-

Posts

5,783 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by jlpservicesinc

-

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

Shaina, love the design. Goods, you are a natural.. Your skillsets have excelled and it really shows.. I have owned steel-handled and wooden-handled chipping hammers and prefer the wooden ones.. Much lighter and while they are called chipping hammers are rarely if ever really used for removing flux or inclusions via being swung like a hammer. -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

It's all forge welding.. asy, super fun... Someone with some decent hammer skills and fire management It's a day class. -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

Hey that is cool. When you get out of corporate you can use those for aging meat or drying herbs. I forged these from the sample pieces made at pv I brought home. -

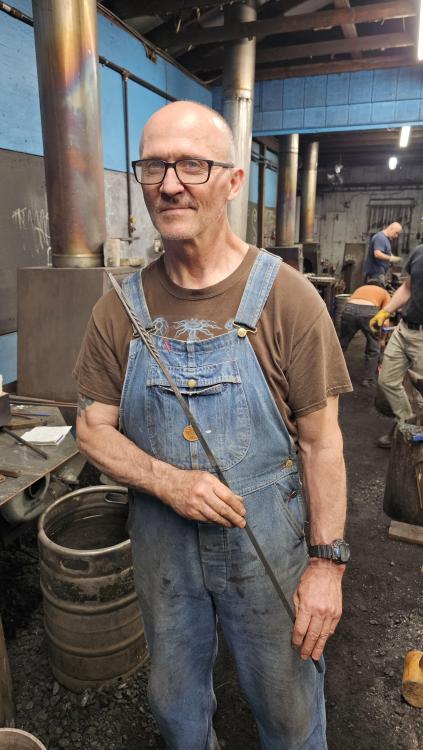

So here is the samples of the items the students covered. I auctioned off the samples I forged for the students to see. The video is of one of the students whom never forged in his life. This was his first class and this is the morning of day 4.. Interestingly nearly all the students completed their drop tong welds within a few hours of each other. The ladies of the group had a hard time with the longer bars.. Something I forgot to mention is to cut the bar to a comfortable length.. LOL.. Its funny how certain things just seem clear but open to interpretation. I could not be happier with the results of the class.. Few people who had lessons previously were a little tough to get to change their fire management.. a By day 2.. All the students knew how to start their fires and to create a welding fire vs general forging fire.. Was awesome.. 20230731_165722.mp4

