-

Posts

807 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by JPH

-

Frosty..the pics turned out better cause I didn't take them that's why!!! As for the curved fuller..I bet if ya tried to make one that was curved on purpose it'd come out laser bean straight!! Actually as knobby as the grip looks..it feels quite nice in the hand..the ridges on the back fill the palm quite comfortably and it sure doesn't slip... JPH

-

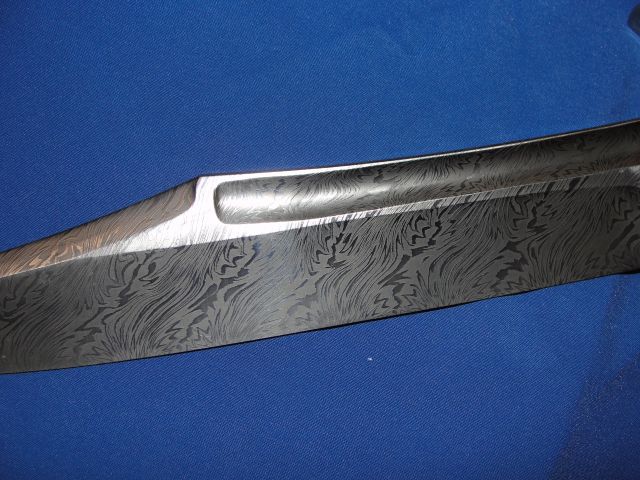

Hello!! Something else I whipped out on a whim from the annals of my twisted mind.... Solar Storm pattern in L-6 and 1070 steel..2" wide blade, full length fuller each side (curved fullers are just sooo much fun..yeah..right!) 14 3/4" long blade..double edged... Hand forged phosphor bronze guard (I am getting pretty good at hot working that stuff) the grip is Reebok horn (the critter not the shoe) . Overall length is 20"ish. This is a LARGE knife.. The Reebok horn is magnificent to work and has a whole lot of character and lends a very stylish and rakish look to this piece..even if'n I do says so meself.. This is website stock..still have to make the sheath for the beast....should be able to do that in the AM...already have the star sapphire cut... I say it came out alright for a whatyamaycallit from my dark imagination... Hope the pics come out JPH

-

How does someone get to be a crumudgeon??? I am just a cranky old Dogface JPH

-

Frosty: I have been doing lapidary work since I was a kid...(and no it wasn't because that was the only way we could make knives back then..geeze...)..in fact they use to call me Jimmy Git Rocks...cause I was always looking around for "stuff"..Usually all I found was leverite but every now and then I'd find something good.. The ruby on this is a natural ruby..not man made..I have a very long time friend in India who's family owns a ruby/sapphire mine that sends me a lot of rough..most of it is suitable for aquarium gravel but I do get some pieces that will cab out a semi-decent rock..It's just cutting a ruby/.sapphire takes for ever cause they are so xxxxxxx hard. As it is this stone would sell at about US $10.00 a carat...(Which is what I sell them for when I decide to sell them on my website..) I just cut a 93.75 ct black star sapphire for another project I am working on along the same lines as this dagger..will post that once I get it done..should have the steel finished mid next week... JPH

-

Hello: Something I whipped out on a whim.. 1060/L-6 steel..in my Solar Storm Pattern.. 14 1/4" x 2" blade with twin fullers each side. Forged phosphor bronze mounts with my own "fossilized" Bovine Ivory grip. Sheath is set with a 77.7 Ct Star ruby that I cut a little while back. This little guy is heading down to Irwindale for RPFS next weekend... I think it turned out OK for what it is.....and that's the product of a warped individual... I have no idea why I made this...it just all fell into place and this is what I wound up with.. JPH

-

Hello!! SLTT: Stuff Like That There, OK I am not in in anyway as sophisticated in your set up as you have described here.. I am just a guy that has made a couple of swords over\ the years so..;. OK I will admit that i have three to five years plus or so in forging swords and all...HOWEVER!! I am little more than a guy that started doing all of this in my neighbors place and all that but In have been doing this for a few years ( at least 7 or so..plus a bit,...) or so who knows so.. Now I don't all that much as far as "Fancy/Schamcy heat treating goes..I am just a "HammerHead sorta guy but I do know that if you are careful... JPH

