Welshj

Members-

Posts

309 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Welshj

-

I'm sitting here trying to figure out what the cast piece is that you're hanging the the chain from? At first, I thought control arm from a car? No... not that... lol. Gives it a pretty cool steam punk look overall the way you have it set up.

-

Zbarret- sorry for the thread hijack! Looking forward to seeing how you finish that blade out- I think it'll look pretty cool anyways. Please update when you get her done.

-

I honestly dont know... It's been over six months ago when I worked in a steel processing plant. I worked on what we called the pickle line. We processed hot and cold rolled steel coils through a hydrochloric acid wash line. We had a rockwell tester on the line that we ran sample tests of coil steel on for each customers coil. It impressed me that it was that hard of steel... I knew it was pretty tough, as I'm unable to drill through it with anything I have to include carbide bits. I remember it being 113-115, because I had taken a oxy/act torch and heated two small spots to just about melting- on the tang of a blade I'd made... hoping to soften it enough to drill pin holes through. After it cooled down, I tested the spots I'd heated. 101 on the same rockwell machine. Had my co worker who ran the line daily repeat the tests in case I messed up. Same results. Our average readings on the mostly mild steel averaged 40-50 reading, and an occasional high of 60-80 range of rockwell.

-

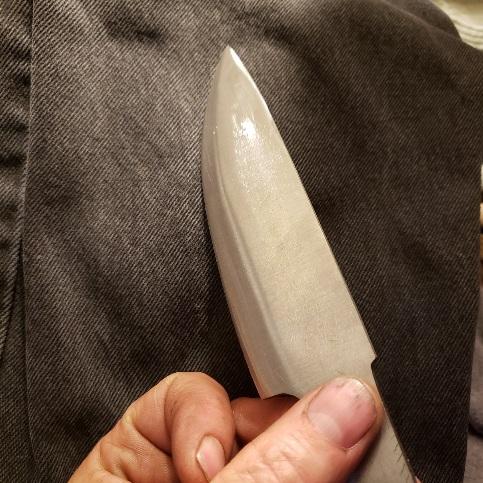

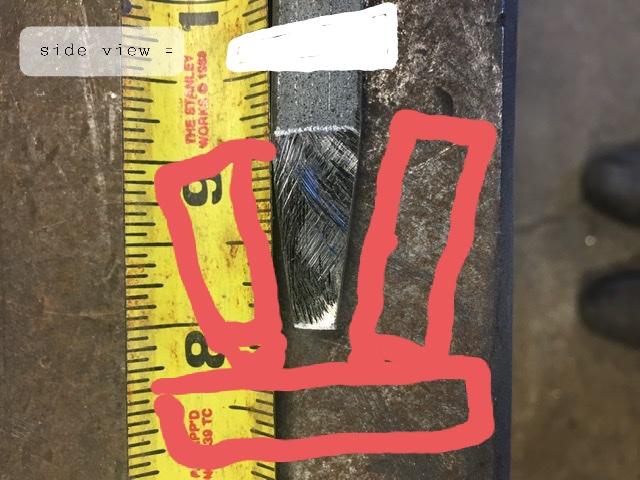

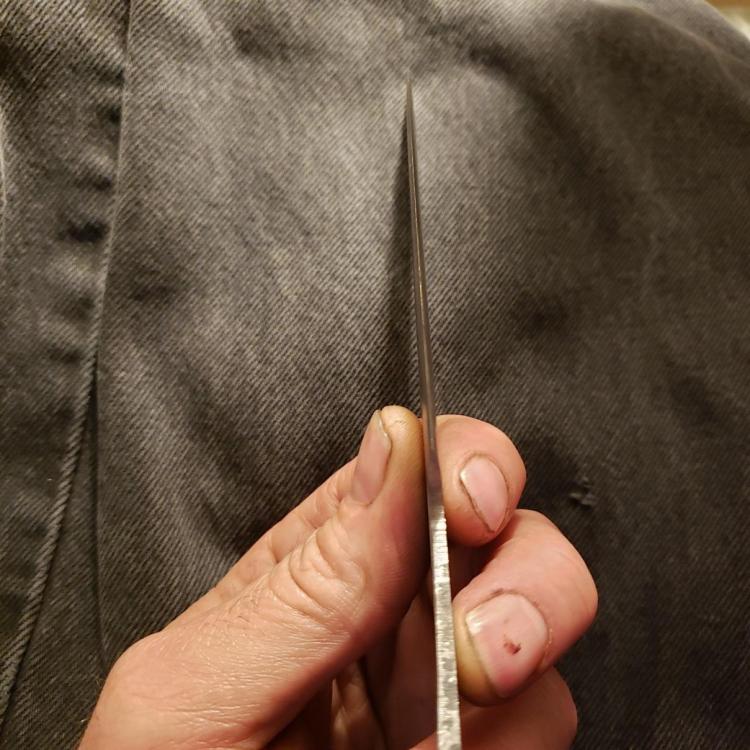

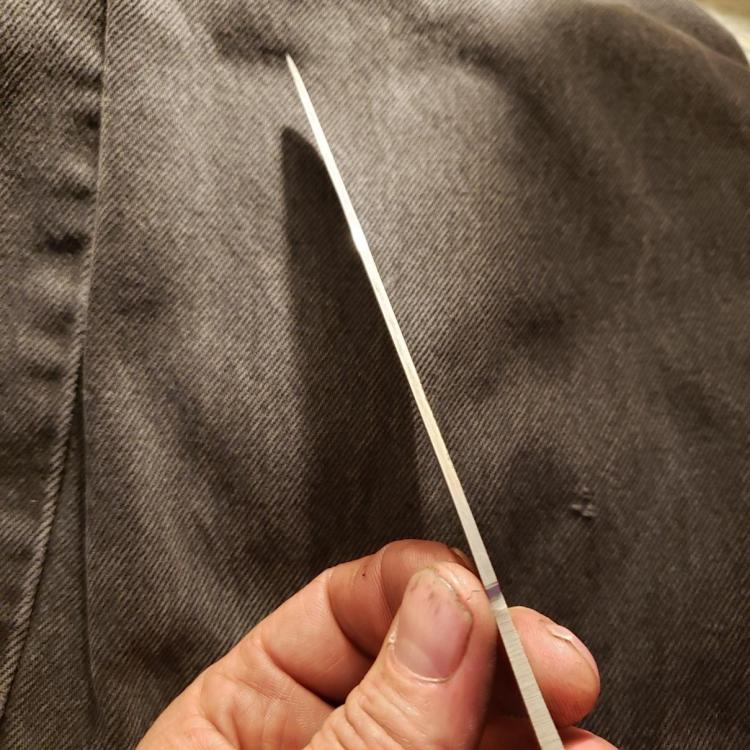

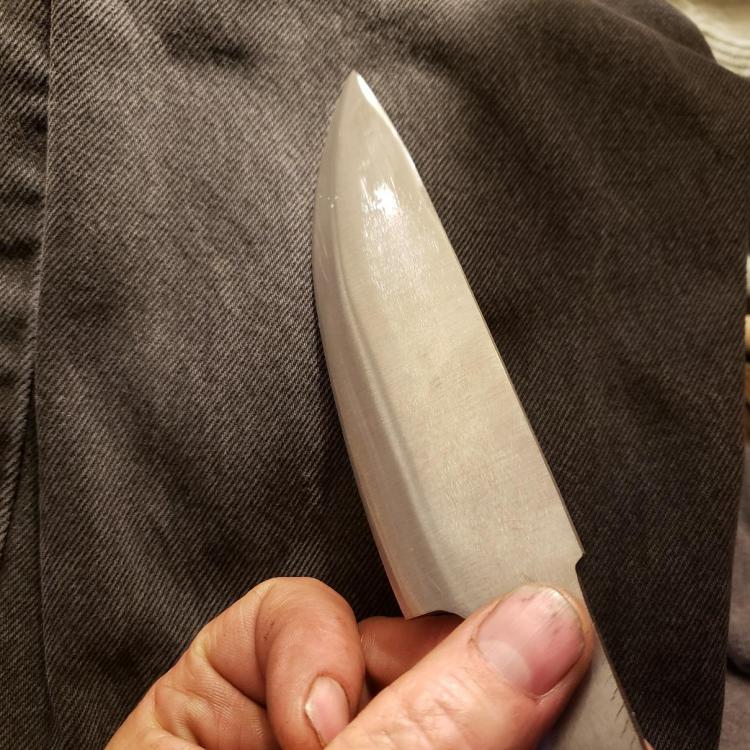

