-

Posts

331 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Benona blacksmith

-

.thumb.jpg.04efa31b17e0217d84870be46a7a0461.jpg)

How to hold it...........newbie question

Benona blacksmith replied to Chris C's topic in Hand Hammers

I make hammers and axes and find all the different shaped holes to be extremely useful. For making knives not all that practical. I need to make a new stand for mine so I can use all the edge shapes. Right now it's just a down and dirty oak 4x4 stand. Back to the original question. You may find the first few initial blows to get the punch started can be a pain but once you have it started it's easy to keep the billet in place with the punch alone. But forging some flats like you did helps immensely. -

.thumb.jpg.04efa31b17e0217d84870be46a7a0461.jpg)

Swedish'ish cross peen hammer.

Benona blacksmith replied to Benona blacksmith's topic in Hand Hammers

The balance is good. There is almost equal amount of material in the peen as there is in the face. I really like the peen side. It's not so aggressive and is easy to get the hammer marks out. -

.thumb.jpg.04efa31b17e0217d84870be46a7a0461.jpg)

How to hold it...........newbie question

Benona blacksmith replied to Chris C's topic in Hand Hammers

You would be amazed how universal and handy a swage block is. I have a 250 lb antique cast iron one and a 66 lb Holland anvil one. I prefer the Holland anvil one for most things as I had a miss blow on my cast grey iron one and hit my friend in the chest with the shrapnel from the cast iron. That's another reason I belive cast grey iron anvils should not be used. Cast ductile iron is okay for general smithing purposes on swage blocks and anvils. -

.thumb.jpg.04efa31b17e0217d84870be46a7a0461.jpg)

Swedish'ish cross peen hammer.

Benona blacksmith replied to Benona blacksmith's topic in Hand Hammers

-

My latest hammer "design". Losely based on a swedish cross peen and a hammer that I see John Switzer at black bear forge use. I still need to wedge the handle and shape it to my liking.

-

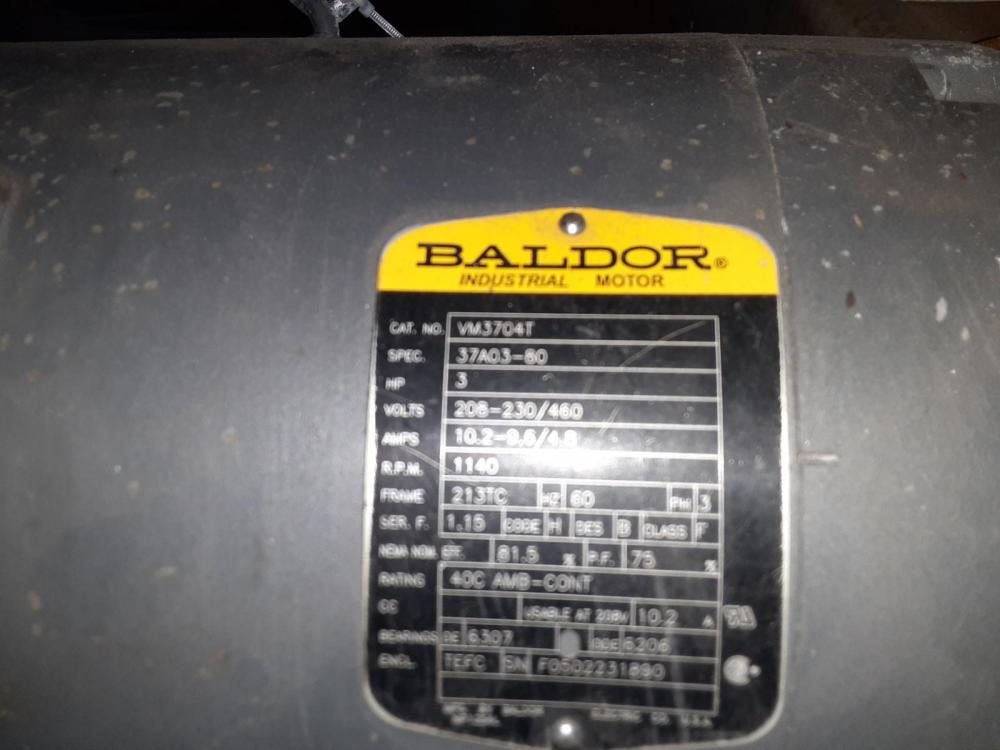

Here is some more pictures of my new grinder. I have to order a new contact wheel for it. I'm thinking 12 or 14 inch. I have another one coming for parts also that's missing the tensioner and tracking wheel. the tensioner works on air. I have thought about gutting the air cylinder and using a spring inside it.

-

.thumb.jpg.04efa31b17e0217d84870be46a7a0461.jpg)

Re-softening a clay tempered blade

Benona blacksmith replied to Olorin's topic in Heat Treating Knives, Blades etc

-

.thumb.jpg.04efa31b17e0217d84870be46a7a0461.jpg)

What did you do in the shop today?

