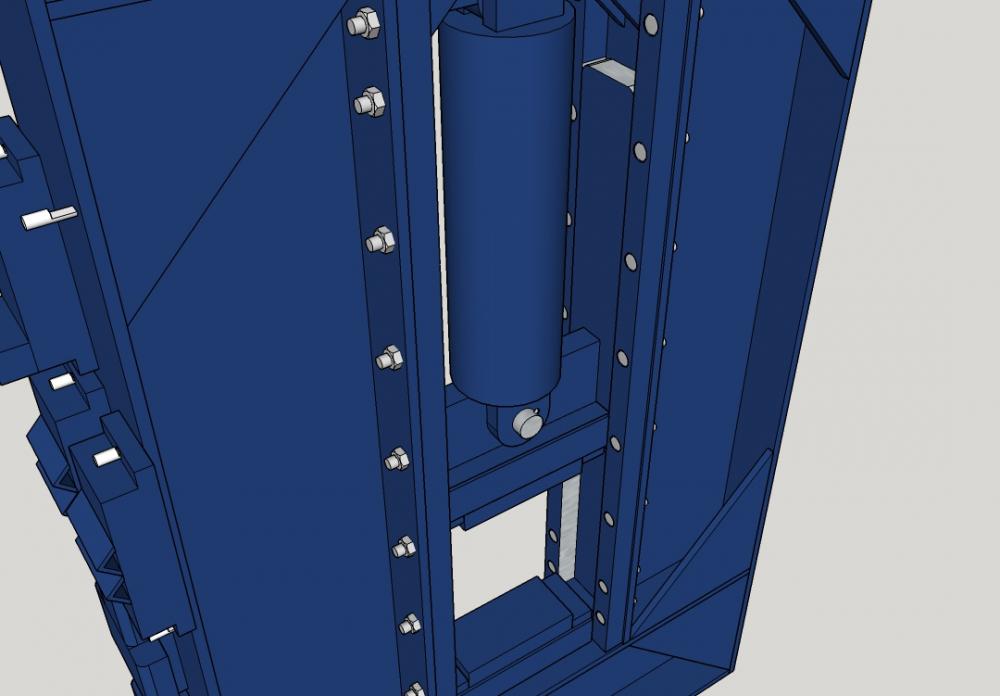

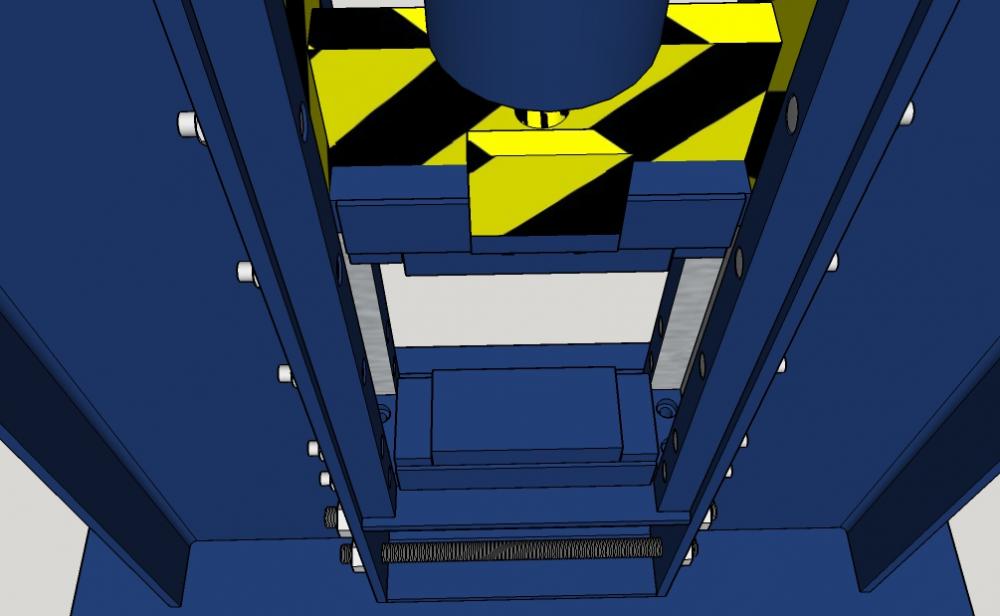

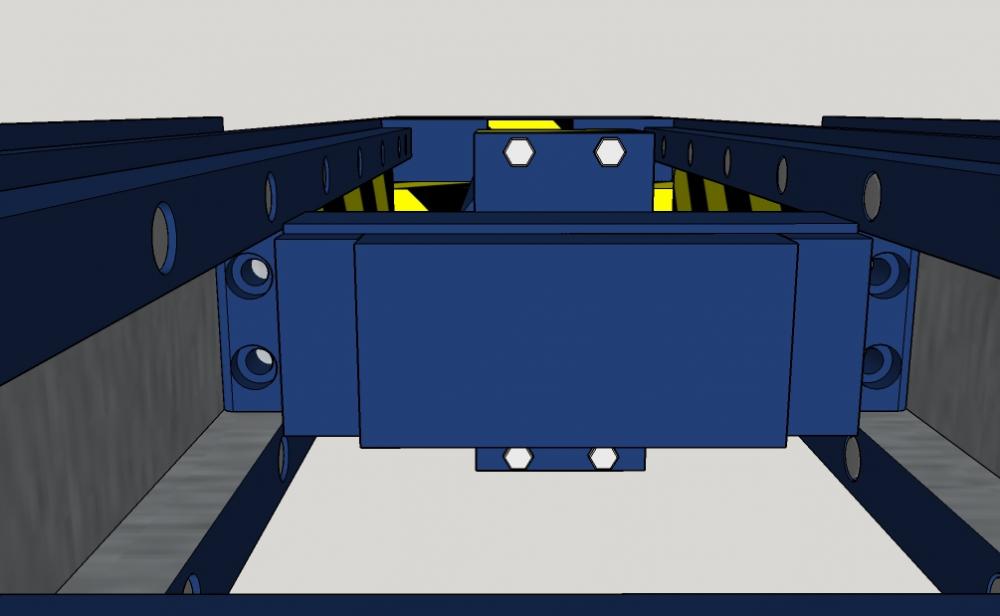

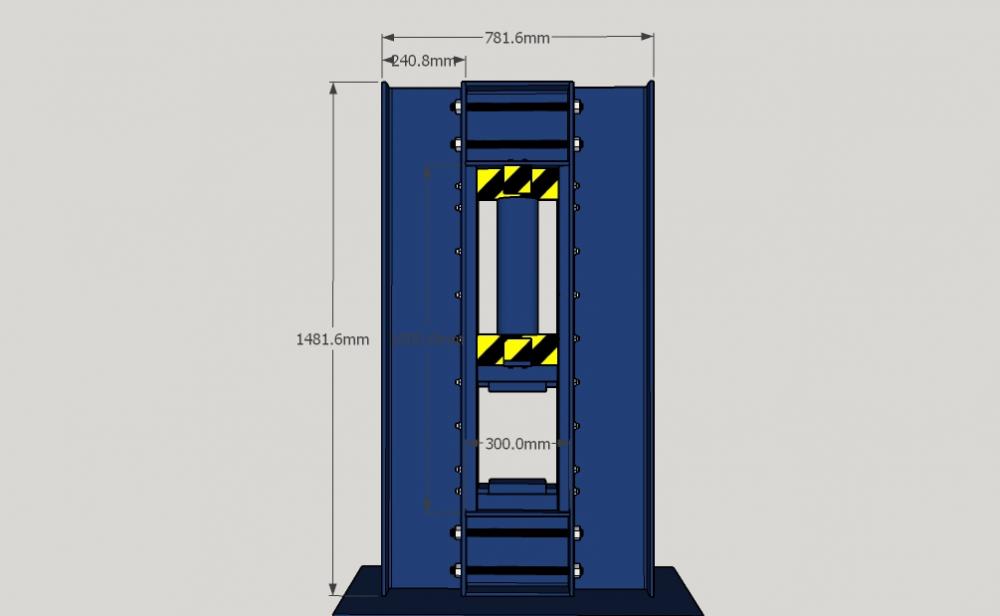