-

Sorry got locked out on edit. Now, comes the part that I have to apologize for: The assistant was very supportive the whole time.. I ask for feedback several times a day to see if I covered the bases and such.. He was psyched and learning as much as the students. He does bloomery iron.. So has a bunch of experience and has been at if for about 5 years IIRC. Anyhow, Here it goes.. Somehow when I was asked, I got things twisted as to what the subject of the course was.. I thought it was a " Beginners and Beyond" course... Turns out it was an "introductory" Yes, you got it " introductory course".. This basically means you learn about the basics (chalkboard or projector with flyers and handouts) then a short demo, then you might punch 3 or 5 holes hot and cold, do a little metal slot, hot cut with a chisel, maybe hardie if they are lucky. maybe have a bit of a joke in between with some snacks. etc, etc. Ideally having some sort of a fun project with something to bring home but not be completely spent and have a great time to boot.. I had miss read my introduction as the title or intro for my story on who and what I do.. Under that was the experience level " beginner and beyond".. That means to the PV group that this is a "beginner or someone who has previous experience" I completely thought that was the level of experience they needed to be to engage in the course I was offering.. What I mean is I would take them from a "beginner and move them beyond".. The shop coordinator returned from going away on the morning of day 4 to see me demonstrate and guiding the students in a totally new direction after the divergence of forging nails (pyramid and rose head in the morning) and (T head nails in the afternoon) way I had from day one.. (the group was too unfocused the first day after lunch, and day 2 they were still too unfocused so decided to change directions in what I thought was an intermediate format class based on my description)..... Beginner and Beyond.. LOL.. The instructor shows back up just as I'm bringing in the " multi twist blacksmith basket drop tong welded basket" to which she expects to find me doing a little fun project with a lot of ABC chalkboard and a few minutes of forging time in between.. The morning demo on the basket was 3hrs long.. LOL I was thinking the whole time how great the Shop coordinator would be so happy with the progress of the students.. Her feedback was explain more things on the board 1 or 2 items tops then forge.. I said. it's too late for that now.. That ship sailed.. Had to go this direction to unify the group. This was after the 3hrs demo on basket drop tong. yes I had everyone hot cutting on the hardie, upsetting, Lap welding with both American flat scarfs and European style scarfs, managing their fires properly, etc. etc. The assistant was stoked.. The Shop person.. Little less so.. From a teacher aspect It was a stunning time.. From the students' stand point, the feed back was sensational.. Being told by everyone what a great time they had even the people who really were just there because.. My point is.. I completely missed the mark and it wasn't till this morning I went to look at the course outline that I realized what happened.. I feel like crap since it was the Coordinator who invited me down after seeing my work at the ABANA conference a few years ago and decided to take a chance. I would love to go back and teach something else or even an intro course again especially after being there and understanding now what is what.. Everything happens for a reason and whether it be the student relationships or with peers or looking deeper inside or to others for answers it unfolded as it should of.. I have no regrets about teaching the students the way I did and I would do it all the same again knowing maybe 3 or the students would have gotten left behind at the "Introductory" level. But I'm also hopeful there is enough position feedback from the students that I might be invited back.. Though I completely missed the mark on what I was supposed to expose. I broke a lot of rules by overreaching in the class structure.. Basically taking a group of 9 students who signed up for an "intro course" and moving them into another spot. But I also feel terrible about it and will never forget about the infringement and betrail though not on purpose.. I accept full responsibility for all of it. Live and learn. I deeply apologize to the people who lead and assist at Peters Valley Blacksmiths shop and the students.. Much love..

