-

Posts

152 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Kansas City, Missouri

-

Interests

Bladesmithing (duh) particularly western or old fashioned bowie knives. I also play electric and acoustic guitar I mostly play 90's grunge or classic rock.

-

Shainarue started following Jaegers Forge and Foundry

-

Show me your anvil stands

Jaegers Forge and Foundry replied to pkrankow's topic in Stands for Anvils, Swage Blocks, etc

I've also heard the leg test to see if you can put a bar of stock between your legs and keep it at a good height. My old stand was knuckle height and I've found it worked, but thank you! that's some interesting history behind the reason we keep it at knuckle height. -

Show me your anvil stands

Jaegers Forge and Foundry replied to pkrankow's topic in Stands for Anvils, Swage Blocks, etc

Okay good to know thanks for all the suggestions I'll look for thicker plate but I wonder I have more of the same thickness plate I have on currently would I be able to stack/layer it and yes 3-4 inches below my knuckles I did run out of square tubing but I so have some 2 inch diameter steel pipe that I could use as feet but the only trouble with this is cutting it 90 degrees as I don't have a chop saw but I have ideas -

Show me your anvil stands

Jaegers Forge and Foundry replied to pkrankow's topic in Stands for Anvils, Swage Blocks, etc

about 3-4 inches Thanks I'm planning on adding a thicker plate at the top and the bottom, and yes I do plan on adding a t under the stand using angle iron or something -

Show me your anvil stands

Jaegers Forge and Foundry replied to pkrankow's topic in Stands for Anvils, Swage Blocks, etc

I recently made this anvil stand today I'm going to add a hammer rack and fill the legs with sand as well as supports on the legs The only issue is it's a bit to short So i figured I'm going to add wood boards to add height to it but I don't want to deaden the weight if I add boards under the anvil or under the stand its self with it deaden the hammer blows? -

Thanks will do!!

-

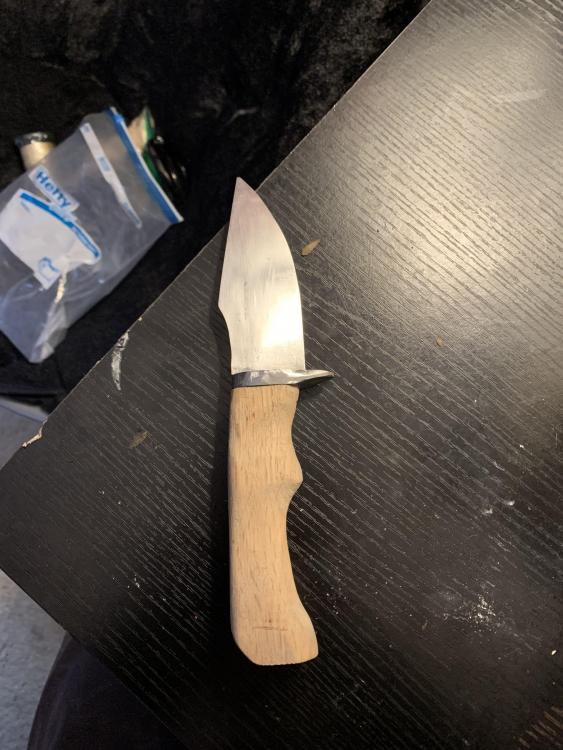

Not much work in the shop lately due to end of semester finals. I've been trying to get up to the shop when I can I was able to complete this hidden tang Bowie knife I've been working on it here and there since January. The handle wood is from a broken ax handle, the guard is a cut off piece from a pipe fence that was left over from when it got put in. And the blade it's self was from another half of a pry bar from an old project. Now all I have to do is make a sheath, kydex looks easy but leather looks better and fits the rustic old western style.