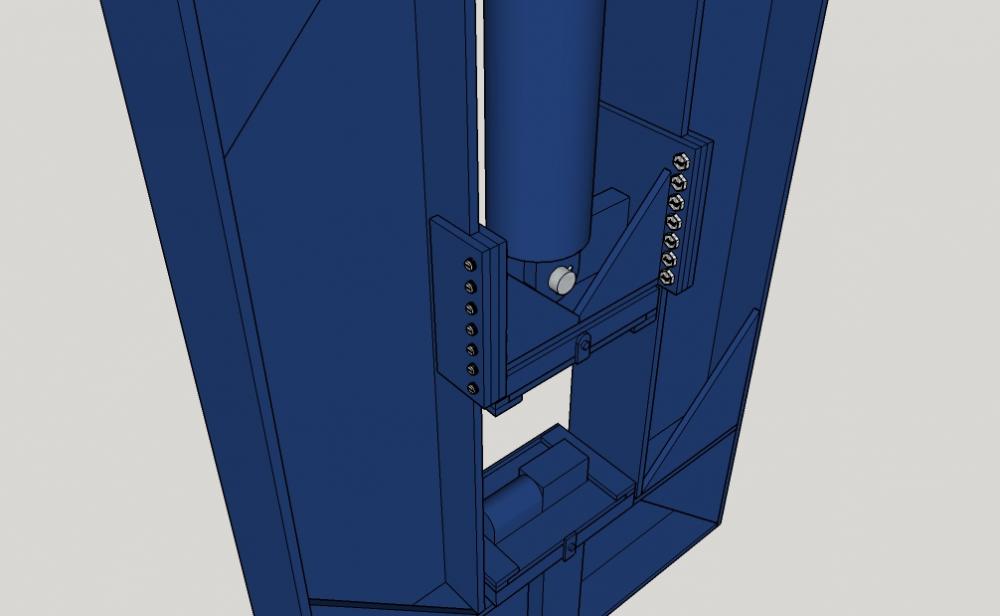

Help! I can't decide which guide system would work better and be more rigid. Comments and critiques are welcome.

