7A749

Members-

Posts

184 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by 7A749

-

Thanks Tom. I actually got it on eBay. One of those online consignment shops was selling it for the place that had it. I was sort of surprised I won it. I only bid because it was about an hour away. I figured for sure someone was gonna outbid me. I had been looking for awhile and didn't know a whole lot about anvils when I got it. I researched it enough to know what it was and that it was a "good" brand of anvil. Right before I bought it, I went out to a resale dudes farm in Leslie, and he had a very large (like 400 lbs) cast anvil for $600. I should have bought it, but didn't really need one that big and I wanted a wrought one. I do have a baby cast anvil that I mounted on a trailer hitch type base. It's handy for small stuff. It's a cute little thing

-

How to cut a rail road track

7A749 replied to MrDarkNebulah's topic in Blacksmithing, General Discussion

Assuming it's ok and legal to remove, a gas powered abrasive saw as Thomas mentioned would be my go to method for in the field cutting on something such as that. A gas cutoff saw would make quick work of cutting and removal, not to mention just about any big box store that rents equipment will likely have one. I wouldn't want to mess with oxy fuel purely because of the fire risk. The cutoff saw will indeed throw sparks, but can be controlled to a much greater degree and it's a lot more portable. "Rooftop" torches would be my next choice. Even the small sets can cut thick stuff for very short periods of time. Such methods would be suitable in the event it couldn't be removed as a large piece and easily transported back to the shop. Those gas saws really are the bees knees for stuff like this. They're messy and loud, but they get the job done fast and are as easy as a chainsaw to use. IMHO of course -

Why would you deliberately damage an anvil

7A749 replied to stan's topic in Anvils, Swage Blocks, and Mandrels

I bet you're entirely right about that too. I've been repairing welding machines for about ten years, and I've seen some really rough machinery come out of big shops where low paid operators just beat the living daylights out of it. That's a big reason I usually advise ppl looking for gear to stay away from retired rental machinery. It gets beat like a rented mule, and the rental outfits know this, so they're usually looking to move it about as soon as the factory warranty runs out. They generally have their own certified Inhouse technicians working on the stuff, so it's in their best interests to liquidate it as soon as it becomes a liability. As long as the manufacturer is footing the bill for the parts and labor, all is good. Once it's on them, not so much. I know that isn't necessarily about blacksmithing and anvils, but the principle applies that if something doesn't belong to someone using it, they often will treat it with disrespect. Unfortunate but true in many cases. At least in commercial applications from my experience and I've seen my fair share of beat up gear. I'm glad the top of it looks good tho. Just a darn shame somebody had to gouge it all up like that because they were too lazy to use a piece of scrap for the task. IMHO of course -

That's good to know. I found the info on an ABANA forum page and the guy with the info sounded quite knowledgable. He was using AIA as a reference. I plan to buy one for myself at some point, it's quite a nice book from what I've read about it. I have seen one of the older HB anvils with the tool steel top plate at a shop I've done some work at. The top is heavily damaged and delaminated, but I told the owners if they ever decided to part with it to let me know. It'll have a nice home here, even if it didn't get used much I imagine this anvil will suit me just fine for likely the rest of my days. The majority of forging work I do is on sheet metal, and I actually use a low steel top work table to do a lot of it. Of course, if a screaming good deal on another anvil happens to come along, all bets are off Many thanks for the info.

-

Why would you deliberately damage an anvil

7A749 replied to stan's topic in Anvils, Swage Blocks, and Mandrels

It sort of reminds me of all the wire feeders on welding machines I've repaired where guys used the tip of the hot MIG gun to adjust the feed rate. Knobs all burned up and the face all smashed in and gouged all over. Its likely not theirs, so it's not their problem. In this case, at least they didn't treat the face like they treated the rest of it. It's still serviceable. I couldn't see myself doing that, but I take relatively good care of my tools. IMHO of course -

I have a 150 lb Hay Budden on a metal stand. Serial number puts it around 1910 if my research is correct. What I've read says the later model HB anvils made after like 1908-09ish had one piece tool steel tops. Please correct me if this is wrong. Been spring cleaning, pulled it off the stand and cleaned it up, put a new coat of clear lacquer on the sides to keep the rust away. I made some simple toe clamps to hold it down to the base. It has a great ring and prolly 80% rebound at a guess. I think it's had a couple minor repairs made to the edges of the face, but if they actually are welds, they look good and there's no cracking around the areas. I've done nothing to it besides hit it with a wire wheel and put clear lacquer on it periodically. It came out of a machine shop in Grand Rapids that closed its doors after like three generations of men ran it. Got $350 in it IIRC. Had it about 12 or so years. Don't need anything bigger, nor do I have the room. I consider myself lucky to have gotten one of these in good shape without it costing a fortune.

