-

Posts

20,937 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by JHCC

-

New Member, Looking for input/ suggestions for FA Propane Forge Burner

JHCC replied to Dusty93's topic in Introduce Yourself

Hi, Dusty. Please put your location in your profile settings, so it will show each time you post. A few hundred posts from now, no-one is going to remember you mentioned the Cape here or know that this thread is where to look. That said, where are you on the Cape? -

This is only worth doing if you can get full penetration on your welds; any gaps will act as shock absorbers and reduce the effectiveness of your anvil. Someone suggested on here once that rather than putting the various pieces together and welding around the edges, putting a piece of 3/8" (or thereabouts) rod as a spacer and then filling the resulting gap by building up beads from the inside out. Since your consumables are paid for, this actually might be not so unrealistic. It would certainly give you plenty of practice running beads. (NB: While the sketch above shows the setup to weld the face onto the body, you could do the same thing to join together the pieces that make up the body itself.)

-

While in southern New Hampshire on business, I stopped by a couple of favorite tool stores and found a few goodies. From the Tool Liquidation Center in Derry: And from the Vintage Tool Shoppe in Fremont: Total expenditure: $41.

-

How to brass coat a steel bell in the forge

JHCC replied to BELL MAKER's topic in Finishes for Metal

That's quite interesting. I've heard about the trick for estimating the correct forging temperature for aluminum, where you rub it with a pine stick and see what kind of mark it leaves: brown needs more heat, black is just right. I wonder if anyone's compared the stick trick with the Sharpie trick to see how they compare. -

How to brass coat a steel bell in the forge

JHCC replied to BELL MAKER's topic in Finishes for Metal

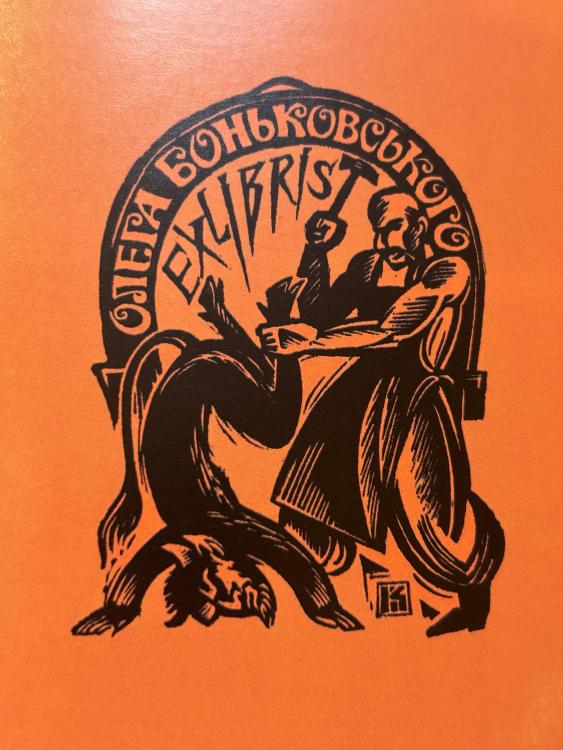

Leaving aside historical methods, you can get a thin layer of brass on a steel piece by heating it and scrubbing it with a brass brush. At the correct heat, a small amount of brass will melt off the brush and adhere to the steel. Here's an example from the Ukrainian armorsmith Vyacheslav Perepelitsa (who, interestingly, uses a rotary brush mounted in an electric drill to great effect): -

Picked up a few more items from the scrap bin today, including an old shotgun barrel. Thinking of creative applications….

