-

Posts

619 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Another FrankenBurner

-

Naturally Aspirated Ribbon Burner. Photo heavy.

Another FrankenBurner replied to Frosty's topic in Ribbon Burners

How large are those ports? They seem big by my eye gauge. I suspect it is burning in the plenum. That fourth image looks like it is still running? The last image looks like the flame is burning right after the injector. -

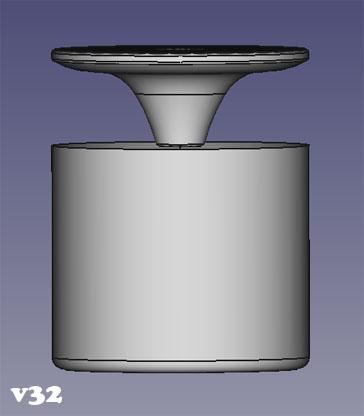

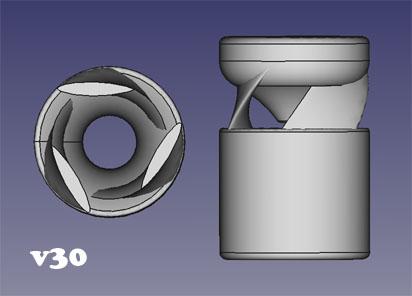

I have printed and tested v31 and v32. V31 induces more air and has better mixing then v30. V32 did not perform as well. It produces a large secondary flame. The changes in the flame are all small lately. I have to pay extra attention to see them. I played with jet position while paying closer attention and have found that a 1/4" back from the throat is the best position in several version. This is much deeper into the reducer then I had been positioning it usually.

- 863 replies

-

The jet position is flexible. I have positioned it directly in the throat and all the way back at the mount block. Between 1/4" behind the throat and 1/4" behind the end of the reducer, it is hard to discern much difference in induction. I usually position it around where the ribs and the reducer meet. I just noticed the aerospike versions induction curves are much better than the rest.

- 863 replies

-

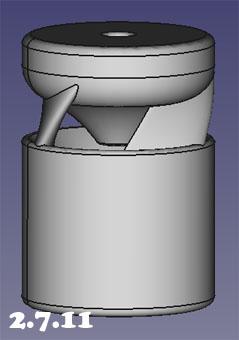

I was a bad scientist and I changed more then one thing at a time. I will go back and print each thing in it's turn but I had an idea and went with it. I have enough versions now that the version system I came up with is no longer entertaining so I counted the versions and will be adding them linearly from now on. Here is the new golden boy: He is version 2.7.11 with some changes: The ribs have been lengthened to 1/2 inch (from less then 3/8) The airfoil has been changed to a laminar profile The inlet to rib ratio has been bumped to 60/40 (from 50/50) This burner induces the most air of the bunch. The flame has visible rotation like 2.7.11 but without the instability I was seeing. Now I am printing versions with one change at a time, like I should have, to see what each change brings. V31 is the same but the inlet to rib ratio is back to 50/50. I also intend on removing the small radius at the top of the reducer to see what a sharp edge does there.

- 863 replies

-

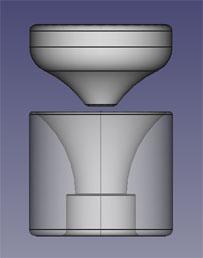

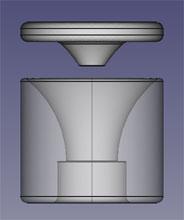

The first image of the small flame is below 1 psi. The aerospike really moves the air. I tried to create a semi match of the reducer shape in the spike. Now I want to play with lengthening the ribs a little bit as they were so short the first time around. See if it hurts or helps. I have also modelled what I thought Frosty might have been saying. A thin disc with a smaller spike. I look forward to seeing what a high rotation flame will do when the burner is put into a forge. When you say fins in the nozzle, are you thinking straight fins or something opposing the flame rotation?