-

I work for an auctioneer once in awhile cleaning out places and setting up auctions. We did one a few weeks back. An older lady who happened to be a pretty good painter. She had some medical issues and suddenly died. The kids hired the auctioneer to sell the house and contents. Four auctions worth. The place was packed to the rafters. Literally. One auction of nothing but old postcards. That'll be a truckload of dough right there. But one thing worth noting was the fact that she had THOUSANDS of books. Books of all kinds. All of them, high quality and some were very expensive when purchased retail. He couldn't hardly give them away. Many boxes stuffed full of them remained unsold. How sad. I understand the Internet has made written information such as this largely obsolete but for a fella going to go out into the bush and live off the grid, he would have reading material to last him ten years easy. I grabbed a few books on birds (my wife does feeders for them) and old depression glass. Prolly a thousand records too, and the majority sold as a single lot for five dollars. Yes, five dollars. I prolly spend too much time on the Internet, but most of it is as an administrator on another welding forum. I'm not big into videos on YouTube, it just isn't my thing. Should read more, but work keeps me pretty busy. Since joining this board, it's the only one I do besides WW. Just something else to keep me perpetually occupied

-

Get those babies out and jam man! Yeah, I was never any good but a persistent case of carpal tunnel kinda put the kibosh on any serious attempts to start playing again. I had the right hand operated on in '04, the left wasn't bad enough then to do it under workmans comp. Now, it's so bad I can't hardly drive with my left hand on top of the steering wheel because it goes numb in a couple minutes. It's hard to hold anything with it either for extended periods of time. I can't grip tongs or hammers for long, the hand just goes dead numb. Don't have insurance now so an operation is out of the question for the moment. Im not selling the 'Paul tho. It would hurt too much I really like your creative perspective. The mixed media art medium is very cool indeed. Rock on bro.

-

Excellent!!

-

That is super das!! I got a Les Paul myself. Can't play anymore but seeing that makes me wanna try!!! I love your stuff. Really. It's awesome!!

-

Leaving the Country--Sell or store?

7A749 replied to Ridgewayforge's topic in Building, Designing a Shop

I guess it depends. I never plan anything that far in advance because who knows what's gonna happen five years from now. If your folks are cool, and won't pull a 180 on you, then yea, store it there. My mom is the only living direct relative I have and we don't get along real well. I wouldn't leave anything there unless I had the ability to quickly move it in the event of an issue (we've had more than a few, she's quite fickle and can turn on a dime). The one advantage will be if you do sell it, is that if five years from now, you decide to stay in Rome, meet some one, etc you don't have to sweat liquidating the stuff, or spending big coin getting it shipped over. What you have in it will make a difference too. Not bashing your gear, but it's not like you got real high dollar stuff by the sounds of it and it could all be replaced without taking a beating. At least from a spectators observation. If you were sitting on a 400 lb pristine Hay Budden and had a rather large collection of pics, specialized tooling, etc than storing may be a better option since replacing the stuff would likely be difficult and expensive. Not trying to play devils advocate, just offering a different perspective. I buy and sell stuff for a living, mostly welding machines. I spent several years storing stuff, moving stuff and handling stuff I thought I would eventually use. I ended up giving most of it away at auction before my divorce was final. All the money and time I spent on storage ended up being a waste. Considering that your circumstances are different, and it sounds like you got cool folks, then at minimum keep the anvil, vises and forge. Peripherals can be replaced easily enough. The Bible says you don't know what your life might be tomorrow. I tend to plan short term and keep options open. Oh, I've found that brush on clear lacquer that you can buy at any hardware or big box store protects metal nicely and can be recoated as needed. I have it on all my blacksmithing stuff. Keeps the rust away and can be removed easily enough. Best of luck with your studies and whatever you decide to do. IMHO of course -

That's really cool. Something I have yet to do.

