bird

Members-

Posts

26 -

Joined

-

Last visited

Recent Profile Visitors

1,087 profile views

-

Yep. Not to be a jerk but I'm pretty sure I'd prefer to work in mine . I didn't use kiln shelf but I did use high alumina refractories and 2" of fiber all around. I might have to get a bit of ITC100 or some such and see if I can tell a difference though. Good point on temporary or removable mass.

-

So granted, I'm picky about my tools and made some aesthetic decisions as well as a few technical ones about limiting ceramic fiber exposure, but maybe the type of forge build I posted notes on a bit ago is pretty ok. I like it, but I'm always interested in improving. Fair point. I use that forge for anything from 3/8" up to 1 1/2" square when it's smallish volume works. For production forging and large heats I have a much bigger forge built similarly but proportionally more massive. I only run it when I must. Whether or not the forges can keep up with me or I with them depends entirely on how many parts I'm working at once. Maybe I'm just lazy (sometimes it seems hopelessly so) but there are plenty of moments in the process when I can only focus well enough on one or two parts and that's part of why I like to set up my forges for quick reheats. I can always dial the burner back and more or less match my number of parts to heating and working times, but waiting on heats is unprofitable. Very.

-

So I should cast thicker floors and use lighter walls for best performance? What do you think is an optimal wall/arch construction for balance of performance and durability?

-

So I don't have a technical material science background and I'll ask you to excuse me in advance if, in attempts at precision, I butcher the technical language. It seems like you're saying that thermal mass is still a good thing in our forges, but not all masses are created equal? We like high alumina refractory because it keeps more heat in our forges, or at least slows it's loss down much more than fire clay based products. I tend to think of forge mass as a reservoir of heat I can dip into to heat and reheat my steel. This is why forges I build tend heavy as I favor faster heats over initial start up time. Is this wrong? I have no empirical evidence but I swear I've worked in light mostly frax forges that visibly cool when I put steel in and I've always expected this to be reflected in longer heating times. Common sense suggests that unless we just use our burners like torches, we'd need hot mass to heat mass. But if my observation and reasoning are right, aren't we in a catch 22 where we need and rely on heat transfer for our heats?

-

For the same money or less you can build something better, but it will take time and basic skills. There's plenty of advice here on IFI to help you if you want to go that way. I can't speak to that forge in particular except to say it doesn't cost much. It doesn't look worse than the rest. I personally think that flat ceilings and rigidized fiber are bound to fail but lots of people use them all the time and fix or replace them as needed. It would get you started.

-

PS I misspoke. I didn't mean for safety, I meant for durability. I always turn the gas off at the bottle and bleed it through the regulator and valve so I'm not worried about heat back through the system as a safety issue. It's just about the longevity of the burner.

-

Probably no big deal either way but I'll still keep running my blower after the gas is off for one simple reason. Think of it like your car, or maybe my 25 year old truck: the engine is warm and I'm driving around town. I stop, and when I turn the truck off, the fan stops and the coolant stops circulating and for a few minutes, the engine can reach higher temps than it does during operation. Same thing with the gas forge. The burner always has cool air and gas flowing through it when running. Only the face gets hot. You can look acros it in the hot forge and see the shadows in the orifices telling you it's cooler just behind the face. So on the one hand, there is always a tremendous heat differential there, but if I turn the gas and air off simultaneously, the balance of the burner casting will get hotter than it does during operation. It should be fine, but the burner is the least consumable part and I'd rather not shock it.

-

Buzzkill: it isn't. Ribbon burners aren't supposed to be in the forge. It is just a flat face. The face of the burner is about an inch and a quarter back from the arch face on the top and about a half inch back at the bottom. The refractory is designed for thermal shock but to be safe I always run the air for a while after I turn the gas off. The insulation of the arch wall plus the air blast keep all but the face of the burner pretty cool.

