John in Oly, WA

Members-

Posts

932 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by John in Oly, WA

-

The solder and flux is a bit confusing. Not to mention spendy. There's a Harris SBSKPOP Stay-Brite Silver Bearing Solder kit (96%-4%) says works with stainless and copper (the HDepot description says not for aluminum). Another description I found said the Stay-Brite 8 is not for aluminum. Another said good for all ferrous/non-ferrous alloys.

-

I will look into the wine funnel. The SS concentric reducer arrived yesterday. The inside will need a bit of machining to make a smooth transition from large end to small. It has an odd ridge in it around the diameter, aside from the linear seam weld. The SS pipe for the mixing tubes and nozzles also arrived. I have plenty of 1/4" copper refrigeration tube and MIG tips. The 1/2" aluminum bar and the SST is on the way. Need to pick up some solder and flux.

-

Cable Damascus Bowie, With a Hammon?

John in Oly, WA replied to jmccustomknives's topic in Knife Making

Very nice work! And the live edge on the guard is a bonus treat. -

Hardie Hole size

John in Oly, WA replied to foundryguy's topic in Anvils, Swage Blocks, and Mandrels

Nice work! -

Two more window knives and a kukri with book micarta

John in Oly, WA replied to TheoRockNazz's topic in Knife Making

Nice work. The handle on the kukri is especially nice! -

That was another thing I was wondering - does the fan run full blast, or do we need a variable speed control. Looks like speed control is a good idea.

-

The wine funnel you posted a link to says "Currently unavailable". In the meantime, I went nuts this weekend and bought a schedule 10 - 2" to 3/4" stainless butt weld concentric reducer which has inside diameters of - large end 2.157" and small end .884". Then I bought 24" of 3/4" schedule 40 stainless pipe from Online Metals with an I.D. of .82" hoping to be able to blend the .884" reducer to the .82" pipe for a smooth transition AND I bought a LEM sausage stuffer tube - 2" base, part # 607B 1" O.D. AND a piece of schedule 80 - 1.25" stainless steel pipe with an I.D. of 1.278" for nozzle material. Along with a couple of computer fans that seemed to come closest to meeting the 3:1 ratio of funnel opening to mixing tube diameter. It's a little smaller than 3:1. Still need to find the aluminum spacer/inlet tube block and then get the specs on capillary tube diameter. So, I thought I'd build two burners - one with the LEM SST and one with the SS concentric reducer. And now seeing your last post, may have to buy 70mm fans.

-

Brands and Blacksmithing advice?

John in Oly, WA replied to AggieBlacksmith's topic in Blacksmithing, General Discussion

But he's really good at it - knows his stuff. -

I found the LEM 1" SST with the 2" base here for same price - https://shop.jayssportinggoods.com/lem-products-inc/stuff-tube-ss-2in-base-od-1in--271113 It has a little more flare at the base end. The stainless reducer I found, the small end is .884", so that would fit the schedule 40 7/8" dia.

-

I can play around with reducers later.

-

I was looking at the LEM and the funnel looked a bit short. I couldn't find a sausage stuffer tube with a longer funnel, so just to confuse things a bit more, I then started looking at stainless concentric reducers. Then began wondering about the ratio from one end to the other. I think I remember you saying 3:1 max. But is that ratio of diameters, which comes out to be .75" to 2.25" - or areas, which comes out to .75" to 1.3". I found concentric reducers with I.D.s of Large End 2.157" to Small End .884" and thought about just welding them to a thick wall mixing tube. Ah, all the possible variations! Lets go with the LEM SST and the 3/4" aluminum block and see how it goes.

-

Yes, got mine yesterday and it seemed a bit small. I'd like to stay on course with the 3/4" build. So, we're looking for something with an inside diameter around 7/8" and that will be a 3/4" burner? If we could find a 1" sausage stuffer tube, would that work?

-

Beautiful work! I love the theme.

-

Not real familiar with all the characteristics of stainless. I know it doesn't machine well - kind of (there's a word for it) smears. My metallurgical education is ongoing. But I think it's a matter of what is workable in a cost/benefit scenario. Mild steel would probably scale away or melt faster. Something like titanium I know nothing about as to availability, or workability, but I think it handles high temps well. 310S or 330 stainless is supposed to handle high heat cycling better than the more common 304 or 316, but it is hard to find. So, 316 with the understanding that the flame nozzle is somewhat sacrificial.

-

@Mikey98118 I was looking at OnlineMetals. They have 304 and 316 SS. Looks like they have a good selection of thick wall SS tube. Be nice to find some 310S or 330 for the nozzle. Also got notification that the sausage stuffer tube had been delivered, so I'll post the measurements and you can let me know what will work for the other parts.

-

Thanks Mikey. Glad I could help JBradshaw. I'm just used to overlapping things according to the direction of flow - like downspouts on a house. We'll see what the actually inside/outside diameter is and the SS tube/pipe diameters available to see where it ends up.

-

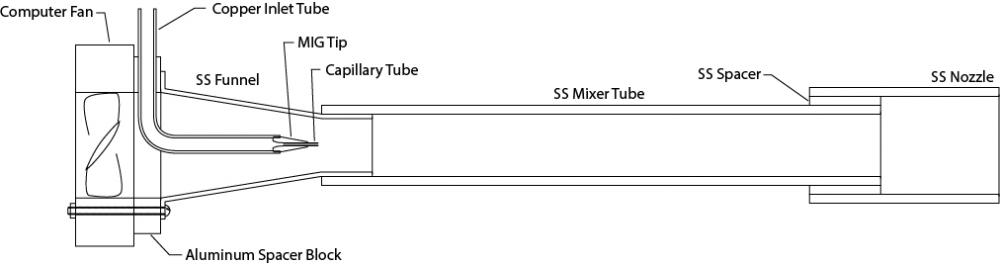

3/4" sausage stuffer tube ordered. Looking forward to this build. A rough sketch of what I imagine the burner will look like:

-

Hi Mikey - how would you make the transition from this sausage stuffer tube with a 2" exit diameter to the 3/4" mixing tube diameter? But that's coming from a position of knowing nothing about vortex burner, or any other burner, design.

-

Nice set Theo!

-

They're not hard to build. Old propane tanks without the overfill safety float can often be found for free. There are a lot of examples right here on IFI showing people building their first forge. And as Wayne said, he has plans and materials available on his site. I think it's the best way to go. Cheaper than buying one and you know what you've got when it's all said and done.

-

This is what I have for a Trenton Anvil Maker's Initial list so far. If anyone has any name info to add, that would be great. A - Mr. Anderson C - Mr. Cheeseman R - Jack Ruble S - ? T - "Doggie" Taylor W? - Cy Wright W? - Karl Wright X - ? Z - Charles Zulty

-

The "S", I've been told, is the initial of the last name of the person at the foundry that made your anvil. Although I don't have a name for S in the list I've started yet.

-

I was wondering if the bolt was too big for that idea. The other trip up in that idea is, would the post office even accept it with all the mail being run through machines these days. Probably have to be for hand delivered letters only. Is a bit sad losing some of the things I always considered standards. Some schools aren't even teaching cursive writing any more.