-

Posts

807 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by JPH

-

SB: I think you are making this more difficult than it really is..the key to a good weld is proper temp all the way though..clean (no scale, crud or inclusions) with weld surfaces that are "smooth and "dent free" and enough flux to just coat and prevent oxidation..Other than that it is really not that hard to do. Believe me if I can do it..just about anyone can... JPH

-

Hello: Hope no one minds..I have been doing this a wee bit and i think I have enough figured out to be of some help. Gas vs coal: Gas..clean burning USUALLY hot enough to weld and can be carburated to run at a "welding heat". Coal: Gets destruictively hot if not careful and can be dirty and this can be a problem with welding Number of pieces. I usually weld 1 1/4" sq x 16 to 18" with between 80 to 125 pieces the first weld...draw and cut into 4ths or 5ths, reweld and you are basically ready to pattern. Folding takes way to long and wastes alot of materials. below photo is the first weld done on a faggot of 120 pieces of 1095 and L-6 with some SS HT foil thrown in just for giggles...with my 8# forging hammer Just make sure you are hot enough and well soaked.. Clean weld surfaces and not too much flux and you should do OK just my 2 bits worth..may or may not work for you... JPH

-

Hello: OK I am no expert on this stuff as far as chainsaw chains go but I do know a little about solid phase welding... If "Chromized" means what I think it does that could be part of your problem right there. Cr is nasty stuff to weld under a hammer as it gets downright cranky to work with... JPH

-

what did you do to that poor lamb? Oh there is no Ni in that cable. It is 10XX steel, usually 1060 or 1070. What you are seeing is weld de-carb and crystalline differences. I second the suggestion of sealing that mineral wool..It can and it WILL FUBAR you .. JPH

-

Hello: I still have a few of my Japanese series hanging about that I am finally finishing off and I am listing on my web site as they are done so I figured I may as well post pics here cause once these are done and gone that is it!! This is one of two Dai-sho that I am finishing up..the last one is in red/black in "fighting" mounts. Both blades are Kobuse 1070 jackets with a mild steel core, what I call my Gen II blades. Mounted in a Dragonfly motif in bronze with gold and silver leaf highlights/details and finished in a very nice blue over black lac and silver leaf. Sealed with 6 coats of hard, clear lacquer. Katana: Blade length 27 1/4" Tsuka is 10 1/4" Wakizashi: 19" blade Tsuka 6 1/2" Both tsuka are blue samegawa under black ito. Both blades show a really NICE hamon and could benefit from a polisher with skills better than mine. Both have one full length Bo-Hi on each side that was scraped in. I think they turned out rather nice and I am so relieved t be done wiuth this series and can get back to doing some serious work.. JPH

-

Knife Making Log, Advanced Class 201: Damascus patterns

JPH replied to Glenn's topic in Knife Making Class 200

I am no expert by any definition of the word but the difference in the etch is the result from different hardness in the two areas of the blade. In other words think of a "temper line" ... This is actually (well at least to me it is..) a very good thing as the part that is suppose to be hard is hard and the rest isn't... Nothing to worry about at all...at least I wouldn't worry about it.. JPH -

How to: Forge Weld Leaf Spring

JPH replied to teenylittlemetalguy's topic in Blacksmithing, General Discussion

Ummmm as an armchair kinda guy What is the problem welding 5160? I mean if you have a clean weld surface and at the right temp you should get a decent weld. 90% of welding problems stem from a dirty surface or improper temps. I weld all sorts of weird stuff..some of them really high alloy and it takes a little tweaking but it can be done. Back to sitting down JPH- 27 replies

-

- forge weld 5160

- alaska flux

-

(and 1 more)

Tagged with:

-

OK Hairless..fess up and tell then the Ka-Boom story JPH

-

Hello: I don't know what you all are using but the black emery I get from Jantz is like 600 grit and I use it for EVERYTHING from bronze, steel, horn, ivory and everything else...no problems at all... I get a very smooth and clean finish.. I am not one to polish anything up to a mirror unless I HAVE to... IF you are getting scratches I would suspect that you have some contamination with something that shouldn't be there. JPH the att. pic is a 1095 dagger buffed with the black emery on a sisal wheel