-

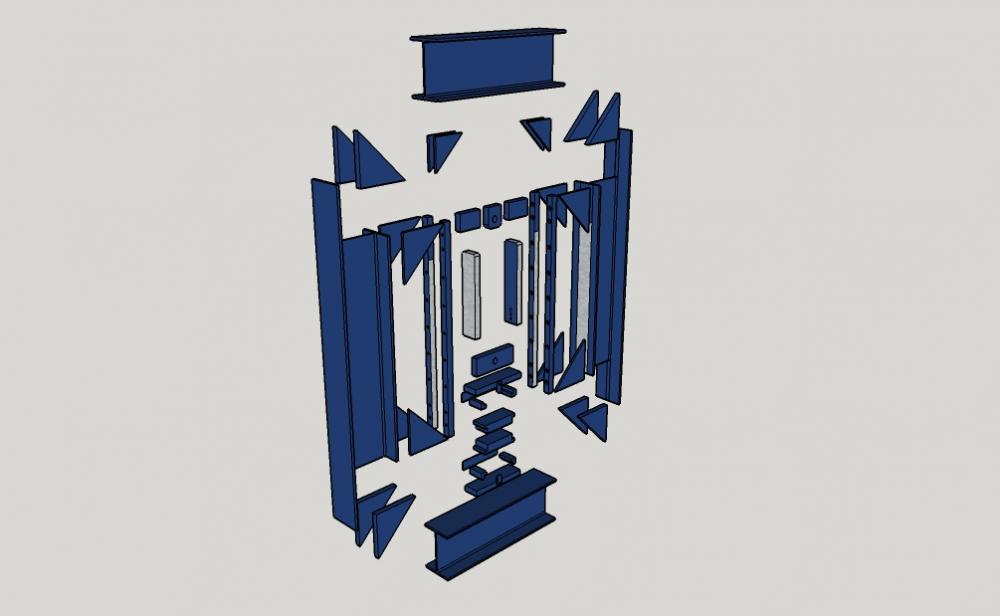

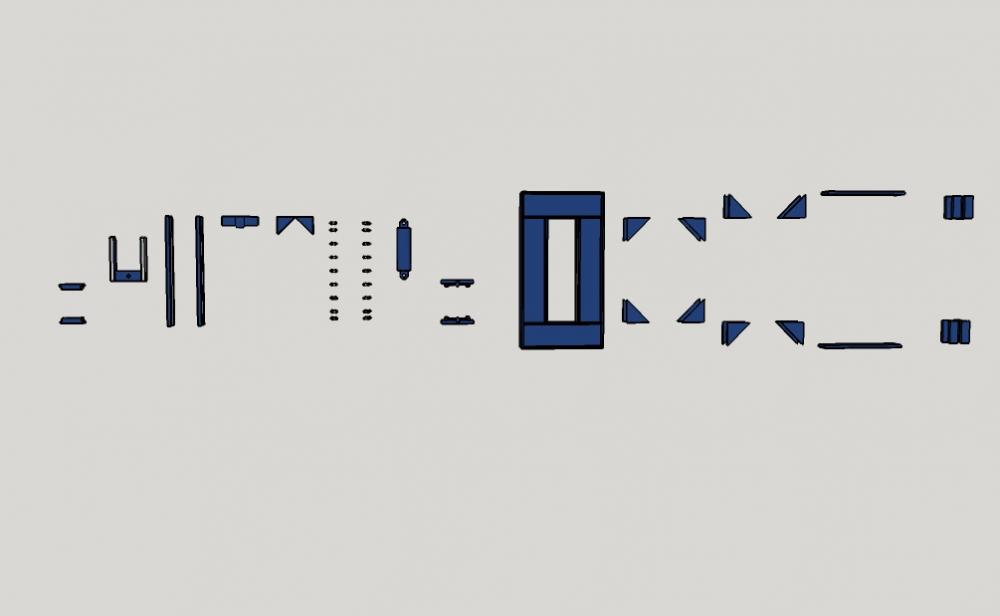

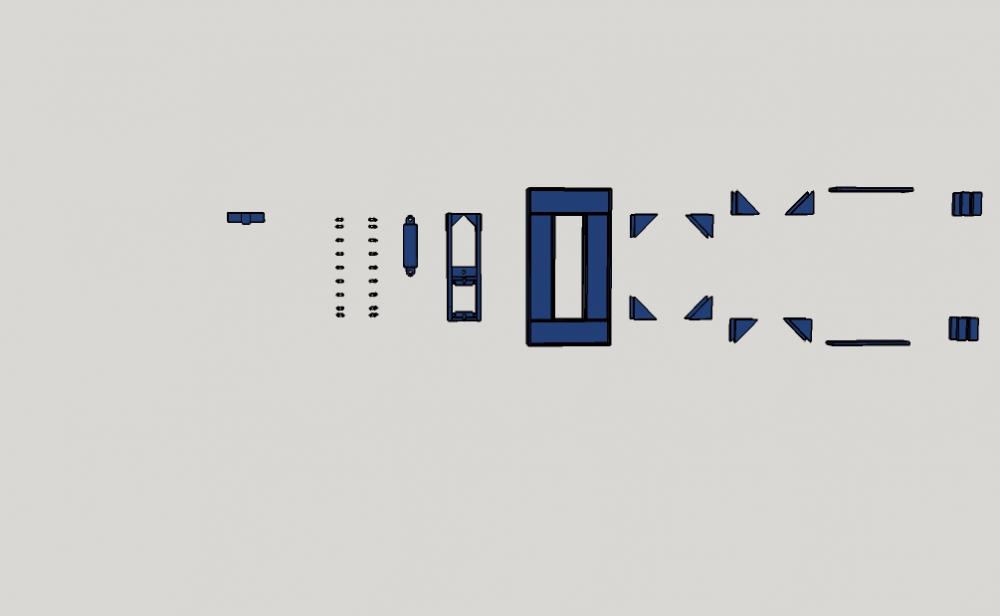

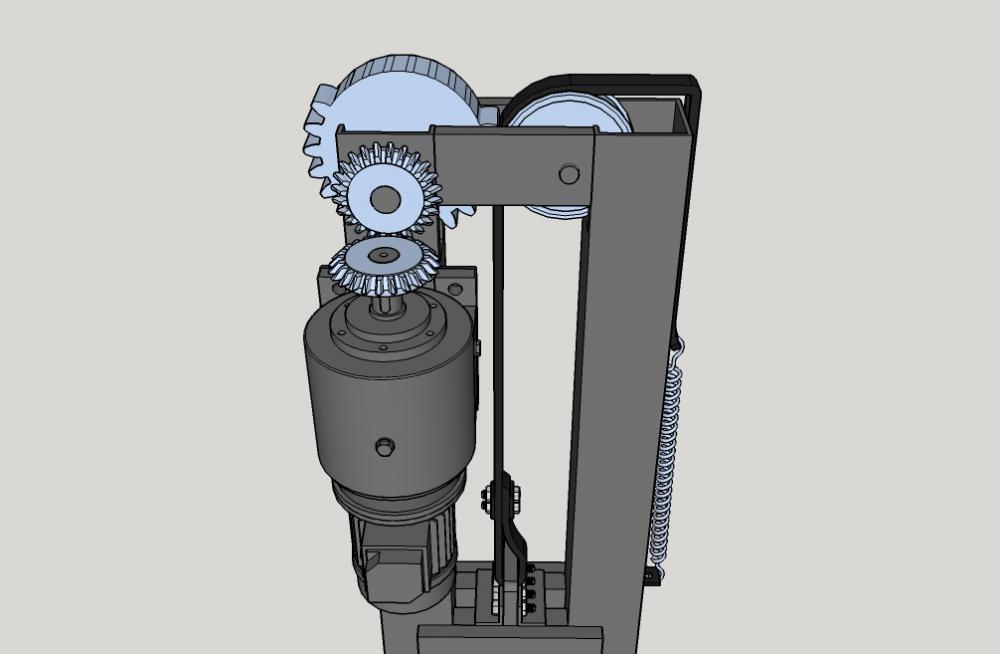

Here you can see all the pieces quite nicely. Give me a shout if anyone wants the design (Sketchup). Regards.

-

Ok, Thanks, I'll get a new cylinder then. How much HP would I need for say a 30+ ton press? Do you think the design is ready or does it still need modification? Regards.

-

Thanks for the input, I'll see if I can get an engineer to have a look at it. Would you have any idea if the hydraulics off of construction vehicles and machinery would work for the press? Regards.