- 863 replies

-

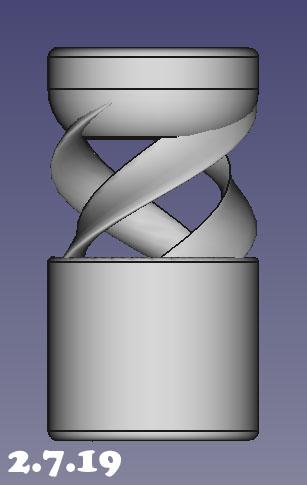

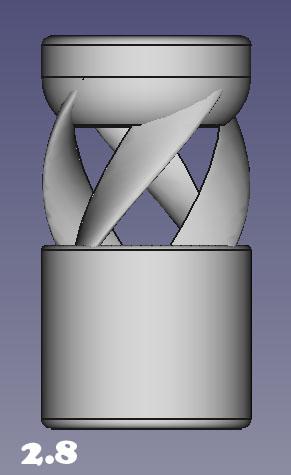

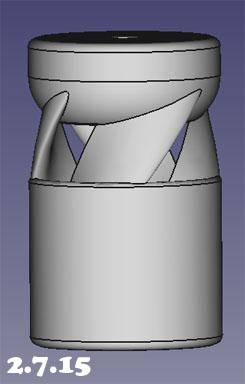

I tinkered a bit more. I played with 2.7.11, 2.7.15, and 2.7.19. I gave bad data when it comes to 2.7.11 which is the aerospike version. With the shortest ribs of the bunch, it induces around the same amount of air as golden boy 2.7.8. It is partly unstable at start up. It has visible high speed rotation in the flame. The rotation causes the flame to come out in a cylinder. The flame is impossible to blow out with my lungs. I can blow out all other versions. It is a weird flame, it seems to oscillate. I also noticed during the smoke tests that the smoke which rolls in from the side of the ribs forms it's own small vortex on it's way to join the main vortex. I definitely want to play with the aerospike a bit more. Here is a low pressure flame in the 1.25" nozzle with the 030 mig tip: Here is a 5 psi flame with the 030 jet: Here is a short video to show the small smoke vortex: Untitled.mp4 2.7.15 which has the 4 ribs which were short produces the greatest vortex. It is visible in the flame. The reduced air inlet area causes the induction air to rush in but it reduces induction volume. Here is the best image I could get which sort of shows the rotation. This is with the 023 jet: I also played with 2.7.19 which has the extra twisted ribs. It induces better vortex then 2.7.8 without decreasing induction air like 2.7.15. I may play with more twist a bit more. Unfortunately I broke it when switching out mig tips.

- 863 replies

-

I think part of it is that when I asked why, they pointed me in the direction of the answer. My daughter is home schooled. I wanted her to graduate thinking that learning is a great thing. I sure didn't learn that in school. I think we are born scientists, curious about the world around us. Unfortunately, that goes extinct in some people. With my daughter, we encourage it and get out of the way. On a regular basis, she becomes the teacher. Who knew you could learn so much from mouse trap catapults, water rockets, and paper airplanes? Are you meaning draw air in from the back with a fan looking assembly?

- 863 replies

-

As stated by someone somewhere else recently, a good rabbit hole can be fun. I will be playing with the dual vortex on the side just because it's cool. I still happen to think the tornado in coke bottles is cool though. Luckily I have a daughter to give me a reason to build those again. I even get to call it teaching. I enjoy working within the confines of naturally aspirated. We could add energy and do a lot of cool things, but working only with the potential energy of the fuel is challenging and entertaining.