I'm working on a cleaver for a friend right now. It's just a stock removal blade- as it's cut from a piece of a large industrial saw blade. I tested it awhile back at work with a rockwell tester... it reads out at 113-115 rockwell hardness. For my finish on it- I clamped it down to a piece of hardwood mounted in my vice. I then took a DA sander set to full spin, with progressively finer papers. Got it down to 800 grit for a pretty fine polish, hand polished with some 1500 grit, then took to my bench grinder with a cloth buffing wheel and polishing rouge. Just takes some time! Picture is obviously before polishing, shaped to my friends drawing- size and dimensions he wanted.

-

Blade restorations/Improvements

Welshj replied to Jaegers Forge and Foundry's topic in Axes, Hatchets, Hawks, Choppers, etc

Ah! I missed that. Good eye. -

Yup... one critique. Use it well! I like it, basic, simple and clean.

-

1- you have a dad that loves you alot, and wants you to know where your future comes from. You're already working for it! Keep working on that, if you have to work harder to accomplish your goals... so be it. As long as you're working towards a positive effort in life... you're the one benefitting! 2- if you want to make knives, like latticino said... take that class if the opportunity presents itself. Even after forging and heat treating, you have to grind a blade to get a finished look and edge. No matter what the material used- you'll never have a sharp knife if you don't understand the basics of shaping and grinding the edge. That's my goal too- but I want to learn to make other things as a smith myself. Nothing wrong with that... 3- let no one tell you what you can't do. Let them tell you how not to do it, but never that you can't... it's up to you to figure out how to safely accomplish it. If you find later that you can't- then at least you know you tried, and learned from it. That's where learning from others comes in as well. You sound like somebody with a good head on your shoulders, and who's not afraid of putting in the work... don't lose that. Good luck in your endeavors!

