-

Posts

19,438 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by JHCC

-

Buy them. Your skill level is not yet good enough to make decent tongs, and it's much better to have some decent ones that actually holds the work securely than it is to waste time, material, and fuel on ones that don't. It's a safety issue as well: an insecurely held workpiece can flip out of the tongs when struck and go flying through the air, burning whatever it ends up hitting. You don't want that.

-

jeremy k, I see that I can expect you to give me the boot when I ask you for a hand.

-

What did you do in the shop today?

JHCC replied to Mark Ling's topic in Blacksmithing, General Discussion

Ooh, pretty. What's your wrapped material? Mild steel? -

There are some threads on the forum that show the regions of the fireball. Basically, oxidizing is close to the tuyere, reducing is at the top of the fireball, and neutral is in between. Now, go grind that crack out before someone gets hurt!

-

JABOD My First step toward blacksmithing.

JHCC replied to Strike's topic in JABOD - Just A Box Of Dirt

Keep in mind that too much air can actually cool your steel by convection. If you're not getting above cherry red, that may be part of your problem. I used to use a leaf blower when I first started out, and ended up angling it so that only about 1/10 of the air was actually going into the forge. The rest was blowing at me, which helped me stay cool! -

I'd call it a "Drop Point Hunter" technically, and "Stunning" aesthetically.

-

What did you do in the shop today?

JHCC replied to Mark Ling's topic in Blacksmithing, General Discussion

Good thought, and worth doing. This is in the middle of the chain that connects the hammer arm to the treadle. I stomp on the treadle, the treadle pulls the chain, the chain pulls the arm, the hammer goes along for the ride, and thump. Adding the spring means that when tension is applied to the chain, the spring has to take a moment to compress before it starts to pull the arm. This gives a slightly softer feel to the treadle, which I hope will make it easier on the knees and hips. If the spring were to fail, the springs at the back of the hammer would pull the hammer up and away from the anvil. In other words, failure of this link would not result in the uncontrolled descent of thirty-six pounds of steel and lead. -

What did you do in the shop today?

JHCC replied to Mark Ling's topic in Blacksmithing, General Discussion

I think I saw one of those (in pieces and incomplete) at Quad-State. -

Lisa was just marveling this morning how she — a professional musician with degrees from two world-famous conservatories — “could have married a man with such an unusual sense of pitch.” One nice thing about the removable pages is that I’ll be able to take them out and make photocopies for shop use.