- 863 replies

-

Matt Watson: What is the intended goal of your idea? I think it's a case of "There is no free lunch." Your idea would require energy and would be a partial blockage of the mix tube. It takes very little blockage to severely reduce air induction. Also, 3d printed, there would be enough friction, it probably wouldn't rotate with just FAM flow. Mikey suggested fins inside the mix tube but they would be intended to purposefully remove some energy if we had a vortex which was too strong at the flame end. Any time I try to aggressively control anything, it is more harmful then helpful to performance. The best performance has been when the geometries go with the flow. All shapes are designed to cause as minimal drag as possible while encouraging flows to move how we want them too. Doing any more takes energy which reduces induction. You say you are new to this and learning as much as you can, read Burners 101. It is long and there is a lot of information, take your time. I have read it twice and learned from it, both reads. If after that, you are still hungry, read the T burner thread, Mikey's book, Ron Reil's pages, Zoeller's pages, the Hybrid Burner pages, and Wayne Coe's pdf's. There is a lot of information out there. Just remember that some of it is aged. Frosty: Even crude hand drawings with a good explanation, will work. Nothing too crude though, I don't want you to get moderated. I don't think I am creating the very cool dual vortex. I think the short ribs and lack head room cause the streams to flow through so fast that it is almost linear flow. I will play with it a little more with smoke and really pay attention. I saw a severe drop in air induction so I didn't play with it much. I am pretty sure I have a good picture of the airfoil you describe. I understood how lift works with wings but when it came to burners, I didn't know if or how any of it would help. I took the safe approach and went symmetric. Increasing the outside velocity makes sense. The four rib model with smaller air openings absolutely increased vortex because it increased the induction velocities but at a cost of induction volume. Here, a drawing would be great so I can get it right. Definitely worth a shot. With the vortex, the stronger it is, the more the air is induced at a lower angle of attack. The streams line up. Said backwards, the weaker the vortex, the more likely the air is to come in around the ribs from all angles. Some of it, at the centers of the inlets, induces straight in towards the accelerator. If we get the outside air streams to higher velocities, it naturally changes the direction of the straight induced air into the inside of the next rib. That was a stumble of words, did that make sense?

- 863 replies

-

Each print costs less then $1. If you can explain things clearly or put up drawings of your ideas, I will CAD/print them and report. Agreed. It is hard not to be enthusiastic about how cool it is. I drive my wife crazy routinely. I think it could be thinner as well. I originally made it thick so that the jet would be axially aligned and so the choke had a good flat to seal against. I don't think much length is required for either purpose. The smoke rolls down the radius and into the back of the vortex. It seems smooth flowing. Are you thinking skip the radius and have a thin flat disc instead? I have not been fair to the aerospike yet. The ribs were too short on that model and I suspect the spike too large. The spike ended where the reducer began so the mig tip barely came out of it. I was thinking it would kill dead airspace up by the accelerator. Instead it causes the streams to flow in and straight down the mix tube. More forward push. It doesn't induce as much air but it's output velocities seem higher. I had already created another version which has a thinner disc with much smaller spike. Part of the spike will be the jet itself. You were right about the four rib version. For the most part, there isn't much change at all. I think it may induce a little more vortex and a little less air but, if so, it is small enough that it is hard to tell. Version 2.7.8 is still the golden boy. Changes are variations of him at this point. I still haven't printed 2.7.19 with the extra twist yet. You were also right about the 030 mig tip. Version 2.7.8 runs neutral from 1 to 10 psi with the stepped/flared nozzle. Above that, it begins to go purple. A 1.25 inch diameter flame at 1 psi is pretty awesome. If I put the smaller nozzles on it, it can be run on the peg still. I tried the 035 but that was too much. I got a neutral flame above 15 psi, a bit much. I think the 030 is a good balance. I was wondering about this one. Originally I went with a standard symmetric teardrop airfoil. I will be playing with airfoil shapes. If you describe it and think it might be a good idea, I will try it.

- 863 replies

-

I'm on the same page. I have not lost sight of the burners purpose. I was just tinkering with vortex as I wait for bigger jets. I was trying to see how much is too much, why, and how to get there.

- 863 replies

-

The 2.7.11 fins are too short, shorter then 1/2 inch. I took 2.7.9 and made versions with 1/2, 3/4, and 1 inch length ribs. The 1 inch ribs induce more air and more vortex. I suspected when printing the more extreme ribs that they would be poor performers. I agree that brute force can do nothing here. Now I am trying to learn what the vortex wants so I can feed it properly. Make him happy to exist. In the smoke tests, 2.7.15 has the strongest vortex. 2.7.8 has clearly visible vortex with smoke but he also induces much more air. I will have to think about this and research to fully understand. I have played with many rib profiles and 2.7.2 has been the most successful. When monitoring smoke, it flows around 2.7.2 ribs without turbulence that I can see. I intend on small changes to it soon. I have a few more big changes to try first. I am still playing with the extra rib but bringing the rib/inlet ratio to 50/50. I am also making the rib length 1 inch. I am also playing with 3 ribs with the 2.7.2 rib profile but decreasing the helix pitch length to see if it hurts or helps. I have not printed either yet.

