-

Posts

108 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Ross Moffett

-

Hi Frosty, Is this what you were suggesting? I'm not sure if a wider channel iron would be better, giving me more room to work? Ross. Frosty.skp

-

Hi Frosty. Thanks for the advice, do you have by any chance an example? I've understood most of what you are saying but an example would help, am I just being thickheaded? Ross.

-

New bladesmithing specific logo - looking for input

Ross Moffett replied to TheoRockNazz's topic in Knife Making

Don't know if this will help but here's my logo, maybe it'll help you decide on something. I modified a Celtic knot so there is an "M" in it but besides that its pretty simple, Keep it simple. Cheers Ross. -

-

Thanks, it just takes time to get used to it. Ross.

-

Hi Jeremy, Thanks for your help and advice. Ross.

-

-

-

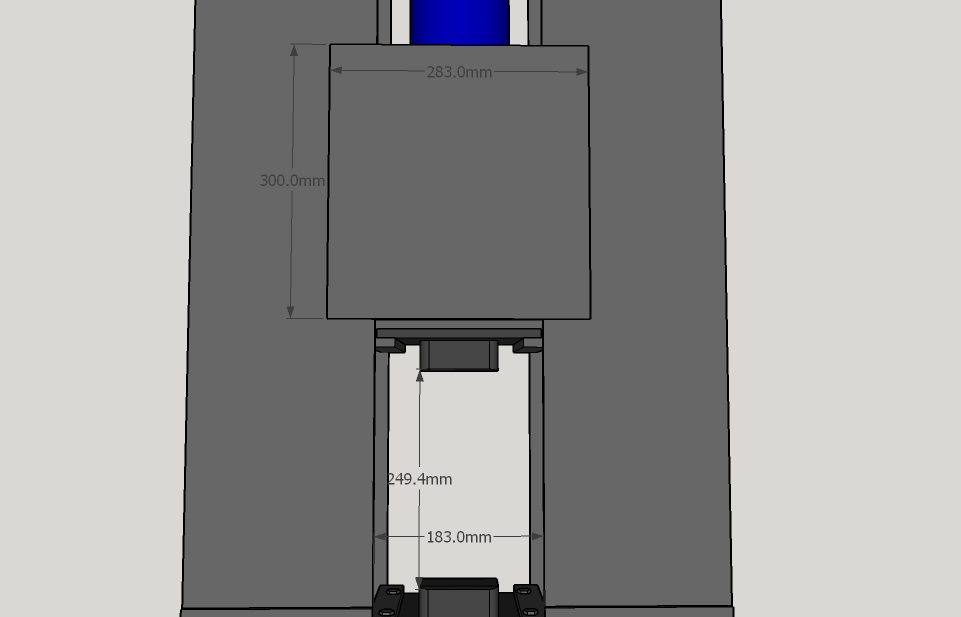

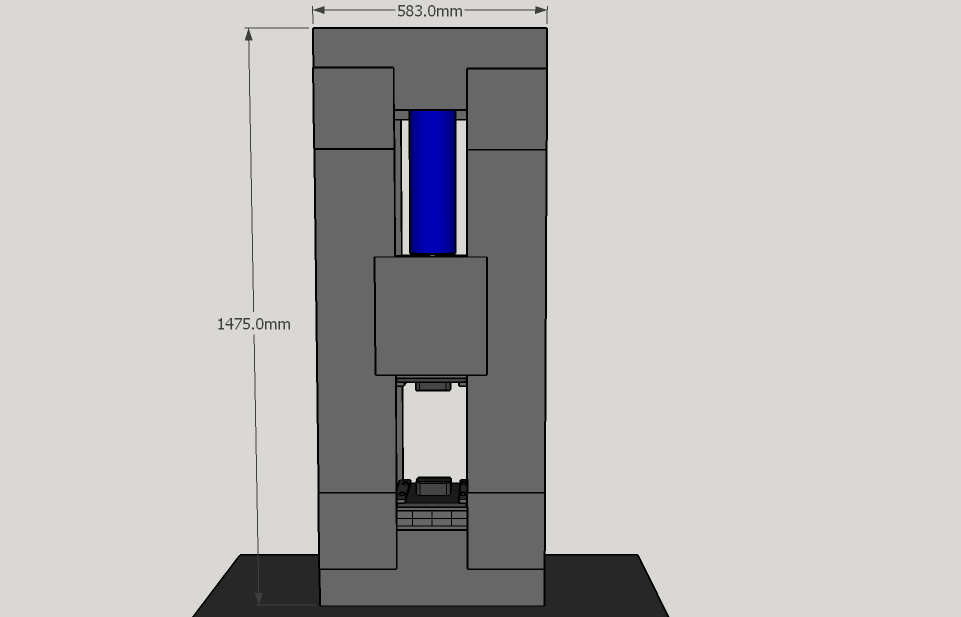

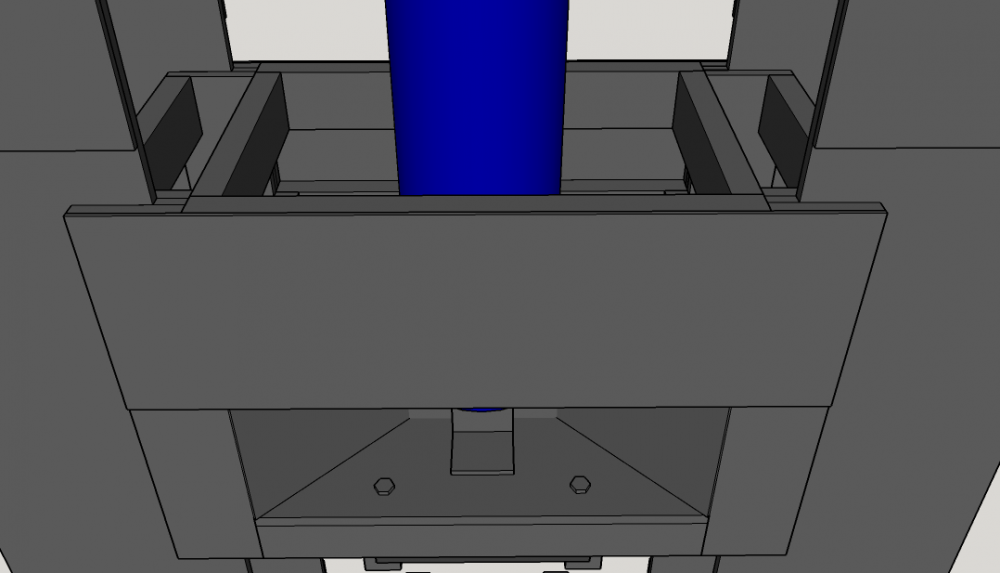

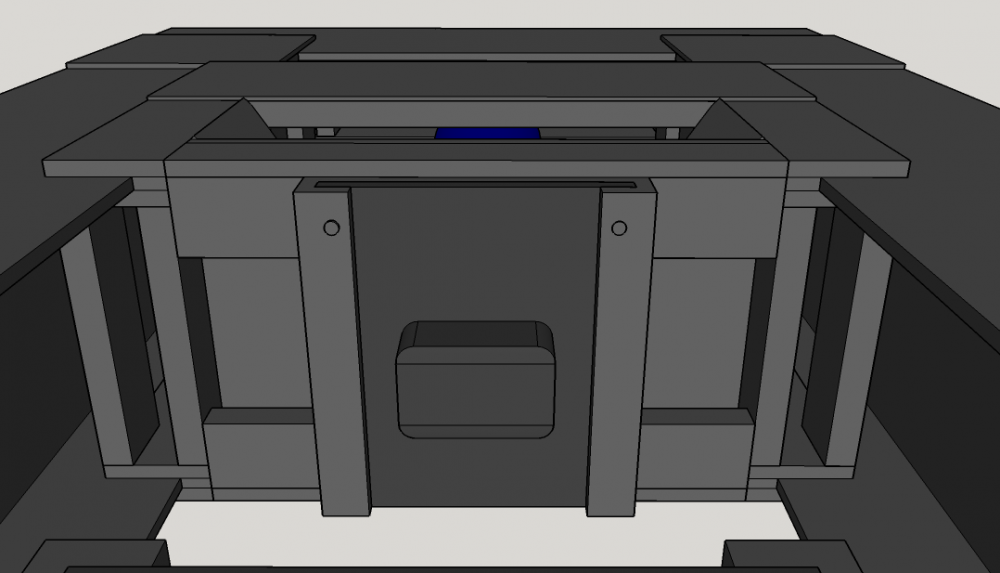

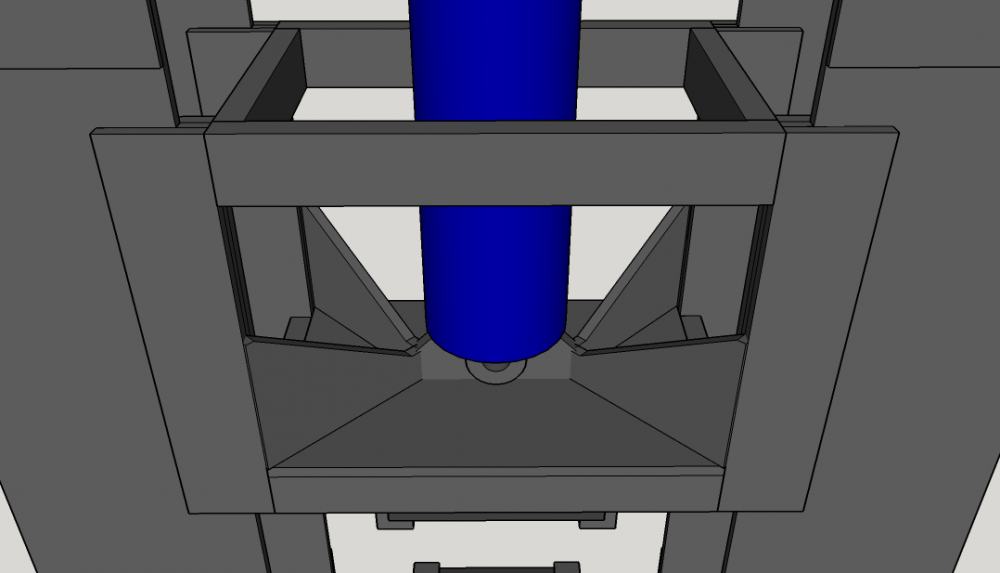

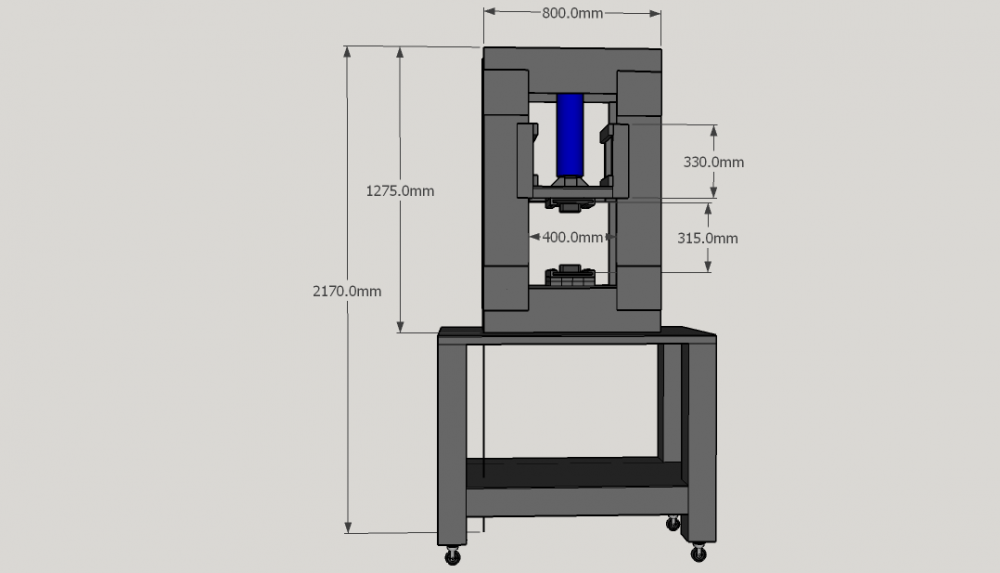

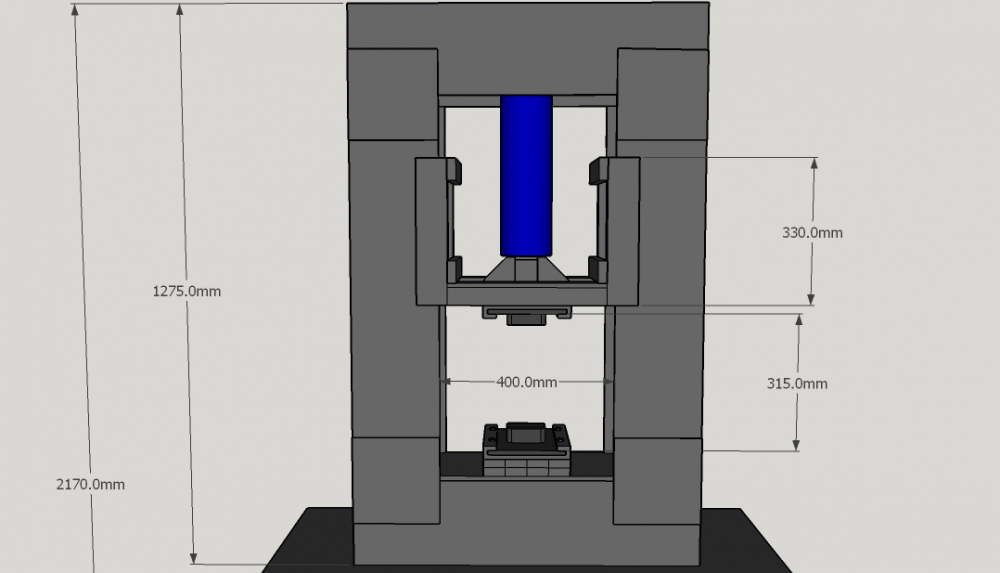

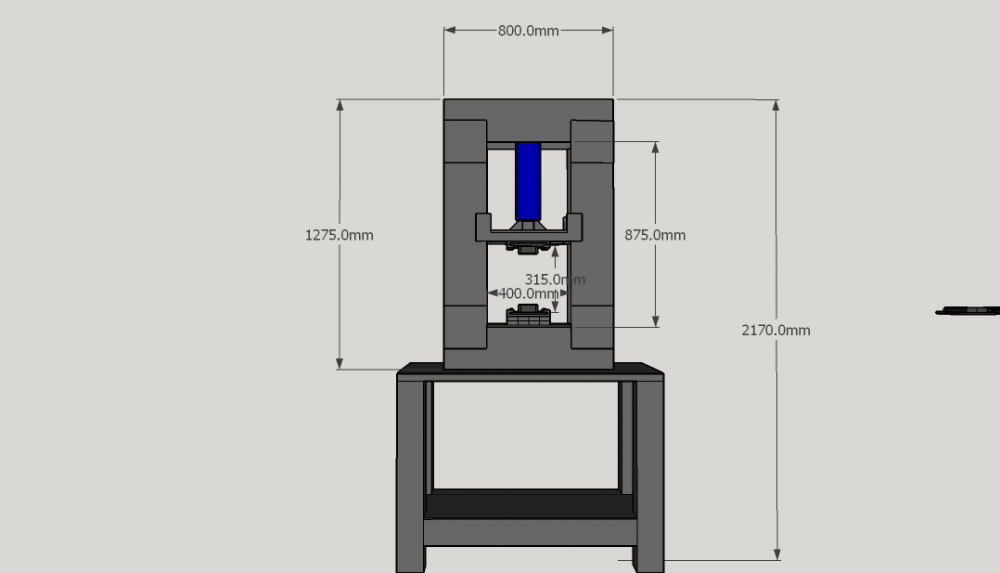

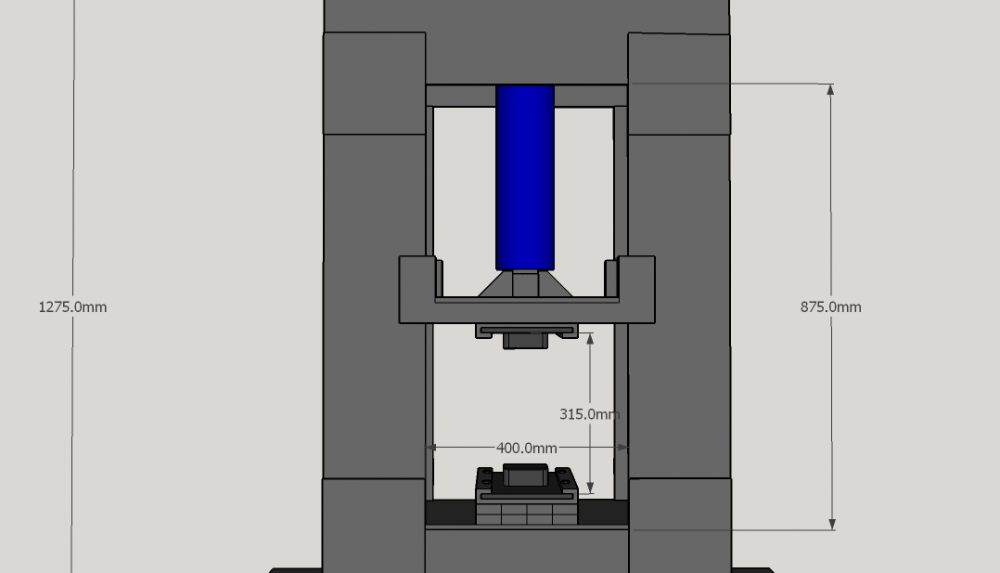

Hi Bubba, Sadly this design isn't accurate because I'm on holiday at the moment and I don't know exactly what the sizes of the metal pieces I'll be using. I will be making a new design once I'm back home, which will be accurate, though it may differ slightly from this present design. I'll upload the new design once I've made it, preferably with a material list. This present design was just to get some idea's of rough sizes and so on. Ross.