-

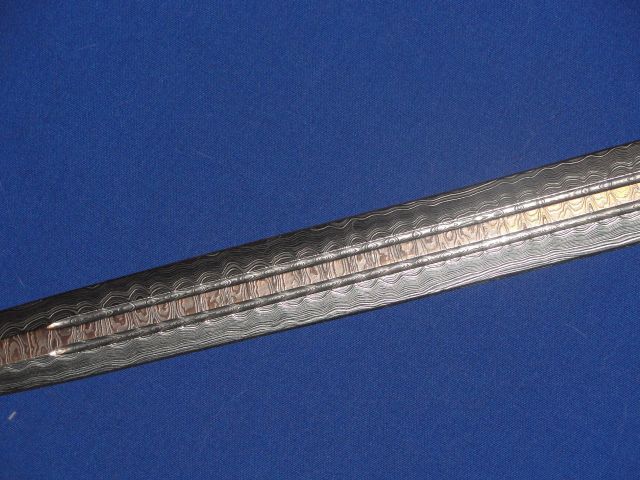

Hello: etching doesn't have to be all that difficult..I soak mine for 45 mins to an hour and a half in 1/2% ferric chloride (depending upon the ambient temp) clean off with baking soda, oil and then lightly buff on a sisal wheel using black grease compound (emery) and I get this result.. I am not one to go into all sorts of elaborate methods unless they are needed.. Just remember..99% of the time a slow etch is much more attractive than a fast and aggressive one..At least for me...

-

Hello: Here are two blades I made up from some leftover materials I had from "paying" pieces. The first is a welded wire/cable Long Knife made from straightened out drain snake and some 304 SS thrown in for contrast. Blade length is 21" with two fullers on each side. The second one is a three strand twist pattern, 14" blade, with forged phosphor bronze mounts, fluted horn grip. The sheath is set with a 20+ Ct blue Star Sapphire. These are currently posted to my website.. Hope these pics turn out. JPH (a dull person cause I like shiny knives)

-

Hello: I second what Frosty and CRS said... you CAN NOT compress grains... HOWEVER you CAN reduce the grain size by impact (forging) at the proper temp, as well as using proper thermal cycling to help reduce grain size even further....couple these two together and you will get a grain size like powdered sugar.. There is a term used for centuries that is rather confusing that that is "edge packing".. this a term dates back to who knows when and it is used to describe the process of thinning out the cutting edge bevel(s), thereby reducing the grain size while doing so. This term has been misinterpreted to mean that you can "pack the atoms tighter"..which is totally wrong. There is so much folk lore and other old wive's tales that surround forging that one has to be very careful if what one reads..A lot of them are just that..an old wive's tale.. The one you are talking about is one of these. Any decent bladesmith will know that you can not "compress the grain closer together" and a so called "Master Bladesmith" that is spreading this misinformation should be spoken to in a very harsh manner and told to stop spreading this fallacy. JPH

-

Hello: Here are some things I made up this last week for the upcoming show this weekend up here in the Las Vegas Valley. All are "ladder" patterned, the dag is 1095/WI and meteoric Fe..the rest are 1095 and L6. The leaf blades and the Dag have my (in)famous bovine ivory grips...the shortsword is mounted in bronze and Burmese Blackwood.. Hope these come out OK JPH

-

ROFL: No use folks..he already knows all there is..RR spikes are not *high carbon*..they are medium carbon at best...and not all of them are..Do they make a usable knife? All depends upon the material and the thermal treatment. I can get them hard enough to take and hold a using edge..but I know a few tricks in doing that. others do as well..it's all in the material and knowing how to use it to its best advantage. Wire wrapped grips? NOT new..in any sense of the word...not "exotic" either.. Since when are rapier's "exotic"?? I make about 2 dozen of them a year... Man this guy is way over the top... JPH

-

CR: Feel the way you want to feel...say what you want to say...I spent 32 years of my life defending your right to do so.... All I ask is just afford me the same ... I will never ever even think about joining a group whose members act in such a way as they have towards far too many fine folks simply because they choose not to be members of said group. Believe me...( folks that know me and my background will attest to this...)..I am being very, VERY reserved in these replies (no... mi amigos.. I am not ill...just remembering what my Papuli taught me years ago...). I have no use at all for the ABS, and I never will. The passage of time does not make what happened any more acceptable..nor does it make what is still happening correct either.. I have no more to say on this what so ever. JPH

