-

Posts

9,749 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Daswulf

-

All good suggestions George. Only demonstrating on this one. No plans of selling. How bout penannulars? Were they popular then?

-

I have been invited to demo at a highschool renaissance fair. While it doesn't have to be period work, what items might peak interest other than blades? Any useful reference materials are welcome.

-

And here I just ordered a new set of nonstick pots and pans because the teflon coating is wearing off the old ones that we just got as a gift about 2 years ago. I did some serious research to see what would last longer this time. (Liz will only use those type but doesnt take the care they need to remain non stick) once they are scratched up they are worse than the good old stainless steel pots and pans. I don't mind the stainless ones but prefer my. Cast iron that is probably older than my parents. (Liz won't use them, or maybe I don't let. Her because she tried to clean them with. Soap and water before. I did show. Her the proper way but it is too much work I guess. Not that it is.) Anyway cast iron has withstood the tests of time. Maybe they will have some in a museum in a couple thousand years from now. I. Will try to teach my kids the wonders of cast iron cooking when. They are ready. revereware is good stuff with a copper bottom. Back to copper.

-

I agree Frosty. The two world wars wiped out a lot of previously made metal items. That is probably nothing compared to if the materials were more scarce.

-

Permenant magnet chuck for tacking and grinding

Daswulf replied to Daswulf's topic in Machinery General Discussions

Man, what a deal. Sure, hard work but you can't beat it if you can haul it and store it. I was at a farm auction like that and unfortunately after winning some large piles of scrap and some other things, I had to pass on the giant lot of nuts and bolts because I didn't have room in the truck to haul it all. And it was too long a drive to make it back in time later. Major regret tho as I could use all of that even more now than back then. -

Amazing how much in history has been recycled.

-

Permenant magnet chuck for tacking and grinding

Daswulf replied to Daswulf's topic in Machinery General Discussions

I believe it falls off once the top is magnetized. I will let you know when I get it and test it out. I should have it by the middle of the week or next week. -

Just to say, sometimes, Many times cleaning off the patina ruins the value on antiques like swords, bayonets and the like. Just so you know that going in. Not going to say I wouldn't think they would look great cleaned up and displayed.

-

No! Do not machine or grind the face. As frosty said it will take away the hardened steel faceplate and it will be more prone to damage. It will smooth out some with use and if you need a flat surface find a bit heavier flat chunk of steel and use it just for the finish work. The one part of the face towards the horn looks good enough. Use it and find out how it works for you.

-

What did you do in the shop today?

Daswulf replied to Mark Ling's topic in Blacksmithing, General Discussion

Nice work Chad. On another one maybe make the top hook swivel in the holder base. That might be a nice feature. I would go with the clearcoat but I recommend using an engine or exhaust clear like Duplicolor VHT. They harden better and are more durable. More expensive but the price is very worth the quality. Last thing you want is to rust stain clothing. -

Are these good anvils with side swages?

Daswulf replied to Jacksman's topic in Anvils, Swage Blocks, and Mandrels

They look purpose made to me. At a guess the look like they were made to fit maybe a type of power hammer. Doesnt look like the depressionswere made to be swages. Just what they look like to me. From what i see they look quality so I would check for ring and rebound for the final analysis on if they are good or not. Glenn always said, You bought the whole anvil, use it hoe you need it. Paraphrased of course. The shapes on them could be handy. -

Permenant magnet chuck for tacking and grinding

Daswulf replied to Daswulf's topic in Machinery General Discussions

Lawyers are attracted to such things but they charge a high Fe. -

Permenant magnet chuck for tacking and grinding

Daswulf replied to Daswulf's topic in Machinery General Discussions

Sounds like Chuck needs more iron in his diet. -

Lubed threads are better than unlubed threads. Anything is better than nothing. As others stated, an occasional removal and cleaning and relube help. Nice job on the cleanup. Make it work to the work you do. Make it a height that suits you and what you need it to do. There is no standard in varying uses. I have a post vise that the jaws weren't even in clamp down. After a bit of use and it actually bothering my work i filed them even. Might not be an issue for a different use. Again make it suit your needs.

-

That is a cool cylinder Frosty. I don't know if this thing would have the room for something like that but someone clever could certainly make it fit somehow. I have an old hydraulic cylinder (ram?) i hooked up to air once to see if it worked and it did. Its a bit bigger but still haven't found a need for it.

-

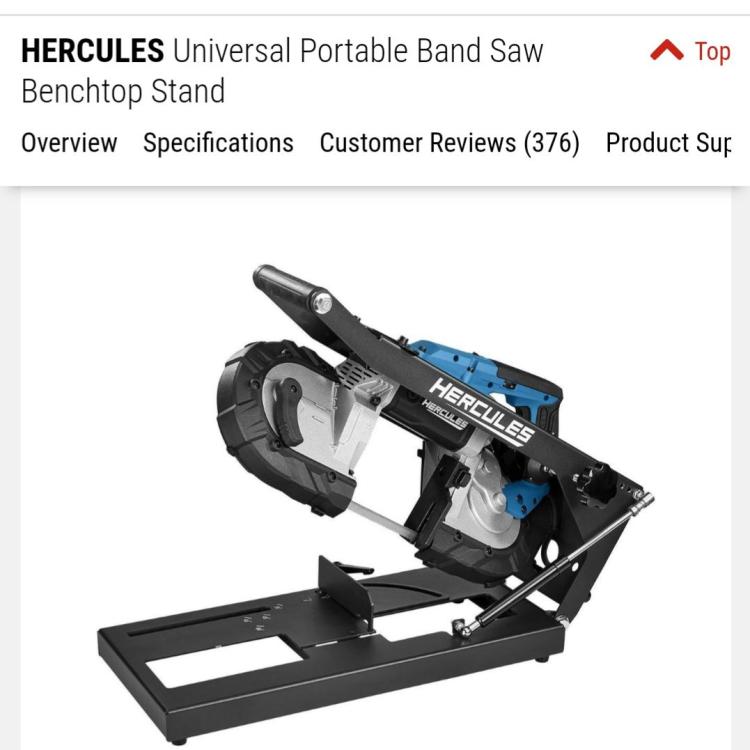

It is a shock like you see on some car hoods and hatch gates. (Working on cars that is the best example i can thing of. But it is a sealed shock as far as I saw. I would love to have a good bandsaw like a jet but it isnt in my budget. Was gifted the bauer corded portaband and bought the milwaukee cordless for field work. This can use both. For the price it is both vertical and horizontal for the same money. The base for horizontal has 3 set bolts and it is on.