-

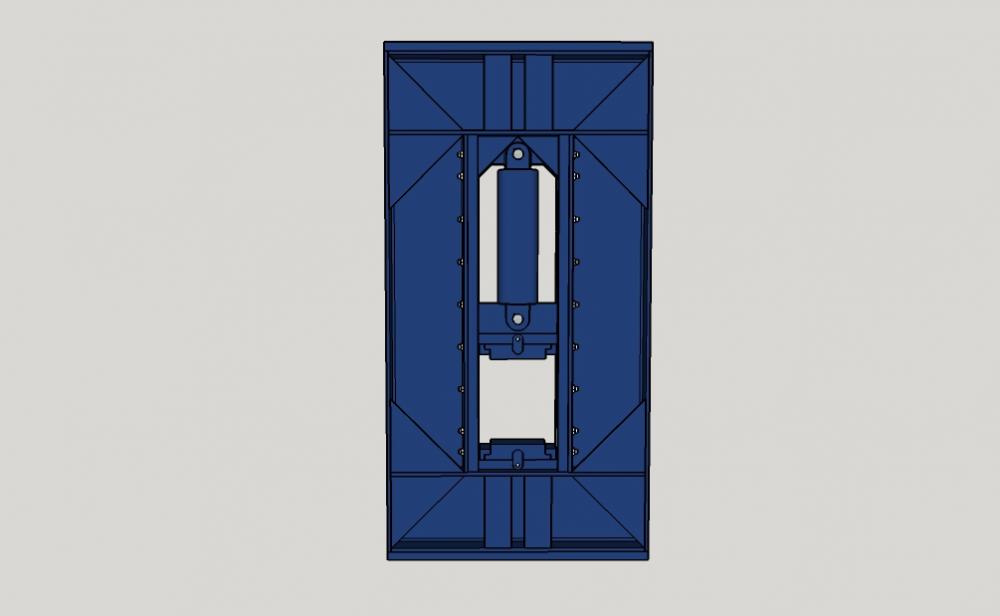

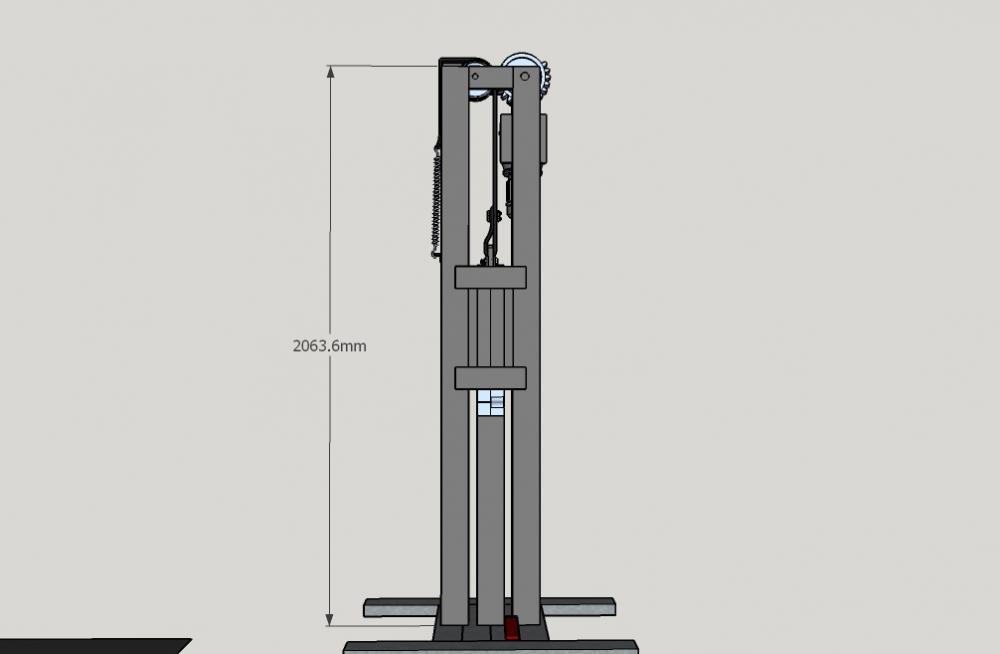

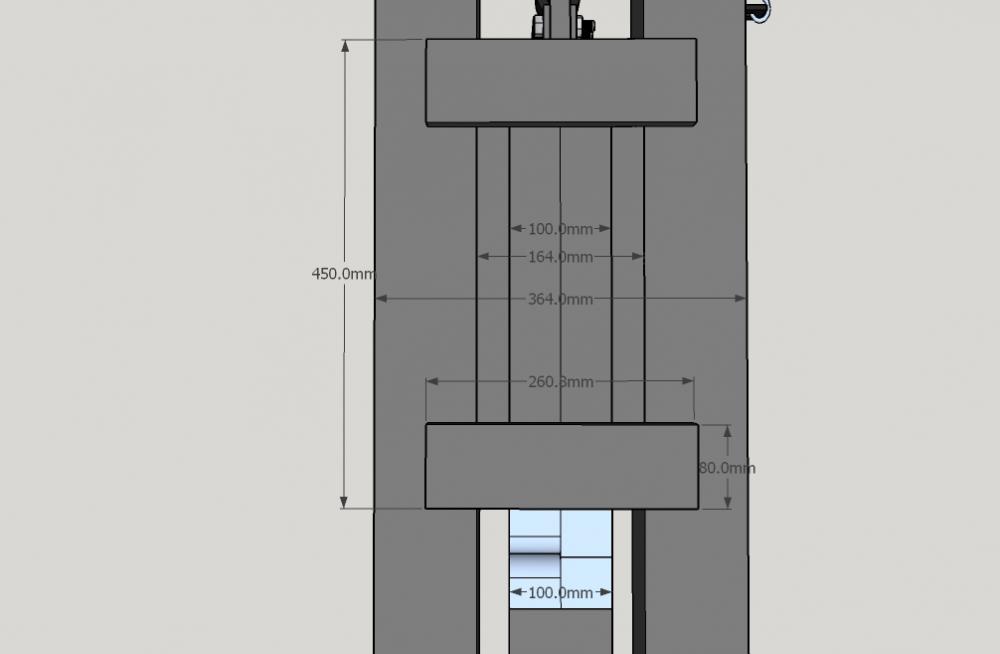

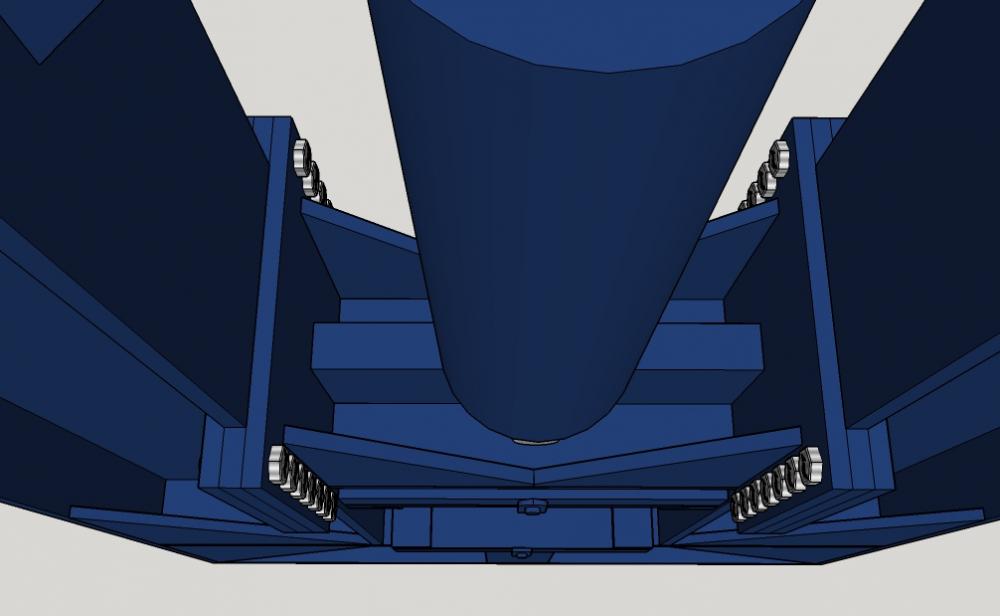

Thanks for all the replies. I've changed the design to incorporate your suggestions, please let me know if I have left any out. Bore size: 120mm. Cylinder length 400mm, obviously this may change depending on what cylinder I can find. I'm thinking around 30 tons + or -. I'm planning on having the press on a base with wheels so it's easy to move around, the base will be around 1 meter high. Once the design is complete I'll post it with a materials list and so on. Regards. redundant photos removed

-

I appreciate any suggestions and critiques to the design, I'd rather have this over-engineered than have something go wrong later on. Is steel on steel fine for the guides or should I have something else there?