-

Mikey98118: I am nobody's expert on ribbon burners but they seem very forgiving. After asking around a bit for specs on forge volume vs burner port area vs mixing volume and not getting much (I'm sure it's out there) I just winged it and I lucked out. I'm very pleased. I had a Pine Ridge ribbon burner that's 4 1/2" x 6 1/2" that's not supposed to be used for smaller volumes than .75 sq ft. I basically made one about 2/5 that size. 11 crayon size orifices in a 2" x 6" face. A baffle at the gas-air mix inlet is just a piece of flat stock about 1/2 as long as the burner centered with a notch in one long edge. A needle valve on the gas and a homemade butterfly on the air and I am very tunable. I say go for it.

-

Scrambler82- glad to help. To be clear, the inner steel shell is a mold for the casting which is not part of the finished forge. A steel liner on the inside would just burn up. But you could take Frosty's idea and use a sonotube or stove pipe for the inner mold and be on your way. Frosty- a longer floor has crossed my mind, but I worried about the temp differential/ heat sink causing potential problems. I usually go with an adjustable sliding stock rest built onto the stand. Just some square bars sliding in square tubing welded to the underside of the table. Also to be clear, the burner isn't exactly built in. I made a plywood blank- the "core" - that was a bit bigger than the burner and fit it to the inner arch form to create a void in the casting so I wouldn't need to break it out later to fit the burner in. The burner is independent and bolted to the stand. For that matter, the whole design is "modular" in the sense that the burner, arch, and floor are all independent and may be rebuilt/ recast separately at any time without disturbing the other parts other than to unstack the unit. The finished forge is dry-stacked and only the bolts through the flange of the outer shell to the stand hold everything in place. Anyway, good ideas all. I'm no expert I just wanted to share what has worked for me and encourage people to think at least as much about the box as we do about the burner. Think less about how fast your forge heats, and more about how fast your metal heats and maybe save yourself from breathing ceramic fibers and building disposable forges at the same time.

-

having trouble forge welding

bird replied to fleur de lis's topic in Blacksmithing, General Discussion

A few people have mentioned fire maintenance and oxidation, but not enough. Limiting the available oxygen to your part is as key as heat and cleanliness. Limiting the oxygen will allow your steel to get hotter than it normally would without burning. (Nothing burns without oxygen.) And that heat is one good way to facilitate welding. Start at the beginning. You said you might break down and build a coal forge...what are you using now? Specifically, what's the depth of your firepot and where is your metal with respect to your air and fuel? It seems technius Joe differs (with some interesting reasoning) but most people will say oxidation is the enemy when you're forge welding. In the presence of excess oxygen, your steel will actually burn at lower temperatures. The fire will have oxidizing, neutral, and reducing (oxygen starved) areas, in that order, from where your blower enters the firepot. You need to heat for welding in a neutral to slightly reducing environment. In practice this means (varying slightly with firepot shape and blower power) you need to heat for welding about 3 1/2" -4 1/2" above your air inlet and have your work surrounded by fuel (that's consuming oxygen). Generally at least 2" of clean fuel over and around your work. If you are using a flat bottom bbq or rivet style forge, get a couple of fire bricks and build up the sides of your "pot" around the air inlet. Charcoal will have lots of orange sparks. Your steel will spark differently. Look for bright yellow "sparkley" sparks like from a 4th of July sparkler. Just a few. You shouldn't be able to see your part well. If you can there's not enough fuel around it consuming oxygen. A small taper that heats quickly can be a good tester: touch it to your part in the fire and see if it sticks a bit. If it does, you're ready. Finally, are you outdoors or indoors? Daylight will make your fire and part appear cooler than you read by color and make sparks harder to see. Work in shade if you can. Hope this helps. Good luck. -

Thanks for the comments/compliments guys. Scrambler82: you could use that tank, and maybe you should if your shop has a real big hammer, a crane, and a manipulator so you'd need a forge that big . I know if I had a 500 gal tank I'd be designing a whole hog smoker. Seriously, that's huge and heavy. Frosty's sonotube idea is a good one. The shell isn't structural in the finished forge. 18 or 20 gauge is plenty. Frosty: Good ideas. With a sonotube I'd still want to contain the fiber insulation but I guess rigidizer would probably be fine on the outside. Truth is I had a slip roll and brake handy but not a sonotube so for me the way I did it was the cheap and easy way. The half octagon was a purely aesthetic choice, but I am partial to the doghouse forge.

-

Not to throw a wrench at your plans but for the kind of control you want why not go electric?