-

Hello: Using "tempering tongs" on a double edged blade most certainly works..I do it all the time..just depends upon the tong jaw design that's all...then again..what do I know about how you (or anyone else) work?? What facilities you have..tooling..level of skill and SLTT???... so...all I can do is give suggestions as to what works for me..I've been at this a couple of years now and I did manage to figure out a thing or two in that time... JPH

-

Geeze folks...is this too obvious?? Ok you have a gas furnace/forge..you know the excess flames that come out the front/back? Temper the blade in that..just move it back and forth until you get the colour you want..oil quench..clean off the oil when at ambient, brighten the surface.. and use a red hot piece of iron/steel bar to draw back the areas you want softer by placing the bar on the area..watch the colour..they can come up quick.. This is very simple but it tales some practice..I suggest you try this on a piece of scrap the same basic size as your blade to get the feel of it.. doesn't take long.... JPH

-

Question about the effects of TV coverage

JPH replied to Kozzy's topic in Blacksmithing, General Discussion

Hello: Ref tools..since I my name was taken in vain.. Tools do not make one a better craftsman..I have seen fantastic work that rivals any from anywhere that was produced with basically a rock as an anvil..a hole in the ground for a forge and one small hammer..Now poor tools will cause problems, no doubt but it is the one who's mind and skills are driving that tool that makes the difference. Granted good tools make some things easier.. Since my presses where brought up..I still weld by hand..I like to have a high degree of control and "feed back" when I weld so I know (more or less) what is going on during the weld. Yeah I use a couple of presses...but they are for the slow "grunt work" and are labour saving devices...nothing more..and if you do NOT know what you are doing with/around one..you can very easily FUBAR your work or YOU. There isn't anything in my studio that can not put the hurt on you or worse, if you do not respect it or know how to use it properly..and even then..they can get ornery and bite ya. I have been doing this a couple years now and have seen alot of fads come and go from the "Bowie Knife" craze to the "Rambo" knife to the Tanto to the "stealth" knife to the Bowies again..to the tactical knife..back to Bowies to "liner lock folders" to "camp" knives and who knows what the next great thing will be??? I have seen this many times before and once the craze is over things should settle down a good bit... Watching a TV show or reading a book isn't going to make anyone a blacksmith (or anything else)..It takes the person actually getting off their hiennie and doing it...95% of the folks that manage to do that will see that this sort of thing is a lot more involved than what is shown on the screen... Anyway that's the way I see it.. JPH -

Hello!!! Here's this last weekend's product for my website and probably RPFS (Renaissance Pleasure Faire, South) in Irwindale, California...(this starts next month and it's a killer for me to keep up with the demand...) Here are two ladder pattern blade short swords, a cable blade dirk and a couple of small Star Twist type critters... Now on the short swords I got the ladders really "tight" this time..I am more or less happy with the way they turned out...as for the other pieces, they turned out OK as well. These are all more or less "website" stock as I call them... and as I said above they will probably end up down at the Ren-Faire in Irwindale that starts next month... These are my "bacon and beans" sorta pieces that I like to keep around as they seem to sell quite well in those sorts of venues and the like... The next bunch I have in the queue to be completed will be PW pieces, mostly in Star Twist with a couple Ladder pieces thrown in as well..these I am planning on tarting up a bit and when I get these done later this week..I will post them as well.. As it is I hope you enjoy the view of what my "production run" sorta pieces look like.. Hope these pics turn out.. JPH

-

Frosty: You Sir are correct..I was referring to the WI pieces on two sides of the center "snake"..the three pieces were basically the same dimensions...3/8" sq when I welded..however I really should of used at least 1/2 x 3/8 welded on the 3/8 side to give me a bit more "wiggly room" when I patterned the center core piece. The WI came out so velvety smooth and nice..gave great contrast to the shinier snake core.. Well at least I know my theory is solid..just have to hammer out the details and particulars...I'll get it figured.. I might of been born at night but it wasn't last night... JPH.