-

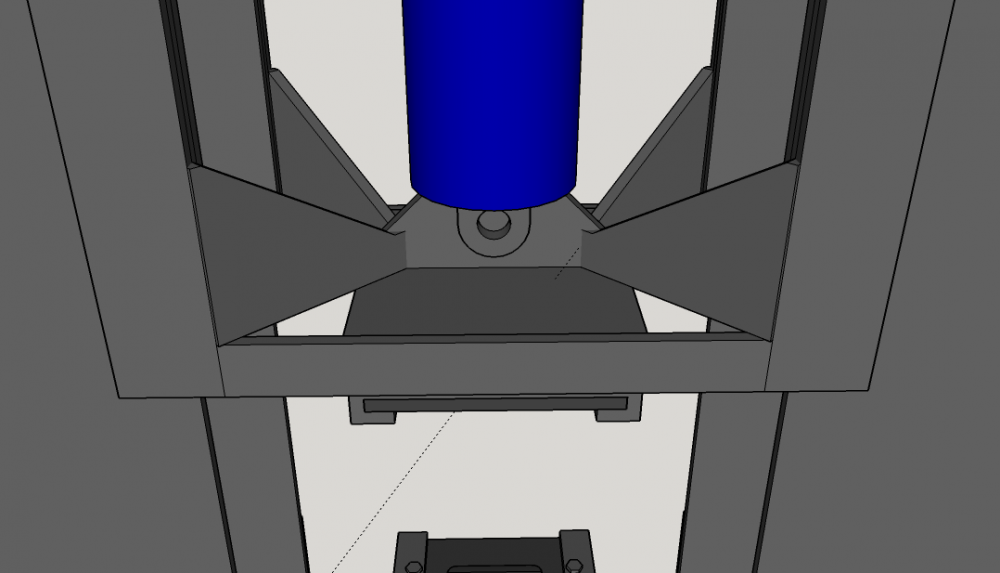

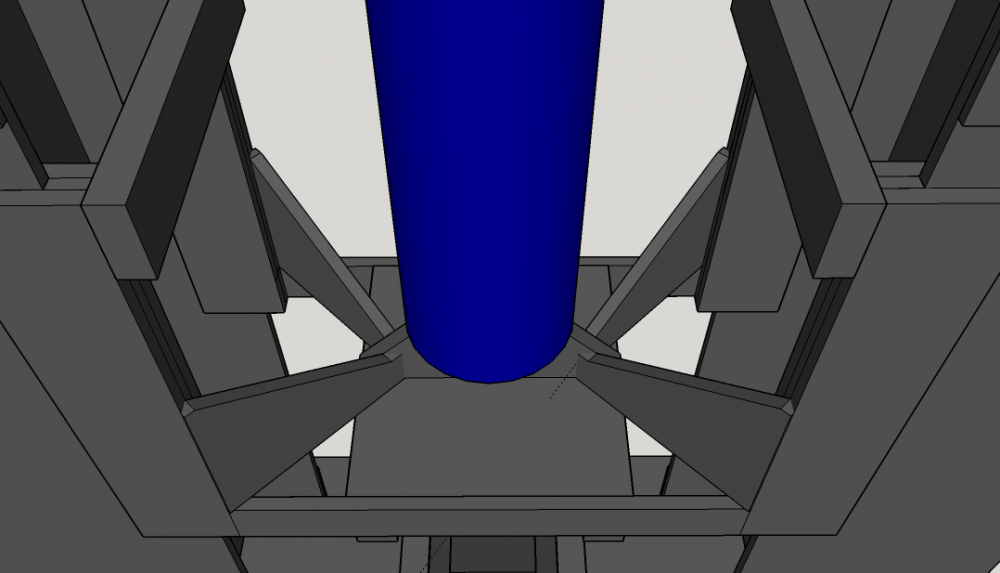

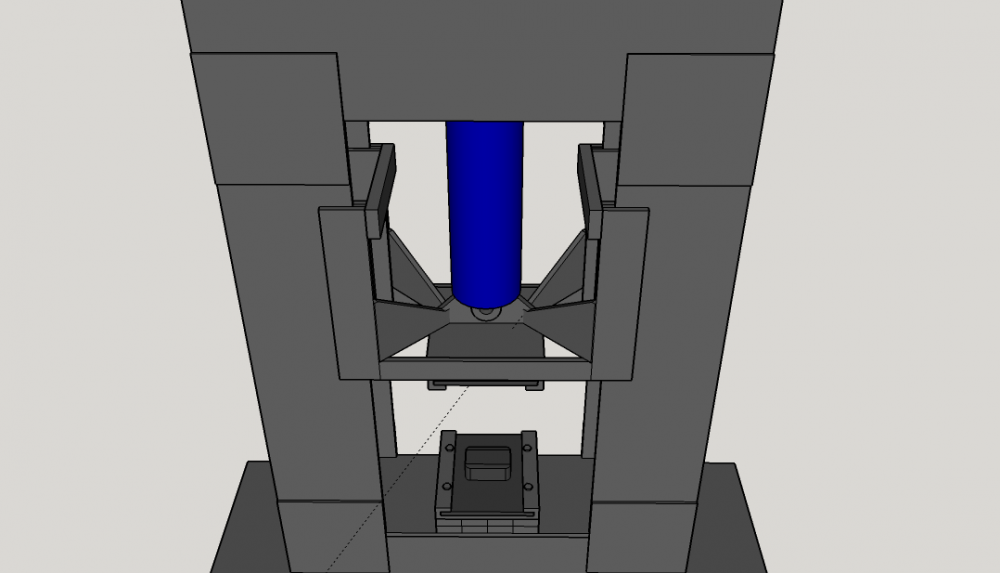

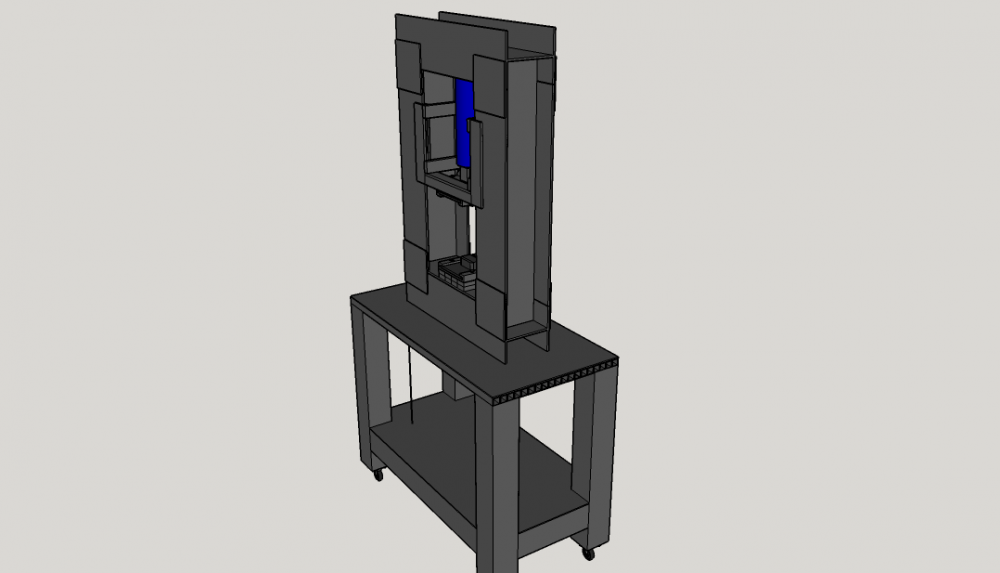

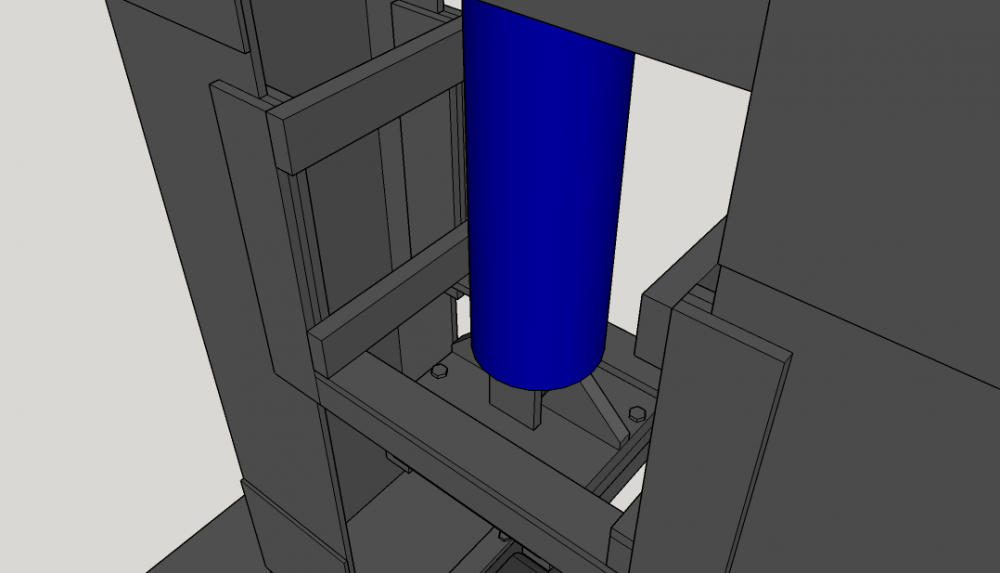

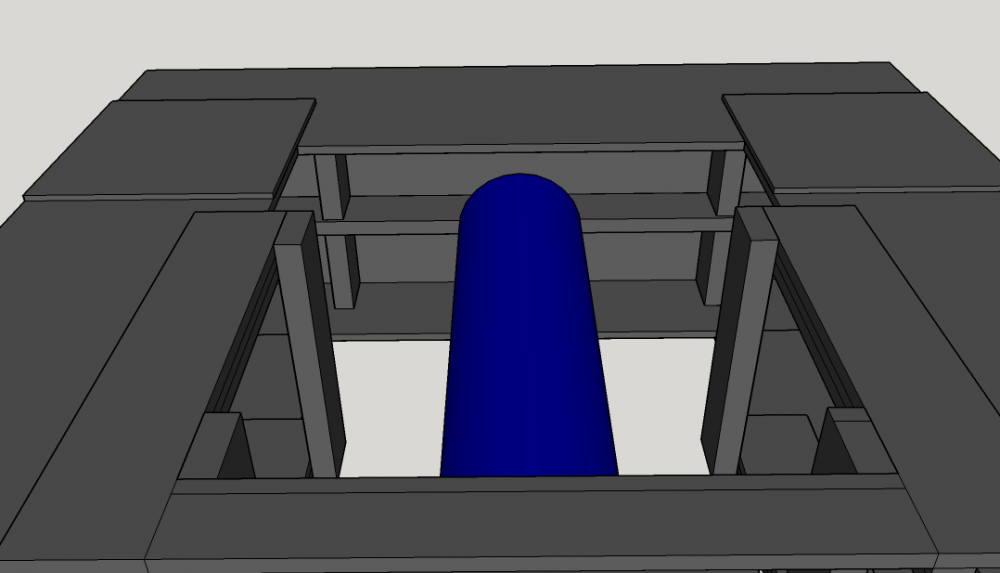

