-

Posts

5,776 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by jlpservicesinc

-

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

JHCC, You are freaking me out.. I'm not used to you getting the shop all organized. -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

JHCC, that is a great cart for you shop. Very nicely done and designed. super handy for sure. Will you mount the gas saver on the cart too? -

3,000 lb Chambersburg

jlpservicesinc replied to RailForgeWV's topic in Power Hammers, Treadle Hammers, Olivers

I am so envious. I met one of the Hallmore guys that pulled all the machines out of the Navy shop after the auction few days ago. Of course everything happens as it's supposed to or else I would have a 1500 open frame hammer. I'm happy for you though and maybe on my journeys I can stop by and see it in action. Thank you so much for rescuing this hammer.. And also thank you for posting information about such a wonderful historical item. that is awesome. Fantastic job on mounting it.. How much clean up did it take? cosmoline and such? -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

Anvil. If it's how you create the aestheticics you want then you can't be wrong. They are how you get there and from what you have said you get the results your after. How can one argue or point out a wrong or right value or attribute. It's how you get there. Kudos. I use my varied skills to get the acitics I'm after. It's pretty simple. More than likely we are saying the same thing or not. Don't really know. Hugs to you. -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

Frosty, I've been brought up decently.. I'm willing to share mine.. Funny.. Safe to use inside.. Inside where??? The potential for such a tool is perfect around the farmstead. I'll need to dial it in though. Frosting :Jumping up is used extensively in the horse shoeing trade". Making a smaller bar larger or section of bar larger to the next size or Jumpin it up. Heel calks. toe weights, laterial offset shoe.. Etc, etc. the old farriers would only care 2 sizes of stock in the truck. So, Lots of jumping up was done. -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

All the skills should become mundane. It shows mastery. Forging to me no matter the items is all the same. Some just take longer based on size or complexity. Understanding where a skill ot technique is best used with the ability to apply it. the thing that im still gaga for is applying hammer blows and watching the metal move rapidly. Gazz, very cool. -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