- 863 replies

-

All of these burners have a sliding choke on them. As you said, mostly as a safety measure. I do partially close the air inlets once in a while to tinker but usually they are wide open. I have enough vortex that I think it needs to be toned down but you think I am on the right path. You have previously stated the more the better. What is your thinking on that? Is there a limit? What is the end goal with your vortex burners?

- 863 replies

-

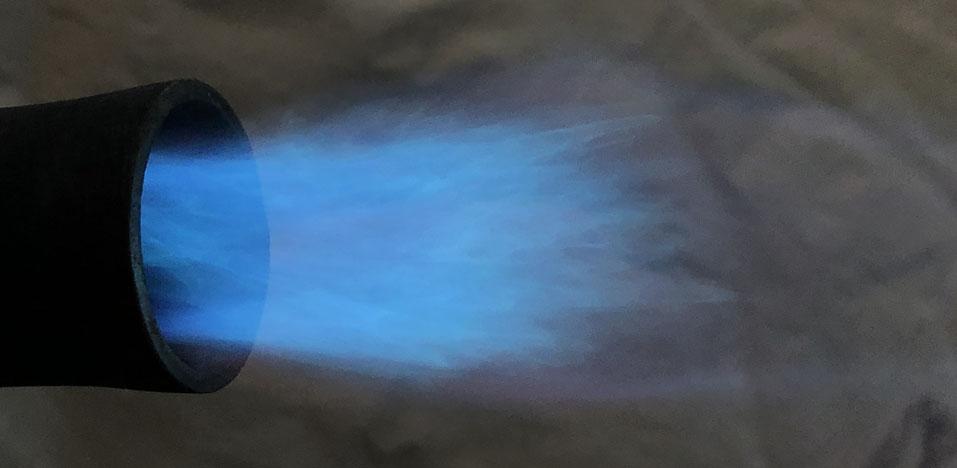

Frosty: I have written a few responses and deleted them. I got nothing. Your wordcraft is strong. I am still awaiting mig tips so I have been playing with dynamics. I have been focused on more power to the vortex. Most of the experiments were flops. I tried a cone drop shape on the accelerator block. This caused less vortex and more push. I tried curved airfoil ribs. First in similar dimensions. Then in a constricting pattern. Then in a very aggressive angle. All versions induced less air. The similar dimensioned curved ribs showed turbulence in their curved section with smoke. The constricting pattern blocked too much air. The aggressive angle got in the way of the vortex I think. Then some vortex success with another rib. More powerful vortex. Too much. It comes out the pipe rotating very fast and spreads. If the pressure is higher, the center of the flame is void and a full rotation can be seen in the flame. It is louder and has a scattered secondary flame. It induces less but I did not change the length of the ribs to keep the 50/50 ratio. If a longer mix tube is used to calm the rotation, it doesn't induce as much. Mesmerizing to watch the flame. Here is a low pressure shot: In my playing, I discovered that 2.7.8 which has 1 inch long ribs does better then 2.7.9 with 1/2 inch long ribs. I am now printing a version with 3/4 inch long ribs. I am up to 2.7.17 with all the vortex play and 2.7.8 is still holding it's place. It induces a lot of air, it forms a good vortex in the inducer, it mixes well, it has good range, and it can do all of this at very low input pressures. Now we'll see what that does with a bigger jet.

- 863 replies

-

I see a mig tip that is too far back and a choke that is partially closed.

-

What is the final inside volume of that forge going to be?

-

The downside to your own design is that you have to design it. In order to get it working well you have to understand the science happening there, trial and error your way to a working burner, get lucky, or a combination of that. I recommend you look into the Mikey burner since you are replacing the tube anyway. Then there is no designing needed. Build it to the recommended specs, tune it, and it works. His design is similar to what you built so the build would be similar. What is this burner's intended purpose? I am just curious because of it's 1 inch size.

-

Naturally Aspirated Ribbon Burner. Photo heavy.

