-

Posts

616 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Another FrankenBurner

-

I will do some smoke tests since I am waiting for mig tips at this point. Also since I am waiting, I scaled and printed a 3/8 version of 2.7.9 to see if it could induce enough air with an 0.023 mig tip but I have to make mix tubes and proper nozzles. I stuffed a 3/8 nipple into it and faked some nozzles and it runs rich. I haven't given it much of an attempt yet.

- 863 replies

-

Naturally Aspirated Ribbon Burner. Photo heavy.

Another FrankenBurner replied to Frosty's topic in Ribbon Burners

Do you have any pictures of it running that you could post? -

If your main goal is fuel savings, there a lots of ways to accomplish that. Several have nothing to do with your insulating choices. The insulating properties of the kaowool win over all the castables and bricks for insulation value and lack of mass. The downside is that it is fragile and when heated, breaks down and creates hazards you don't want to be breathing. Usually 2 inches is recommended. There has been recent discussion about 1 inch being enough and also some talking about trying 3 inches. With 2 inches, I can hold my hand on the shell of my forge for a few seconds after it has run for hours. Three inches might provide some savings but I wouldn't expect it to be much. The reradiating coatings (like ITC) are used to increase internal temperatures inside the forge. The coating absorbs energy, becomes very hot, and radiates that energy to heat your work. ITC is a poor choice in that it breaks down quickly in the forge environment and is expensive. People are happy with Metrikote and Plistix which serve a similar function. A thin coat is better then a thick one. You could put the coating directly on the rigidized blanket. This would prevent the hazardous breathing situation and produce a forge which heats very quickly to highest temperatures. The walls are fragile to bumps. If you are clumsy with metal placing, it might break through and require patching. This is where kastolite comes into play. It is tough at high temperatures. It is somewhat insulative but it is also mass. This is added to toughen the walls at a cost of fuel efficiency, heat up time, and maximum temperature. The thinner you can get away with, and still armor properly, the better. There is one caveat though, these rules of thumb are if you are a typical hobbyist user. If this forge is to be heavy used, with lots of metal through it quickly, and it is not shut off often, more mass can be helpful in stabilizing temperatures. A general recommendation which several have reported happy results with: 2 inches of rigidized kaowool 1/4 - 1/2 inch of kastolite 30 thin coating of Metrikote or Plistix Your shell is very large, you could fill in the extra volume with rigidized perlite. Mikey had recently talked about it in Forges 101. I have never tried it though. Other ways to save fuel: Better burner design (Ron doesn't use Reil Burners anymore) Proper baffle walls An idle circuit (big savings for me) As to forge shape, I have never built a forge with square corners but Mikey is usually advising against them. He tends to uptalk the oval shape quite often. Square corners do bad things to flow dynamics. With your current shell, if you suspended the blanket with perlite, you could roll the blanket to create a more rounded interior. The next big question you should be asking is how are you mounting the burner in what position. Square forges tend to have the TDC mounted burners which Mikey also advises against. This is not intended to be discouraging at all. Hopefully any of it is helpful in getting you to a hotter forge.

- 14 replies

-

Frosty also said the ITC100 won't last, in his post. It is not designed for this and it flakes off quickly. Wayne Coe sells Metrikote and Plistix and Larry Zoeller sells Plistix. Both options are better options for the hot face. On the kastolite, it is recommended not to over kill it. It is used to armor the walls against clumsy hands hitting the walls with the metal and to cover the fragile hazardous blanket from the flame. Add enough to be protective but no more. As you add more, the forge requires more fuel to heat, it takes longer to preheat/cool down, and it can reduce the maximum temperature it can reach. I have seen recommendations between 1/4 - 1/2 thick layers. I use 3/16 inch currently and it is tough enough for the occasional bump but I am careful when placing my iron in the forge.

- 14 replies

-

Frosty: Here is a shot from the top to hopefully explain the ribs. I mostly have no clue what I am doing so at one point I looked into airfoil design in an attempt to streamline. I have ordered 0.030, 0.035, and 0.045 mig tips. I will take your advice and not get out the tip cleaners until I have an upper bracket. I am expecting the 0.030 to be over sized. It would be nice if I am wrong. HojPoj: That is a fun idea. Bigger selection in sizing, super cheap, and listed by their actual diameter. Wouldn't that be nice. Like you, I suspect the turbulence/spread makes them poor performers. I have seen a few posts in which people had drilled out their own jet, left the length short, and it didn't work well. Cheap enough to play around with anyway.