-

Hi Thomas, I did not have a side panel but I will add one now and I will also change the all thread to bolts. Thanks for the suggestions.

-

My plan is to use the all thread to hold the frame together while I'm welding it and also as a bit of extra support. Regards.

-

Here's my forging press design I've been working and just wanted to know what you guys think of it. Should I maybe add something like Vesconite to the guides, at the moment it's just steel on steel? Ross.

-

That's a very nice piece you have there!

-

Need help with drop hammer design

Ross Moffett replied to Ross Moffett's topic in Power Hammers, Treadle Hammers, Olivers

Hi Jeremy, Will do, thanks for the advice. -

Need help with drop hammer design

Ross Moffett replied to Ross Moffett's topic in Power Hammers, Treadle Hammers, Olivers

Ok ok, I'll see if I can get Clay Spencer's hammer design but I'm in South Africa so I'll ask him if he can email it to me instead of posting it. Regards. -

Need help with drop hammer design

Ross Moffett replied to Ross Moffett's topic in Power Hammers, Treadle Hammers, Olivers

Yes I know you can buy hammer plans but I'd rather get something for free since I'm going to have to change the plans anyway to fit the metal I have and I couldn't find anything for free (or am I just bad at researching?) And I was going to design it myself but then I decided it would be easier to base it off of already made plans. And hey I'm young and young people like to ask questions (even if they aren't the most thought through questions or the right ones) Sorry for the confusion. -

Need help with drop hammer design

Ross Moffett replied to Ross Moffett's topic in Power Hammers, Treadle Hammers, Olivers

