-

Posts

135 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Shetland Islands

-

Interests

Welding, Machining, Blacksmithing, Boats

Recent Profile Visitors

2,289 profile views

-

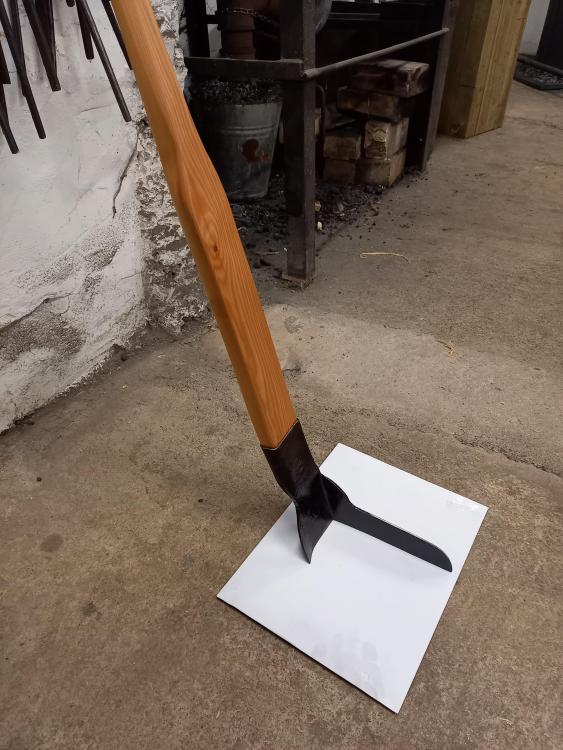

yorkshire pattern?

-

Making Peat Charcoal

Jonnytait replied to Jonnytait's topic in Solid Fuels: Coal, Coke, Charcoal, Wood, etc

-

so you are saying very sharp edges are ideal for the anvil? how does this not cut the steel when forging set-downs/shoulders?

-

Anvil identification, Looks like a fisher

Jonnytait replied to SilentForge's topic in Anvils, Swage Blocks, and Mandrels

Thanks, looks like a perfectly good tool. Theres something interesting about the russian made steel anvils -

Anvil identification, Looks like a fisher

Jonnytait replied to SilentForge's topic in Anvils, Swage Blocks, and Mandrels

I would be interested to see that anvil, if you have a photo of it? -

I think the ones in the photos were all ash, not 100% sure though as i sometimes use hickory as well

-

Thanks for the input! They were made from EN8, similar to 1045

-

Anvil on oak block- end grain vs side grain

Jonnytait replied to Machine shop's topic in Stands for Anvils, Swage Blocks, etc

It will make absolutely no difference. The only thing that matters is that your anvil is secured to the stand very firmly, and that the anvil stand is secured as well. -

Wow. Why is everyone so grumpy? jason0012 wasnt asking what his own steel suppliers prices are, if thats all he wanted to know he would have picked up the phone and asked them. Look at his previous posts and work. He's not daft. It looks to me like he was just trying to start a discussion on current steel prices.

-

Thanks lary, yes I have power hammer tooling to make the job easier. Nothing too fancy just offset dies I made up

-

What did you do in the shop today?

Jonnytait replied to Mark Ling's topic in Blacksmithing, General Discussion

-

I thought I would make a thread to share the hammers I make, I will post more as I make more! some are for my own use and some are personalized

-

-

Making Peat Charcoal

Jonnytait replied to Jonnytait's topic in Solid Fuels: Coal, Coke, Charcoal, Wood, etc

-

Would you be able to take a photo of it, so we can see what you are working with?