-

Posts

5,798 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by jlpservicesinc

-

Htinva, yours is pretty complete. Other than the clinker breaker and arm missing. I'd give an offer if you are going to sell it. To use it, there are more control issues vs non down draft types so there is added complexity. Not really sure if the down draft is as effective as they advertised. I do plan on making my own designed unit if I can't get one in the next few years. The school will use coal as long as I can get it. So really want to find a solution for startup smoke. Your unit looks like it might have had an electric option and someone switched it to hand.

-

Yes, yes 6660. I've never seen this number used so is new to me. 660, 243, 843. Still very intrigued by the design. Not as straight forwards to operate as there is more to adjust.

-

Yes, please behind blower and hood. 6660.. I think someone at the factory might have added the extra 6.. The 660 will be on the side of the forge usually..

-

JLP Blacksmith Teaching Center.

jlpservicesinc replied to jlpservicesinc's topic in Building, Designing a Shop

Thomas, way back in the day when I was smithing full time, I would do the same thing. Just call it a day since it was going to be unproductive anyhow. When I first started I would try to push thru the mojo but then after 10 or 20 attempts if finally sunk in to put the hammer down and walk away. I am a certified cave diver. I've been 1200ft back in a cave down in Florida.. It's amazing how the caves form and what else is amazing is how clear the water could be. One dive I could see the end of the cave after it opened up.. Was 750ft from where it opened up to the far wall. -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

The hatchaxe is wrought with 5160. I personally can't see making a tool out of a good working steel and then adding another good working steel to finish the results. ( I appreciate and understand wanting a certain hardness and going after it).. Job well done. So certainly not critiquing in anyway.. Was more curious vs anything. Mild steel or wrought iron yes, or Damascus yes from a design point. Just me though as I'm lazy. 4140 gets 53-59Hrc. with a fine grain. 4130 get 48Hrc.. For my own axes and tools I like a higher carbon content with a higher Hrc value 60-62Hrc I also don't use my cutting tools for prying. If I do chip the edge I understand it was me vs the tool so dress it back. Been years since I chipped an edge. Maybe 40 years and it was the middle of winter and didn't preheat the blade at all. All of my own personal tools (felling, limbing,) were designed with a pre shape.. (pre shape=about 30 sharpening) The pre shape accounts for wear or about 30 miss strikes on the ground.. The top edge on most axes is missing and this pre-shape accounts for this higher wear area. Also helps with leading edge cut in and fine work. First photo it's hard to see this leading "wear edge" 2nd photo is easy to see. also makes it easier to use when making kindling. David, thank you for checking in.. As for the school. Step forward each and every day. Just not leaps and bounds. I'm excited that everything done, while it might lead to another thing to do, it's also progress. Just gotta keep the eyes focused forwards like tunnel vision till the end. Hugh undertaking and just so many things to keep lined up. The elbow.. LOL.. Well I still have an arm and as long as I don't use it, it doesn't hurt. LOL.. I can push or pull about 20lbs now with the wrist straight.. Bend the wrist in use and this power drops to about 3lbs. But walking by the blacksmithing trailer yesterday I was feeling like lighting the forge and giving it a go. So that's encouraging. Ah, videos.. I highly doubt there will be any new videos or real "How to" content until the school is settled. Filming in the trailer is super tough and the video film quality is "meh".. Like most things I really have to have inspiration and desire.. Sadly the growth of the channel has been lackluster and so without feedback, the desire to produce in-depth content is lacking. I see time and time again that making videos to make videos and to entertain is more important.. I feel like once the school is done and having things setup will make filming easier and More proper.. Few realize all the videos were actually filmed in the demo trailer.. Eh, time will tell. I do owe a hinge making video to Zack P. and that is on the list.. -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

4140 you can heat treat just like spring steels.. It will respond favorably.. Way back yesteryear and today, I use water for quenching 4140 but people today are more conservative and worry about water cracking.. 4140 has and does hold a decent edge. Axes and hatchets are one of those items that the edge meets a certain sharpness desire and then pull it back just a little based after use depending on the wood being cut. Black locust here is a great test wood.. Still pulling fingernail curls up is a good sign it will last a tad bit longer in hardwoods like oak, ash, elm.. Did you see the video of me limbing some black locust and maple about a month ago with the hatchaxe? -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

David, Nice work. Why the added steel in the bit? 4140 does a decent job. Alex, I don't think you ever sleep. Your level of production impresses me every time you post a photo. For one person I don't see how you do it all. I would have to automate to even come close to what you accomplish.. Very impressive indeed. -

