Buzzkill

Members-

Posts

2,052 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Buzzkill

-

-

US Navy SEAL Trident

Buzzkill replied to basher's topic in Spears, Arrows, Pole arms, Mace/hammer etc.

Thanks for the explanation, basher. Awesome work on the trident. Loving it! Then again, based on your other work I've seen I'd expect nothing less than something darn near perfect - and it looks like you'll deliver again. -

US Navy SEAL Trident

Buzzkill replied to basher's topic in Spears, Arrows, Pole arms, Mace/hammer etc.

Thanks for the link, Steve. I'm still not 100% clear on the purpose of the smaller belt. Is it to prevent belt drift side to side when slack belt grinding or to provide a happy medium between a flat platen and a slack belt with no backing - or both? Regardless it looks like a very useful attachment that I need to look into. -

US Navy SEAL Trident

Buzzkill replied to basher's topic in Spears, Arrows, Pole arms, Mace/hammer etc.

Cool stuff. Can't wait to see the finished product - and more WIP pics I have to ask about the attachment you're using for polishing though. Is the small belt around the 4 wheels to increase resistance for slack belt grinding, or is there another purpose I'm missing? -

If it weren't for customers and employees running a business would be fun. One of my dad's favorite sayings, passed on from an unknown source, is "People will do what you inspect, not what you expect."

-

It's mostly a question of funds. I already have a fair number of the components I'd need to go with propane, so in theory the additional cost would be far less. Besides that I like to build things for myself rather than purchase something already made. I believe Frosty once asked, "Why buy something for 10 dollars when you can build it for 20?" Some of the points latticino brought up have me questioning whether that would be my end result. I'm going to ponder on the whole thing and do a bit more research before going any further with it. I don't want to waste all the time I could be forging only building yet more things for forging. That's kind of like working a lot to afford an expensive car to drive to work. I posted this mainly to have other sets of eyes finding the flaws with the design, but also with the overall concept. I got what I asked for, but welcome additional comments and suggestions as well.

-

Ok, here goes. Rebar isn't your friend here. It is a crap shoot in composition. You don't know if the piece you have will harden until you try, and it may not be the same throughout the same piece of rebar. If you just want to make something knife shaped and aren't worried about it holding an edge then mild steel would be a better option. I learned the hard way and pretty early on that it pays to have a design drawn out on paper or at least well thought out in your head before you start a blade. The idea is to make the steel move how *you* want it to move. As silly as this sounds, another thing I had to keep in mind is what I wanted to accomplish with each heat. Know where and how you want to strike before you remove the piece from the fire. Otherwise you end up wasting time and the steel cools off while you're trying to figure out what you want to do. Having said that, you did make a blade shaped object that will at least look like a knife with just a little refinement. It may not function like a good knife because of the unknown quality of the steel you used. If you are going to put a handle on it then should probably thin out the tang area for balance purposes. Also be careful about putting sharp angles in transitions between widths. These create spots where your blade is likely to crack and break during use. Even if you have to round the corners with something like a chainsaw file after you complete the forging that will help avoid cracks. Assuming you've been bitten by the blade making bug I hope you'll take the time to read through at least the stickies in the knife making section. There's a lot of good info in there that can help point you in the right direction and save you a fair amount of trial and error on your journey. You've got a good first step in there, but if you're like me and you have limited time for forging you'll want to make all of it count.

-

Very nice! Thanks for posting this.

-

Thanks again for the advice. This is exactly the kind of thing I was looking for. The point about the propane potentially backing up is especially appreciated. Somehow that thought didn't even occur to me. You've given me several good points to think about and with the weather starting to be reasonable for forging outside again this project will likely be delayed anyway.