Another FrankenBurner replied to Frosty's topic in Ribbon Burners

That burner is a side arm burner. The best I have seen for side arm are the modified side arm or the z burner. Both use a larger fitting then the mix tube size for increased air inlets. Even still, if you follow the link to the z burner page, you will see a rich flame. A Frosty T produces a better flame with similar fittings. You might try an 023 mig tip, it seems trivial but it makes a difference. -

As far as design, the air inlet holes remind me of a Dave Hammer burner and the jet mount system reminds me of a Mikey burner but this burner is a Lee Wehr design. Unless your fuel pressure was lower then you are going to be using normally, the flames visible in the air inlets should be concerning. A choke is used to reduce air induction, not to prevent flames from sucking back. As is, that first image shows a very rich flame which requires more air. The .045 mig tip would make this worse. Be very mindful of carbon monoxide. We all should always, but rich running burners produce more. It is a stealthy danger so adequate attention and ventilation always. Those air inlets are quite forward, towards the flame end, then usual. Typically they are as far back, towards the gas jet end, on the pipe as they can be. Where does the gas jet end in the 1" pipe? I suspect it is quite a ways back behind the air inlets.

-

A nice little twist of my own. It's usually Frosty who likes the play around with words. Thanks Mikey.

- 863 replies

-

Thanks for the clarification Mikey. I have been studying vortices lately. I also borrowed my grandfather's copy of Basic Science for Aerospace Vehicles by Northrop Institute of Technology and have been reading about airfoils, turbulent and laminar flows, drag, boundary layers, skin friction, etc. I have a handful of idea's to play with. My latest experiments have all been geared towards a more powerful vortex.

- 863 replies

-

My intention was not to argue. I am not the arguing type. If a discussion has devolved into an argument, it is no longer constructive. When I do question or disagree with a statement, my reasoning for discussing is to educate myself. I have no convictions in any of this. I'm just the curious type and question everything, trying to get to the whys of things.

- 863 replies

-

I was under the impression that flame holding was the original reason that flared nozzles were added to homebrew burners. Ron described making solid fuel fires inside a forge, which used aussie burners, until the forge got to autoignition temperatures, so the flame would not be blown out. Isn't having an increase in volume after a straight mix tube important? Whether that be a forge or nozzle of some sort. I am able to maintain a clean flame out the mix tube sans nozzle but it's btu output is low and the mix tube velocity is critical. Too high and I get blow off, too low and I get suck back. This range is pretty small. If I want for higher output, I have to move more volume. The only ways I can think of doing that are higher velocities, larger geometries or a combination of both in the case of a nozzle.

- 863 replies

-

Mikey: I reread principles material on vortex burners and think maybe I am understanding a little better. The intent is to create a fast moving vortex so that more air can be induced without providing additional push/pressure. Instead of focusing on how much air I can induce, I should be focusing on creating as strong a vortex as possible, as it will induce all the air needed along with a host of other benefits. Do I have that right? In the latest burners 101 post about burner dynamics, you mention both spin and vortical flow, could you elaborate on the difference? I am thinking spin is air spinning down the outside of the mix tube where as vortical flow is a fast moving cyclone down the center of the mix tube. Do I understand that correctly? If so, is there anything I should change to attempt more votical flow? Frosty: I was just thinking of how to make a tapered tube. I will not change more then one thing at a time. I am confused enough without making it worse. Especially when Mikey comes in with a mental curve ball. For smoke, I rolled a piece of paper towel tightly and let it flame until an ember. I created a small ember to see a small piece of the stream and a long one to see it flow around the ribs and such. I learned a bit about what is going on in there. I have some video's but I have to see if any are good. Between lighting, holding the camera, holding the smoke, and remembering there was a hot flame at the one end, I suspect the video's are fairly poor. If so, I may try to pull out a few stills.

- 863 replies

-

I think I am misunderstanding, are you saying that the main factor to amount of air volume induced is the jet orifice diameter to mix tube diameter ratio? With the same mix tube and jet diameter I have printed inducers which vary the air induction widely, depending on their design, so I am confused as well. I induced smoke into a few of the versions. It induced straight in until it entered the fast moving cyclone inside the inducer. The closer to the throat, the tighter and faster the cyclone. Now I just need Frosty's smoke pressurizer. I also want to play with the aquarium and food coloring. Fun to actually see something instead of imagine it. I also played with the 3/8 burner some more. I am able to induce enough air to have a neutral flame at 5 psi. It's btu minimum is higher then the 1/2 inch. I have a piece of fire suppressant pipe which is also 3/8 pipe but the ID is larger. It runs neutral at 3 psi. Amazing how small of changes in dimension make such big changes in flame. I am trying to figure that one out as well.

- 863 replies