-

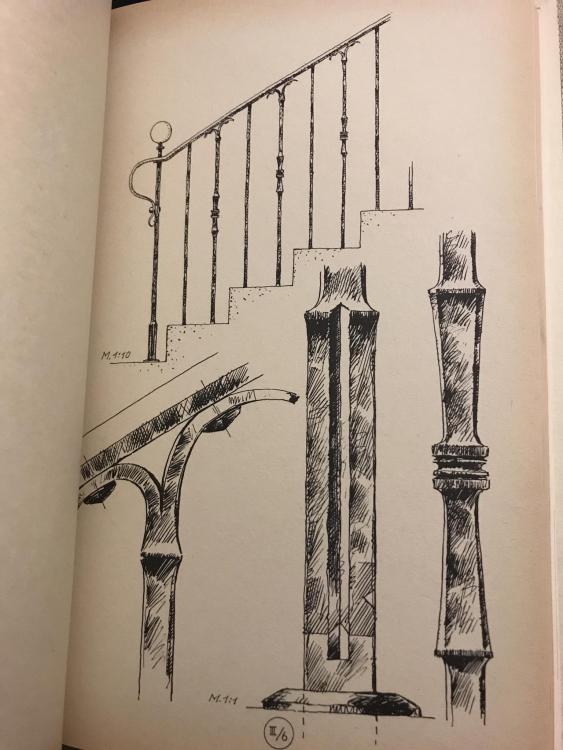

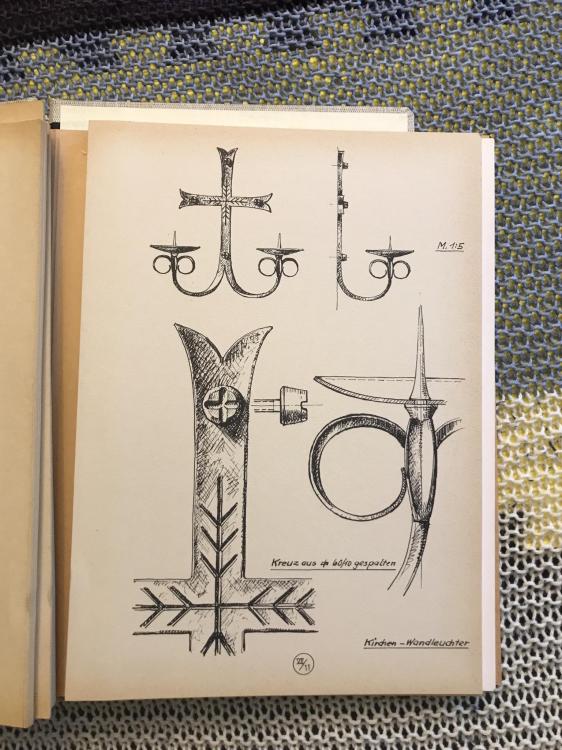

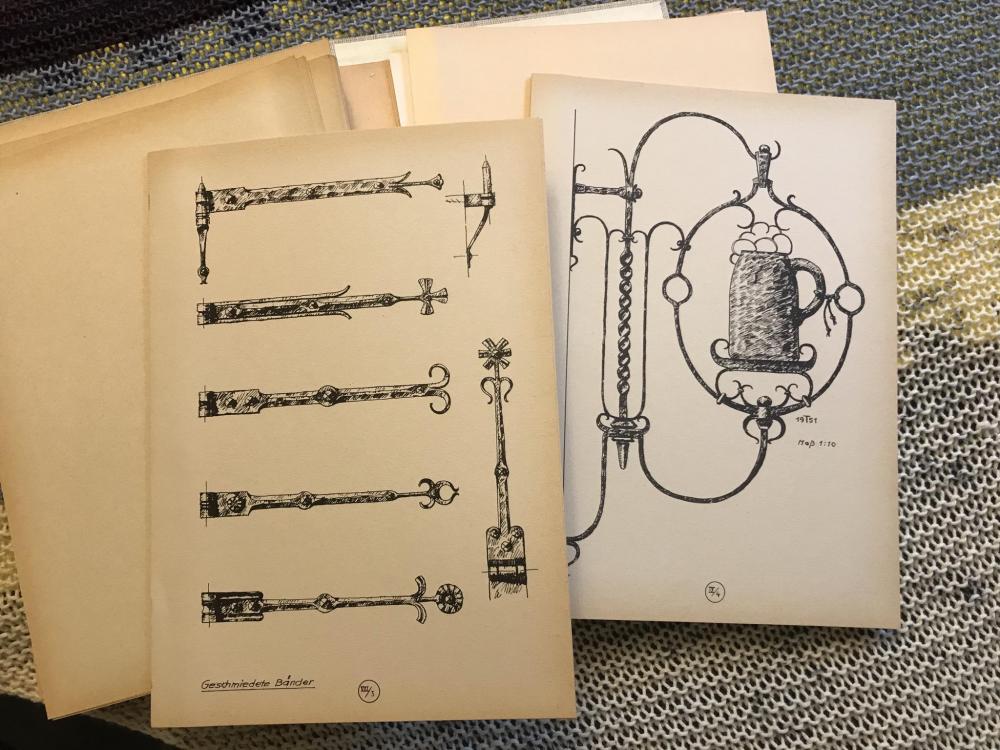

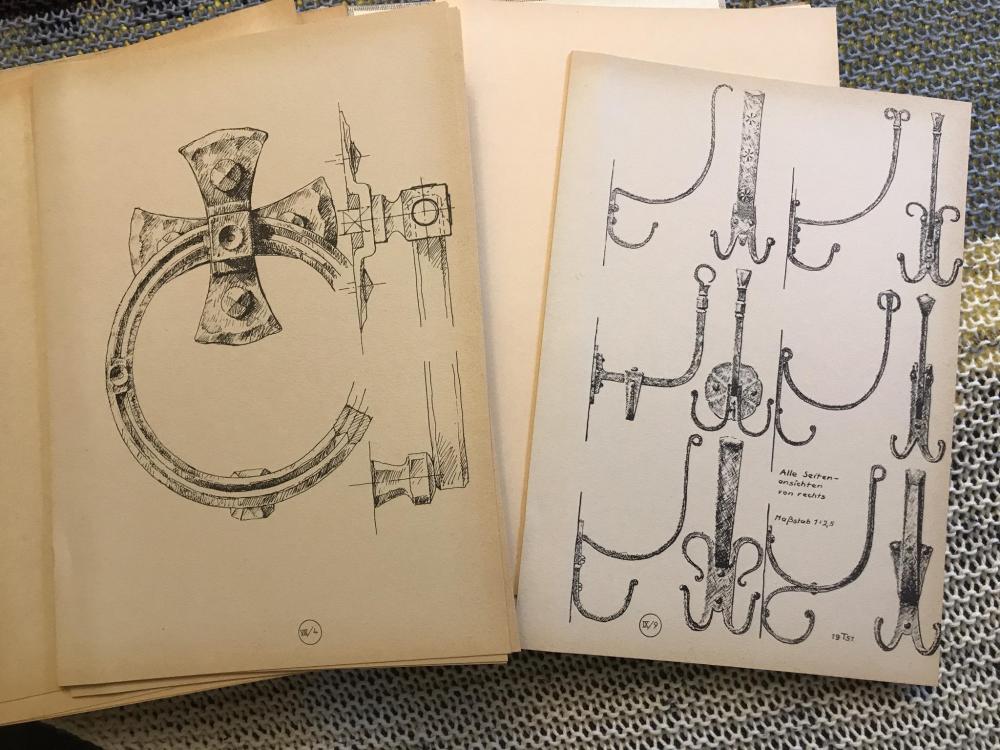

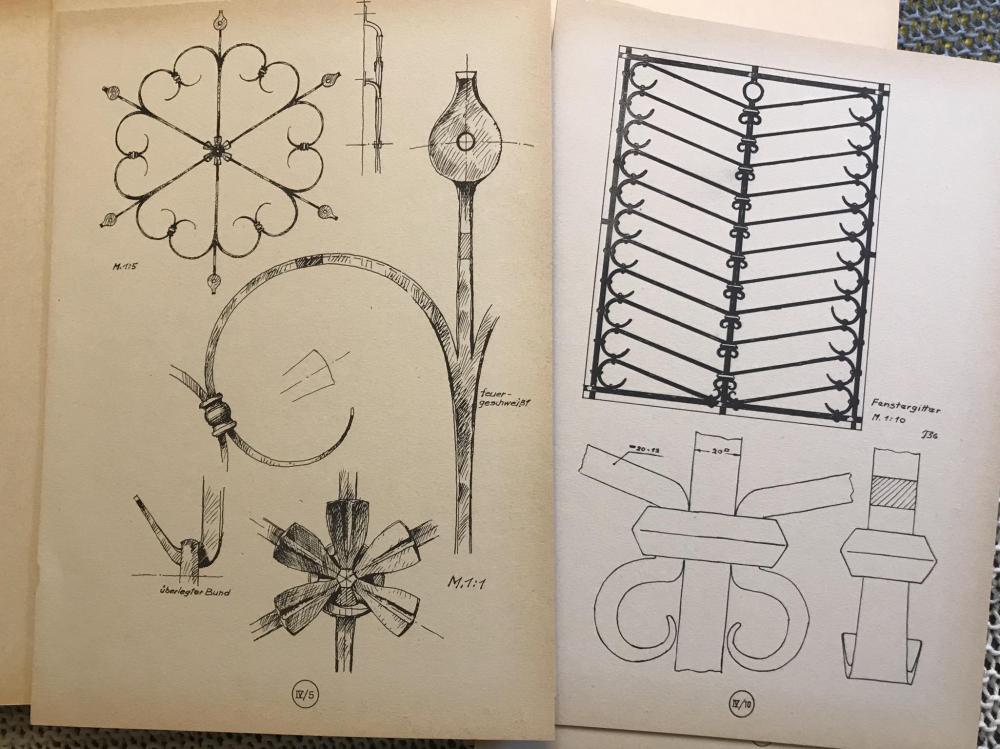

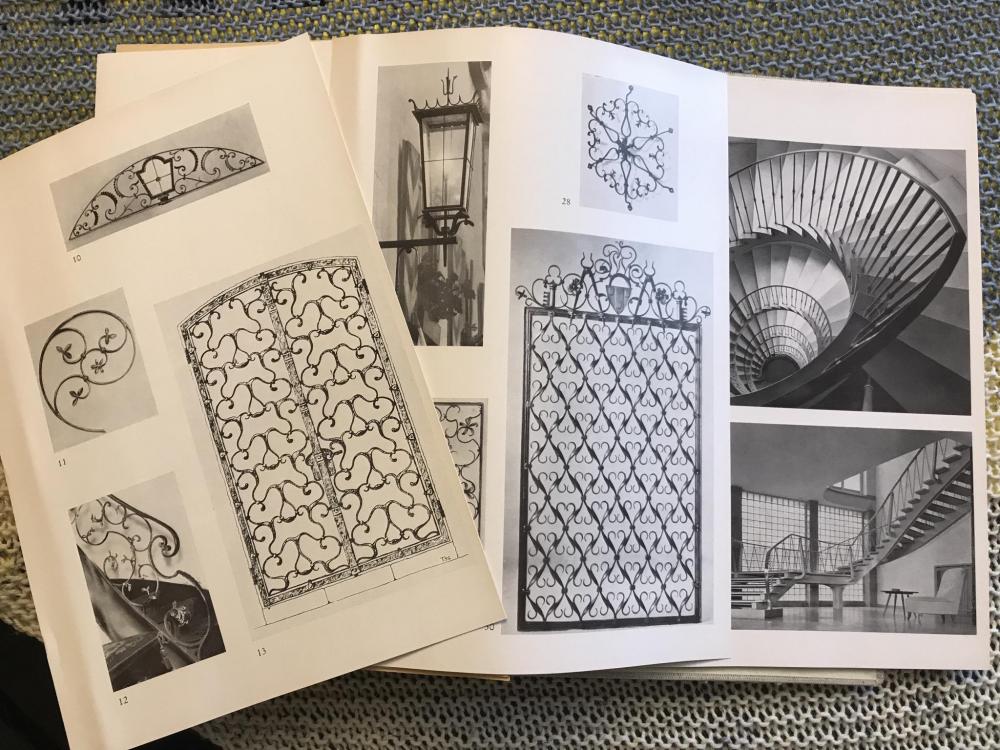

I don’t read German, but it looks like it was published in Munich in 1959. The pages are in an unusual setup. They are not bound together, but are a collection of single sheets (about 140-150; I haven’t counted) held together by a spring-loaded binding. Most of the sheets have drawings of some kind of ironwork (mostly architectural), and there is a small section at the back of photographs. Here’s a sampling: Apart from a little browning of the paper, everything is crisp and sharp, and there don’t appear to be any missing pages. I don’t know if any had ever been taken out before I did just now. Not bad for $3.49.

-

The last two books arrived in the mail from a used book seller, by the way; not related to Quad-State.

-

What did you do in the shop today?

JHCC replied to Mark Ling's topic in Blacksmithing, General Discussion

I clean up before I forge! Longer answer in two parts: First, when I'm doing work that doesn't involve firing up the forge, I just make sure I have a clear area around where I need to stand. I do a fair amount of squeezing-in-bits-and-pieces-of-cold-work-when-I-can, so I tend not not waste time on cleanup; this means that junk tends to migrate around the shop area