-

For what it is... it looks like you've got a fairly decent grind on it. I like the profile, and I can't really tell what your bevels look like. I'm new-ish to smithing, but I've made a few blades over the years by other methods. The biggest thing about grinding a blade- is to watch your heat. You don't want to see bluing or coloring in the metal... that means you're taking out what hardness, and tempering you may have done to it. Frequently dipping in water to cool while grinding is common for heat control. If you haven't hardened it- you dont want to go too thin on the blade, especially the edge. The thinner the blade, the more prone to warpage from what I've seen. Long periods of grinding, keeping the blade in contact with the wheel or belt- will cause over heating. It's best to be patient, and make slow progress over time... than to try and hog it to shape quickly.

-

Blade restorations/Improvements

Welshj replied to Jaegers Forge and Foundry's topic in Axes, Hatchets, Hawks, Choppers, etc

Post a pic, let's see it. My little brother has made a hobby out of finding old axe heads and restoring/rehandling them. You'd be amazed at what you can do with one. As long as the eye (my term), or the opening for the handle- is structurally sound... I'd clean it up and keep it an axe. New handle, and you have the use of your granddad's axe. -

It was a triangular cross section of bearing race doubled top and bottom, with a piece of flat military vehicle leaf spring between to make a rectangle... Best guess would have 52100 for the bearing, 5160? For the spring? I knew from go that it was going to be a challenge, but that was the point... just experimenting. I got maybe half of it welded together, but it slid apart from there on. Kind of figured it might. But I had just got my burner dialed in closer to forge welding heat... and just wanted to try with what I had on hand.