- 863 replies

-

I tested another version today. Major changes to the flame. I took the trumpet restriction and doubled it's length. This change increased air induction by a magnitude. With the 0.023 mig tip it is producing an oxidizing flame with the pressure needle resting on the minimum peg. I ran it with another tip, an 0.025 which has been drilled to 0.032 actual. It also produces an oxidizing flame. It's low pressure range is the best I have produced. I am going to use torch tip cleaners to enlarge the jet. I also ordered some 0.030 mig tips to see if it can support that large.

- 863 replies

-

Naturally Aspirated Ribbon Burner. Photo heavy.

Another FrankenBurner replied to Frosty's topic in Ribbon Burners

Sorry for the confusing post. I promise it sounded legible in my head when I wrote it. As to specific terms, I can use whatever anyone likes. I generally try to adapt to the terms being used in the discussion. I am mostly just going to lurk until I have built a couple so I am not just another guy talking without knowledge. It's a fun topic. -

Naturally Aspirated Ribbon Burner. Photo heavy.

Another FrankenBurner replied to Frosty's topic in Ribbon Burners

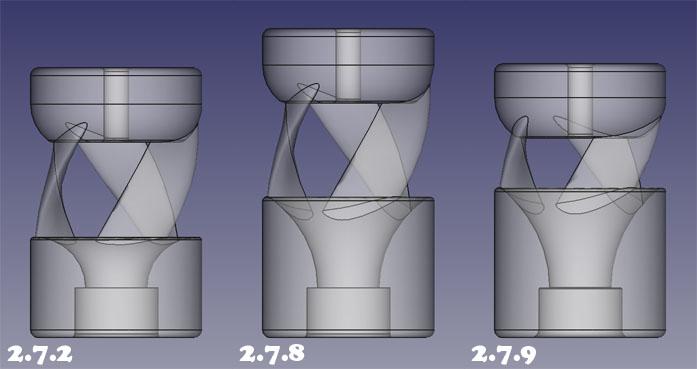

If you are asking me, I am talking about the shape of the ports. Usually ports are just straight cylinder voids left by removing crayons. I am talking about either a taper, a partial taper, or a step of some kind. Here is a quick rough CAD of what I mean (tops being the flame face): -

Naturally Aspirated Ribbon Burner. Photo heavy.

Another FrankenBurner replied to Frosty's topic in Ribbon Burners

Increasing induction was part of my mental picture of tapered ports in a NARB. Less back pressure and more throughput, allowing lower pressures to move more air for cooling and cleaner burning while giving us the flame holding characteristics. Tapers slow the stream as they increase in area/volume. If looked at backwards, the further upstream you go, the higher the velocity of the FAM. This may provide a natural brake to flame propagation backwards. I am basing all this thought on my experiments with tube burners. When using a tapered nozzle, as the fuel pressure is decreased, the flame rolls back into the nozzle further wherever the propagation velocity and the FAM velocity match. It gives the burner a larger range of operation. As long as the velocity at narrow end of the taper is higher then the propagation velocity, the flame will not flash back into the plenum. The major downside and possible idea killer is the fact that as the flames move back into the block, they heat the block more/faster. In tube burners, I have run higher end orange nozzles without flash back but with more ports giving more surface area to heat the flow, it may make the problem worse. One possible solution to this could be to use straight ports and have the tapers only make up a portion of the length. Another thing to balance. I had previously mentioned a shoulder or stepped nozzles right at the outlets of straight ports. Is this what you mean by a bell section? I didn't clearly follow. I think this would be more resistant than tapers as are stepped nozzles on tube burners vs tapered. They require higher input velocities and the amount of step and overhang are more critical then a tapered nozzle. The upside I can envision is that the flame would not roll back into the burner block beyond the steps unless it flashes to the plenum. Another possible solution. If the ports are closer together, the block has less mass and less hot face with the same amount of cooling. It isn't as convenient for spreading the heat to a wider area. This may be why the Giberson burner heads have ports which are so concentrated. It also makes it easier to balance flow distribution among the ports. Having more ports which are smaller provides a similar solution. Less mass, more through flow. If we are getting crazy, striving for perfection, we could think about making the ports on the outside of the header different diameters then the inside ports to balance the flow across them. Thinking about the logistics of using shaped ports of differing diameters to get the header flow balanced while getting the entire throughput balanced with the induction device, makes my head hurt. This is the greatness of 3D printing, if we actually figured this out, we could easily print a mold which matches all this. I envision lots of experiments on the horizon. Maybe in plaster or hydrocal. Something cheaper then kast o lite. Inducing enough air at lower velocities and still having enough energy to mix it all and spread it evenly across a plenum is quite a chore. As far as I am concerned, the Frosty NARB is "good enough." Wide range and it makes metal hot. Thinking and tinkering are just part of the fun. -

Naturally Aspirated Ribbon Burner. Photo heavy.