-

I was showing everyone the way I work.... The way I work I dramatically different because everything is very much seamless.. Sometimes I don't even look at the anvil or metal while forging... The assistant was very eager to learn so as soon as I showed something he had not seen if there was an open forge he'd try it ASAP. The shop is well setup for modern smithing methods.. Anna has done a spectacular job of getting the shop in prime shape with new gas forges, 9 coal forges, New double burner gas forges at each work center (2 students per gas forge). I gave lectures, show and tell on any subject that came into view.. The coal forge care and maintenance was terrible.. I finally got a little tire of people running their forges hollow to weld in so stopped the class and brought them over to see what happens in a coal forge and where the oxidizing, neutral and carbonizing aspects of a fire were and the reasons why we keep coal banked and constantly creating coke.. They all loved that.. 1/4"sq CR all brought up to welding temps in an oxidizing, then neutral, then carbonizing parts of the fire.. They were surprised how much it sparked in the oxidizing zone.. Then the bar would not throw sparks until removed from the fire in the neutral zone, and in the carbonizing zone it took longer to get to a welding heat but the sparks were crazy lively.. They were also very surprised how thoroughly the bar picked up carbon once in the carbonizing zone and these 200lbs guys could not bend that 1/4"sq piece after it was hardened in water. I snapped sections off to show them grain growth and why it's not good practice.. I then notched the bar I had done this to, about 1" long, forge welded back in this section and from one welding heat.. Letting it cool to a dark red color forging it brought it back to orange color by hammer work and forged out a nice longer taper. I then snapped this newly forged taper every 1/4" and showed them how forging refines the grain structure. The part that was forged from that dark red when hammered brought it back to about orange.. It was ductile enough to bend it cold in the vise using the hammer into a rat tail shape. I then snapped off the pieces and showed them the difference. I think you would have loved it.. To do all this was about 10min at the forge.. The discussion afterwards was about 20 min. Shaina, they made thousands of types. More types of nails then they make today in fact. Of course, a screw is a screw except for the bit used to drive it.. That is maybe the largest difference.. Back then a slot screwdriver and square wrench Larry, Not just excited with the results.. These students nailed it.. LOL.. Now comes the kicker.. The shop supervisor went away and only the assistant was there who was having a blast.. Great feedback at the end of the day on the class and how it was evolving.. I asked a group of students how they felt things were going and if they had any questions or comments.. The first guy who had 0 experience thought it was great.. He said he loves it and wouldn't change anything.. He had never been to a class so it was easy to adopt my methods of fire management (having some) and all the lovely other tidbits. 2 of the guys said it was a little confusing because the other classes they had taken it was a show and tell.. Go do 1 or 2 things and then be shown the next step.. They both said, We don't really know where it's going because our notes are not really organized enough to keep the steps straight.. In the first few minutes of class, I mention every 5 min I'm here for them to learn and to have fun.. I'm there to answer any questions and problem-solve anything they might run into.. Both of these guys had previous class experience, yet had no fire management skills. (what happened in the first few classes? I don't know) They were relying on each other to try and piece together what they had seen.. A very weak-legged way to learn especially when the instructor is there every 5 to 10 minutes.. Yes, I circulate around and around watching everyone, explaining little things, and trying to teach them why their forge fire needs to be loved and cared for. (day 2 they all ready knew how to setup a forge welding fire and to feed it.. Most beginners have a problem because they want to see the metal so they open the fire.. They believe a larger open fire will give the heat they need.. All it really promotes is bad fire management, lots of scale and oxidized flux. It's not that these guys are doing it.. The part that I don't understand is why was it not corrected from the very start.. Harder to unlearn then to learn.. Yes. I know all about time and busy and blah, blah.. Anyhow.. I told the guys the same thing.. " I am hear for you to learn.. I am hear to help and to have as much fun as you can".. Ask me anything at any point I am hear to help.. (it was 95F and 95% humidity brutal and the guys were hot and tired) they just did their first forge welds on the icicle.. I then said.. You guys can't see where I driving you.. But, when we get there you will be totally amazing and you will see why I brought you this way.. Yeah, yeah, grumble grumble.. One guy got up and went back in.. The other guy said he's had classes and no one.. NO one has done them this way and he prefers the