-

CR since you asked: Let me fill in some background.There was a time when I was seriously considering joining the ABS. In fact one of my dearest associates was a MS in that group..(In fact he was one of the founders) and well..we were talking at the SOF convention out here in Las Vegas waaay back when...when another ABS MS came up to him and said "We need to stop making this many Master Smiths"...This person shall remain nameless.. My friend just looked at him and said that they will discuss that later. My friend then turned to me and said that there was a lot of stuff happening in the ABS that he did not agree with and that I wouldn't like either... He suggested that I do not join....I agreed and I didn't join..He resigned a week or so later..His name is Bill Bagwell.. Few years pass..book I comes out and everything goes down the rabbit hole..I get calls and verbal threats made against me and my family...saying that I had no business writing anything cause I am NOT an ABS member..I gave away "secrets" and all this other drivel. I called the Pres. of the ABS and was told basically to go pound sand. So...it only gets worse when books II and III come out. So why would I ever want to join a group like that? To be so arrogant and oppressive that they think that unless you are a member you couldn't possibly know ANYTHING of any value at all?? Oh come on...So I just continue to march and be a pain to them. After all living well is the best revenge.. So you can defend them all you want and spout off how great they are and all that..There are quite a few of us folks on the outside that have different experiences..I for one will continue to publish and do my research in spite of their objections.. JPH

-

Steve: You beat me to it..however the publication date of book I is 1987...just being a PITA. I had no idea until recently that you were getting the same heat from the ABS stormtroopers over your book as I have for mine. I am wondering what they have in store for me when book IV comes out. That should prove to be very interesting. JPH

-

CR: I am happy that you found my writings of some value. On the ABS front..there is more of a chance of Benjamin Netanyahu joining Hamas than me even considering joining the ABS. I have my reasons.. JPH

-

Hello: I am going to just say...there is a whole lot more to this.. (several folks on his site are aware of what happened and have seen it for themselves..) and I am just going to let you all defend them as much as you wish. As I said I have no use at all for any group like that and i will continue to write and research even though ABS "Master" smiths don't like it much at all. If they changed the "no stainless" stance over the years..maybe they are listening a bit...I still have no use for a group like that. I have nothing more to say. JPH

-

JC: Back when I was being bombarded and other pleasantries.... the ABS guidelines said "No stainless steel blades"..to me that is pretty plain that they want to regulate what I use to make a knife. Just because they can't get stainless steel to perform decently doesn't mean everyone else would have the same problems. Sean McWilliams and I were hand forging stainless steels back in the late 1970's and early 1980's and getting some really DECENT results. Terry LaBorde was also making stainless steel pattern welded barstock back in 1979/1980 or so, but for some reason it simply wouldn't sell..Ahead of its time I guess... I am not sorry to say that I have little use (if any) for a group like that .that would arbitrarily "ban" any material just because.... If someone can make a knife that can pass the tests out of high carbon, stainless or some other forged materials that meets their testing requirements as far as the way it works..I say let them do it... I even had two different so called "ABS MasterSmiths" say that stainless steel is impossible to forge..gee..if that is the case..how in the world did they make the steel to begin with?? So I just shake my head..laugh and continue to march.. JPH

-

Hello: As someone who has been doing this for a wee bit..and someone who will never achieve any sort of even base acknowledgement from the ABS for all that I have been doing for this art... I will say this: I will never, ever join a group like the ABS. Yes there is a sour history between them and I and it all comes from their end. Granted I am an anomaly in this field..all due to circumstance and a bit of hard work..My joining any group would not benefit me at all...(and besides why join when I can continue what I am doing without someone else looking over my shoulder and trying to regulate even the materials I use to forge. If I want to hand forge stainless steel I will...) I know that this is not the case with the majority of folks doing this...the final decision is up to the one making it whether to join or not.. Now this being said..I like to stay low profile and out of the lime light for various reasons..one of which is my privacy. I am too old a bunny to change now... JPH photo attached to back up my bone fides

-

Hello I guess I am very, very dull by your standards Steelfinger..so I will spare you any of my dull comments on your work..I will say this...you have pretty much alienated folks on this site..some of which have been doing this for more than twice the amount of time that you have walked on this planet..shame that.. Pity..pity... JPH

-

Frosty: For the size of work that I do..a 25# LG is ideal... I had a 50# and a 100# LG and I sold them.... they were just too "much" hammer for the stuff I am doing,... But they surely can MOVE some iron when used properly... JPH

-

Frosty: It might be small but it is Mighty...It'll still do the job for the size of stock I work with and then some... JPH

-

Hello: Frosty...I also have a small and dainty 25lb Little Giant that isn't pictured that is so cute that it should be on a charm bracelet...l love that little powe hammer..does a whole lot of work when you know how to use it... iani: 50 foot of barstock is not that much for me and my set up..I have been doing this for a little while now and I am more or less comfortable with my current set up so it';s just get it hot and hit it... JPH