-

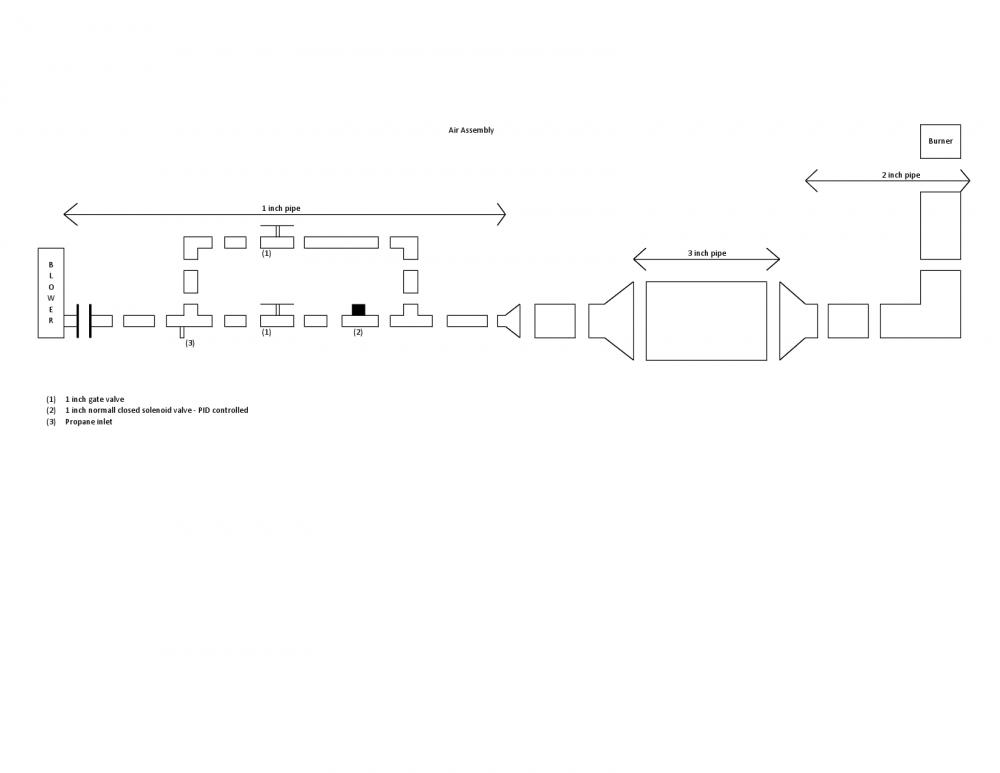

Thanks for the reply latticino. There are a couple reasons I want to fairly accurately control the temperature. One is heat treating and the second is to help me with recognizing the color of different steels at certain temperatures. This is still a hobby for me, so I can't dump a lot of money on things like this. I already have an old portable air tank, ceramic fiber blanket, kiln wash, kiln shelf, and the blower. The blower is from a bouncy house type of toy and it will easily blow material on the floor around 15 feet away if it's not restricted. Since it was made for maintaining a static pressure I don't think that it will be any problem. I'm curious as to why wait until the 3 inch pipe to dump the propane in. Won't it mix somewhat through the rest of the system and then even more when the velocity is slowed by the larger opening? I'm not challenging your recommendation; I just want to understand it. The reason for the 1 inch pipe to begin with is mainly cost. A normally closed 1 inch solenoid valve is around 40 bucks. A 2 inch valve is over 200 dollars. I share your concern about whether or not I can get enough air through the 1 inch pipe though. I'll have to look into the zero pressure regulator, but my guess is that's another relatively expensive component.