others teachers way of doing it.. I said.. I understand but that he is doing well and that stick with it a little longer he will fully understand.. LOL.. They next day we came in and one of the guys said he was hot and tired and trusted where I was bringing him.. That afternoon was the icicle prep and welds and twists.. After talking with both these guys and getting the feedback and letting them know I was there for them with any questions it became like a great bunch of people hanging out.. No longer did they feel isolated.. They started reaching out.. By the end of day 3 both of those guys told me independently that they appreciated why I took that direction and now they fully understood with huge smiles on their faces.. That made it all worth it.. Because of my experiences, everything is seamless.. There is no order of difficulty.. It's just working metal at the anvil, forge and vise. As a teacher it's tough because a group of 5 students is easy to figure out what each person needs.. With a group of 9 students with a few classes to students that are there, just because to students who are thirsty or curious.. Figuring out how to present information to each person becomes a challenge. This was a long response but is the reason why I love to teach. there are so many things I do that people have never seen them before.. Anyhow that's neither here not there.. Proud.. Every person in there worked their hearts out.. They all talked about what a great class it was and were very thankful.. 2 of the people said they weren't sure about smithing so took the class on a whim.. One of the 2 people absolutely fell in love with it and she was crushing the work and asking so many questions. I love that engagement. Now, comes the part that I have to apologize for: The assistant was very supportive the whole time.. I ask for feedback several times a day to see if I covered the bases and such.. He was psyched and learning as much as the students. He does bloomery iron.. So has a bunch of experience and been at if for about 5 years IIRC. Anyhow, Here it goes.. Somehow between when I was asked, I got things twisted as to what the subject of the course was.. I thought it was a " Beginners and beyond" course... Turns out it was an "introductory" Yes, you got it " introductory course".. This basically means you learn about the basics (chalk board or projector with flyers and hand outs) then you might punch 3 or 5 holes hot and cold, do a little metal slot, hot cut with a chisel, maybe hardie if they are lucky. maybe have a bit of a joke in between with some snacks. etc, etc. Ideally having some sort of project fun with something to bring home but not be spent and have a great time to boot.. I had miss read my introduction as the title or intro for my story on who and what I do.. Under that was the experience level " beginner and beyond".. That means to the PV group that this is a "beginner or someone who has previous experience" I completely thought that was the level of experience they needed to be to engage in the course I was offering.. The shop coordinator returned from going away on the morning of day 4 to see me demonstration and guiding the students the way I had from day one.. (the group was to unfocused the first day, and day 2 they were still to unfocused so decided to change directions in what I thought was an intermediate format class based on my description)..... Beginner and Beyond.. LOL.. The instructor shows back up just as I'm bringing in the " multi twist blacksmith basket drop tong welded basket" to which she expect to find me doing a little fun project with a lot of ABC chalk board and a few minutes of forging time in between.. The morning demo on the basket was 3hrs long.. LOL I was thinking the whole time how great the Shop coordinator would be so happy with the progress.. That was not the case.. yes I had everyone hot cutting on the hardie, upsetting, Lap welding with both American flat scarfs and European style scarfs, managing their fires properly, etc. etc. The assistant was stoked.. The Shop person.. Little less so.. From a teacher aspect It was a stunning time.. From the students stand point the feed back was sensational.. Being told by everyone what a great time they had even the people who really were just there because.. My point is.. I completely missed the mark and it wasn't till this morning I went to look at the course outline that I realized what happened.. I feel like crap since it was the Coordinator who invited me down after seeing me work at the ABANA conference few years ago and decided to take a chance. Everything happens for a reason and whether it be the student relationships or with peers or looking deeper inside or to others for answers it unfolded as it should of.. I have no regrets on teaching the students the way I did and I would do it all the same again knowing maybe 3 or the students would have gotten left behind at the "Introductory" level. But I'm also hopeful there is enough position feedback from the students that I might be invited back.. Though I completely missed the mark on what I was supposed to expose. I broke a lot of rules by overreaching in the class structure.. Basically taking a group of 9 students and turning them into forging and forge welding machines.