-

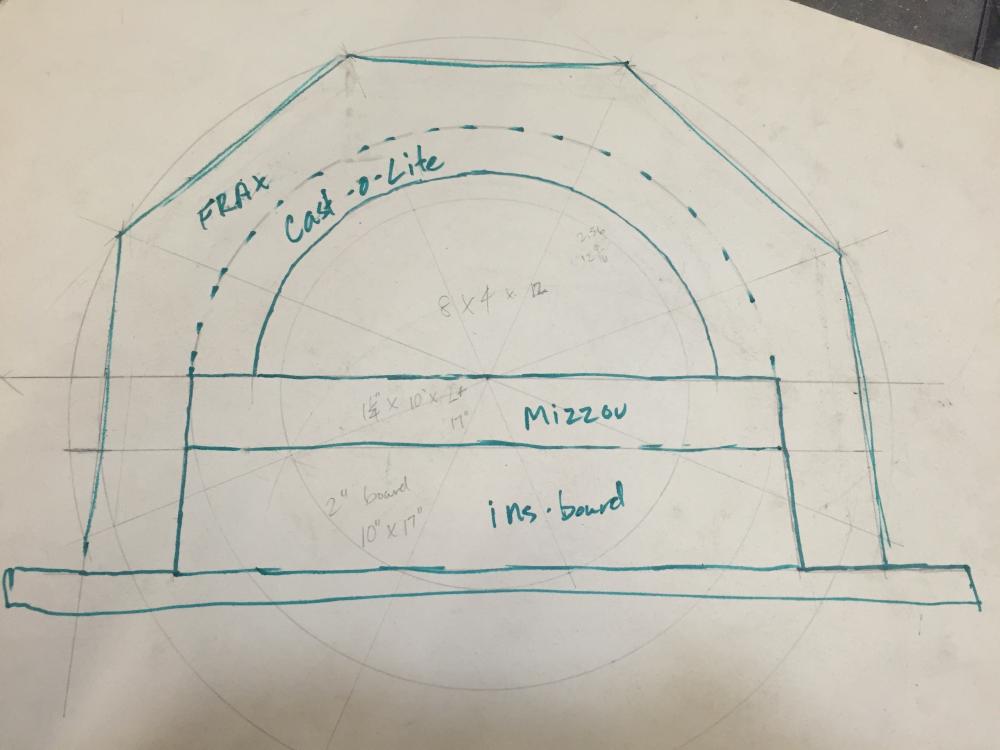

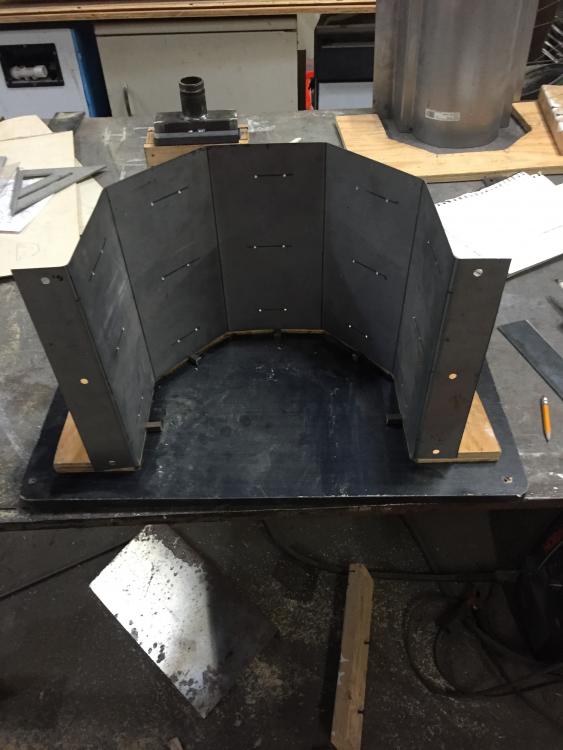

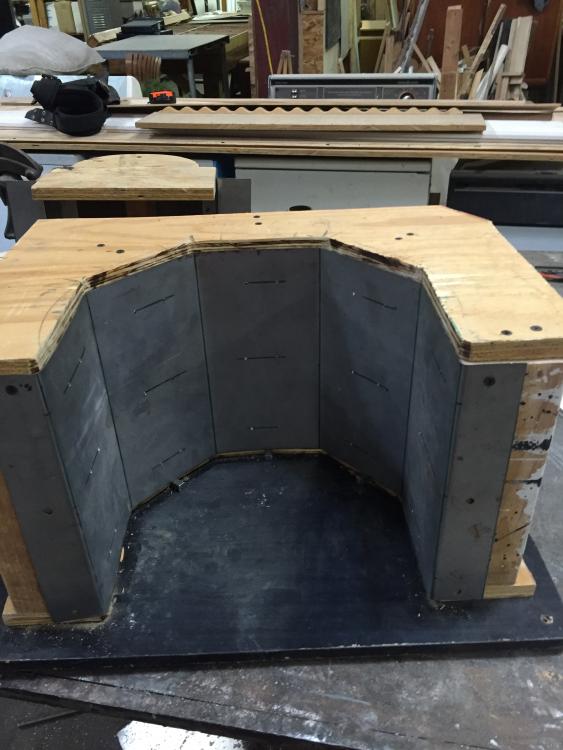

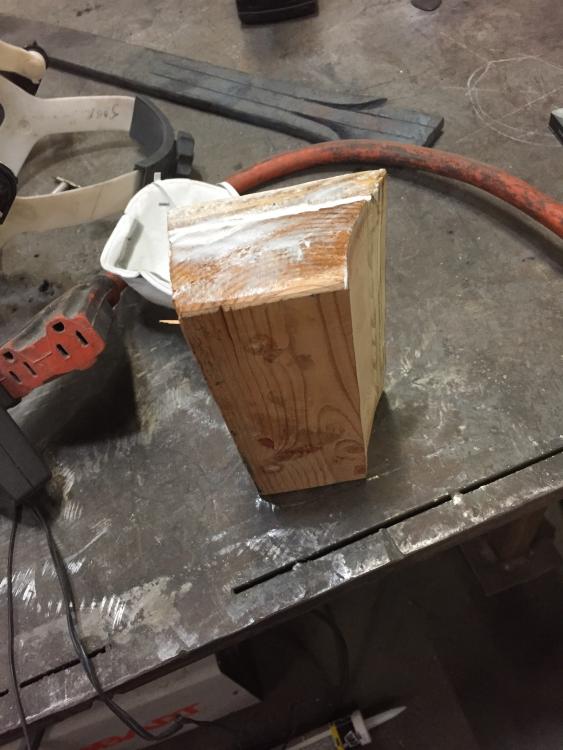

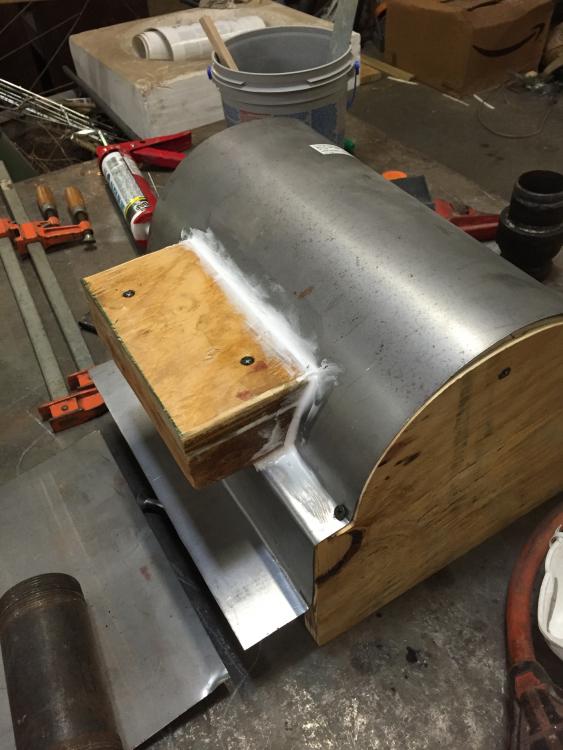

So there's a lot of talk about building burners and which design is better, but not so much about the box you put the burner in. To me, the box in the more important part. No matter how efficient your burner is, it is the box that will largely determine how hot the forge gets, how quickly you can get to work, how long you wait for heats, and how scaly your metal gets. Here are some of the things I want in a gas forge, and why I want them (Your desires may be different, and you'd want a different design. The design I'll show is not the one I'd build for example if I were a knife maker or if I only had a half-hour at a time to forge.): It should get hot and stay hot when I fill it with metal. Insulation is key, but so is thermal mass. I want enough of a heat sink to make sure the metal heats and re-heats quickly rather than the forge cooling significantly when I add the mass of metal. It should be durable. Who wants to spend lots of time building and fixing forges instead of using them? You should be able to adjust the atmosphere, at least from neutral to rich. Too much oxygen makes heavy scale and makes welding hard to accomplish. The burner matters here, but also, a forge should have doors. Without doors, it is hard to control the atmosphere except by gas pressure, which is wasteful. Doors should not prevent access to the whole chamber when necessary. Why build and heat a volume you can't access? If you use ceramic fiber blanket, it should not be where it can be abraded. If your forge or doors use a steel shell, keep the steel out of the flame path as much as