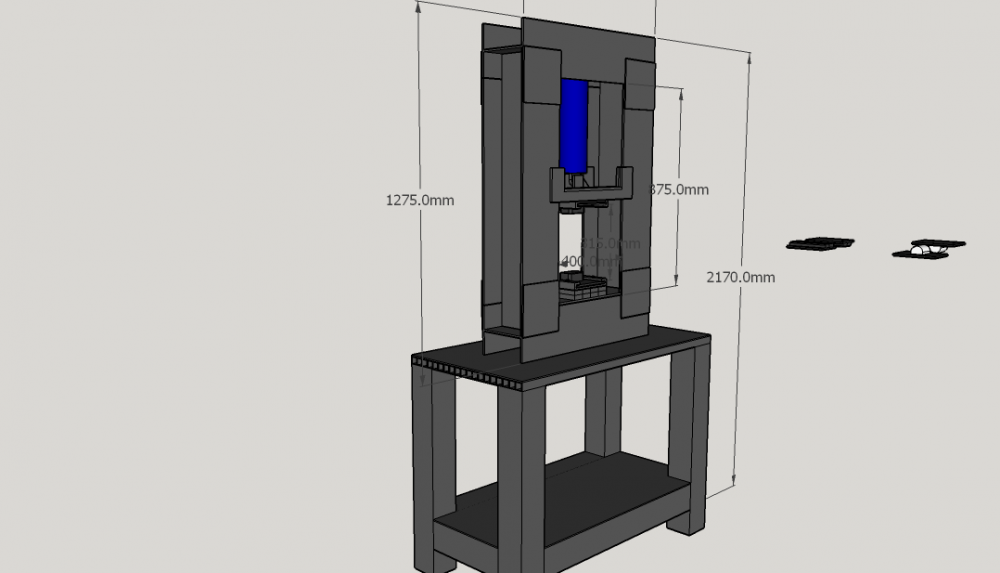

Here you go. Sorry for not uploading pics sooner. The link is a 3d design, you can only use it if you have sketchup though. Ross. Please post pics or give us updates on how it's going! Ross.