-

Anvil molds, white cast vs gray cast

JHCC replied to Quarry Dog's topic in Anvils, Swage Blocks, and Mandrels

A lot of better-quality anvils and swage blocks in current and recent production are made from ductile cast iron, which has additional elements (usually magnesium or silicon, I believe) that cause the excess carbon to form spherical nodules that are more resistant to cracking than the usual flat flakes. Malleable iron similarly has the extra carbon in a nodular structure, but that's a product of casting in white iron and carefully managing the subsequent heat treatment. Ductile iron was developed in the mid-20th century, and I doubt that Fisher would have bothered to change from a proven material to a comparatively new one unless it offered a significant benefit at a comparable cost. That's just my speculation, though. "Gun iron", by the way, was a form of cast iron created by reheating pig iron in a finery furnace, not -- as with the production of wrought iron -- to burn off the excess carbon in order to produce wrought iron, but to oxidize the excess phosphorus that would otherwise weaken the cast object. -

Custom stand for a Rigid #9 anvil

JHCC replied to EricB1403's topic in Stands for Anvils, Swage Blocks, etc

I like the handle for moving the anvil around. -

Yea, it is a hefty tome.

-

Dropping in at the town metal recycling bin yielded a big lug wrench, a chunk of 1-1/2” schedule 40 black pipe, a four foot length of 3/8” round, and this beastie: Whatever it is, it’s 3” in diameter and just under 14” long. One end is drilled for a cotter pin or something, but I don’t know why the other end should have a couple of tapped holes and be fitted with what appears to be a zerk.

-

Also make sure to read the READ THIS FIRST page first.

-

Bienvenido! You've got the right approach, starting with what you have and working from there. If you're using the weights as an anvil, you should mount one of them on edge, to give more mass underneath the hammer blows. If forging on a rounded surface seems odd to you, consider that this is how traditional Chinese "turtle" anvils have been used for centuries!

-

Runfa 40kg Install questions.

JHCC replied to Asphalt Puppy's topic in Power Hammers, Treadle Hammers, Olivers

To follow onto Larry's thoughts, if you think seriously about what locations you would use a moveable hammer, you may find that there are only two or three places that really make sense. In that case, it might be possible to create a series of mounting blocks (with their tops even with the floor surface, obviously) that you could rotate the hammer between. That gives the advantage of mobility (if needed) and the advantage of more solid mounting (which is always a plus). I don't know how the mounting bolts on your hammer are set up, but you might be able to use the same kind of setup as Torbjörn Åhman's for his Bêché 75kg hammer. I've linked this video about the foundation bolts to start at the moment that demonstrates how they work: (The full playlist of him preparing the foundations and mounting his hammer can be found HERE.) -

Specifically, 2H₃PO₄ (phosphoric acid) + Fe₂O₃ (iron oxide/hematite) = 2FePO₄ (ferric phosphate) + 3H₂O (water). Phosphoric acid also reacts with Fe₃O₄ (iron oxide/magnetite), but the formula is a bit complicated.

-

How Should I Choose and Apply Coatings for Carbon Steel?

JHCC replied to Eder Bastos's topic in Finishes for Metal

Addendum: Raw linseed oil (often sold as "flax seed oil") can be used as a finish for cooking utensils; boiled linseed oil with chemical additives (e.g., metallic dryers) cannot. -

What did you do in the shop today?

JHCC replied to Mark Ling's topic in Blacksmithing, General Discussion

-

What did you do in the shop today?

JHCC replied to Mark Ling's topic in Blacksmithing, General Discussion

-

I actually took a course on “The Prisoner” my senior year in college.

-

Refractory cement upgrades

JHCC replied to ZebraPaste's topic in Gas Forge Refractories and Supplies

What specific properties or improvements are you trying to achieve? -

Good point. As with all salvaged steel, beware of plating! In rust we trust!

-

DIY power hammer or treadle hammer?

JHCC replied to MadGronk's topic in Power Hammers, Treadle Hammers, Olivers

That's a nice looking hammer, beslagsmed. -

I have not tried it yet, but it’s worth noting that the “Bowling Alley Wax” currently manufactured by the BWC Company is (according to the company website, anyway) the same formulation of carnauba and microcrystalline waxes and mineral spirits as the original Butcher’s Wax *before* the latter was acquired by S.C. Johnson. It also comes in “Boston Polish” (amber) and “New England Brown” (brown, unsurprisingly).

-

-

Also got a nice chisel for two bucks at a ReStore. With the cranked handle straightened out, I think it will make a nice slot punch.