I think I'll go for a 50#. I'll make the anvil as solid as I can then. I've done research and watched videos and read peoples comments on power hammers but I just want a second (experienced) opinion on what I've heard, read and seen. I'd love to get a proven and tested tire hammer design but I haven't found one yet. Regards. -

Need help with drop hammer design

Ross Moffett replied to Ross Moffett's topic in Power Hammers, Treadle Hammers, Olivers

I'll start designing then, do you think a 50-pound ram is enough or would more be better? Must the anvil be solid and do I need something like Ultra High Molecular Weight Polyethylene in the ram guides? Regards. -

Need help with drop hammer design

Ross Moffett replied to Ross Moffett's topic in Power Hammers, Treadle Hammers, Olivers

Firstly as I said to TP I've only ever used a power hammer once. The reason I decided to make a drop hammer was mainly for the experience and because it is fun. 1# As far as stock size goes it'll mainly be Damascus billets about, 10 x 5 x 5 cm. I'd like to be able to work the billets down quite quickly. 2# I think a 50-pound ram would be sufficient and at full speed around 2 hits per second. I'd want combination dies. 3# yes, I don't think I'll have to buy anything, he recently had some old machinery and equipment taken apart. The tire system does look easier than using a belt system, though I do have the available resources to do either. I'll do some research and decide on what EXACTLY its purpose is going to be. Thanks for your advice. Regards, Ross. -

Need help with drop hammer design

Ross Moffett replied to Ross Moffett's topic in Power Hammers, Treadle Hammers, Olivers

I looked at Clay Spencer's power hammer, (very nice!) it's a 50-pound ram and running off of a "56 1 HP TEFC unit, wired for 110," (direct quote) The motor I've got is a: Vetsak, 3 KW, 6.6 amp, 1430 rpm, 3 phase, 380 volts, 50 Hz. Regards. -

Need help with drop hammer design

Ross Moffett replied to Ross Moffett's topic in Power Hammers, Treadle Hammers, Olivers

No haven't. I did recently visit a blacksmith (don't know if he's a member though) and used his power hammer and that's the only time I've used a power hammer. Should I design the hammer first then only choose a motor? The metal I'm going to use for the ram is a 5 X 5 cm square bar, 45 cm of it weighs about 20 pounds. Regards. -

Need help with drop hammer design

Ross Moffett replied to Ross Moffett's topic in Power Hammers, Treadle Hammers, Olivers

I won't use that specific design, I'll do lots of research and then make my own and see what metal I have laying around. Am I right in guessing that a 4 horsepower motor will be more than enough? I probably won't have to buy anything since my dad has a rather large scrape pile and recently took apart some old machinery. I'll start a new topic once I've started on the power hammer design. Regards, -

Need help with drop hammer design

Ross Moffett replied to Ross Moffett's topic in Power Hammers, Treadle Hammers, Olivers

Just what I was thinking making a tyre hammer will be much simpler, (now that I've looked at some designs) cleaner and more effective. Here's the link to a patent I found of a tyre hammer https://www.google.co.za/patents/US639538?dq=belt+drop+hammer&hl=en&sa=X&ved=0ahUKEwipi9vWy-bWAhVHC8AKHX2-D4E4ChDoAQhmMAk let me know what you think of it. Regards. -

Need help with drop hammer design

Ross Moffett replied to Ross Moffett's topic in Power Hammers, Treadle Hammers, Olivers

Well, the main reason I'm building it because it's a fun project and for the experience. I'll probably be using it for drawing and for the initial weld on Damascus billets. I'll have a look at the patents and see what I can find. Regards. -

Hi, I've been working on a design of a belt drop hammer, but I'm getting completely befuddled on how to do it best. What type do you guys think is best: steam, air, board or belt. Yes, I have spent several hours looking at power hammer designs (and practically drooling I might add) but I haven't found anything really helpful. Tell me what you think. Regards. drop hammer - Copy.skb

-

Hi Jeremy, Sorry for not replying sooner, but I'ver not had internet access for the last few days! Nice press you have there. Now I'm back home I can start looking what scrap I have available, then make a new design. Ross.

.thumb.jpg.7d226250b736ae4caade9bae80cc9b04.jpg)