Another FrankenBurner replied to Frosty's topic in Ribbon Burners

My thinking on the tapers, I'm not sure if they are accurate. Balance the size and count of the ports so that the Fuel/Air Mix(FAM) velocity is beyond the propagation velocity right at the outlet. When the propagation velocity increases due to a heated block, the flame will move back to a tighter area of the taper where the FAM velocity is faster and matches the propagation velocity. A downside to this is that the flames would be deeper into the block to heat it more/faster. I am not sure if it could be balanced to prevent blow back or if it would just make the problem worse. -

Naturally Aspirated Ribbon Burner. Photo heavy.

Another FrankenBurner replied to Frosty's topic in Ribbon Burners

I should have specified, I have no idea about that recipe and was not suggesting it. I was just sharing it. The Potter's Center said they have used it as a kiln wash and it flakes similar to ITC. They said it is cheaper for reapplication and it is tougher then ITC. They mentioned using it in a throat arch as it could take a beating. -

Naturally Aspirated Ribbon Burner. Photo heavy.

Another FrankenBurner replied to Frosty's topic in Ribbon Burners

That clears it up. I did not understand how zircon worked, just what it did for us. Understanding that it is a poor conductor explains the how. Thank you sir. I'll have to pick up a bag of zircon flour so I can play with it. Which reminds me, I was at the local Potter's Center, chatting them up about all this kind of stuff and he gave me an "ITC replacement formula" they had. He didn't know where the recipe came from. By weight: 2 parts Alumina Hydrate 2 parts 35 mesh Kyanite 2 parts Zirconium (Zircopax, Opex) 1 part Vee gum T or Bentonite -

Naturally Aspirated Ribbon Burner. Photo heavy.