-

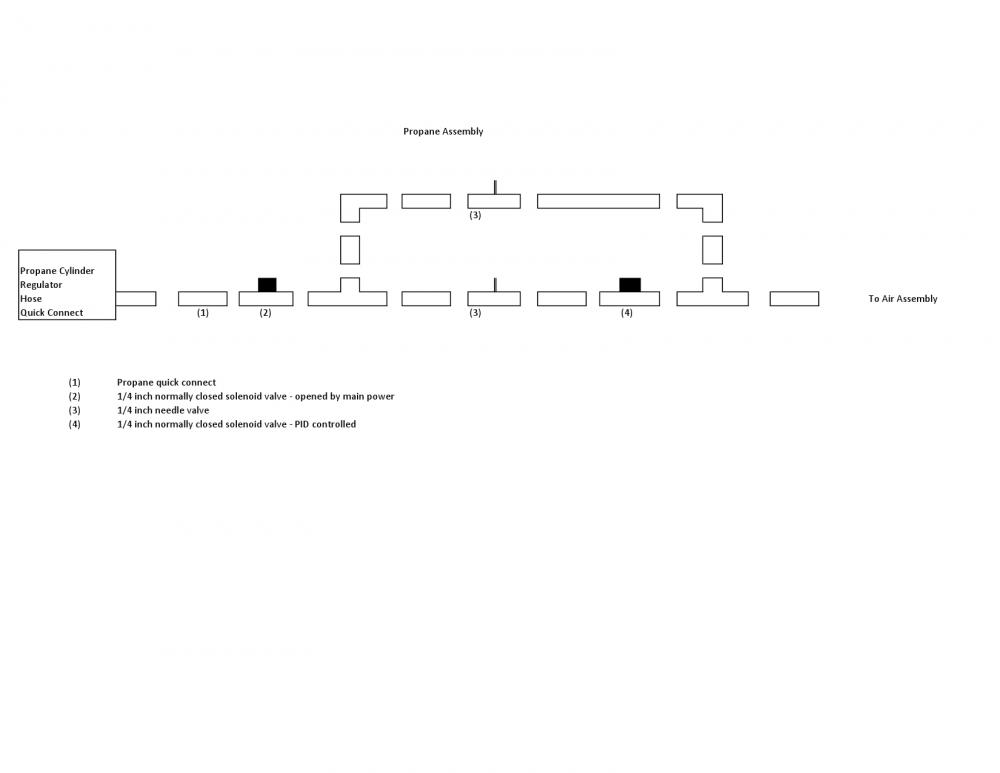

I've been designing a thermocouple/PID controlled forced air/propane forge with the hopes that I can get +/- 10 degrees F accuracy over a range of about 1400 F to 2300 F. As an overview what I'm attempting to do is have an idle pathway each for the propane and the air at just above the lowest settings that will produce a stable flame in the burner. At this point I'm leaning towards a ribbon burner. The main pathway for both would be tuned to a high heat with the atmosphere adjusted how I want it. These pathways would be off by default until the PID sends the signal to the relay which would then open both simultaneously. Hopefully the designs of both will show up well enough on here to make sense. What I'm asking for is any details I've overlooked or any known reason why my design won't work. I already know that to close a rectangle with pipe I'll need a union or at least one fitting and pipe nipple with left-handed threads on one end. The section of 3 inch pipe was included because I read that it makes a good mixing chamber, but I have no experience with that. If you see anything else that may be a problem please let me know.

-

Thanks for the clarification. I tried blocking both (one at a time) on this blower, but I guess the motor is strong enough that I could not detect a change in rpms either way. It sounds like the bottom line is I can restrict either the intake or the exhaust without harming the motor, and that was my main concern. Now I just have to find an inexpensive way to use a solenoid (or other relay-activated electronic means) to open and close the air to set points to move on with my design.

-

I guess I still don't understand this Smoothbore. I thought it was if you closed off the air *inlet* then the impellers weren't trying to push as much air and that would reduce the power used by the motor, but if you closed off the exhaust, the back pressure created more work for the motor. I really do want to understand this because I'm designing a forced air propane forge and I have a blower from the kids bounce toy that has been in storage for a decade. It puts out way more air than I can imagine would ever be needed for a forge, so I need to determine if it's better to restrict the intake or exhaust or if it's better to divert the excess air somewhere.

-

My opinion is pass on this one. Major cracking on the heel, but more troubling is what appears to be a crack across the entire face that is in the sweet spot of an anvil. I'll bet if you were to do a rebound test on it you would not get very good results. If you can pick it up for pennies per pound then maybe, but otherwise I'd recommend waiting for a better anvil.

-

Nice work Nick! How are you holding the chunks of hot bar in place when you are making the original slits? I've been thinking about trying to make a hammer or two, but without a helper I'm picturing hot metal dancing off the anvil with every strike since I haven't grown that third arm yet. Did you build a hold down especially for this or am I missing something really simple here?

-

JPVT, since you got the regulator from Hightemptools it should be fine. I'm not an expert on this topic, but it seemed to me like your burner wasn't getting enough air and/or the propane stream wasn't aimed down the center of the tube well. At 7 psi you should have a good roaring flame with a fairly stable flame cone at the end of the flare. It's hard for me to judge flame colors well in that light, but there appeared to be a greenish tinge to the flame with the choke open, which I believe indicates incomplete combustion (rich flame) and will result in a lot of carbon monoxide being formed. Hopefully Mike or Frosty will help out here. If it's fairly easy to remove your choke system I'd recommend trying it without the choke to see if your flame improves. From the photos that looks like it might be too restrictive even when fully open. Other than that you can play with the depth of the mig tip in the opening which may help pull more air in as well. These are just my guesses from looking at the short video and the pictures, but maybe one of the propane burner gurus will be able to help with the troubleshooting and get you burning stable and hot.

