-

Posts

9,763 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Daswulf

-

Show me your Bottle Openers!

Daswulf replied to Arbalist's topic in Blacksmithing, General Discussion

Here are some I succeeded at. There are always wrenches at the fleamarket. Get them as cheap as possible. They ended up making great bottle openers. Can't remember where/if i saw the design. Whatcha think? -

makes perfect sense JHCC. thanks.

-

It is a good price after looking at even regular brick prices. I figured it was, but asking on here really did help me with ideas, concerns and information. I could get used brick for free on Craig's list but this is fire brick ( don't see that on there for free if at all) and the potential Is there. The freeze/ thaw in Pennsylvania, and the fact they have been uncovered in the elements is a little of a concern but I'm sure the value is there. Still going to try to get it a lil cheaper.

-

Thanks Vaughn. It's a tough call. Think I need to check these out in person. Have a talk with her and get her story and let her know some of the concerns. Maybe just see if she wants to deal more. Worst case I build an outdoor bbq. sure there are some good ones in there.

-

it's always nice to know the size by reference or known object. looks nice to me tho. nice work.

-

Thomas, get 4 or so and see how they react to heat after drying out well? i could do that i think. sounds like a good test too. i'll be safe about it of course.

-

judging by the picture, looks like they have been sitting out a while. Probably have been.

-

Thanks Charlotte. Good info to know. For the most part it would be fine as my initial idea was for a brick forge for coal. I Was mainly concerned about the brick I'd be using closest to the fire. Tho I had thought with excess brick I may be able to have some for other future projects. I'll see what I can find out from her and go from there.

-

Thanks for the heads up Frosty. I'm asking more questions on them now. I'm not in a hurry for anything and this was way more then I was going to need. But "if" it's a deal I'd take it. I just ask around about stuff and sometimes I get a hit. If I don't have anything by the time I'm ready for it I will definitely call around and find a source.

-

Thanks Thomas that's a good point. Looks like they have been out in the elements for a while. I'd never heard that but it's something I'll look in to. Edit: I looked around online and I don't think I'll have any problems with em for how I would be using them.

-

I've been looking for some fire brick on the cheap and a friend of mine said his mom had some. Well she has a lot and wants to get rid of all of them. I finally got sent a few pictures. Is .50 cents a brick a good price for used fire brick? I believe it was used for a pottery kiln. I could probably wheel and deal on a bulk price but that's where we are at right now.

-

Scrap Yards near Richmond, VA

Daswulf replied to Prokopto's topic in Blacksmithing, General Discussion

Best advice I could give you is to get in the yellow pages or online and search for some and give em a call and ask. Can't hurt. -

the top turn handle rotates an inner shaft and the lower part that holds the "bit" and the "wheel" at the top rotates the threaded part that lowers it.

-

wouldn't it need a hole at the bottom for the rivet to exit? the end does rotate separate from advancing it.

-

Had picked this hand operated drill press at an auction. Looked interesting. Only thing is it seems to have a punch in it and I don't see how it would get changed out. Looks like it would mount to a table or something. The wheel lowers it and the handle turns the bit. Unless someone changed it for a single purpose or just jammed that punch in there, I don't really see the need for the punch in a drill press. Any thoughts?

-

Leave the chips and use it. Looks like a good functional anvil. Others can tell you more but get forging on it and you'll learn what you need and don't need, and how it works for you. My one anvil had a really bad edge on it and I cleaned up and welded up one side. If I had been reading on here I would have left it alone. It has held up so far but hey. Just get using the sucker. Anvil dosnt need to be pretty to work.

-

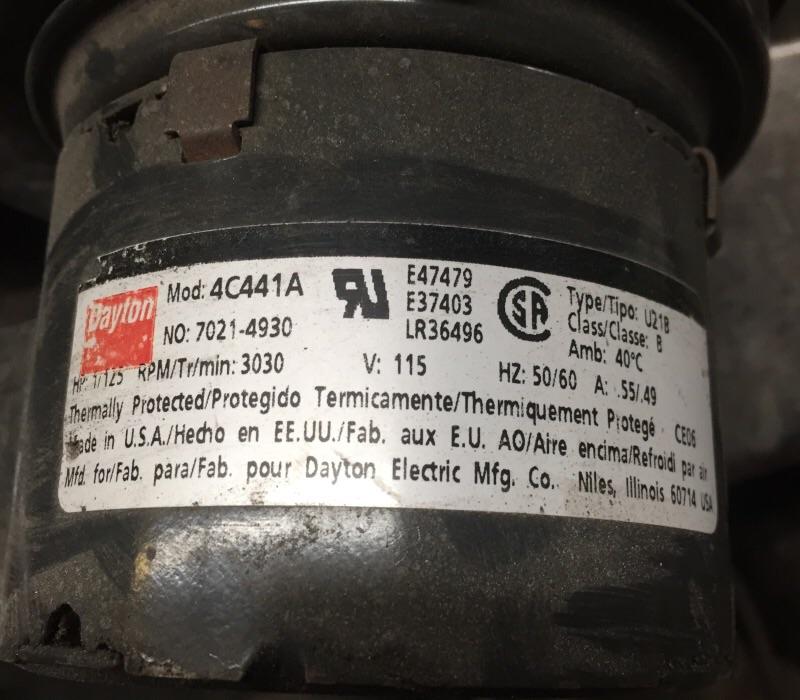

A friend of mine gave me this Dayton blower. It's really quiet even when on full. Only thing is it is smaller. But it blows perfect for my brake rotor forge. The outlet is 2" diameter and so is my pipe diameter so it fits it perfectly. They probably make larger ones as they are a well known maker but they may be big money. I was lucky to have scored it for free. I had the plate to restrict air flow until I bought a variable speed switch. But that's what I use and it's super quiet.

-

I'd invite you out if you're not too busy. I'd be up for some help learning a bit and got some cold ones to share. I'm about 45 minutes south of Pittsburgh.

-

Nice score at the scrap yard! Way to save that great equipment from being turned into car rotors in china!

-

Nail header failures, but I'm not quitting.

Daswulf replied to Daswulf's topic in Tools, general discussion

Thanks Glenn. Good advice. I won't be able to fire up the forge this weekend so if I can get ahold of some clay I'll try that. Charles, I'm not struggling, I'm getting it wrong with ease. -

I have a bit smaller pair like that. Now I know they are handy pliers anyway.

-

First cut off hardy.

Daswulf replied to Daswulf's topic in Hot Cuts, Anvil devils, metal cutting on the anvil.

Didn't have a jackhammer bit, but ya can't beat a good design. -

Nail header failures, but I'm not quitting.

Daswulf replied to Daswulf's topic in Tools, general discussion

Lol after 12 tries I had to try something. -

Nail header failures, but I'm not quitting.

Daswulf replied to Daswulf's topic in Tools, general discussion

-

Could have drilled it out to reduce the weight, but that's just an uneducated guess. :)