Another FrankenBurner replied to Frosty's topic in Ribbon Burners

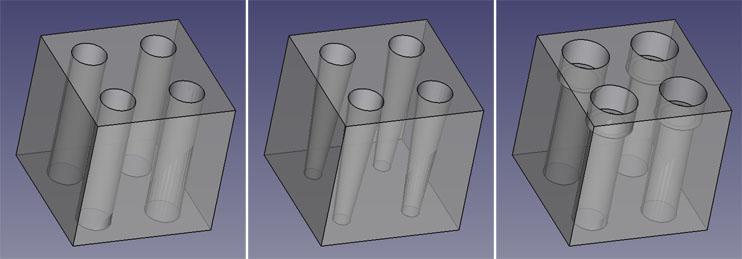

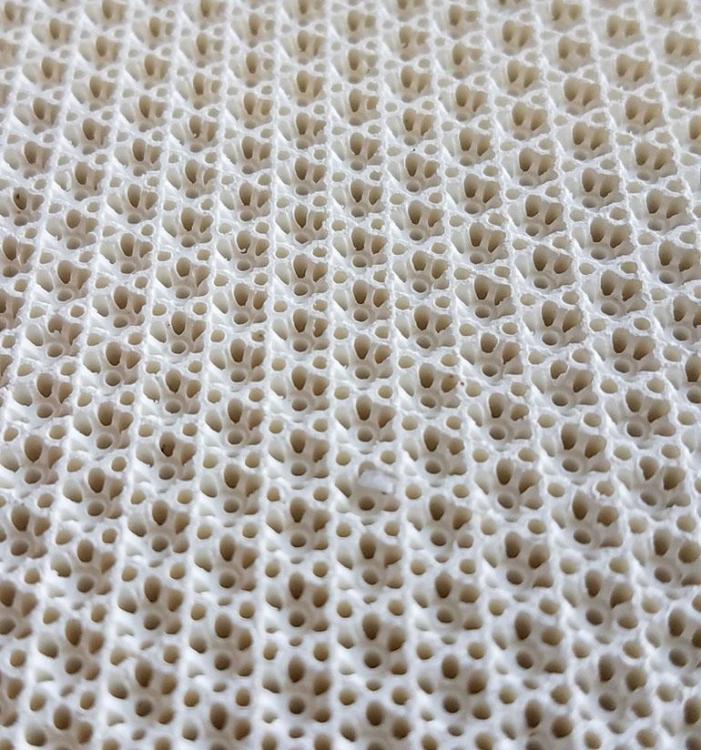

An idea I had been rolling around to prevent blow back, use more smaller ports. It's less convenient to make but it would provide more cooling to the block. The block could also be shorter to maintain laminar flow which would mean less mass to cool. I have seen commercial NARBs which purposefully run the block hot for infrared heat transfer. They run a large orifice at a little over 1/10 psi through a stamped venturi without blow back. All of the commercial versions which I have dealt with have lots of very small ports. Here is a picture of the plate in one of them, it is 1/2 inch thick: I don't know if what I am thinking is viable so I wasn't going to mention it until I had played with it a bit but you all were talking about plenum pops. I also don't know how more smaller holes vs less larger holes reacts to pressure changes etc. It seems as much a balancing act as the NA burner driving it. My other thought was to 3D print a mold for the block which could add tapers or steps at the outlet to act as nozzles on each port. A question for Frosty, I thought that the purpose of zircon was to absorb energy, become very hot, and radiate energy. If I have that right, wouldn't adding it to the face of the block cause the block to heat more because it has a hotter face? Or did I misunderstand the function of zircon and it would somehow provide a shield in this case? -

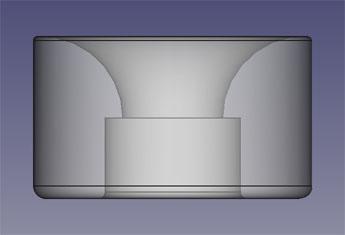

It is rotating clockwise currently. That could be easily changed if you think we should try it. I printed a previous version in both directions and did not notice a difference in the flame aside from the direction it was rotating. I plan on playing with diameter to determine the optimal diameter. Like with the experiments with the ribs, I will change nothing but the diameter for a few version to see how diameter changes affect the flame and what the maximum size is before it becomes a hindrance to performance. The only complication is the shape of the trumpet. To maintain the curve of the trumpet on larger diameters, that section will be longer. If it is not lengthened, the trumpet gets sharper which makes it more of a conical funnel. The current trumpet is approx. 1.7 inch diameter, 1/2 inch long, and necks down to 0.622 inch throat diameter (1/2 inch pipe ID): Originally my focus was on inducing enough air as this has been such a problem in the past with burner designs. The burner being printed with proper shapes makes it easy to induce too much air so it is no longer the focus. Now the focus is the cleanest burning flame over the largest range of pressures which is still stable. A few of the burners had a perfect flame at an exact pressure and were very picky about tuning. I had one burner which produced a purple flame but also had a large secondary flame which I took to mean improper mixing. I am pretty happy with 2.7.2 so we will be working on casting him in aluminum for some actual forge testing. We are also in the process of making another forge for these burners. This time using a cnc foam cutter to cut the inner profile for a mold for the kast o lite. I am attempting an oval split forge with burners angled upward from the bottom half. I am shooting for 350 cu. in. with more floor space. I took a 4.5 inch diameter circle, cut him in half, and split the halves by 3 inches. The forge is 12 inches long, my math came out to 352.8 cu. in. When I am done tinkering with the induction portion of the burner, I will be 3D printing forms for a NARB to match the burner.