-

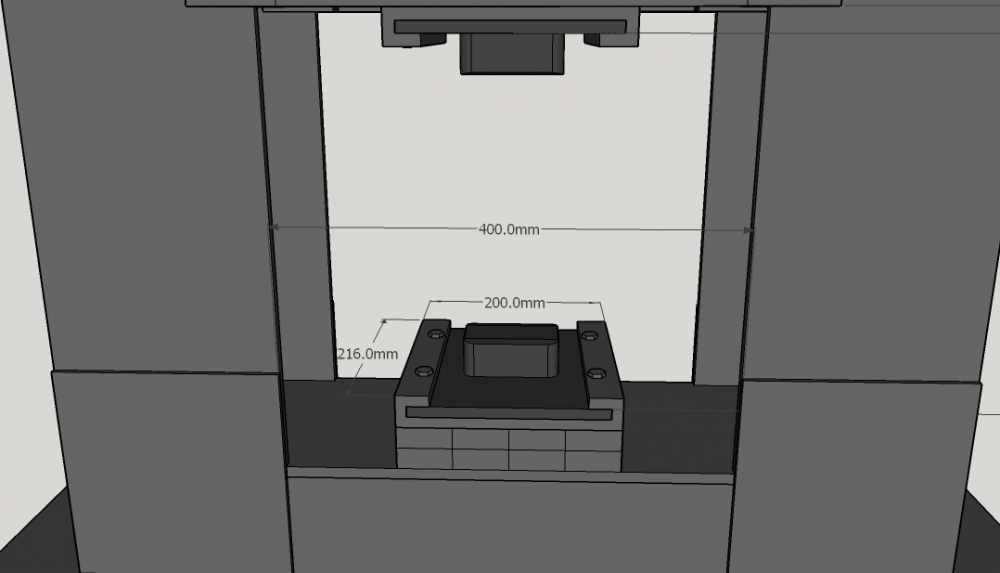

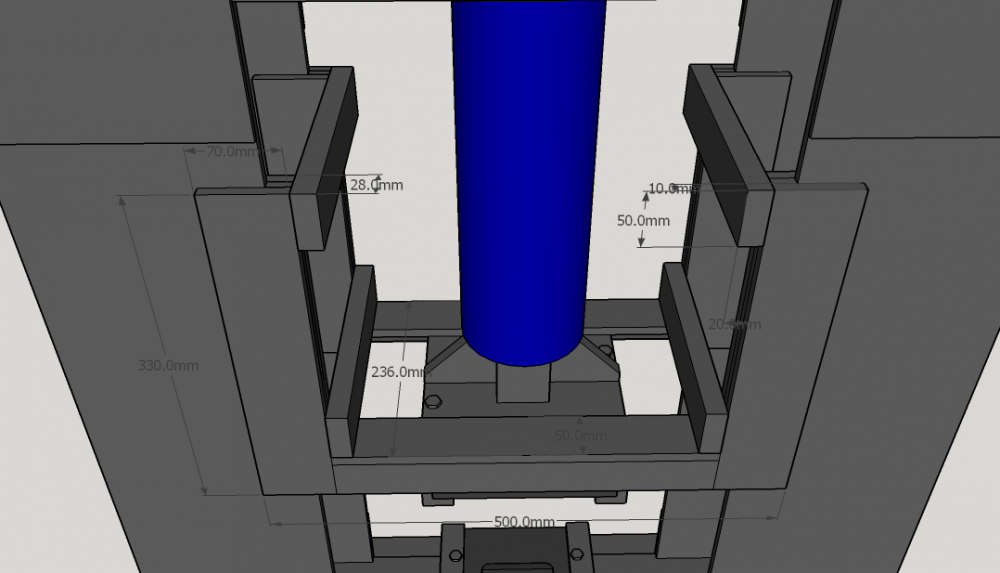

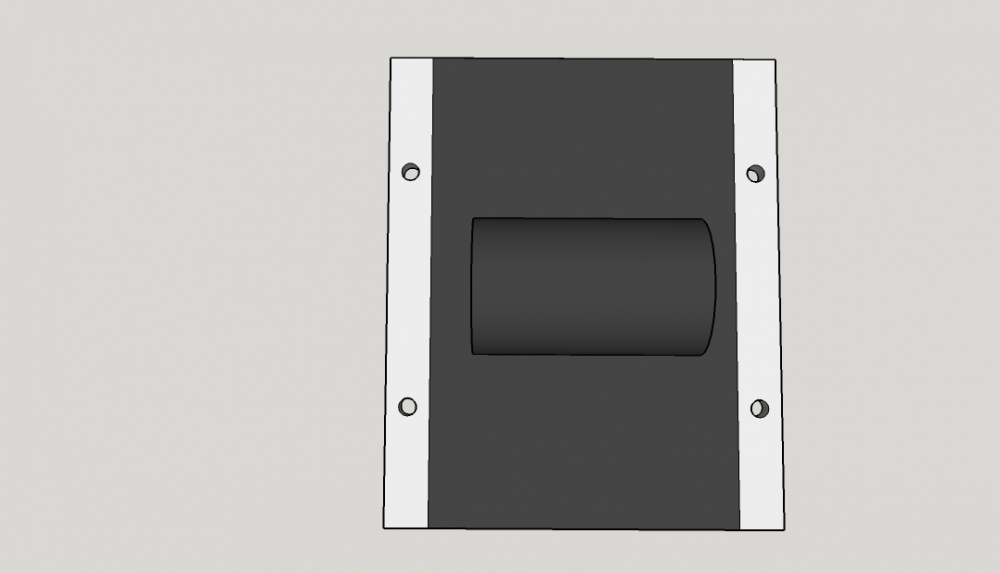

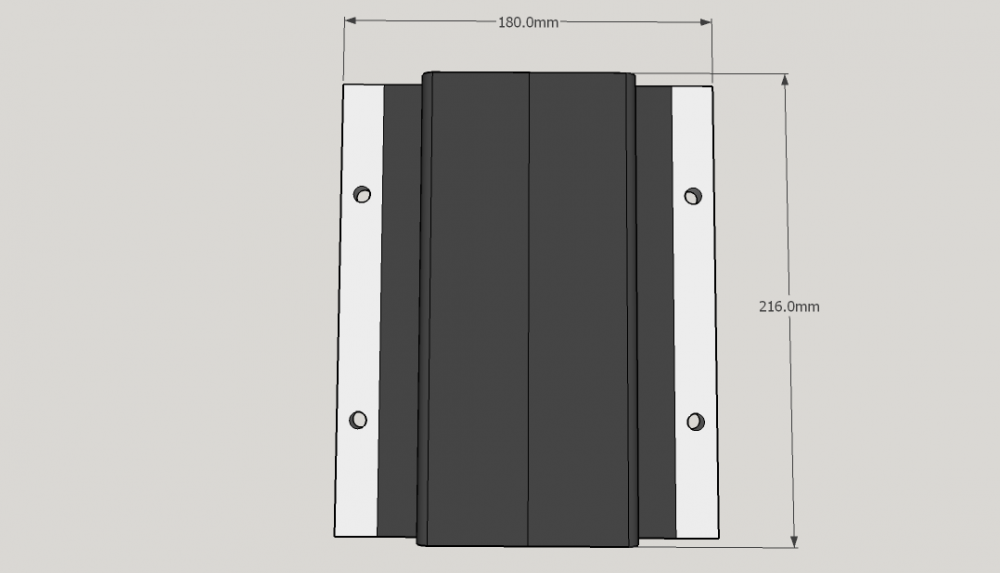

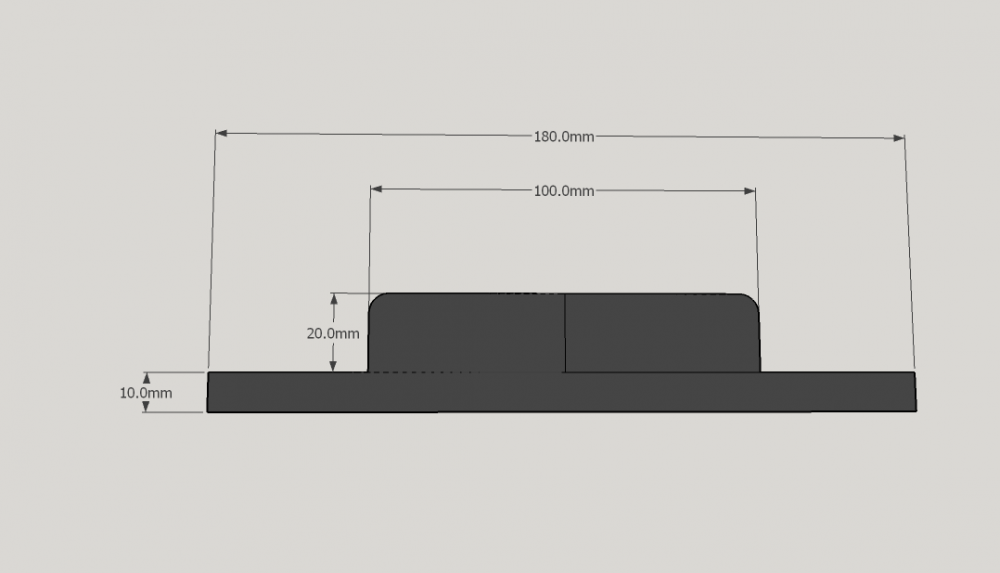

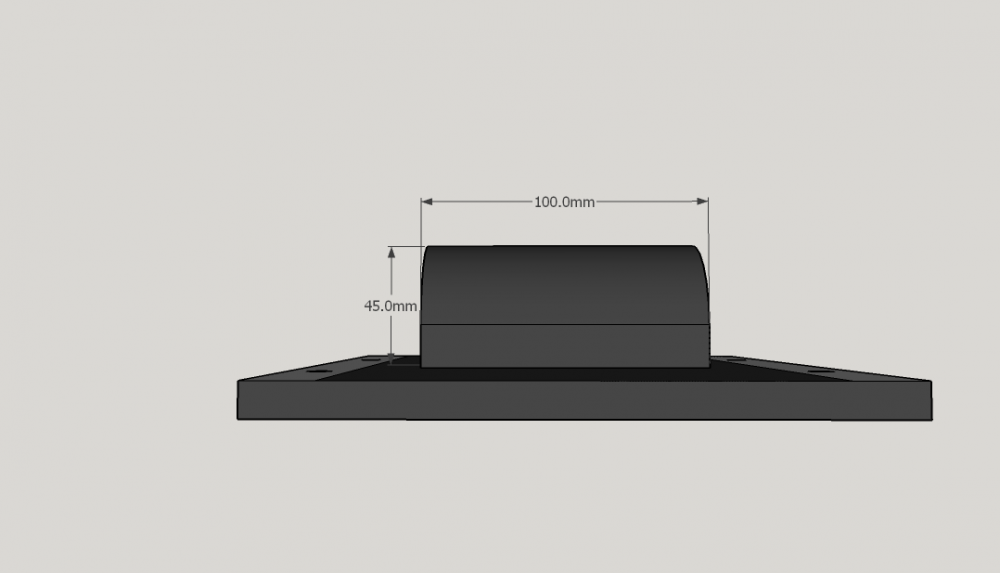

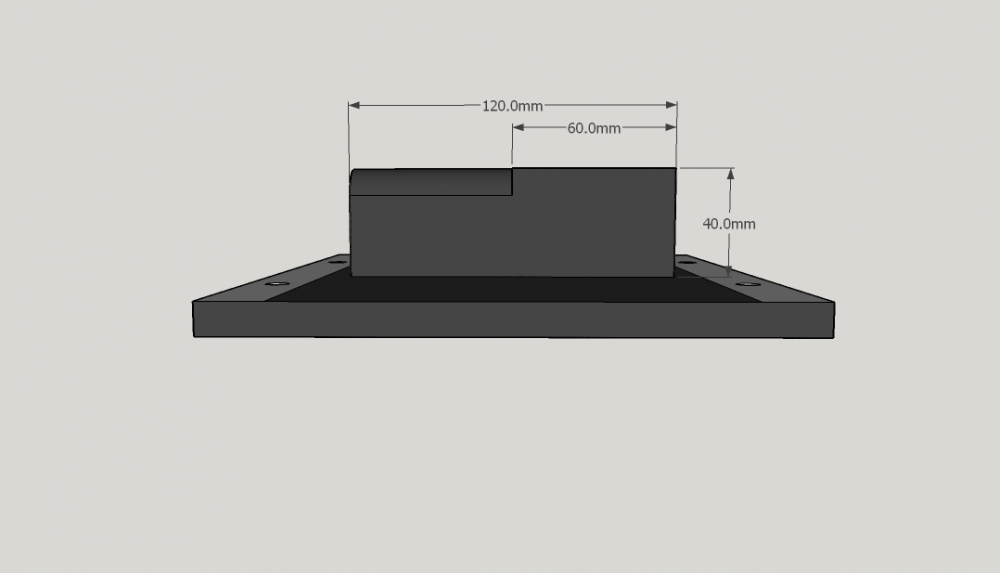