-

Thanks. 1 more half day to go. It's been terrific. There's been maybe 50 lessons beside the main course load, from carbonizing mild steel, welding stuff when convential thought says you shouldn't, forging to maximize efficiency. List goes on and on. It's really been fun. Going to be stellar when the school is finished.

-

I asked 9 people, 6 of whom never forged in there lives to get and execute a drop tong weld in 4 days. Here's a bunch of photos of students work and a few of my demo pieces and some tools up to day 4. These gals and guys ranged in age from 16 to 65 and have been crushing it. 4 days to get a drop tong welded multi directional basket twist handled fireplace poker. Not possible you say........ Day 1 nails (pyramid, rose head, and T heads, day 2 nib finial S Hooks, day 3, 4 bar icicle (free hanging basket twist) and welded side rake. Day4, multi twist Blacksmith basket twist fireplace poker (drop tong). 4 of the students completed the drop tong welding process as of day 4. 1 had no previous Blacksmith experience at all. I've been having such an amazing time. About 90f in the shop day 1, day 2 pretty close with high humidity. 20230731_132639.mp4

-

Congrats. Will it move into #1 anvil position?

- 661 replies

-

- Cast anvil

- Fisher & Norris

-

(and 1 more)

Tagged with:

-

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

So last forging day before heading off. Samples plenty. First horse heads. Middle 1 is #3, Figured they would be a welcomed beginner project. The 3rd one looks decent.. Still have to work out the little details I'd like to add. Like getting a proper ear. Trivets, nails, hooks, and tool steel/heat treatment, will be covered in the class. The Tulip hook is rather intense for beginners. Will have to see how the students are. Super excited. -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

thank you again.. Our inflation rate is pretty high right now, so the dollar will not buy as much as it used to either. Forged this small Tulip hook today. More class prep. Yes JHCC nothing political.. -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

Very reasonably priced now. You'll have to get more paying gigs and stash the money away for a new tool. "We agree on a price with the customer. I don't have any calculation formulas. I try not to offend myself, and not to scare the customer away. I don’t pay rent, I have my own workshop, I don’t have hired managers who need to pay salaries. We try not to pay taxes))), only for those payments that go through officially. If workers are hired, they are usually paid piecework. Percentage of the total cost." Alexandr Thank you.. Being that I'm from the USA and have limited travel abroad I am always curious as to what the wage is for a given item or work.. Really I'm just interested in what people do and how they make a living. It seems all over the world it's about the same. Try to do great work for a decent pay.. Thanks -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

You guys are too serious.. it's all a joke.. Before too long, I'll probably be propane myself. I dread that day. Solid fuels are so precise heat-wise. -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

Wow, you have converted over to the dark side. Sadly with the way the coal mines aren't running these days it's probably the wave of the future. Unless of course, someone has ample time to make charcoal or other biomass-type fuels. Going simply by today.. The heyday of soft coal is in the rearview mirror. -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

Alexandr that is fantastic. I still don't know how you do it alone.. Your production rate is off the charts.. If you don't mind me asking.. what do you charge per hour or shop rate? I did some forging today in prep of Peters valley. Few show and tell items of possible class materials. JHCC.. Lots of finer and finer sand paper. -

JLP Blacksmith Teaching Center.

jlpservicesinc replied to jlpservicesinc's topic in Building, Designing a Shop

Bummer. would have loved a visit.. Been a few years now since the last visit. Hopefully next time.. Of course, by then I hope the school will be near completion. -

JLP Blacksmith Teaching Center.