-

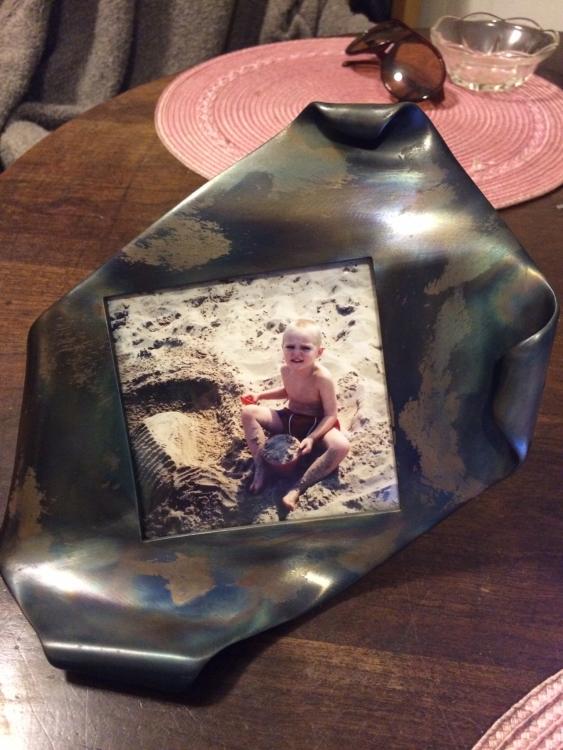

Thought I would add a couple picture frames I made. The pics aren't the best, I had more of them and I made a mistake last year and wiped out over 10K posts and all my pics off WW while using decimator to ban a spammer. Oh well. Anyways, Heres a couple frames I made.The first one I made for some friends of my moms. Their only son was heavily involved in coaching girls softball, hence the home plate shape and hanging whistle. Unfortunately, he took his own life after a bitter divorce. He had two teenage daughters he left behind. I did it for $100 and wouldn't take a penny more. His mom and dad cried when I gave it to them. I did too.The second one I did originally for my now ex wife, but I took it back shortly after our separation. It was an anniversary gift with a pic of her and I when we were first dating.Put a pic of my son in it. He was like four at the time. Both are mild steel and made from scrap. I heat colored both of them, but never applied a protective coating to the second one and it tarnished. The effect ended up looking kind of cool, dunno if I'll refinish it or not. I used an automotive grade clear coat on the home plate frame.The base the home plate frame is attached to is the same style construction as the "scroll edged" frame. I used a pair of vise grip needle nose pliers to twist the scrolls while hot. After I finished the general shape, I metal finished it with an angle grinder and non woven abrasive wheels on my buffer. The home plate frame is welded together from several pieces, then attached to the base by TIG welding.Both of the Windows for the pictures were cut by hand with a cutoff wheel, and hand finished with a file. Nothing was cut with any CNC equipment.

-

Yeah, I gave the Cable TV fed tube up when my ex and I split five years ago. I drank too much and spent too much time in front of it so excising both of those things from my life helped a lot. Now don't get me wrong, we LOVE our guys from Moutain Monsters and I get a big kick out of their search for Bigfoot, etc. We like some of the ghost hunting shows too and Finding Bigfoot is another favorite as well. At least in my opinion tho, those guys get along great, there's no mugging for camera time and it's just good fun. Of course, the Moutain Monsters thing is a put on, but it's entertaining and I genuinely like the cast. It's really sad that a show about blacksmithing comes on, but quickly turns into another run of the mill reality show with all the crap that comes with it. It seems to also be standard practice to create or insinuate constant tension and conflict when it doesn't exist, since I guess it boosts ratings. I've had a few ppl tell me I should make a YouTube channel, but watch me wrench on machines would get boring in a hurry. I suppose watching me flip out when I lose my temper (sometimes frequently )might be interesting, but I already have enough problems and the whole world knowing what flips my switches isn't my idea of "good programming" Oh well.

