-

Posts

331 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Benona blacksmith

-

.thumb.jpg.04efa31b17e0217d84870be46a7a0461.jpg)

Favorite handle making and wedging method?

Benona blacksmith replied to Justin Topp's topic in Hand Hammers

When our furnace xxxxxxxxx a month or so ago I took to the woods and cut down any standing dead timbers I came accross without looking into what they were. We needed heat so I supplied it. Now I have my furnace running again and dont need to fire wood. I started turning what I cut into charcoal and my dad showed up yesterday and informed me that what I was burning is Ash! now up picking through as i split and keeping all the good handle materials. There is still quite a few trees on my property that are still standing. Those will be used for axe handles. Now I need to make me a draw shave!!! I gues I know what I will be using this Ash charcoal I'm making for!!! -

It is inspired by the hofi hammer but in no way is an exact copy. Weight is 3.2 lbs. I will get some actual measurements in a bit.

-

With all this talk of different hammer techniques and hammers to be used with the techniques, I decided to forge a hofi inspired hammer. I just need to grind heat treat and handle it and it will be ready for use. Then it will be time to try and learn a new technique!!!!

-

They understand what you mean. There trying to give you another idea to achieve the same/different result (if that makes sense)!

-

.thumb.jpg.04efa31b17e0217d84870be46a7a0461.jpg)

What did you do in the shop today?

Benona blacksmith replied to Mark Ling's topic in Blacksmithing, General Discussion

Cut one big chunk with the chop saw and forged it all down to 2 in inch x 2 inch and hot cut into 4 pieces under the power hammer then forged down from there. -

.thumb.jpg.04efa31b17e0217d84870be46a7a0461.jpg)

What did you do in the shop today?

Benona blacksmith replied to Mark Ling's topic in Blacksmithing, General Discussion

Hammer making tongs, hammer eye punch and drift all forged from forklift fork. I might trim the hammer eye punch down a bit. -

.thumb.jpg.04efa31b17e0217d84870be46a7a0461.jpg)

Power hammer build

Benona blacksmith replied to Ted Ewert's topic in Power Hammers, Treadle Hammers, Olivers

I really like the magic winter dust. It Keeps me cool while working in the shop. I'm debating on putting AC in the shop for working in the summer. I dont know how you guys closer to the equator can handle it. Maybe my blood is too thick? -

.thumb.jpg.04efa31b17e0217d84870be46a7a0461.jpg)

Making my own flux

Benona blacksmith replied to Benona blacksmith's topic in Fluxes used in blacksmithing

Video unavailable This video is unavailable. This is a perfect example of why the alloy content cant be different within inches or from one end of a bar to another. -

-

I have 2 sets of forks and 1200 lbs of the 2 inch round. And about 300 lbs of the 3 inch round. I understand not all forks are created equal and that's why I'm getting both sets tested!

-

.thumb.jpg.04efa31b17e0217d84870be46a7a0461.jpg)

Power hammer build

Benona blacksmith replied to Ted Ewert's topic in Power Hammers, Treadle Hammers, Olivers

I have no heavy equipment just a 1 ton chan fall and ingenuity. I move everything with rollers and leverage. This is the hammer I built with the 500 lb block of steel. the 3800 lb block with my hand for reference and in the background you can see a pallet for reference. The motor is 30 hp and weighs 500 lbs and will be used for a rotary phase converter. And the hammer I replaced the homemade hammer with. -

.thumb.jpg.04efa31b17e0217d84870be46a7a0461.jpg)

Power hammer build

Benona blacksmith replied to Ted Ewert's topic in Power Hammers, Treadle Hammers, Olivers

Big Blu has scientifically proven what the optimal anvil weight for a given tup weight is. I know your hammer runs good and moves steel. I just want to reiterate that a solid mass IS the best option. Even if you could get ahold of a large axle in the 250-300 lb range. I have a 3800 lb block of steel waiting for me to make a big hammer with. I will get a picture of it later along with a picture of my homemade hammer. My main working anvil weighs 426 lbs. I can tell the difference between it and my 200 lb anvil. I dont even have my 100 lber mounted anymore. -

.thumb.jpg.04efa31b17e0217d84870be46a7a0461.jpg)

Power hammer build

Benona blacksmith replied to Ted Ewert's topic in Power Hammers, Treadle Hammers, Olivers

So its 1:3 ratio. So when looked at in perspective it's like using a 1 lb hammer on a 3 lb anvil. There is a reason real hammers use solid mass for an anvil. It's definitely not because of its cost effectiveness. The video you seen with a wooden anvil was a trip hammer that was made way back in the day before they had the readily available materials we have now and that machine would have been better served with a solid anvil. But what do I know. I'm just a hillbilly in west Michigan that has proved this myself with my hammer? -

So I was quoted $600 for 4 samples. A bit more than I was hoping to pay but would be worth it in the end. I also found a place that will use there XRF gun for 49.99 per sample. I will probably go that route. I'm not messing with any crazy alloys so that should serve me OK.