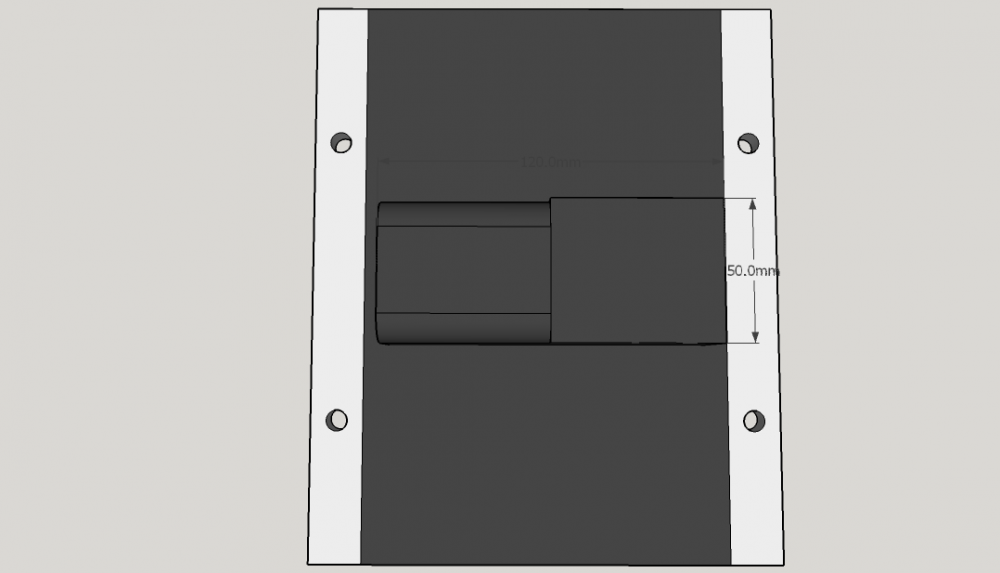

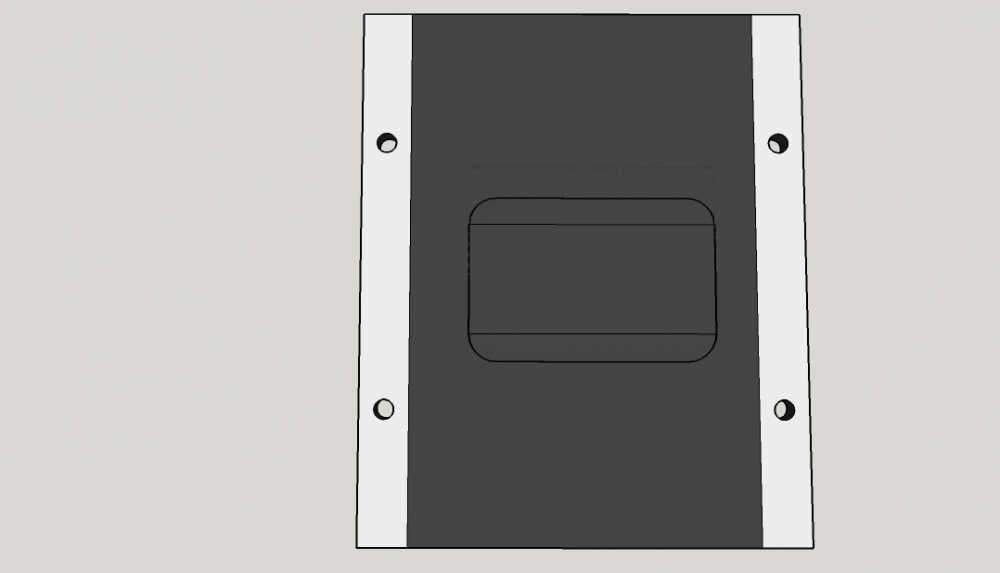

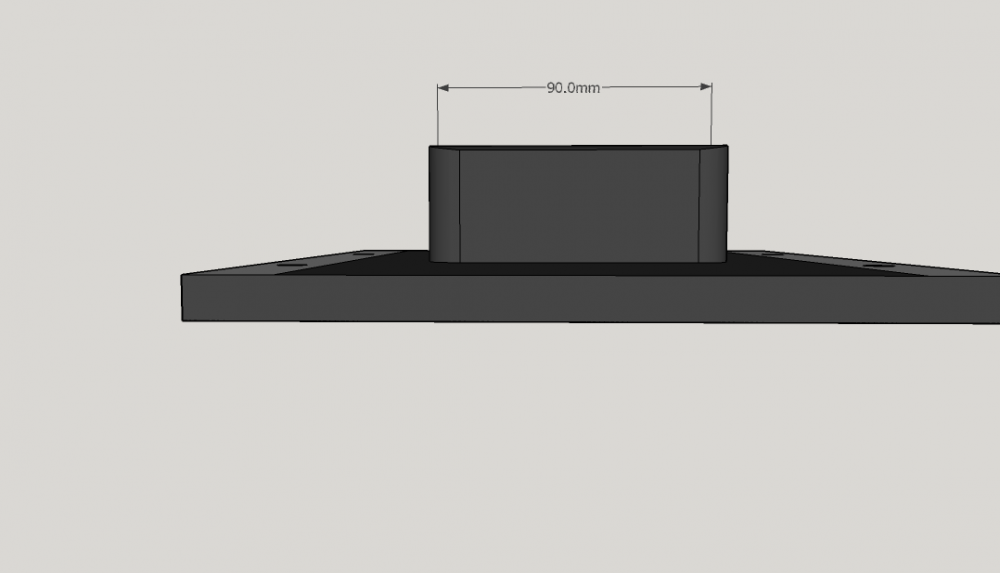

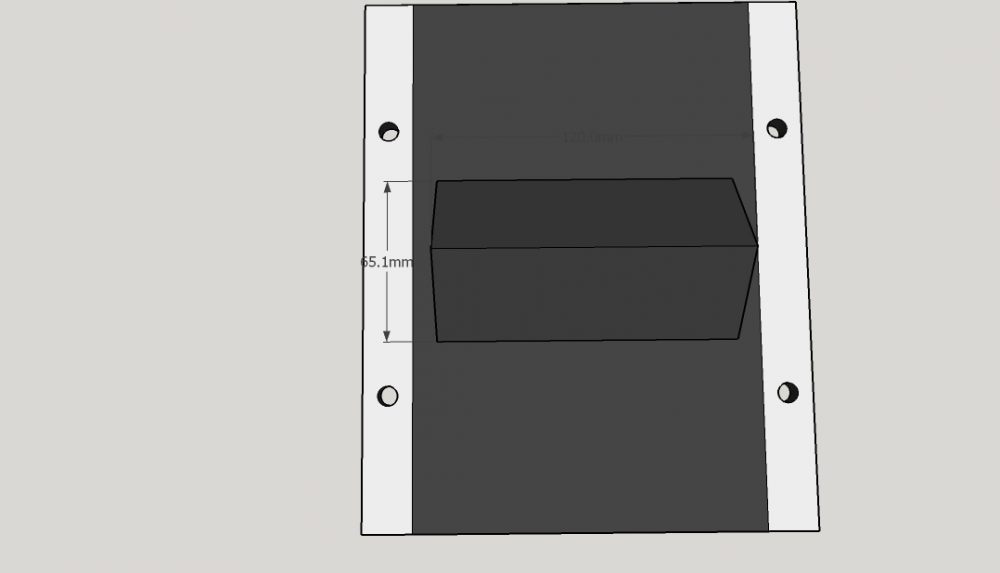

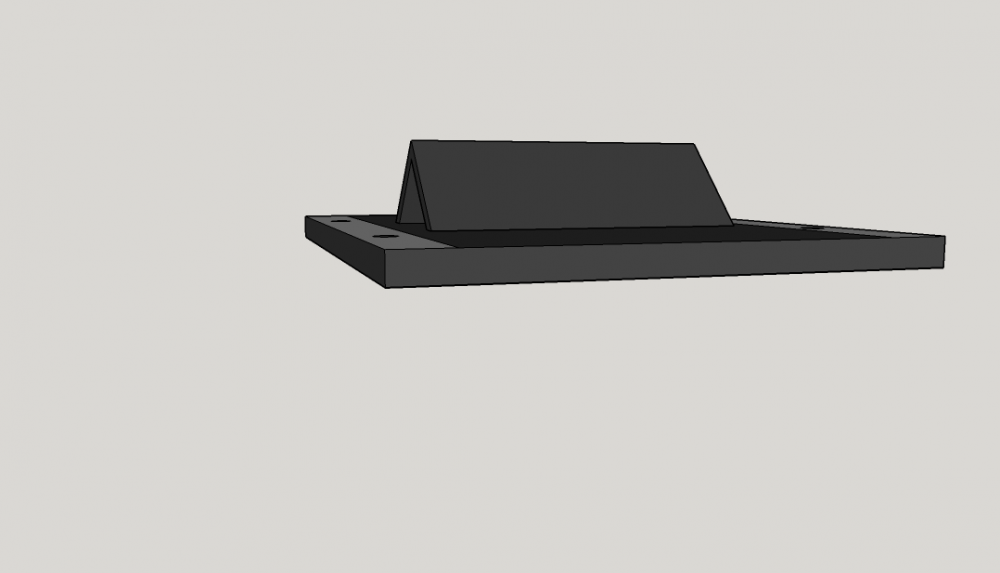

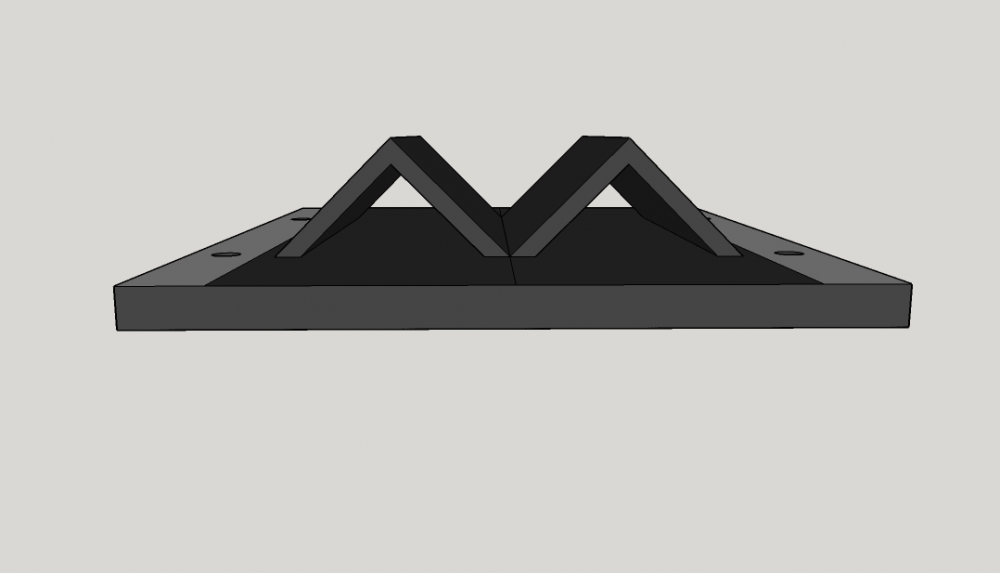

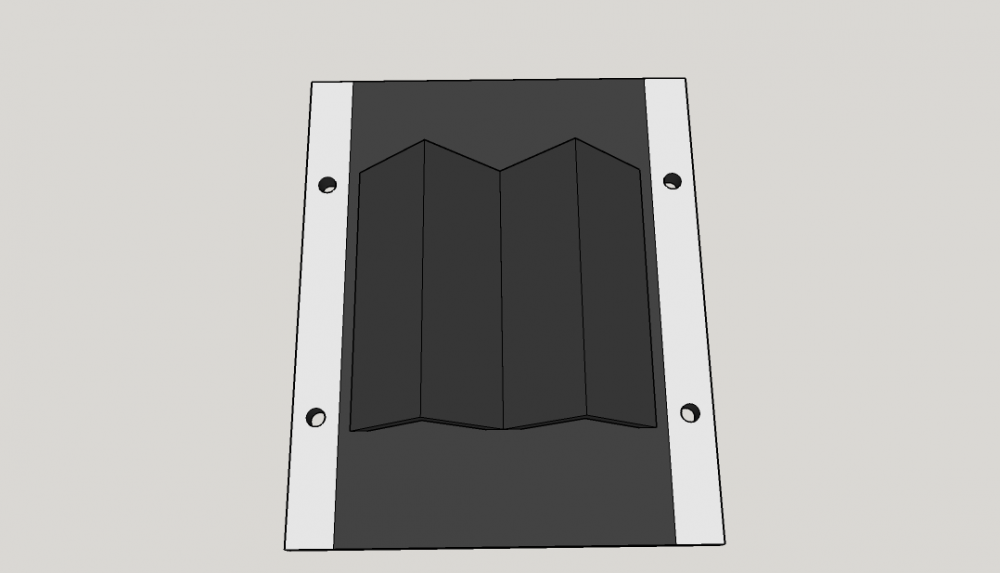

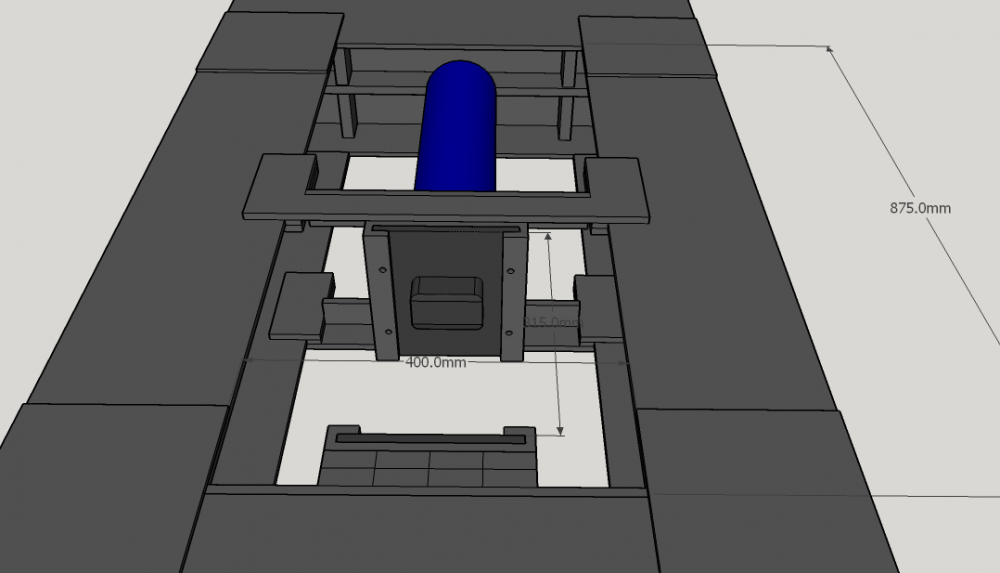

