stockmaker

Members-

Posts

140 -

Joined

-

Last visited

Contact Methods

-

Website URL

www.gunstockmaker.com

Profile Information

-

Gender

Male

-

Location

Burbank, WA

-

Interests

Woodworking, Metal Working, Bird Hunting

Recent Profile Visitors

2,483 profile views

-

I can offer only a little feedback on the 140# Rhino. I used one in a two day smithing class a couple years ago. For the most part during that class we all used the 240# Rhino's as they were in closer proximity to the forges. In both cases I was very impressed with the durability, function, and price point of these anivil's. I had intended to buy the 240# version and was saving money when my dog ate all the chewable doggy aspirin in my hunting bag, it cost much more than a new anvil to save her life. Later on I got a much used Peter Wright for free and have stayed with it for now.

-

Hello Jonnytait, your big anvil and anvil stand looks impressive, wish I had one like it. I love to watch the TV show "Shetland", it only comes on here for a short time each year, fantastic scenery. Nice to hear from you.

-

Thank you, your point it is well taken. I was thinking about mushrooming of soft metal, I have 5160 strips welded to the top of my guillotine dies which are cold roll steel, the 5160 is annealed and so far has worked well. But I am going to go with what you suggest, I like the buffer idea. To tell the truth about my hammer selection, head hardness is down on the list, I have a couple that are 4140 and lose when I hit the anvil face, the rest are unknowns to me, my guess they are hard. I am not saying that head hardness is not important, I am saying I don't think about it as much as I should.

-

Thanks for the advise, I will try cutting off the cracked end and welding on some 5160 and see how that goes.

-

I like this fuller, but don't dare use it anymore. Is it repairable, and if so, how would you suggest I go about doing that? Thanks.

-

What did you do in the shop today?

stockmaker replied to Mark Ling's topic in Blacksmithing, General Discussion

I made a bickern out of a rail road spike hammer and a car axial. The hammer head weighed 10lbs to start and 6 lbs when attached to the axial, total weight when finished is 11lbs. No heat treat involved so far, I am hoping I do not have to do it, time will tell. The work was inspired by Daswulf's stake anvil project this past winter in this forum. -

Naturally Aspirated Ribbon Burner. Photo heavy.

stockmaker replied to Frosty's topic in Ribbon Burners

I used drinking straws once, would not recommend it, they are too flimsy, it was a mess. Keeping them vertical and in line while the refractory material was poured in was very difficult, and a couple of them lifted from the wood form. -

Rusty hammer build along

stockmaker replied to Jason Fry's topic in Power Hammers, Treadle Hammers, Olivers

Good the hear on the welds. Remember it's not the end of the world to have to grind off a weld, that is the voice of experience taking. Good job on the cost, I have a motor, so hopefully I would be looking at $.2 a pound for the scrap. Again, thanks for the updates. -

Rusty hammer build along

stockmaker replied to Jason Fry's topic in Power Hammers, Treadle Hammers, Olivers

Thanks so much for the pictures/progress reports, very interesting to me. If you feel comfortable, I'd like to know your rough cost for all parts. Jason, I am a little concerned about your welds, they are what they are, but if you have any more big structural welds to do, I think you may want to ask an experienced welder to do them. I see you are not getting good penetration on almost all of them, and it looks like some are done over rust which could easily have been cleaned off. So clean your joints, go slow, and ask for help on the big ones, and maybe have someone take a close look at the ones on the top plates, for safety they may have to be redone. I hope not, but now is the time to look it over. Thanks again for the updates. -

Hello Anthony and welcome. I too have a Wayne Coe/John Emmerling type ribbon burner, however my gas injector is a 1/16" hole drilled into the 1/4" copper pipe which fits into the 3" air pipe. This will make my pressure different from yours, and since both you and I have needle values in the gas line does it really matter what the pressure is at the regulator ? I am assuming you are measuring pressure at the output of the regulator? I set my flame by sound and sight, too low on the air and it vibrates, and gives off Carbon Monoxide, too high and the clear blue flames about disappear and I notice metal does not heat up as fast, I have never blown out the flame, but also I have never turned up the air all the way. My regulator is set to 4lbs, the needle value is rotated to about half it's rotation to produce a clear blue flame with just a little dragons breath, but it's the gate valve on the blower that gets adjusted most of the time for me, I have a 112 cfm blower with the gate valve set about 1/3 turn open, mark your gate valve handle so you know how far it is turned, I have one knob on the round handle painted white. Have you started it yet? If not ask Wayne what pressure he runs, I think his gas injector is the same as yours. For first time start up before fire set your air so you can lightly fell it come out of the ribbon head with your hand than go from there.

-

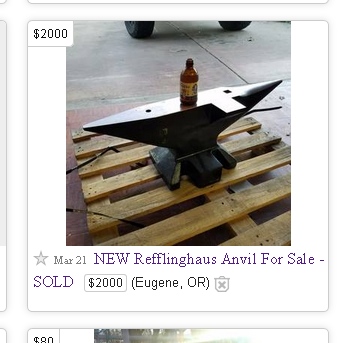

This anvil sold in one day on Craig's List. 275lbs, it was basically new. Right now there are 3 or 4 used anvils for sale in my Craig's List which is odd, there are usually none. They are asking from $4 to $6 a lb for them.

-

Naturally Aspirated Ribbon Burner. Photo heavy.

stockmaker replied to Frosty's topic in Ribbon Burners

I used Wayne Coe's burner head refractory, not sure what it is, but I made five heads, four naturally aspirated, and one blown. Wayne has two types, I used them both and both performed well, no leaks, no cracks. This high tech refractory is tricky to mix up, if goes from too thick to too thin in a heart beat, you want it thin enough to flow around your forms and against the plenum body, but not so thin that you weaken it. You also need to vibrate the whole assembly while wet to insure a good flow. -

I had the same problem with a brand new galvanized pale I bought, it leaked on all the seams including the bottom. I used Dap Butyl-Flex Adhesive, this is the stuff they use on Rain Gutters and my steel shop roof, it can be bought in many places in the US, the big box stores for one. This pale is my water quench bucket that is now frozen, it has been in use for about a year and a half and just started leaking alittle, this fall. It froze last year too and I thought that was it for the fix but it held for a few more months. Can you tell me why I would want to buy a galvanized pale that did not hold water?

-

Ausfire I love your pictures this time of year, here I set today in the middle of an Ice Storm and a frozen quench bucket while you have green trees and sunshine. The old cars in the background are pleasing as well. I bought a 40mm ammo can last month for $15 for oil quenching.