-

I live in just that! three walls, the back, and two side are eight to nine foot deep with my rear roofline a foot off the ground. The concrete in the back is 18" thick... with a sprayed on rubber sealant. The roof is put together with long span "w" trusses that the po "beefed up" meaning extra supports. But some things the man did make no sense to me at all. My garage is offset attached to the house, with an attic space opening between to two... about a foot tall and just big enough to barely crawl through on my belly... right into a truss. Smh. Septic system seems like an afterthought. I have to pump up, and out to where they raised it over the ground level into a back filled hill.

-

So, a few updates since my last post... I picked up two 100 lb tanks for $120 locally. Great shape, and only 2 or 3 yrs old. Much better, longer forging time! I've dropped down to the 1" diameter tube frosty suggested with great results. I'm now well within the range of forge welding- just not within the skillset yet. I've tried, but chose a poor... combination of steel and shapes to attempt. But it was more for the experience of trying. (52100 bearing race, and spring steel.) Also forged a handle, and door hook hardware for the shed, as well as a couple blades. Also got power run out to the shed, and some lighting arranged. Waiting now on completion of my belt sander from a machinist friend who's building it for me. Got a sneak peek update picture the other day- right now, he's awaiting motor delivery due to the coronavirus mess... to get motor mount plates setup and aligned.

-

So many things can be done... with anything! I have an older 12" craftsman wood lathe. It has a 48"? (or so) bed on it. Its mounted on an old 1" thick mdf board that's around 3ft x 6ft. While trying to find something to build supports, legs... etc... I happened to set it on an old antique coca cola cooler shell I bought for the wife to plant flowers in. Guess who no longer has a flower planter? It works perfectly!

-

Some of the deepest pain and loss I ever suffered... with my best friends, as well as the most joy and love. Totally understood frosty. Thanks for sharing her story!

-

What did you do in the shop today?

Welshj replied to Mark Ling's topic in Blacksmithing, General Discussion

Well, not in the shop exactly... yet. Started digging a trench to bury a line out to the shed to run power out from the house. 2" pvc pipe, run power and air from the compressor in the garage. -

tapers on a picket fence... help needed

Welshj replied to JW513's topic in Blacksmithing, General Discussion

Frosty- agreed. The idea behind the jig was for a method of making them identical... he would indeed have to forge each taper, but could then "size" them to finish with the jig, so they were the same. It was not intended as a way to forge them- but... to size them identically ? -

PWS- that's an awesome piece of family, and military history!! Thank you so much for sharing that. I can, and can't- at the same time... imagine the things he saw. My wife tells me that I'm not the same man I was before my iraq tours... that I'm more... hard and emotion-less than before. I can fully understand his vice after that time. Not all wounds are visible, and some never heal.

-

I'm sorry, it has nothing to do with your question... but I found this both very insightful, and extremely funny statement! Depends on the leaf spring- I have a couple truck driver friends... one brought me a broken leaf spring from his truck. It's easily a full inch thick...

-

tapers on a picket fence... help needed

Welshj replied to JW513's topic in Blacksmithing, General Discussion

Well, anytime I've had to reproduce any type of identical pieces... the first thing I do or think of- is a jig. I would think for forging those... a simple piece of flat plate steel with two angled pieces welded in a "V" shape with angles matched to fit that taper. Then a flat stop piece at the narrow end of the "V". Hardened, or tool steel if possible for the 3 jig pieces- to withstand repeated beating. Height of the angled pieces should be the same as the stock, then ground down to the height of the desired point on the taper. Hammer point to a close, oversized dimension, stick into the "V" jig, hammer to final dimension, flip 90 deg and finish other side. Forgive the rough, on my phone edit... but just an idea. -

What did you do in the shop today?