jlpservicesinc replied to jlpservicesinc's topic in Building, Designing a Shop

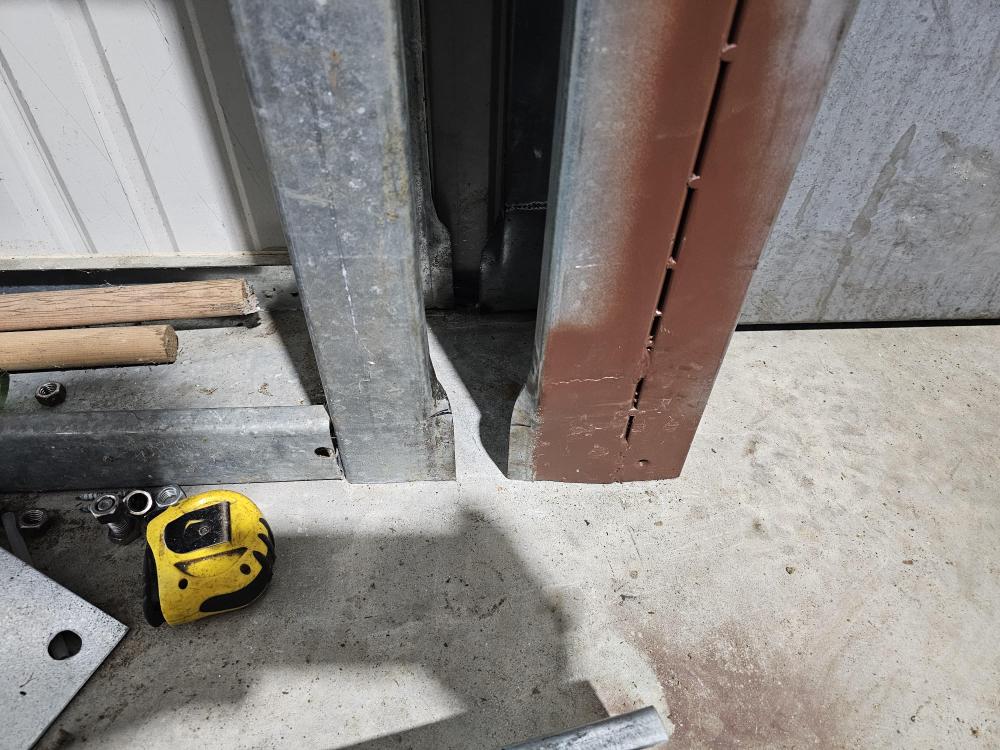

Thanks. it's going to be spectacular when things finally get finished. LOL.. 3 years of a wild ride for sure. Huge, huge learning, and many curves to boot. Many do and redo's. Also all the learning about the support equipment like the manlift.. Which I love, love, love. Back in 1986 my stage fright was pretty intense. If I stopped and looked into the audience I was a mess for about 5min until I could get back into the swing of things.. Swing of things.. get it.. Talking to the audience was ok.. But no looking. Now, I don't really see a difference. People there or not there.. Interestingly while I don't talk much on the videos it's simply because there isn't really an audience. What I mean is, the flow of having people hanging and watching is not there. Often times I explain things while forging or during reheat times.. Reheat times get cut out of the videos. While I'm demonstrating I just explain and talk to people as I work. Comes with being comfortable with the materials and methods. Seamless really. You are welcome to come by anytime. I hope to have an open door policy with fellow smiths if possible with many hammer in's and educational events as well as some smaller group things. Onwards.. shop news I worked in the shop more. I pulled the workman door and welded on some steel framing to it so it would be solidly mounted in the wall solidly. The door was originally designed for wood construction vs metal construction so the jamb was thin.. Was impossible to mount the building trim properly.. I used larger diameter tapcon screws to and used silicone between the metal touching the floor. Now the door is rock solid.. Of course the next time I do a door I know the correct steps. I had to do a few extra things after welding the frame on like putting bolts thru to pull the center into a neutral position. The door I bought was adjustable which means it slides on thin metal sliders. Now it can't do that. Doing it again I would weld the sliders and put in a cross bar spacer for the correct spacing. By getting the door frame done this means I can install the insulation and interior siding. That is a huge next step. -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

Shaina, Looking good. You have had some great progress. Hows the ABANA course going? Billy that is cool. Nice job. -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

That's a great yorch lamp. What did you use for the torch part? -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

It's been in the mid 70 to low 90s. The humidity has been off the charts this summer with 70 feeling like 95 and 90 feeling like 100f. We have had so much rain the raspberries have little flavor. We have been getting 3 to 4 days of rain on a regular schedule meaning weekly. Only nice thing is not much risk of fires. Few days ago I finished the chain makers tongs I'll need for teaching at Peter's Valley. 3/4"sq jaws, 7/16" reins. -

Howdy, I've never been there. I did talk with Dick Sargent who was the lead there for years before the current group. Anna is the shop director and is the reason for the invite. What a great person. Swings a mean hammer to boot. I told Anna about the teaching curriculum and was then told about no chain makers tongs. Argh, electric blowers. Ick...why, why, why. I can see electric for large stock but not for general smallish work. Seems so fiddley to me. My original shop would have a stream of water thru the center so as long as there is ample work around space that's OK. I used to love the water trickling sound. "Very nice as usual" thanks. Arm and hammer swing have started to return to previous retirement ability though the dislocation does show itself. Hammer swing is starting to show the right return in metal moved.

-

I will be going down to Peters Valley to teach a beginners and beyond course. Forge welding is a basic skill so usually gets taught day 1 or 2. Where I'm going has no chain makers tongs so.. Need some tongs, make some tongs. These are a little lighter than I would make for myself but should be about right for students.

.thumb.jpg.098d3a68f9693191026f9cdc7ef6dc73.jpg)