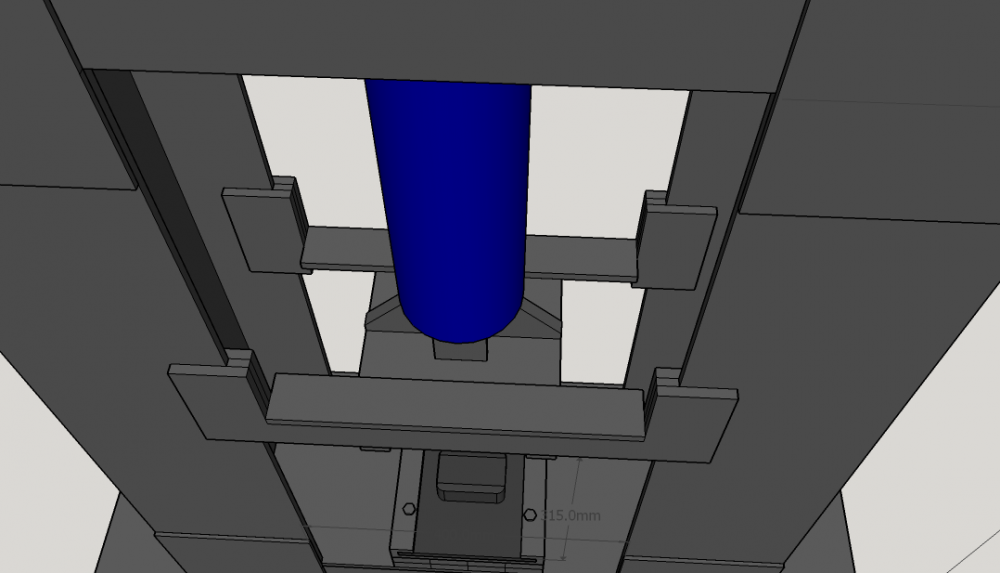

HI, I'm Interested what press dies people are using, what variations they've come up with and what dies you like best. Here's some dies I've designed, please feel free to criticize. Ross.

-

Awesome, I can't wait to start on my forging press! Regards.