somewhat. (I will sometimes do a cleanup when things are really bad, as they're getting now.) When I'm actually going to be forging, everything gets cleaned up once the fire is lit and is coming up to forging temperature. Second, the area behind the anvil doesn't get cleaned up as much, because the treadle hammer is back there and I therefore don't forge on that side. -

Welcome aboard! If you haven't yet, please READ THIS FIRST!!!

-

JABOD My First step toward blacksmithing.

JHCC replied to Strike's topic in JABOD - Just A Box Of Dirt

I would say the exact opposite: leaf blowers are generally waaaaay too strong, while mattress inflaters are better for moving a large volume of air. They're also a lot quieter, which will be easier on your ears. -

-

What did you do in the shop today?

JHCC replied to Mark Ling's topic in Blacksmithing, General Discussion

-

Who-all's heading to Quad-State 2018 ?

JHCC replied to Steve Sells's topic in Events, Hammer ins, Where to meet

I actually came home with money in my pocket, but that was because (a) I had to leave early for a family emergency and (b) I had set some money aside to pay for a replacement screw and box for my post vise, but the guy packed up and left before I got back to him. Well, that’s a head start for next year. -

They are now!

-

Welcome aboard! If you haven't yet, please READ THIS FIRST!!!

-

That's some really impressive stuff, and what a thrill to have Lin Rhea praise your work! Great job!

