-

Posts

80 -

Joined

-

Last visited

Profile Information

-

Location

Quebec, Canada

Recent Profile Visitors

1,292 profile views

-

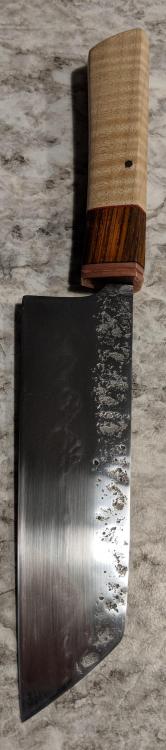

A hand forged Japanese blade sold commercially by a high end cutlery dealer in Montreal. You guys sure like to gang up on people. So now tell me, why would such a respected and esteemed institution sell a knife that's unsuitable for the kitchen?

-

Old stock new files from Nicholson if you can find them. Otherwise, Simonds USA or Nicholson Brazil are ok.

-

Over sanitizing brings other issues as well. Our immune system is weakening over the years. Of course, this isn't a good reason to risk food poisoning but let's just be reasonable...

-

I had no problem with it until the "kitchen knife unsuitable for the kitchen" part. An obvious lack of tact IMO. Less suitable, maybe, but downright unsuitable is an opinion and not a fact.

-

Oh well, one would think someone would take the time to properly wash his 300$ kitchen knife. Anyways, this question was brought up during the knife design with the client which is also a friend of mine. I hope we can now close the can of worms. No more unthoughtful opinion about a kitchen knife supposedly unsuitable for the kitchen on someone else's thread. Thanks

-

It's going to have regular use in a kitchen, not a professional one that is. First, the textured part is quite high and most food won't touch or barely touch it. Second, this is not a butcher's knife in any way. Third, we often see texture in Japanese knives and nobody complains about it. All in all its just about common sense...

-

I like pretty much everything about them, including the story. They look like real performers that are going to be used for generations.

-

In my book, if it cuts well, holds it's edge and doesn't chip, you have a good blade . The rest is ergonomics and aesthetics.

-

Tempering questions

Joël Mercier replied to BladeSmithInTraining24's topic in Heat Treating Knives, Blades etc

end of story. -

Tempering questions

Joël Mercier replied to BladeSmithInTraining24's topic in Heat Treating Knives, Blades etc

That's a good question. I am following. -

Thank you sfeile! And I am left handed too . This was a commission for a friend's girlfriend. Both right handed of course.

-

This is the nicest compliment I've received about my work. Thank you very much sir! And thanks Lou! Much appreciated.

-

Thank you DuEulear!

-

-

Fine work, and I agree on the slicer part. It seems scary sharp just by the look.