-

Hello!! I have been working on this the last two days and this is what I came up with. This is a Pattern Study piece and while my theory was sound my execution needs to be worked on a good bit more... I still need to work out the ratios on the size of materials I need to get the undulations I desire in the center core prior to welding the pieces together. (The twist are more or less a no-brainer..had those figured out about 40 some years ago..) but the center core pieces, while they did work..the result wasn't as "snake-y" as I wanted so I finished it up anyway and this is what turned out. The 15" long blade is welded from A203D/E, 1070 and some highly refined wrought iron. The WI runs down either side of the snake in the center. It is so NICE and very fine grained that when etched it gives a "satin" or "quilted" look. This I did out of some 19th Cent graveyard fence I squirreled away some 35 plus years back.. Bovine ivory grip that I "fossilized" with KMnO4... along with phosphor bronze mounts. I know what I did wrong on this as I figure I will need about 1/3 more width on the outer pieces before I pattern the center core piece so it is not a complete fail..more like a study piece really... As I have said many times.... "Experience is what you get when you didn't get what you wanted".. Still not too bad a piece for two days' worth of work. Currently posted for sale on my website

-

Hello: Just finished this up today from a blade I hammered out a week or so ago. It's a 27 7/8" long three core twist/counter twist offset pattern "Dark Age" style sword in 1070, L-6 and 1095 steel with some SS HT foil just because.. Full length fuller on both sides, one piece Bovine Ivory grip with SS studs and phosphor bronze mounts. This is one of my "generic" swords for stock on my website. Didn't turn out all that bad for a couple of afternoon's worth of puttering about and goofing off a bit. JPH

-

Hello: Something I whipped out today..forged from a cut off from that faggot I welded up for that Bowie I made recently.."solar storm" pattern in 1095 and L-6 steel..9" clip point blade, forged phosphor bronze single branch guard and pommel plates with some file work. Blade is flat ground..something I do not do very often. Stag grip that I processed and enhanced..I am getting pretty good in treating this stuff.. Came out OK for an afternoon's work from a cranky old Dogface. Available on my website.. JPH

-

Hello: Been tying up some loose ends out in the studio and this little guy is one of them. Nothing really special just a "experiment" piece to figure out patterns and all that... It's a sexy little 22" leaf blade in L-6 and 1095 in my "Solar Storm" pattern that I have been puttering with the last few months or so..Forged phosphor bronze mounts (the guard was a real bugger) and fluted black horn grip. Didn't turn out half bad for a broken down old forge rat... Hope these pics come out OK JPH

-

ROFL: A wise man once said..If you ask a man a question that calls himself an expert, run..if you ask someone who others say is an expert listen to that man... It's not how good you THINK you are..it's what you are able to do and what others see that can take a step back and give honest opinions... As far as "Master" goes...that term is so over used and ill applied that it really means very little nowadays...cause it seems that just about everyone and their uncle Charlie is a "Master" ...just ask them.. Just my 2 cents' worth.. JPH

-

Fergy: Ref the Japanese swords..they are coming to an end..I have two more to post today and after those..I have three more left to do and I am DONE with them..I never really was all that "into" these types of swords and after doing 125 of them..I am even less so.. I don't even want to look at another one of these so when the last three are done and posted..that is IT!! All 125 will be done and gone... JPH

-

Frosty: Believe me if a cranky old Dog Face like me can do this..ANYONE can if they put their mind to it... OK granted I am looking at the big 5-0 in doing this..geeze..I am getting along in years..but I did start as a wee youth in NW PA..taught by a very skilled and talented Amish Blacksmith who's name was Joachim Hauffmann..I learned ALOT from Herr Hauffmann...Mostly swear words in Saxon German... Seriously..if I can do this stuff..anyone can..Just get out there do do it.. JPH

-

Hello: Really these are pretty much stock type pieces..nothing really special or out of my normal range..I just do he best that I can..after all..remember the words of General Geo. S. Patton: "When a man does his best..what else is there ?" No... these are for populating my depleted website. More is coming..need to put up the last of the Japanese stuff as well as make more site stock in PW, WC as well as HC steels.. here are some close ups on the blades. I do have a reputation to live down to ya know... JPH