-

Two items of note: First, I found someone on eBay selling a box of five 2 x 90 Norton R999B belts in 24 grit for $22.50 including shipping. I know that's a really coarse grit, but I figure it will get me started and give me capacity for rough grinding things other than knives. Hard to beat the price, too. Second, there was someone at Quad-State this weekend selling a practically identical grinder (fitted out with a 3-phase motor and VFD, along with some 1 x 90 AO belts) for $750, marked down from $900. Feeling even better about what I paid!

-

Who-all's heading to Quad-State 2018 ?

JHCC replied to Steve Sells's topic in Events, Hammer ins, Where to meet

I wasn't able to come down on Friday as originally planned, and so missed the cross forging. Looks pretty awesome. Oh, big lesson learned from my first Quad-State: Start saving your money for tailgating NOW!!! -

What did you do in the shop today?

JHCC replied to Mark Ling's topic in Blacksmithing, General Discussion

I haven’t weighed them, but they’re about 39”/1m nose-to-tail. -

What did you do in the shop today?

JHCC replied to Mark Ling's topic in Blacksmithing, General Discussion

Added a short spring section to the pedal linkage on my treadle hammer: And tried out the new shears from Quad-State: Bit of a learning curve, but got some nice bowl blanks cut out: -

For example, “Intro to Heat Treating” has been pinned to always show up first in the Heat Treatment section