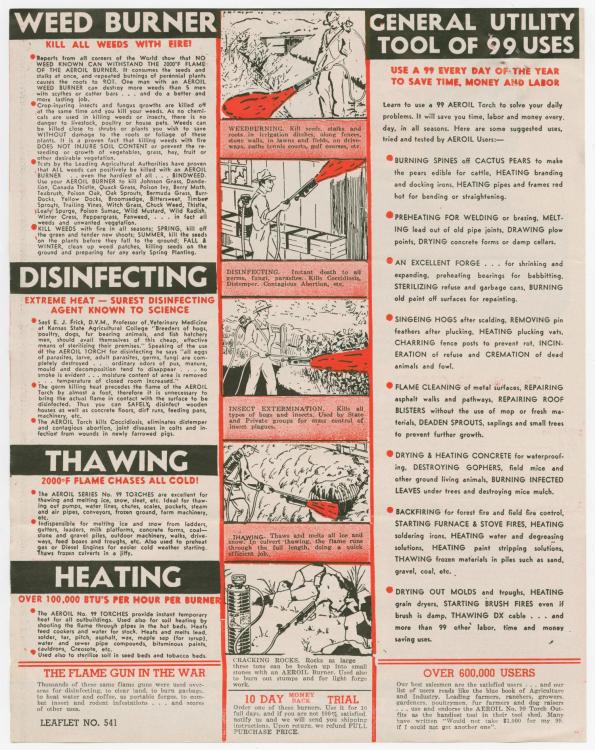

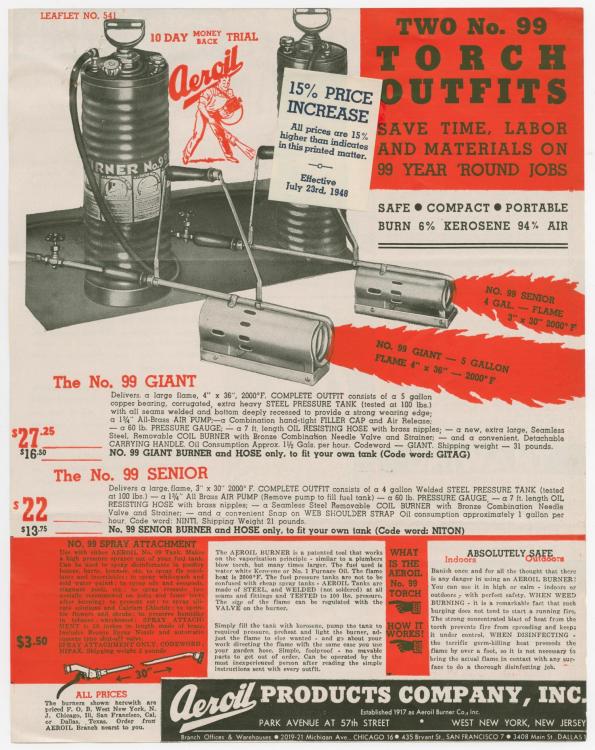

Why does everyone run away from "upsetting". Upsetting and forge welding are 2 very important skills, yet most people try to avoid them. It's hard to get good at something when mentally it's thought of as something to avoid. I embrace upsetting every chance I get.. It's how one gets better at something. Before one knows it, it's not a big deal at all and it becomes fluid. Don't get me wrong there are certainly certain applications that upsetting is not the best way but it also should not be ran from. I do understand.. But I also know to embrace difficulty If I really want to learn from it and then it becomes nothing. I'm not criticizing. I'm always hopeful people will move their skill sets forwards. Anvil, forge welding as you know is a basic skill and once demystified it opens all sorts of missed opportunities. So, the sooner it's embraced the sooner greater skills can be achieved. For the class there will be chain, fireplace poker, trivet and maybe a tulip hook if things go well enough. I was able to get the tong jaw blanks down to 3heats out of 3/4" sq while demonstrating. Of course there was more talking then anything else.. Took a little bit to get going again after lunch.. It's so rewarding seeing the metal move so fluidly. Gazz I have attached several information sheets for the torch. Sadly I have not found an owners manual or instruction sheet. Just advertisements. The unit I have was military and was charged via external air source or pump. The Civy units had hand pumps. -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

Today I lit for the first time both my kerosene/diesel fuel 2000F Aeroil burner and my new to me Gasoline blow torch. There is something to me about old gear that somehow makes sense. I don't have enough confidence yet to fully open it up. It should burn nearly blue when fully Choochin. 20230625_184846[1].mp4 And here is the gasoline torch. Both items have been pressure tested and cleaned before trying. I might have to clean the gasoline torch 1 more time. Pressure tests were good with no leaks. 20230625_200947[1].mp4 -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

Nice. Nothing worse than having a welding project and the batteries are dead. I use rechargeable batteries on all the welding hoods so that's a plus as long as I stay on top of plugging in the chargers . -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

JHCC to maximize the life of the batteries in the welding hood, Ideally they should be kept to get light. I hang mine so light is easy for them to scavenge. -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

First demo since last October and the Fitchburg forge in competition. Also first real forging day since I dislocated my elbow back in Dec 2022. Today was a demo at the Steam and Gas show in Orange Mass. 5 pairs or jaw sets for chain makers tongs for the class " beginner and beyond" at Peters Valley, NJ They have no chain makers tongs and welding is covered on day 1 or 2 of the class. I had no 7/16R in the trailer so finished tongs will have to wait. 3/4" sq starting material. Also a little demo on leaves and organic shapes in metals. -

that is very cool. Thanks Glenn for clueing me in.

-

JLP Blacksmith Teaching Center.

jlpservicesinc replied to jlpservicesinc's topic in Building, Designing a Shop

As a side note I will be teaching at PetersValley end of July. https://petersvalley.org/workshops/introduction-to-blacksmithing/ -

JLP Blacksmith Teaching Center.

jlpservicesinc replied to jlpservicesinc's topic in Building, Designing a Shop

I am not selective with wood at all. nearly all the wood in the pile was pulled from a place that the trees were full length on the ground for 3 years. The wet trees were put down there when the lot was prepped for the building. It wasn't until the furnace was installed that I went in and cleared the place where they were all stacked up. Apple, maple, cherry. Just dumped there. These are the standing dead.. 3 cherry and 1 ash. If it will smolder it's wood enough for me. I throw paper, card board, in. -

JLP Blacksmith Teaching Center.

jlpservicesinc replied to jlpservicesinc's topic in Building, Designing a Shop

Great information Glenn, I never even considered burning the same tree's wood together.. Makes great sense. The tree that was wet has been down for 5 years but in a damp area. The moisture preserved the wood but with it being split (though it was cut to length) it was like a sponge. It was these pieces that were being moved up to the splitter when I broke my arm and dislocated my elbow on the mini dozer. I had thought I could get away with burning it even a piece at a time on top of some well-seasoned dry firewood. The furnace is controlled via the thermostat which includes the waste oil and the wood/coal side. So if the temperature is set to 60F when the temperature is reached it closes the dampener and the fire smolders and turns everything to charcoal. Once the temperature drops down to 58F the damper will open to feed air again. If the dampener opens but the temperature at the thermostat continues to go down 5 degrees from the set temp, ( we'll say set at 60F and drops to 55F the oil side of the furnace will come on until it reaches 60F then shuts off the oil side and opens the damper for the wood/coal side. This is great because there is always heat.. Wood, coal, oil, biomass.. Pretty much anything you can put in it. the damp wood was a learning thing and during the winter with low moisture in the air I figured the wood would dry out a lot faster. I have 3 trees now that are standing dead in the area that is wet.. So will be interesting to see how dry they are. I'll have to make another wood pile for these all of the wood is 3 or 4 years old split, stacked and covered. Last year I burned about 3/4cord. Year before I burned about 6 cord. I have about 6 cord put up now with about 1000gals of used oil. here is the manual on the furnace. Sadly Yukon went out of business 2 years ago. The EPA regulations of zero burn/condensing furnaces put them out of business. I spoke with the guy before they closed and they said to redesign the furnace is possible and they had looked into it, but what the EPA wanted was dangerous so they did not want to be involved. Gasification is key now. The new stove regs in the next few years will also be implemented. In Rutland, MA you can no longer install an oil fired boiler or furnace in a new constructed home. Only Propane. oil_furnace.pdf -