Welshj replied to Mark Ling's topic in Blacksmithing, General Discussion

Went to my buddy's shop- who's building my belt grinder, and helped him make grinder pieces. He let me use his 2x72 grinder he's copying mine from- to rough finish grind the blade I made the other day. Excited, cant wait to get mine home! Finishing polish, and start on scales soon! -

Another side effect of this forumn? I just found out someone I served with in Germany is a member here! Been catching up on memories via PM's. That's awesome....

-

Any clue as to what this tool is??

Welshj replied to Curt's topic in Tools, ID, and pictorial reference

^all of the above is what I was going to say. It looks to me like a tool used to stretch, twist and run old school baling, or barbed wire fencing. The four holes would let you clamp around four wires, close and pull all four to run along a fence line. The wheel would let you pull it around a post under tension? And the spike in the back you could step on into the ground to hold tension on clamped wire, or even hammer into a tree. I've seen more modern versions of wire tools that have similiar features, but not like that one. -

It matters, because this is a worldwide forumn. Theres a guy the other day asking for advice on welders, he was in the UK... I'm in ohio. So me telling him to go down to bakers propane and welding supply is useless to him. Now, on the other hand- I could prolly tell you I'd found a good place in south bend Indiana that might help you... if I had. The reason for them asking you to update your info with your location is just that. In six months, this thread will be buried, and someone again will be asking where you're from. If it's in your info, as it is now- they can just click on your icon and see it. Now, refractories. What you're trying to do is kind of a crossover from the norm here as blacksmiths. I'm not saying it's a dumb thing, or a reason not to ask here... but terminology being a standard for communication is important. What you're asking- might not be understood... properly. We're talking dangerous stuff here. 2500 degrees is enough to seriously injure if not kill if something goes wrong. Isn't that enough of a reason to properly understand a question, or an answer? Theres guys here who get frustrated when you ask the same question thirty other guys already asked- without even trying to look for it. I get that. But I'm a newbie too, and I'm more patient... it helps to learn. Be patient. what you're looking for is prolly here. I used- Hell's Forge Hellcote 3000 Refractory Cement for Ceramic Fiber Blankets - in building my forge. I got it on amazon, two 5lb packages was enough to coat my forge, and then some. The above is the exact description from the item I ordered on amazon, you can search using it. In my opinion- this is not something worth skimping on. To me, its protecting you and your property from a potential extreme fire hazard. That product is designed to be used over a ceramic wool blanket like normally used in a forge. The wool is a great insulator, versus a "heat sink" like a brick, or cast refractory wall... so it helps your forge or kiln- retain heat and heat up faster and last longer with less fuel. It can also be cast- but at the expense... that's a lot. I think that's the misunderstanding in terminology. You wouldnt believe how many guys ask about using regular "cement" or making cement or even using plaster to line or make forges from. It's literally apples and oranges from real refractory, and can cause dangerous conditions- like stones in the cement exploding from heat. There are many people here with a wealth of information to glean. How you use it, and how you ask for it is important... as you may have to figure out how to live- after you tried doing it.

-

What did you do in the shop today?

Welshj replied to Mark Ling's topic in Blacksmithing, General Discussion

First attempt at a blade. Forged from an old ferrier's rasp given to me by my brother. I ground the profile clean with an angle grinder, and hand files so far. Have a machinist friend who's currently building me a 2x72 belt grinder... so I'm behind on a couple steps. Lol.. first attempt at quenching today as well. File seems to skate! Also beat out a couple hot cut hardy tools. One out of some leaf spring with mig welded shims to thicken it. Its currently tempering in the oven. The other is a "real" one piece. Forging it from a semi truck drag link that's supposed to be 4150? I believe. About 1-1/2" thick... it's taking some time. My biggest hammer is 2.5lbs! -

The one rank I never wanted... lol. All the responsibilities of an NCO, none of the respect or pay! I got to meet soldiers from several countries in my time in Germany, Hungary bosnia, and iraq. Mostly Hungarian, Polish, German, Italian and Japanese soldiers... Never had the honor to meet canadians.