-

I don't even have TV (other than what we watch thru Amazon Prime and Nextflix) and I honestly do not miss it. When Gold Rush first came on, like five years ago, it quickly turned into the standard reality TV fare of as was mentioned "contrived drama", hollow plot devices and a bunch of other behavior that would get me in trouble here if I were to extrapolate on what I really thought of it. It looked kinda promising at first, but it went downhill fast. The obviously manufactured drama really turned the whole thing sour on me, and reminded me of an Alaska edition of West Coast Choppers and Company reloaded. Once the production team had the voiceover narration (done by some studly sounding, gravelly voiced Alpha Male) billing the free facet block some Doctor did on James Harness as "Radical Back Surgery" I was done. Gee, can't tell you how many facet blocks and epidurals I've had on my jacked up back, and none of it was ever considered "Radical Back Surgery" by any stretch of the imagination. But of course, accurate and truthful storytelling with actual skilled craftsmen (and women) performing real tasks without manufactured drama and conflict would be boring as all get out, and would likely not keep the attention of anyone (save for sane, real individuals with an appreciation for for the craft) for very long. I haven't seen any of this particular program, but it sounds like the same, worn out standard reality TV script, just with different characters. More bluster, big egos and bleeping out bad words than anything actually useful or truly entertaining. For the largely brain dead masses that can't get enough of that stuff, Discovery, Inc and the rest watch the profits come rolling in and they can brag about the latest Number One Show On Cable.... At least until the next greatest thing comes along. Its sad and unfortunate that with most reality TV, the only worthwhile stuff quickly takes a backseat to the set up conflict and ego laden performances of the cast. All hoping for their 15 minutes of fame... MAN, AM I GLAD I DONT HAVE TV ANYMORE!!! Sorry for the rant IMHO of course

-

You know, I'm no expert on anvils, or even blacksmithing for that matter, but I buy sell and repair welding machinery for a living, and have been doing it a long time. I know the buy and sell business and I know it quite well. Perceived Demand will always outstrip common sense and even common market values every single time. This guy probably doesn't sell as many anvils as he claims, but he probably has a line of suckers who come back after failing to find something local and shell out the cash for his overpriced wares. I got lucky on my anvil and got a decent condition 150 lb HB shop anvil out of a closing machine shop for about $350 12 years ago. Thanks to TV (it's a double edged sword) and Instagram, Pinterest and other social media making blacksmithing "cool" and "trendy", anvil values have shot thru the roof. I have seen the same thing welding machinery, but not on such a sharp incline. I advise someone looking for an entry level machine to buy what they can afford and look for the best value they can find. I can promise you, I would be looking at an offering from NC Tool/Centaur before I would give some CL flip artist my money on such shrewd and outrageous terms. I've bought lots of stuff from them and they're a good outfit and nice to deal with. Of course, that's just me tho and everyone sees things different. Point being, the CL flip pro KNOWS there's plenty of desperate, clueless marks that will give him what he wants, and as long as there's a steady stream of those kind of ppl calling you for your stuff, you can dictate the terms, as ridiculous as they may seem. You don't need a big, old solid wrought anvil to work metal. As was already mentioned, but a heavy block of steel and save your money for something more important like a forge and other tools you'll need down the road. A good anvil will eventually come along. You may have to drive for it, or buy it from someone and pay a little more than you want to, but it will. Bowing to some chump flipping stuff on CL isn't in the game plan for me. It's more a matter of principle than anything else. I price equipment to sell and I don't jerk my customers around, or demand prices I KNOW for a fact are way out of line with reasonable market values. I like to treat my customers the way I would like to be treated if I were buying something from them. Good business makes the world go 'round. My money will go on something quality that's new before I'll shell out cash to some guy who's clearly taking grossly obvious advantage of a lucrative resale market angle. IMHO of course

-

Yeah, that's sort of where I'm at, (and wanting to go) only I don't have any hammers quite that big. Cleco and IR make a really nice hammer like that for square shank chisels which can be modified to any shape. I use a smaller air hammer with blunted chisels and points to create similar effects to what the guy did in the video. I recently bought a real nice Ingersoll straight air chisel which uses square shank chisels. I need to get a couple for it. I had to modify a large nut for it that acts as a jam nut to hold it together. I turned it in my lathe and tapped it. I only paid ten bux for it and it cleaned up real nice. I can't wait to use it. I need to acquire a large stump like that fella has for deep forming. On the anvil or a table (my preferred method for working hot metal) there's too much rebound. Once you get the larger depressions made, then the hard surface can be used for the finer work. I've used V blocks to do preliminary depressions on stuff, then finish it out on a trailer ball striker. I still have a lot to learn, but I like the pneumatic hammer method a lot. Great video. That guy is super talented. Thanks for the link.