- 863 replies

-

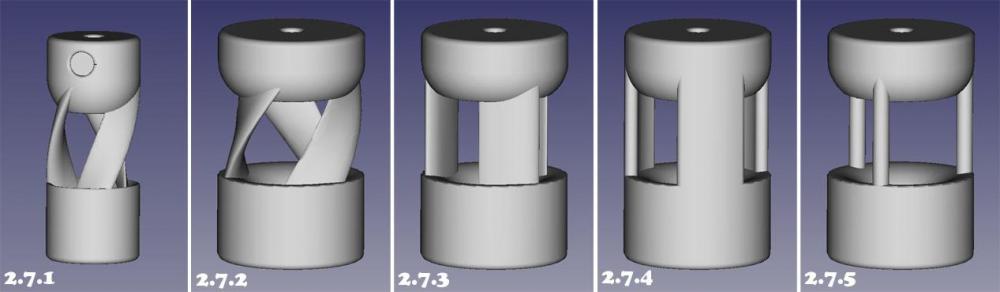

I was able to do some tinkering today. I had previous CAD and printed several iterations of the larger diameter burner with changes to the ribs only. The intent was to determine if the helix ribs are beneficial or harmful to burner function. Below are the burners tested against each other today. These are all 1/2 inch burners. Diameter comparison: Going to the larger diameter is an improvement. Version 2.7.1 always has a small secondary flame, version 2.7.2 eliminates it for the most part. Version 2.7.1 can be turned down to 6 psi before it starts to stall and it is burning very poorly by then. It is happy above 8 psi. Version 2.7.2 will run below 1 psi but it begins to produce a secondary flame if under 2.5 psi. It is happy at 3 psi and above. Both are happy to run above 20 psi. 2.7.2: So far this guy is the winner. The helix ribs reduce some of the air induced but it is because it is using the energy to add extra spin down the mix tube. This makes a flame which appears stable and constant. It induces enough air so it doesn't create a problem. It is happy with a larger range of pressures without having secondary flame show up. It is much less susceptible to drafts then the other designs. 2.7.3: Ribs are straight with the same airfoil shape as 2.7.2. This design induced less air and produces a secondary flame unless at higher pressures. It was not tested long as it was a poor performer. 2.7.4: Ribs are straight, rounded. This design induces more air then 2.7.2. The flame is more turbulent and less stable. It has obvious signs of spin down the mix tube when looking at the secondary flame. The spin almost seems to oscillate or collapse which is what causes the stability issues. It has a fluctuating roar. 2.7.5: To see what would happen with maximum air opening. Going to the linear burner. It induces the most air of the bunch, at the lowest pressures. It has a secondary flame at most pressures. I guess it is poor at mixing. Here are some images of 2.7.2 flames at different pressures. I like it's wide accommodating range. Above 5 psi, it needs a bigger mig tip as it induces too much air. They were all taken shortly after startup to prevent orange in the flame from the nozzle. Low flame, <1 psi, without a nozzle: I had a burner flare from Larry Zoeller meant for a 3/4 inch burner. I made a step out of 3/4 pipe to the 1 inch stainless flare. This gives me a stepped nozzle which is also flared. Here is a small flame at 3 psi: Here is a flame at 5 psi: Here is one at 10 psi: Now I am going to play with the length of the ribs as they are much longer then needed. I have 1 inch long air openings and based on playing with two chokes, I suspect it will be happy with 3/8 - 1/2 inch. As always, any conversation, criticism, suggestion, idea, or education is welcome and wanted. Bigger diameter is better, thank you Frosty, you were right. More spin down the mix tube is better, thank you Mikey, you were right.

- 863 replies

-

I recommend giving the build_a_gas_forge.pdf over at Wayne Coe's website a read, as he uses a hinged design. He uses hinges on both sides as the hinge/latch. This allows him to knock out hinge pins on one side and open just one side or hinge pins on both sides and raise the whole top with fire bricks.

-

Version 2.7.2 next to version 2.7.1: It is 1/2 inch larger diameter. I stretched the airfoil so the air inlets are still 50/50 with the ribs. I am going to print another with smaller ribs. I started to tinker with it but ran out of fuel. It seems happy with the 0.032 drilled mig tip and accepts lower pressures then it's smaller counterpart. .

- 863 replies

-

Are you shutting down the forge in between heats? Especially in the beginning, I needed more heats to do the work. My forge runs for hours at a time.

-

Metal is hot, nice job. Is that a ribbon burner or a blown tube burner? Those bricks look like the hard fire brick variety from the images. If so, they are quite the heat sink. If you ever want for higher internal temperatures, you can switch them out for Morgan Thermal Ceramic K26 soft fire bricks. They are expensive though. You could also go the ceramic blanket with top coat method. Either way would allow for larger forge volumes and/or higher internal temperatures and/or using less fuel. The other thing I have read that you might be interested in, you have a shorter forge with a top dead center mounted burner, the flame impinges directly on the work piece and contains heated oxygen which causes extra scaling. I believe they recommend a horizontal mounting which shoots across the top of the forge with square forges but don't quite remember as I build tube/oval forges.

