-

Posts

1,623 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Black Frog

-

I doubt it will be for sale very long. You'd better move quick, any name brand anvil in decent shape for $200 is going to be gone instantly. Probably around 100#. If you get it, please post a picture of the serial number on the front foot under the horn. The ballpark year it was made can be told from that. Good luck!

-

Anvils: A beginner buyers guide

Black Frog replied to Everything Mac's topic in Anvils, Swage Blocks, and Mandrels

Ha!! ....the harder I work, the luckier I get. :-) -

Anvils: A beginner buyers guide

Black Frog replied to Everything Mac's topic in Anvils, Swage Blocks, and Mandrels

...my Fisher picture. :-) -

Very nice! Yes, would like to see a close-up pic of the side logo stamp! Every new entry helps the database... :-)

-

Chris, according to AIA that would be 1908. To others, it seems that IFI has lost all the pics in this Trenton List thread unfortunately. The past few years I've been creating a Trenton logo database, the firm used many different logos through their history. I've been cataloging the different logos and creating serial number ranges for each style of logo. I'd love to see closeup pictures of your Trenton logo stamp, and a picture of the serial number so I can add it to the list! Each sample helps fill in the gaps of the database.

-

That is what is given in "Anvils In America".

-

How do I proceed with a wounded anvil

Black Frog replied to stockmaker's topic in Anvils, Swage Blocks, and Mandrels

That I do not know. We talked about the grind and weld, and I saw a picture of it once it was finished, he was very happy. -

How do I proceed with a wounded anvil

Black Frog replied to stockmaker's topic in Anvils, Swage Blocks, and Mandrels

I sold a PW that had the same problem that I got at an auction for rather cheap. It was fully cracked in half at the waist. Even though it was cracked, it had exceptional rebound. The buyer had a welder friend, and we talked about a fix. What he did was grind a deep V groove all around the waist following the crack line. Preheated the anvil a bit, being careful of the face temps. Welded the V groove, and the anvil is as good as new. -

Thanks guys! Sling-it, if the leading digit is a "4", that would be a quite late A&H anvil, sometime in the early 1940's according to Anvils In America. From what I've been cataloging, there were at least six different A&H logos through the years, and a variation of the last one that could possibly be considered the 7th. We'll see as more examples surface for me to document.

-

I've seen the anvil- a nice piece. Tool steel was expensive and not found in larger pieces back then, it was common on larger anvils to have the plate made up of several pieces.

-

Thanks! I forget who sent me what, and since not a lot of A&H's made I try to always ask whenever I see one mentioned. A slow going project, but fun to try piece together.

-

Sling-it, with some wire cup cleaning, my guess is that there was/is a leading "4" digit to the serial number, I think I can see it faintly. A&H had several different logo styles, and I've been creating serial number ranges for each style stamp. That style was later in their history, so if that SN had a leading 4 digit, making the serial number 47686 would make sense. Fatfudd and Benjaman, could you please post pics of your side logo stamp and serial numbers for your A&H's? I'd love to add them to the logo database! Also could you two measure face width and heights too? thanks!

-

Swedish anvil info or experience?

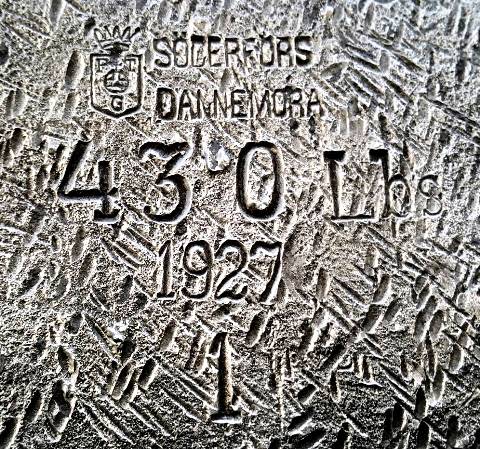

Black Frog replied to Derek Melton's topic in Anvils, Swage Blocks, and Mandrels

Sisco (Swedish Iron & Steel Corp.) was incorporated in 1907 as an importer of Swedish metal products. They were located in New York and New Orleans, the two biggest ports of importing Swedish materials. Sodefors making anvils marked "SISCO" was the same as Horace T. Potts firm importing Soderfors that were branded "Paragon" for sale in the U.S. Great stuff! SCB sent you a PM.... -

Swedish anvil info or experience?