Benona blacksmith replied to Mark Ling's topic in Blacksmithing, General Discussion

-

.thumb.jpg.04efa31b17e0217d84870be46a7a0461.jpg)

Trying to make a wrought face welded hammer

Benona blacksmith replied to Momatt's topic in Hand Hammers

I've always tack welded it. The only time I mess around with teeth or tabs is with an axe. What YouTube video was it? Can you post a link? -

.thumb.jpg.04efa31b17e0217d84870be46a7a0461.jpg)

How big of a hammer

Benona blacksmith replied to Millennial Blacksmith's topic in Power Hammers, Treadle Hammers, Olivers

After running my 88# TZ Runfa for a year making hammers and axes it leaves me wanting more....anyone else feel they want a bigger hammer after spending a small fortune on a hammer? -

There should be 2 other number on each side of the 2. This would be the english stone weight of the anvil.

-

Thank you Jennifer... I made one other pair of tongs based on a video GS tongs on YouTube made. They turned out okay but the boss is really thin and they bend easily. Other than that all I have done as far as tong making is assembling the quick and rapid tongs from kens custom iron.

-

-

.thumb.jpg.04efa31b17e0217d84870be46a7a0461.jpg)

German spring hammer.

Benona blacksmith replied to Benona blacksmith's topic in Power Hammers, Treadle Hammers, Olivers

-

.thumb.jpg.04efa31b17e0217d84870be46a7a0461.jpg)

German spring hammer.

Benona blacksmith replied to Benona blacksmith's topic in Power Hammers, Treadle Hammers, Olivers

It's coming from Austria figured I wouldn't find what I was looking for around here in Michigan or even in the states and had the opportunity so i took it. -

.thumb.jpg.04efa31b17e0217d84870be46a7a0461.jpg)

German spring hammer.

Benona blacksmith replied to Benona blacksmith's topic in Power Hammers, Treadle Hammers, Olivers

Thank you sir for the information!!! -

.thumb.jpg.04efa31b17e0217d84870be46a7a0461.jpg)

German spring hammer.

Benona blacksmith replied to Benona blacksmith's topic in Power Hammers, Treadle Hammers, Olivers

Ok so the motor plate that I posted a picture of I dismissed as having any information about the actual hammer itself. But after looking closer at it, it says 50kg in the lower right hand corner! Unless that's the weight of the motor? -

.thumb.jpg.04efa31b17e0217d84870be46a7a0461.jpg)

German spring hammer.

Benona blacksmith replied to Benona blacksmith's topic in Power Hammers, Treadle Hammers, Olivers

-

.thumb.jpg.04efa31b17e0217d84870be46a7a0461.jpg)

German spring hammer.

Benona blacksmith replied to Benona blacksmith's topic in Power Hammers, Treadle Hammers, Olivers

-

Does anyone have any info on this style hammer? I am buying it but dont know much about it. It is listed as being in good working order. There is no info on tup (bär) weight. Mainly what I'm interested in is the ram weight. I will try and get some more pictures.

-

.thumb.jpg.04efa31b17e0217d84870be46a7a0461.jpg)

Why is rebound important?

Benona blacksmith replied to rdennett's topic in Anvils, Swage Blocks, and Mandrels

I would enjoy that. I will set up a time after all this corona stuff. -

.thumb.jpg.04efa31b17e0217d84870be46a7a0461.jpg)

Forklift fork or railroad track?

Benona blacksmith replied to Benona blacksmith's topic in Swordsmithing

Forged in the bevels yesterday. Still needs some work. My daughter spent the day in the shop with me. She even forged her own little hunting knife with my help. -

.thumb.jpg.04efa31b17e0217d84870be46a7a0461.jpg)

Why is rebound important?

Benona blacksmith replied to rdennett's topic in Anvils, Swage Blocks, and Mandrels

Absolutely not. Cast iron ASO's are dangerous as is an anvil that's too hard. A piece can fracture off and hurt someone badly. I dont even like my 250 lb cast iron swage block for the same reason. My buddy got hit in the chest with a piece of my swage block. I much rather use my Holland anvils swage black that's a ¼ the weight. -

Borax and acetone works. The idea is to dissolve the borax and when you pull the billet from it the borax will get between layers and the acetone will dry off leaving the borax. There is also the kerosene trick.

-

.thumb.jpg.04efa31b17e0217d84870be46a7a0461.jpg)

Why is rebound important?

Benona blacksmith replied to rdennett's topic in Anvils, Swage Blocks, and Mandrels

I have personally met and talked with Dan Moss I would trust his word over Trenton Tye. If Trenton Tye told me it was raining I would go outside to see for myself.

.thumb.jpg.9455a717471580104e2a06414b405d7e.jpg)

.jpg.874cf29a6c70a605ec3d3d0318788a80.jpg)

.thumb.jpg.c8e8fd00d76b15bcc047e488b589b117.jpg)

.thumb.jpg.dbd2ee8621e814ac1c7fc6bfaace892b.jpg)

.thumb.jpg.2f24ca824e4179a14d18f5dee350899b.jpg)