-

.thumb.jpg.04efa31b17e0217d84870be46a7a0461.jpg)

Making Tongs Lefty Vs Righty.. Does it matter..

Benona blacksmith replied to jlpservicesinc's topic in Tongs

It matters to me. I really hate using left handed tongs as they roll out of my palm instead of nesting in it. -

.thumb.jpg.04efa31b17e0217d84870be46a7a0461.jpg)

Power hammer build

Benona blacksmith replied to Ted Ewert's topic in Power Hammers, Treadle Hammers, Olivers

What do you estimate your concrete anvil weighs? -

I just want to get my heat treatment right when I'm making hammers. Forklift fork, some 3 inch round I have and some 2 inch x 9 foot rods with threaded ends.

-

Chemical composition is what I want them tested for.

-

I dont recall advocating any testing methods.

-

I'm looking into sending out a few pieces of steel to get tested and would like to know what the best method to ask for. I know that LECO only tests for carbon, sulfur, nitrogen, oxygen and hydrogen so that's out. ICP testing wont show carbon so thats out. So far OES testing seems to be on track. What else is there?

-

.thumb.jpg.04efa31b17e0217d84870be46a7a0461.jpg)

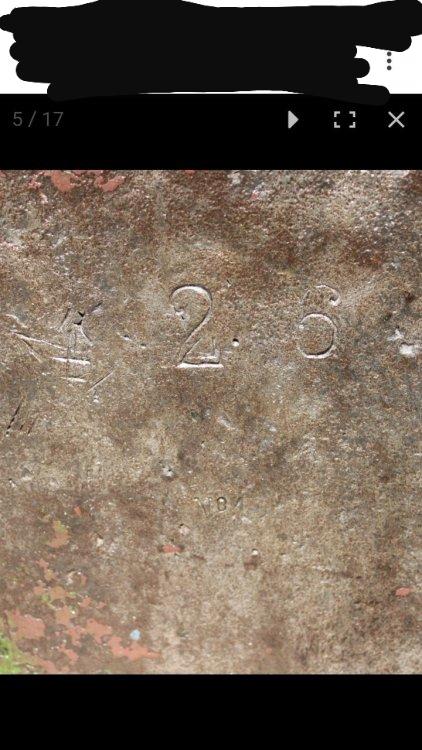

Söding und Halbach anvils serial numbers

Benona blacksmith replied to Zozon's topic in Anvils, Swage Blocks, and Mandrels

Here is a couple I found on my phone I blocked out the website name I bought it from as to not act as advertisement. -

.thumb.jpg.04efa31b17e0217d84870be46a7a0461.jpg)

Söding und Halbach anvils serial numbers

Benona blacksmith replied to Zozon's topic in Anvils, Swage Blocks, and Mandrels

I will get some when I get back home tonight. I've been sidetracked and I havent had a lot of shop time lately. -

.thumb.jpg.04efa31b17e0217d84870be46a7a0461.jpg)

Power hammer build

Benona blacksmith replied to Ted Ewert's topic in Power Hammers, Treadle Hammers, Olivers

You will probably still hear and feel it in the house. My neighbor can feel my hammer 100 yards away he cant hear it though (?). Luckily that is my closest neighbor and he is in his 70's and grew up next to a blacksmith shop and used to run the bellows for him so he doesn't mind....except for the one time I worked till around 11pm! Nice work on the hooks and I'm glad you kept with the post and didn't let our criticism get to you. I built a 60 lb hammer with a hollow anvil filled with sand and oil and I was extremely unhappy with it. I rebuilt it to 85 lbs with a 500lb anvil and it was a lot better and later replaced the 3/4 hp motor with a 1 1/2 hp motor and it was an incredible difference. I have since replaced it with a self contained hammer.

.jpg.7dee842099f38f09574b214b678fe772.jpg.d27fe702566024e0b08da8624c1072a8.jpg)