JLP Blacksmith Teaching Center.

jlpservicesinc replied to jlpservicesinc's topic in Building, Designing a Shop

Information on the school is easy to forget about. It's been years now of work and lack of completion. And the list is extensively long. So it's easy to forget about things. For air make up: Summer time is easy. Open a door. Winter time is when I have been in deep thought about. I want to incorporate some sort of heat exchanger that I can intake the cold outside air and preheat it before it enters the warm shop. I want to install an air duct over the IR heater that funnels the cold air over the top of it before discharging into the building. Also setting up a cold air intake/mixing valve for air to enter the furnace return plenum this will help pull air thru the furnace but also heat it some. Heating or furnaces are complex. If the heated smoke is cooled to much it creates condensate in the flue and this is bad. Last year I had put in some wet wood and it burnt but on the low side of the firing temp. The water in the wood condensed just at the exit of the furnace and damper. It turned back into water and made a mess. Black creosote liquid water.. Felt like a thin oil and smelled like liquid smoke one buys at specialty stores. So technically I was underfiring the furnace. Ideally need to stay above the 250F chimney temp. At some point I will develop a condensing furnace and redo the layout of this unit. I love being able to burn used oil, wood or coal. so will keep these features but will change the firebox design and move more towards a gasification furnace with down draft design going into firebrick for heat storage then to sheet metal with extra ducting. The used oil part of the furnace will preheat the wood side while still providing ample heat. There is also a passive sun tube heater that could be used to preheat the air before coming in the building. So many options and possibilities. -

JLP Blacksmith Teaching Center.