Black Frog replied to Derek Melton's topic in Anvils, Swage Blocks, and Mandrels

Sisco, one of the best. Very high quality Swedish anvil. -

Trenton or Arm and Hammer?

Black Frog replied to Nicemibs's topic in Anvils, Swage Blocks, and Mandrels

From the horn shape, look and placement of the serial number, along with the weight on the side, I would say Arm & Hammer. Can you take a close up of the side logo stamp? I'd like to add it to the Arm & Hammer logo database. PM sent -

Some Kohlswas have raised markings, and so do some Soderfors. And sometimes neither do.

-

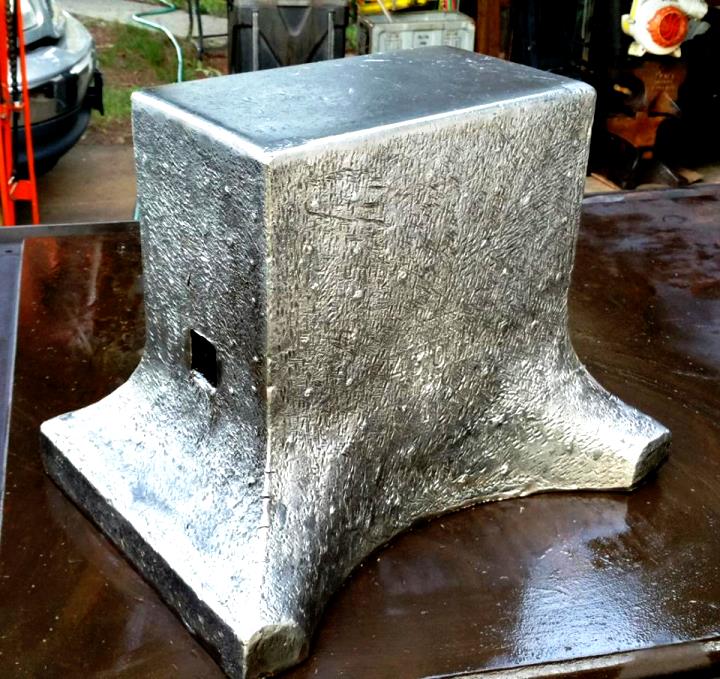

Several Swedish makes had the flats on the feet at times. Possibly Kohlswa. Is there an oval depression on the underside of the base?

-

Practice helps a lot. You can't simply use the stamp stock size for spacing because there's a lot more empty space on each side of an "I" character than there is on something like a "H" character. Those holders where you can put a bunch of stamps together don't look right to me. I don't mind a bit of variation and non-perfectness. The things we forge are hand made items, and I like the stamping to reflect that too, it was hand stamped. A proper stamp holder can make a world of difference in ease and accuracy of stamping. Once you use a real holder, you'll never use a pliers or vise grips again! Here's a fancy brass-handled one I made:

-

Old Trenton has a new home

Black Frog replied to HEAP of JEEP's topic in Anvils, Swage Blocks, and Mandrels

Get dimension measurements of overall length, face width, and height can give a good ballpark weight. The weight stamp should be on the front foot opposite the serial number. -

Old Trenton has a new home

Black Frog replied to HEAP of JEEP's topic in Anvils, Swage Blocks, and Mandrels

Please take close-up pictures of the side logo stamp, and of the serial number on the front foot under the horn! -

Trenton - American or German made - Help Please

Black Frog replied to AdamInTx's topic in Anvils, Swage Blocks, and Mandrels

I'd say your hunches are correct, a German-made Trenton. German ones had no serial number. -

biggest anvil I have seen

Black Frog replied to SReynolds's topic in Anvils, Swage Blocks, and Mandrels

If anything, later mid-production Trenton were hard to find a stamp on. Early Trentons were usually all marked quite well -

What kind of anvil do I have?

Black Frog replied to Bladeguy15's topic in Anvils, Swage Blocks, and Mandrels

John Mc, here's just a few examples of what did go out the door from Columbian with lots of porosity and rough castings. As I mentioned, some were VERY rough. Great anvil nonetheless, but definitely not the prettiest. -

-

What kind of anvil do I have?

Black Frog replied to Bladeguy15's topic in Anvils, Swage Blocks, and Mandrels

Yes, typical triangle -C logo. I could post lots of examples of the varying casting quality of Columbians. Not all were made in Cleveland. And Soderfors was not the only Swedish company casting Columbians at times. This one was amazingly far off on the center seam. They ground the face and bottom smooth, out the door it went.