possible. This goes to durability. when your steel burns up, does it expose fiber insulation? Does it open a gap around the burner? Will your roof buckle and cave in when heat gets between the insulation and the shell? None of these are good in my book. Quiet is nice. The shop is loud enough. For all of the reasons above, I cast forges from commonly available refractory materials and use ribbon burners. In the pictures attached, the arch is cast from 3000 degree lightweight insulating castable and the floor and burner head are cast from 3000 degree dense castable. The entire box is surrounded by 2" of fiber insulation. You can't see it on the arch because I made the castings slightly proud of the frax to keep the fiber out of the flame/abrasion path. The casting is also proud of the steel shell so that there is no steel to erode in the flame path and open gaps. This may look like a lot of work, but with assembled materials, it all took well less than three days, elapsed including the stand and plumbing. Not so bad when I have other forges built this way that have lasted close to ten years. For this rather small forge I did push the limits of casting with sections as thin as 1" for the floor but I think it'll hold up and I didn't want it to take forever to heat up. I did build the ribbon burner but there are other people here more expert than I am. It is 2" x 6" with 11 crayola size jets. I used a needle valve on the gas and a homemade butterfly on the air and it is very tunable and quiet. Image notes: 1 have a plan. 2 the base for the casting form. Note 3/8" blocks to lift steel shell off of floor and allow casting to extend beyond the steel shell. 3 the outside shell. Holes drilled are to wire the frax to the shell. Flange secures mold and will ultimately be bolted to stand. 