jlpservicesinc replied to jlpservicesinc's topic in Building, Designing a Shop

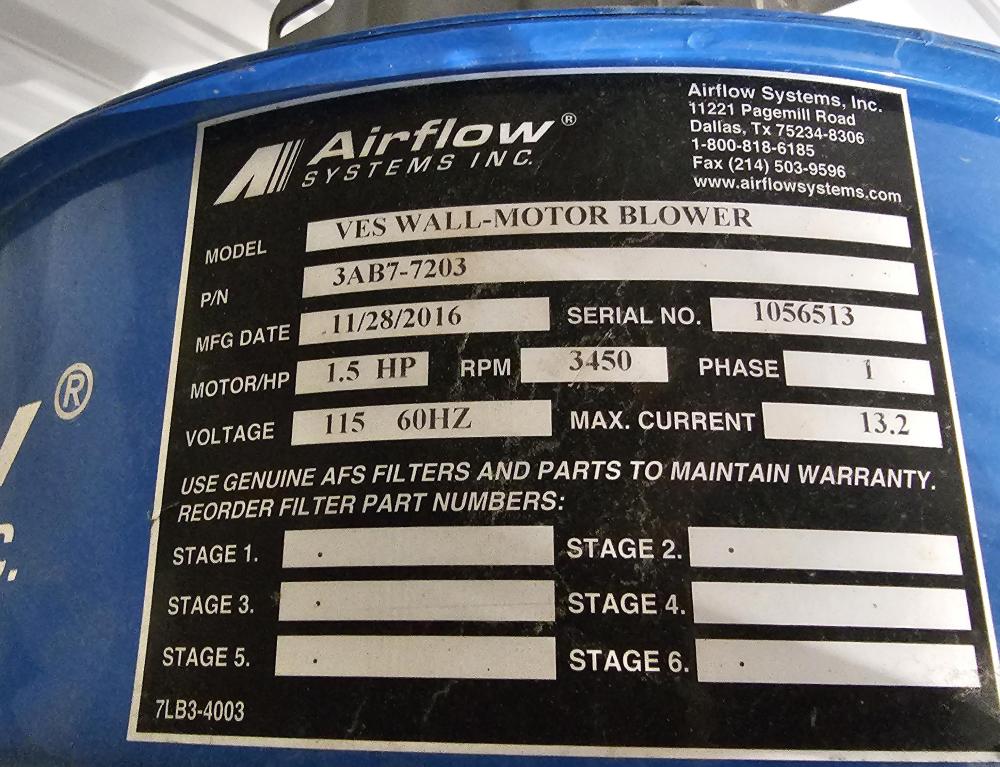

LOL. This unit has its own sucker/blower. I have a bunch of air-handling equipment. I have 2 Torit grinding air cleaners, A commercial Hepa filter I'm hoping I'll use them for the Office. And a rather large furnace blower that I will make into a filter unit for the whole school. Between the furnace filter on the heating furnace, the air handler filter, the Torit units, and the in-floor fume extraction I'm hopeful to keep it reasonably clean. The in-floor fume extraction system might be powerful enough for some light vacuuming duty but that will have to be discovered. This is the HEPA filter I picked up. https://acsi-us.com/product/fa-2000-ec/ -

JLP Blacksmith Teaching Center.

jlpservicesinc replied to jlpservicesinc's topic in Building, Designing a Shop

Here it's rather free for all in terms of design.. As long as the building has an engineered drawing with it the town as long as it does not violate any zoning they sign off. There are so many other better building types and construction. I suppose it has a lot to do with what is acceptable in the market at the time. Steel building here are not well known by the building inspectors. If money was no object I probably would have gone with a conventional real I beam construction with 12" insulation filled panels. The panels we have here are Plywood on both outside layers with foam glued in between the plywood. Fume extractor mount made.. It pinches the flange on the I beam. The top is a bar so the angle can be changed or adjusted via wedge or shim. the unit itself is 27ft long. Currently mounted 11ft from the foundation block support. I can lower it or raise it via 8 bolts. The angle or level of the main arm is controlled via the wedge. -

JLP Blacksmith Teaching Center.

jlpservicesinc replied to jlpservicesinc's topic in Building, Designing a Shop

The white tarp like material is part of the insulation system. here in the USA OSHA regulates what is done on/in job sites. The white tarp material is part of the insulation system and fall restraint. the system is known as Bay Liner or Skyliner depending on the company. Its a long story but was told by the metal building mfg to not do Bayliner when I talked to the insulation company. Well, when I talked to the insulation company I told them I don't want a Bayliner type system but wanted something semi finished. They swore their Skyliner system was nothing like Bayliner, but it's exactly the Bayliner system. It's a huge time suck to install and makes the building OSHA compliant for fall prevention measures. So the workers who are doing insulation or roofing don't have to wear the harnesses with limit straps. The membrane increases the insulation ability so I'm thankful for that. 38 roof and 29 walls. The largest problem is none of it is easy to install. The stuff is burn resistant. Not concerned with holes being put in it. the metal siding goes about 9ft up the sides of the building. Its all money.. Originally I could not afford the extra inside metal so wanted something that would be semi finished. It's a superior insulation system vs the plastic or vinyl backed insulation. https://bayinsulation.com/products/skyliner-systems If I could afford it, I'd cover the inside with the 2" pink form board everywhere and then put the white steel siding top to bottom. -

JLP Blacksmith Teaching Center.

jlpservicesinc replied to jlpservicesinc's topic in Building, Designing a Shop

made some good progress today. Plan is to move the 3ph converter over Saturday. That will give me welding and such in the school in preparation for forge fabrication day. -

JLP Blacksmith Teaching Center.

jlpservicesinc replied to jlpservicesinc's topic in Building, Designing a Shop

Added another grinder to the schools grinding potential. I was also able to get the last section of duct that came with the furnace up into position. I tried to bend the threaded rod cold but it's to hard and just snaps. So that will have to wait. -

JLP Blacksmith Teaching Center.

jlpservicesinc replied to jlpservicesinc's topic in Building, Designing a Shop

I will keep that in mind should the sails of DVD's or Mpeg video disks become required. LOL. AC160, thanks. It works a treat.. I went with slots because I hate cleaning out the back. We have rain, snow, sleet, leaves in the fall and all sorts of other stuff that goes in when items are loaded on the back of the truck. (dust, dirt, etc, etc). Now I don't have to do anything when it snows or the leaves come off the trees.. Really if all goes as designed I won't ever have to clean anything off or out of it. Also I can use the slots for tie down areas for lighter items if need arises. In the Northeastern USA the beds rot out under the liners. So no moisture with slots. If I need to carry dirt or loose materials a few sheets of plywood will work and when done what ever is left just falls to the ground. There is still a slot in the middle which I have not figured what I want to do. Its a toss up as to using the ratchet strap rails, a piece of white oak with pull rings in it, or just more grating of some sort. -

JLP Blacksmith Teaching Center.

jlpservicesinc replied to jlpservicesinc's topic in Building, Designing a Shop

LOL. I sure will. If someone does get sucked into the fume extraction system I'll be filming for sure. Once I get things in place and running I'll shoot video of the different aspects of the school.