-

Posts

18 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by SHVTZHOT

-

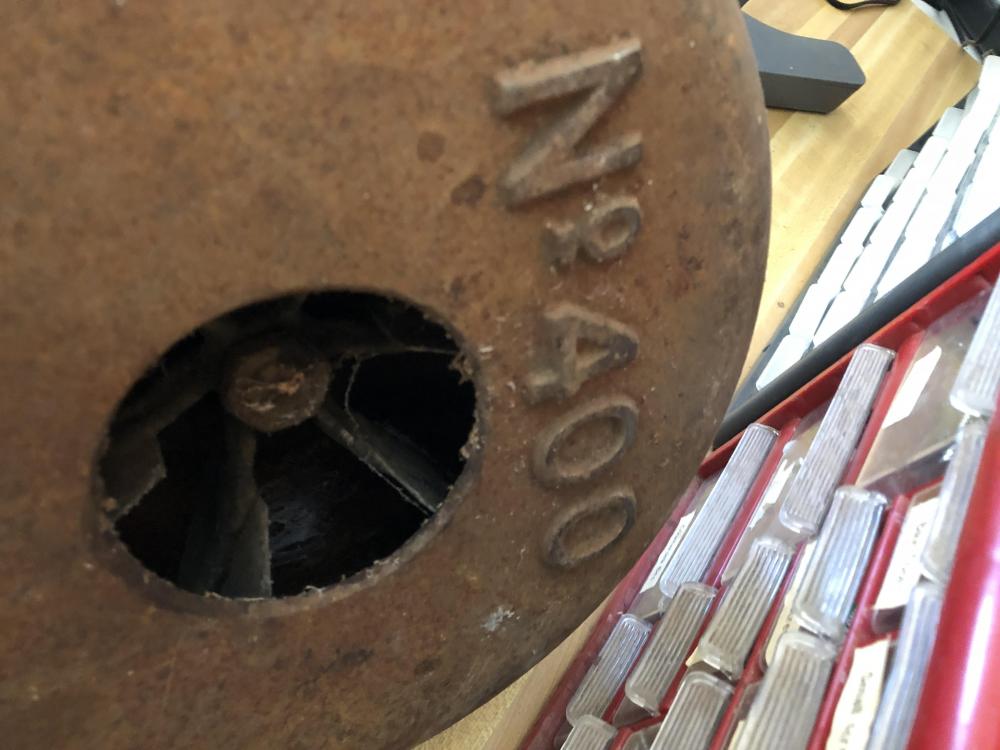

I was able to take a photo of the serial number on mine.I was able to take a photo of the serial number on mine. ”No 384627 The picture here isn’t great but I think that’s the best when I’m able to take. I tried using chalk to bring out the numbers better, but it looks like they just worked stamped deep enough.

-

This one I picked up at an estate sale. I posted pictures of this one on the “It followed me home” thread. I got this and a champion 400 blower both for $200. I was elated! I have no idea how old this forges but this is my first and I am super excited to get to use it. But I believe I’m going to have to get that hole repaired.

-

I also have a fixer upper. I was informed about an estate sale near my home that had a few blacksmithing items. This forge has an adjustable pot and 2 of the mounting brackets on the tuyere are broken as you can see from the photos. There also holes burned into the sides from all the years of use this thing must have had. One of them has apparently been patched but the other is visible thanks to me chipping away at it what I thought was ash cake and crusted along the side. Ewps. There is a professional welding shop also near my home and I will go to those guys about this. In the meantime, can any of you give me some info as to the age of this thing?

-

Good afternoon folks, I am so excited! I found a couple of gems that need just a little cleaning up and I know will be put to good use. I was informed about an estate sale going on today and tomorrow in these two items were of the four blacksmithing items in that sale. I just could not wait until tomorrow, as any of you could guess they could have possibly been gone by then. I got the pair for $200!!! By the way, this is in Wichita, Kansas.

-

I did stop. I started to cut into the pipe about a 16th of an inch before I really decided that I did not like this. I have a 7 inch disc for my craftsman circular saw that is not wobbly. I turned the cutting disc by hand and it appears to be slightly warped. Not good!I will for sure be returning that thing. I guess I’ll just have to stick to the hacksaw method

-

I bought a 10” dewalt cutting disc I tried to use it in my craftsman chop saw. It’s secured like it should be. It’s wobbly. This makes me nervous. I have 7 feet worth of 3/4” -1” black pipe to practice welding on.