-

Hello: Here is this week's work..a herd of Bovine Ivory hilted short swords..gotta love that Bovine Ivory..the hardest part was putting in all those lousy little studs in the grips.. are 1095 and L-6 two in Ladder, one in star twist and the other in my Solar Storm pattern.. They turned out OK if ya ask me.. Made these for web site stock.. Gotta keep bacon and beans on the table ya know.. JPH

-

Durian is great,,you should try the ice cream... I am quite fond of lamb's eyes as well as the tongue..that is old home cooking for me...Chitterlings are also good if prepared by someone who knows the right way..if not they taste,,well..they taste crappy? Balut I got hooked on when I was in SE Asia a loong time ago.. Century eggs..well they do have a pungent smell, but I have had cheeses that were nastier.. The first time I ever tasted chicken I thought it reminded me of alligator..or snake..frog legs are great.. On the fermented front..as I said I just put up some Baek Kimchi for the missus..and thermo-nuclear kimchi with squid and oystrers for me and my son along with some Oi Baegi and regular old sauerkraut using a recipe that I got about 50 some years ago from the Amish gentleman who got me started in metal working's wife . Home made beats the snot outta store bought. Zoroastrians have no dietary restrictions other than if you can't catch it you go hungry...remember vegetarian is from an old Greek word meaning "Bad Hunter"... JPH.. (ya ought ta ask how I got my nickname of Muskrat when I was in the US Army the first time..heh heh heh/.///well back to work for me..got to post some new sword critters to my site...)

-

And here I just put up 5 gallons of kimchi, 3 gallons of Oi-Sobagi and 5 gallons of regular old sauerkraut...I am waiting for the magic to happen now... And you ain't lived until you had a hot bowl of Kurdish Khash.. this stuff will either cute what ails ya or kill ya..either way problem solved.. JPH

-

Hello!! I know I am a bit late in getting to this..had some emergency eye surgery thanks to some misguided yard work...so I am playing catch up... Oh Please!! I hate to say this cause it sounds so arrogant..however I have probably forged more blades out of meteoric/extra-terrestrial materials than anyone else alive today..It's a bit of a PITA but it's not all THAT bad to do..I even wrote about it in book I which was what 29 years or so ago?? Swords that flex 60 degrees?? ow..most of my rapiers can go close to 90 degrees and return to true... All I can say is this guy is either a snake oil salesman or he saw a real Rube in the author and decided to play him for a foo... Rubbing a sword blade to improve its structure and function?? Oh come on... Geeze what some folks will believe.. JPH (Last time I rubbed ANYTHING that hard I wound up needing glasses)

-

Hello: Something a bit different from what I usually make..Experimental piece for book IV..1095 Electrite and L6 steels in my "Solar Storm" pattern. 11" long 1 3/4" wide blade. The curved fuller was a bugger to do but Augustus handled it better than I thought. I gotta love that guy..he's worth every cent I spent on him.. Forged phosphor bronze guard and pommel plate, with a rather nice piece of Red Deer antler for the grip. Overall length 17". Like I said..I usually don't make these sorts of blades but what the heck..gotta do a few for book IV..I have a reputation to live down to after all... Feels wicked and extremely fast and responsive in the hand..This is a Big Guy. Turned out OK for an experiment if ya ask me..I am not really "into" the Bowie type knife..to me they all look like a Seax..I am funny that way I guess..still it turned out OK.not too bad for a ham handed old Dog Face like me... Hope these pics turn out. Available on my website shortly.

-

SB: If you are referring to the black lacquer/paint coating that is on some metal strapping..there is no harm in removing it..and there is no harm really in leaving it on either. I myself remove the majority of it..more out of habit than anything.. welding is one of the most basic techniques in iron working and for some reason folks get this idea that it is almost impossibly difficult when it really isn't.. You do need to meet some requirements but it really is not all that hard to do..As I said before..If someone as ham handed as I am can do this..just about anyone can... JPH