-

Here's a couple flowers I made several years ago. I hammered the detail on the petals, obviously not shooting for realisim here. They were actually going to be part of a montage for my now ex wife. I did weld two of the original four flowers I had to a stand and gave them to a former boss I had who I thought a lot of. She was a neat lady. The butterfly was a reproduction of a drawing my ex wife gave to me when we were dating. I tore the drawing up, but couldn't bring myself to toss the metal piece lol. They are all heat colored and oil finished.

-

Thanks a lot. For those who asked, here's how I fit the mirror into the frame. These pieces of rubber firmly hold it into the brackets I attached to the back. So far, this is the best solution I've come up with. I can hold the mirror upside down by the frame and shake it and it doesn't move or fall out. Of course, I did this over a padded surface.... But anyways, I have to add the hanger for it, then I'll finish up the coloring on it before clear coat. That's the plan anyways. Yea, that sounds fair Doug. As long as the tank is sound you'll prolly be fine. I agree on not beating the guy up on the price. I might suggest offering additional services for more money off it if he's game tho. You never know what he may be thinking. I would be all over trading work for it if possible. My Ingersoll has served me well. Adding that auto drain really helped a lot. When I get time, I'll make a riser up for the dryer I bought and get it installed. Ill put a thread up about the compressor. I'll just copy the text. I have most of it saved as a file anyways.

-

Hey thanks. I'll take a pic of the back. Right now, I'm using two small pieces of rubber that fit into L shaped brackets I forged and welded to the back of the frame. They sandwich between the brackets and the back of the mirror. The brackets have a sort of musical note shape to them for lack of a better term. It's held in entirely by friction. It's quite sturdy, but I'm open to suggestions on a better way. The pix will explain better than I can right now. I'm on the road until tomorrow.

-

I'll be sure to do that ** Thanks Doug. I really understand the link thing because when someone completely new shows up over on WW and their first post is loaded with links to videos, websites and Instagram accounts it kinda leaves me feeling like they're just using the site to boost their own numbers. I'll take some new pix of the forging station and stuff since I didn't have backups when I banned myself last year. Thats great on the compressor. I hope you get it. Once you have a good air supply, the whole world seems to open up at that point. Of course, after playing with some of the stuff you have gotten to use, not much compares hehehe. I've been on a road trip to pick up some welders and a new to me belt grinder. I'll post pix up. I stopped for the night after close to 500 miles. Did Lansing to Euclid Oh, to South of Indianapolis and about 60 miles north of there now. Im beat lol ** Thanks JHCC. Still trying to figure the quote thing out on this site. My head being soup after all day in the road doesn't help. I'm already clueless as it is lol.

-

This blacksmithing thing is getting pretty serious

7A749 replied to Fuzz557's topic in Blacksmithing, General Discussion

Man, it looks like we both have the same problem, only in my case it's welding machinery. It seems to follow me home.... Funny how that works Dont build a bigger place to store it or you'll just end up with more junk, uh I mean stuff Nice pieces tho! -

Thanks a lot man. I've been reading a lot. I love your titles, like "curmudgeon" or in your case, a cranky old guy. We should have that over on WW im sure whatever they called me, it wouldn't be very nice lol.

-

Thanks. I use a needle scaler to create the texturing. I have several different ones, but the cheapie Harbor Freight air hammer slip on gives the best overall texture without being too harsh IMHO. I do the distressing at about a cherry red heat. The needles also create a domed effect on the steel after a few heats. I have three trailer ball strikers I made that fit in the square holes in my table or in the hardie of my anvil. I use those to create larger relief areas, then use various scalers to draw the metal and get the shape I want. I'll post up some pix of the stuff I use. If you got a scaler and a decent compressor, give it a shot. You can really do a lot of shaping and different textures with one after you get a little time with it. I am going to work some stainless soon. I've done very little with it in the form of forging, but have wanted to try it for awhile. I'm going to post a thread in the general discussion to try and get some input on the best ways to go about it. Traverse is beautiful. Been awhile since I've been there. Hopefully we'll have a nice summer. Winter was pretty uneventful. Many thanks!