-

I have an old one similar to this that is sitting in an in-laws' garage. I was very curious to know if I can use it for a fire pot. I am researching old posts on this subject as time permits. So far I don't see that anyone has cut away a small section to lay their work piece in the coke. it looks like that flange for the drain is aluminum.

-

I have read another idea about using modeler's clay too. What a fantastic idea you have! I can borrow some of this from my 4 year old.

-

Thank you, I appreciate all of this.

-

I have seen several videos of people “restoring” old anvils. Some heat the face plate after grinding and hard surface welding. I think (especially in my case being a learner), it would be best not to do this. I’m actually afraid to. I love the history it could have and I wouldn’t want to ruin any future possibilities with it.

-

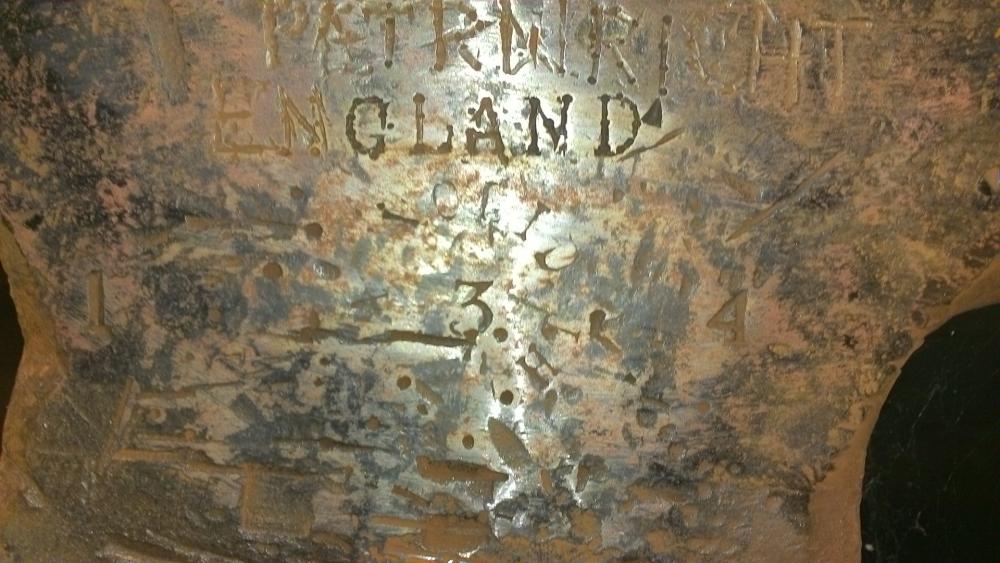

I have this Anvil I got from a local pawn shop. I am interested in it approximate age. Can anyone help? It's beat up! If you look closely, you can see ''SOLID WROUGHT'' in a circular fashion around the 3.

-

Oh I hope so!

-

That’s what I have read. It is beat up! But I am super excited to get started again after 6 years.

-

Now, I wasn"t out to fins a "London Pattern" Anvi. l I just wanted to find one of decent size to get started with. I began learning basics on one like this making leaves, roses, and nails. I thought this style would suit me best. It was only after I bought it that I began learning about many more styles. BTW, feel free to use this picture for a reference if possible.

-

I was informed of this one in a local pawn shop. I got it for $800. I think from what I can tell so far that it is a 200 lb. Peter Wright (134 stone weight). “SOLID WROUGHT” stamped in a circular pattern and and an anchor on each of the front feet ( horn side). I will submit the photos of the feet Soon.

-

My Name is Erron. I'm 42 and I'm a Navy vet, an AF Reserves retiree, and a patriot. I got into blacksmithing about six years ago at a Christmas lighting event here in town, and like the old cartoon characters that would float towards the smell of fresh bread or a fresh baked chicken, I was drawn to the smell of coal smoke and the sound of pinging. I stepped into the warm, dingy shop and was mesmerized. I watch the smiths work for a what I thought was 5 or 10 minutes. It might have been longer. After speaking with one of them for a short time I was hooked! A couple of months went by before I could get back there again there to get to learning. I did that once a week for a year before I was deployed. Fast forward 3 months, my youngest came along and I couldn't go back. Soon I will build a shop in the back yard and begin. I must go back over that basics slowly and relearn what I may have forgotten since then.

-

You might be addicted to blacksmithing if you...

SHVTZHOT replied to divermike's topic in Blacksmithing, General Discussion

If the smell of coal smoke makes you float TOWARDS it.