4 outer shell in mold. Note that top of mold is also proud of shell so that casting will go beyond steel. 5-6 the outside of the shell mold. 2x4s support the shell and keep it from bowing out. 7-8 the inner shell- arch form. This will not be part of the finished forge. Don't forget the mold release. 9 the two halves of the mold mocked up. 10 the "core" for the burner. 11 the core mounted and caulked to the inner form. 12 DON'T FORGET MOLD RELEASE 13 the (not yet caulked) burner core fit to the inner arch and through the outer form. 14 opening for the burner core cut into the outer shell. 15-16 the frax wired onto the outer shell, and with the burner opening cut out. Note that the frax is shy of the top and bottom of the steel shell so that in the finished casting the frax will all be encapsulated in castable. 17 the nearly ready assembly. What this doesn't show clearly is that there is a little more than an inch of clear space between the frax and the inner arch. I will ram the castable onto the frax which will compress and compromise it some but will still leave me with more than 2" of insulation all around. 18 the casting in the mold. Be sure to really ram the castable into the bottom to fill in the lee of the burner core. 19 very simple mold for the floor. 1/2" plywood core makes the lip on which the arch will rest and gives me a seamless floor. 20 the floor casting sitting on 2" fiber board. (forgot mold release: cracked casting slightly. Sairset to the rescue.) 21 dry stacked and ready to burn in gently. 22 Ta daa. Bright lights mess with photography but it really is that hot. Forge floor is 8" x 12" and the opening is small enough to use a brick for doors. I'll probably eventually build doors that are easier to move around but I can get to work for now.