-

Permenant magnet chuck for tacking and grinding

Daswulf replied to Daswulf's topic in Machinery General Discussions

Scott, I saw a lot of releasable magnetic lifters in looking for one of these. Even saw videos of people making electromagnetic welding tables. Thats above my pay grade. In buying something like this i can get to work instead of adding more to do projects to my list that I may or may not achieve. I have stuff to make that I can sell and buying this just gets it all moving faster in my limited shop time. Thanks for your insight from your experience Direwolf. Those are some nice quality ones there. Yes I was warned about magnetic fields affecting welds. This mainly is just for setup, tacking and grinding/wire wheeling. No doubt a machinist wouldn't want a welder near their expensive chucks. I am no machinist. Lol. I don't plan to do any hammering on it. If I needed to adjust something I would do it off of this. Even tho the one I'm buying is a cheap asian made version, it still isn't cheap, and I wouldn't want to ruin it. I really feel the investment would save me a lot of mis tacks from pieces jumping, And a lot of burns from holding pieces while tacking them. Let alone saving on gloves from holding pieces to wire wheel them or having them fling around. I do a lot of smaller flat pieces so it should work out great. Like any tool I feel if I don't abuse it it should last a while. -

I haven't yet. I just got it setup and tried it as a stand up so far. The shock that is on it would make you manually lower it for the cut as it is strong and holds it in the open position. The shock is easily removable with a twist clip. I dont know if the free weight of the portaband would be too heavy on the blade for cutting proper or not messing the blade up.

-

What did you do in the shop today?

Daswulf replied to Mark Ling's topic in Blacksmithing, General Discussion

Thanks George. Some good info there. Some I never thought about that makes sense. I ended up sending her a visual instruction on how it is used and that ended that. They are available online. Not a bad idea to have them printed out ready if selling them. Never put the thought into the name but it fits. The greek fibula tho... still not sure on that one. Kind of. Not trying to have a toga party at the moment. The pennanular was honestly a random thing at my table at the time and the lady picked it out and seemed to know what it was so I didn't give it a second thought till I got messages about it. Some things can just be too much to want to deal with when other things are simple and easy. -

Saw these about a year ago and wanted one bad. They were out of stock every time I went there. Finally went there looking for ratchet straps to help haul home some sliding boards for the kids and thought to look and they had them. They went up about $20. But still worth it vs. the alternative. I have a bauer corded hand held saw and the milwaukee. It will work for both and has brackets to fit hercules, bauer, milwaukee and dewalt. I set mine up for the table to cut for frederick crosses and other cuts. It is well built and heavy gauge. Not flimsy junk. Just sharing incase anyone might find use in it. You would have to remove the table to change a blade. In my limited testing so far it works great. It also has a trigger lock and release lever to build onto it. Cool tool.

-

What did you do in the shop today?

Daswulf replied to Mark Ling's topic in Blacksmithing, General Discussion

Nice work all. Arthur, ive made a whole one pennanular in my time. It was a real experience dealing with the inexperienced buyer on how to use it that Ive passed on making more. Tho, is it good to have the pins bent to lock on the ring better? John, nice scroll pattern. Funny, I knew I had a punch like those but just checked and i have the same ones with no dies. Picked it up at an auction. Goods, the tongs look nice and solid. They no doubt will be well used and enjoyed. -

I just ordered a 10"x20" magnetic chuck for layout and tack welding small pieces, as well as holding pieces for grinding. I have seen these used in some knife making videos for surface grinding forged knife blanks. One night recently I was up at my welding table grumbling about pieces jumping out of place when I went to tack them and this popped into my head. I didn't know what they were called so after a lot of trial on names I finally found them. I debated long and hard on a size to buy vs. Cost, but eventually decided to buy once and cry once. No doubt in my mind that its usefulness will negate the cost in no time. I'm sure most machinists know about these but I didn't. Anyway, when it arrives, I will post more on if it is the time saver and just what I needed or if it was an unneccessary purchase that I could have got by without. There was one video on yt that sort of sealed the deal for me where the guy built one into his welding table. My point in this is to possibly share the idea to those it might be helpful to that didn't know about these like I didn't.

-

Glad to hear things are getting better. Take your time, don't rush into getting back into it. Ease into it. You'll get there.

-

I like it Archie. There are a lot of uses for those metal hands. One suggestion that was given to me while i was selling some as business card holders was to make some to hold ipads or phones.

-

Preheat the ball bearing or whatnot, then weld it to the rod then post heat to let it cool slowly. The quality of the weld will depend on how well you pre cleaned it and prepped it and your actual weld. Pre heating and post heating for a slow cooldown will be important if the ball is higher carbon like a ball bearing. As long as the ball isn't chromed it can't hurt to try. The preheat and post heat will give you better penetration and less chance of HAZ (heat affected zone) cracking or separation. The high carbon would cool and react different to the mild steel. Certainly not pie in the sky. It is doable. If the ball is hollow and mild steel as well just take your time and weld it up.