-

Here's the updated design. Regards. press.skp

-

Ok will do. regards. No problem, feel free. I'll be redesigning it to fit the steel I can find laying around back home. Regards, Ross.

-

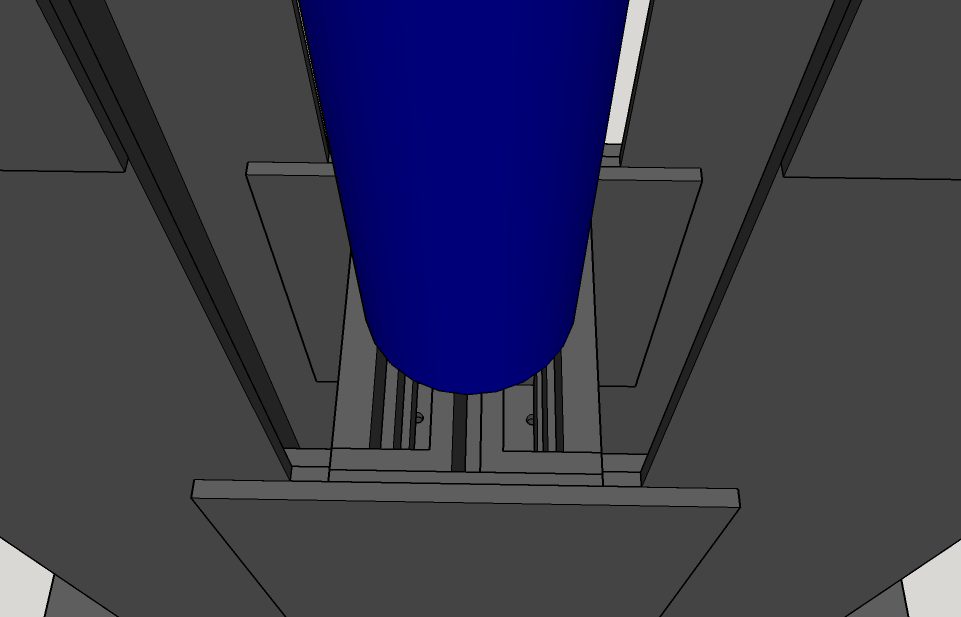

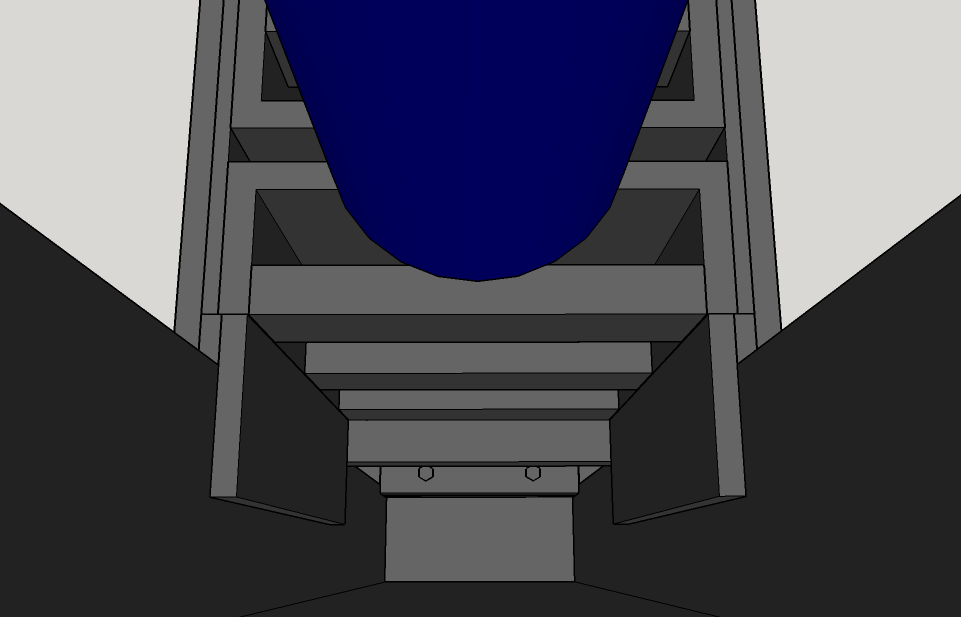

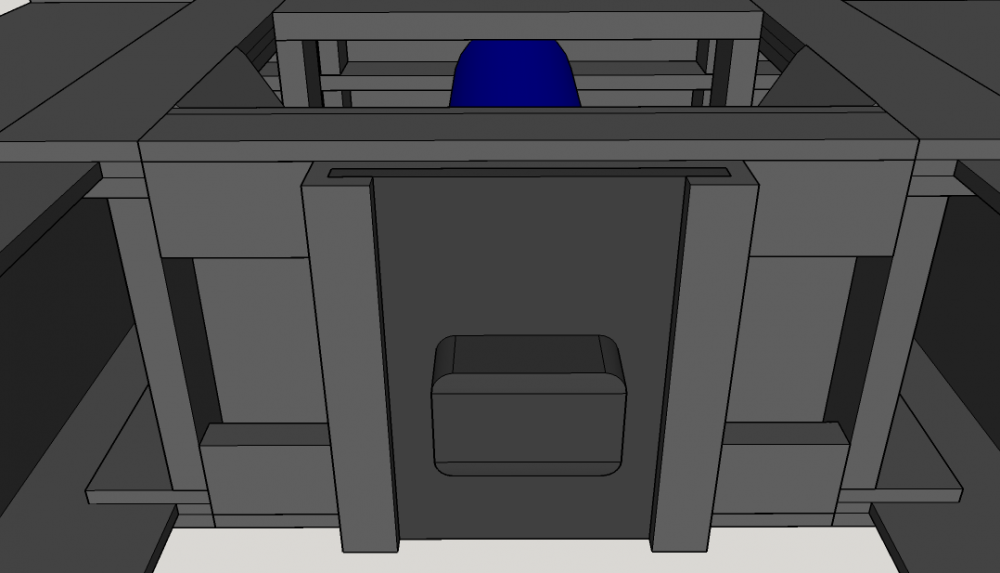

Hi Sorry JHCC, Here's some images, they don't have lots of measurements though but as I said its a rough design. Regards

-

Update: I've made a rough design (very rough, just for getting idea's) here it is. note: measurements are just rough calculations of what metal sizes I'll be using. Please let me know what what you think I should change/adjust. Feel free to use and modify it however you want. Regards. press.skp

-

I'll be mainly using the press for Damascus billets for knife making (like 80% of the time). I've got a bit of experience making machinery but not lots. I'm not a brilliant welder, but I'd get someone else to do the welding, whose good at it (or do lots of practice before hand). I've done some research but I haven't found any place that's explained everything in detail, i'll do some more digging. I'll go by this rule when making the press, if you thinks it's strong enough then make it three times stronger. Ross.

-

Hi, Firstly, yes I do want to build a forging press. No, I don't know anything about hydraulics, BUT I'm very keen to learn. Could someone please explain to me in plain English the what, where and how's about forging presses. Also could someone give me an idea of what I must look for and where I can find it in south Africa. Please note ,its very difficult to get books about making forging presses and the likes in south Africa. Regards Ross.

-

Damascus: 5160 and what???

Ross Moffett replied to Ross Moffett's topic in Blacksmithing, General Discussion

I think I'll just stack up Some billets of: bandsaw (nickel) and bandsaw (carbon), 5160 and bandsaw (nickel), file and bandsaw (nickel), file and 5160, mild and 5160, circular saw and bandsaw (N), circular saw and 5160, circular saw and mild steel. Regards. -

Damascus: 5160 and what???

Ross Moffett replied to Ross Moffett's topic in Blacksmithing, General Discussion

Well I just want to get better at forge welding for now and not worry too much about HT and proper edge holding capability, in other words I just want to end up with some damascus that looks good and could maybe make a "show" knife. Regards. -

Hi. What Damascus combinations do you guys suggest? Remember I'm in South Africa so no lovely 10** steels for me. I've got a plentiful supply of 5160 and bohler uddeholm bandsaws (nickel bandsaws and carbon). i'm going to have access to some mechanical power hammers in a few weeks so I I want to start getting some billets of Damascus ready for then, please leave your suggestions and opinions. Regards.

-

Thanks for all the replies. I'm considering getting the silhouette cameo, here's a video of a guy using one for metal etching.

-

Hi, Has anyone used a vinyl cutter for logo etching? I'm considering getting one and I just wanted to know what your guy's opinions are. Regards.

-

Got a 16 layer billet ready for forge welding, I'll post some pics later of the progress. Regards.

-

I'm thinking the same thing, wondering if a can convert it or use it for forging. This one is also dirt cheap (3000 Rand about 231 dollars) if it works it might be worth it if I can convert it or not. I only managed to find a video showing a Mohrbach typ41 press, it was doing shoe sole forming. Maybe I'll get it, you never know it might come in handy some day. Regards, Ross.