-

Video of curing and other questions

Another FrankenBurner replied to Thursigar's topic in Gas Forges

I have not. I had to google hearth brazing, just now. I have stacked a few hard fire bricks to contain the heat of my torch a few times for odd tasks. I am Ron Reil's apprentice and brazing with the forge is one of the things he wants me to learn. Another thing that came to mind propane, for anyone who doesn't know it. Don't have the bottles inside any structures. That is code here. The bottles have an over pressure safety vent. I have had a freshly filled bottle vent on a hot day. If that were to happen inside, near a forge, it could be very bad. The bottle would not stop venting until it was no longer over pressurized. -

An engineer who knows everything, how original... All kidding aside, that is cool, what do you engineer?

-

Video of curing and other questions

Another FrankenBurner replied to Thursigar's topic in Gas Forges

I am not a professional when it comes to this advice. Most of my copper plumbing experience is with refrigerant lines. I do not recommend soft solder on propane fuel lines. Some soft solders melt below 400°F. In a fire, if a solder connection were to let go, it could be very bad. Several code jurisdictions require brazed connections with a material which has no less then a 1000°F melting point. Some places don't allow even brazed connections for LPG. Compression fittings are also against code in some places, only flare fittings are acceptable. Some places don't allow copper lines at all for LPG. With all this code I am talking about, they are usually for typical applications which are much much lower pressures then what we play with. Natural gas and copper should never be mixed. You can research the code in your area for answers. I work with mostly restaurant appliances and hvacs which are dealing in those much lower pressures. I have seen flare lines and compression lines for fuel gas in appliances but never soldered or brazed. The most experience I have with copper propane lines are in trailers and all those connections have been flared or brazed. I recommend only refrigerant grade (type K) copper lines as the copper is thicker. If flare fittings are to be used and the copper lines are hard copper(ACR), it has to be annealed first. I use a high percentage silver brazing alloy and proper flux. In the industry, it is often called and sometimes labeled silver solder. I have brazed connections with a MAPP torch but it is easier with an oxy/fuel torch. -

Video of curing and other questions

Another FrankenBurner replied to Thursigar's topic in Gas Forges

I would definitely remove/replace enough line to get the kinks gone. The corners of the kink are now very weak, especially if the kink was sharp. If you didn't kink them very badly, you may not have leaks, but I don't like to risk it. Copper is cheap compared to catastrophe. I am a refrigeration tech and have fixed several kinks and previous kinks which leaked(refrigerant). Leaking 30 psi propane near an ignition source sounds like no fun. I also recommend a 1/4 turn ball valve after the regulator before the hose. A remote safety shut off which is quicker then trying to turn off the bottle. You can also plumb your gauge down near/after the regulator to make it easier to see while adjusting. As to the gas(yellow) tape, it looks like you taped the flare fittings. Don't tape flare fittings. Flare fittings use a metal on metal seal. Taping the threads does nothing but get in the way of threading the fitting all the way which could prevent a seal. Tape the pipe(NPT) side of the flare fitting, just not the flare side. Also, for next time, you don't have to tape the mix tube where it attaches to the tee fitting. The gas tape in my tool bag states 3 full turns on less then 1 inch pipe and 4 turns above 1 inch. Some other brands of gas tape state a minimum of 2 full turns. It's a good looking and working forge. Nice job. -

You're welcome, from me as well, sir. Though, the advice I gave you, IIRC, I was first made aware of from Mikey's book. Maybe you just need to thank him twice. It's a good looking and running burner. Nice job.

-

Based on the large exit flame at the burner end of the forge and the small exit flame at the other end, I would guess that a lot of your heat is coming out of the burner and blowing right out the front door. It may have been hotter if the burner were closer to the center of the forge. I finally went and looked up the atlas burners you were talking about and see that your forge looks similar to theirs, in terms of burner placement. Perhaps aiming it more towards the rear would cause it to push more heat that direction. The atlas forge looks to be lined with drilled out soft fire brick. Depending on which firebrick they used, it's durability may be very poor. I am also not the biggest fan of their burner design. I don't own any of their stuff, so I have no clue about them. Based on your burner, I'm sure their forges get hot enough to work, they just need more fuel to get the job done. In smaller forges, this probably matters less to people. That said, your forge looks hot. Nice job again. Don't mind my rant. If you are happy with your forge, it's a good tool.