-

JPVT, I'll leave the diagnosis to guys like Frosty and Mikey, but one thing they will probably tell is this: Pick a burner design that is known to work well and then *follow the build instructions exactly.* Once you start to modify, tweak, or otherwise depart from the original designs you will almost certainly decrease the performance of the burner. While some of these are designs are simple to assemble using easy to find parts and limited tools, the components given are matched up to provide close to the right fuel to air ratio and a hot flame. Unless you have a deep understanding of the design and function of these burners you should not attempt to make modifications. Someone else has already done that homework for you. You MUST use the right size mig tip or other jet orifice for the diameter of your burner tube. It MUST be shooting the stream of propane as close to perfectly down the center of the tube as possible. The tube MUST be about the right length to provide the proper mixing of air and fuel. The air ports MUST allow for enough air to easily flow into the tube. When you modify any of those factors without knowing how it affects the others then you are asking for a poorly functioning burner. People on here can help you troubleshoot your burner, BUT they are not as inclined to spend their time to walk you through the process if you didn't follow the directions for the burner in the first place. The easiest to build burner design I have seen is Frosty's T burner, but even with it care must be taken to assemble it correctly to get a good result. Marshall Excelsior makes a lot of different regulators. Some of them may be compatible with a propane burner for a forge and others are not.

-

My new forge - Taking suggestions, thoughts and observations...

Buzzkill replied to twodogzz's topic in Gas Forges

Twodogzz, I hope you'll post WIP pics of your ribbon burner project. During the cold months I've been working on designs for my next propane forge venture and I'm waffling between a blown burner and a ribbon burner setup. Ultimately I plan to use a thermocouple and PID/solenoid setup to provide accurate temperature control in the forge, but I am curious as to how far either of those can be turned down and still function properly. Of course now that the weather is warming up again that build may be put on hold for a while since I'd rather spend my time hitting the hot steel than building a new way to heat it up. Anyway, I'd love to see the pics of your ribbon burner project in progress. -

I know this may seem odd since you visited a blacksmithing forum, but my favorite way to thin those leaf springs is to get them really hot (glowing orange) and smash them between a hammer and anvil. Repeat until desired thickness is achieved. If you want to stick with just stock removal then you have the tools to do the job after the steel has been properly annealed. It may still be a little harder on the cutting edges than mild steel, but .......... You didn't list surface grinder in there, but that's another option if you have access to one. I should also give you the requisite warning on here about using previously used springs for blades. Many of us, myself included, have done this, but be aware that any used spring material may have micro cracks in it which are not visible and could potentially become evident at the worst possible time. In other words the material may crack/break in heat treat or, worse yet, under heavy use. It also may be helpful if you put your general location in your profile. There are people who visit here regularly from all over the world and it's entirely possible that someone with expertise valuable to you may live close enough to lend a hand. I can't recommend strongly enough that you spend a fair amount of time reading the stickies in the topics that interest you. It is rare to see a question from a new forum member that hasn't been asked and answered before. Other than that, welcome to the forum.

-

Mikey, What do you mean by "burn clean?" The waste oil forge I built didn't produce visible smoke at all once it was hot and not much even when it was first fired. Of course there are always exhaust gases released whenever any fuel is burned and I always ran mine outdoors. For me the biggest drawback was keeping a constant flow of oil with changes in temperature and even the depth of oil in the feed container.

-

I believe one of the forum members was a contestant last season, but I'm not sure he's ever said anything on here about the experience. I find it very hard to believe that any of those judges would be willing to swing those blades as hard as they do into blocks of ice, coconuts, etc. if they were not tempered. The temper phase has no entertainment value for most people so they are not likely to show us any of it. We don't know the time delay between the blade making phase and the handle phase or even how long it is from the time the forging phase is over until they present their blades to the judges. A properly hardened and tempered blade will still skip a file off without it biting in. If you run the colors way up on the temper then a file might bite in, but that would not be proper for the cutting edge anyway.

-

For kiln shelf I went to a pottery store about 10 miles from where I live. I asked if they had any broken pieces I could buy. I walked out with 3 decent size chunks for 10 dollars and easily cut the shapes I wanted using an angle grinder with a masonry cutoff wheel. A metal cutoff wheel would probably work well too.

-

I'd take that as a good sign. Unless I'm mistaken the earlier shows last season featured easier challenges and less experienced/skilled smiths. If that's the case then being towards the end of the season is a compliment. Of course there's always the chance that it's just my perception.

-

You said the big 3 (I assume percentage-wise). There's still 2.9% unaccounted for, so we just don't have enough information to answer the question. If the carbon is over 0.6 it's probably decent edge material, but without knowing the carbon content we can't tell you more.

-

Blacksmithing gems and pearls

Buzzkill replied to Glenn's topic in Blacksmithing, General Discussion

When you need to move something, do not reinvent the wheel, borrow a wheel barrow. Glenn