JLP Blacksmith Teaching Center.

jlpservicesinc replied to jlpservicesinc's topic in Building, Designing a Shop

In Ninjutsu there are so many variables in terms of training area, the use of cords and climbing, water skills, etc, etc. As an teacher it was made clear to all the students that if they felt uneasy about anything, they were not required to do it.. If anything even long term students felt anyway other than good about the activity they were to sit out. I've had students sit out at different times and could be just based on a feeling they had.. Even something they had done 100 or 10000 times before.. Everyone has off days and part of the training was to acknowledge this timeframe and to wait.. Of which most people are not trained to do. Of course there are times that waiting is not an option but then there is always a 1st or 2nd or 10million other ways to get the job done. But in training there is always the option to sit out.. My students have gone on to be SF, police, martial arts teachers, Yogi's.. Very proud of them all. All the people who have trained with me make it a point to tell me how our training has made their activities so much easier.. Cake walk type deals since they had exposure to nearly every situation and scenario they might encounter... -

JLP Blacksmith Teaching Center.

jlpservicesinc replied to jlpservicesinc's topic in Building, Designing a Shop

Sorry Steve, no offense offered. I get it. Liability today is crazy sketchy. Years back I talked with an insurance guy about the blacksmithing business, the martial arts school and the scuba business at that time. He said "Don't do anything". No people on property, no lessons about anything, and most of all don't sign anything".. Really he said it doesn't matter what one does or does not do, it's only if it looks like neglect or one knowing ahead of time (neglecgenice) and still moving forwards and something should happen. Then proof is solely the responsibility of owners/teachers/instructors that they were not negligent. Crazy. -

Where are you located? Is it a 660 with downdraft hood? The 660 was thier commercial line but the downdraft had to be special ordered. I have a 660 without down draft.

-

JLP Blacksmith Teaching Center.

jlpservicesinc replied to jlpservicesinc's topic in Building, Designing a Shop

I like that aspect.. And appreciate this fact. In a way, they will be accessible.. More accessible than direct buried which is what those splices were designed for. Not sure exactly what was ordered by my electrician buddy. Accessibility like all this stuff depends on the person interpreting the code on top of what they learned and personal experience. For the most part if you ask 5 electricians the same question you will get 5 different responses. Most electricians don't divulge information freely. It's probably just me.. I don't seem to get a straight answer from any one. There is usually a rather large song and dance or a complete shut down. Song and dance is defined as the reasons why something is not done, and then the complexity of which why they get paid, what they get paid. Step 1, step 2, step 3, etc, etc. etc. Before the work even starts. NEC 230.33 Spliced Conductors. Services conductors shall be permitted to be spliced or tapped in accordance with 110.14, 230.46, 300.5(E), 300.13 and 300.15.. 110.14 talks about the splice being compatible for same/same or CU/AL etc, etc. 110.14 (B) Splices Conductors shall be spliced or joined with splicing devices identified for the use or by brazing, welding or soldering with a fusible metal or alloy. Soldered splices shall first be spliced or joined so as to be mechanically or electrically secure without the solder and then be soldered. All splices and joints and the free ends of conductors shall be covered with an insulation equivalent to that of the conductors or with an identified insulation device. Wire connectors or splicing means installed on conductors for direct burial will be labeled for use. 240.46 Spliced and tapped conductors: Service entrance conductors shall be permitted to be spliced or tapped in accordance with 110.14, 300.5(b) etc, etc. Power distribution blocks, pressure connectors, and devices for splices and taps shall be listed. Power distribution blocks installed on services conductors shall be marked" suitable for use on the line side of the services equipment" or equivalent. Pressure connectors and devices for splices and taps installed on services conductors shall be parked "suitable for use on the line side of the services equipment" or equivalent. 300.5(e): (E) Splices and taps. Direct Buried conductors or cables shall be permitted to be spliced or tapped without the use of splice boxes, The splices or taps shall be made in accordance with 110.14(B) 300.13: Mechanical and Electrical continuity-conductors: (A) general: Conductors in a raceways shall be continuous between oulets, boxes, devices and so forth. There shall be no splice or tap within a raceway unless permitted my 300.15, 368.56(A), 376.56,378.56,384.56,386.56,388.56,390.56 300.15 Basically reads that each conductor or splice must have a box. 368 has to do with busways. 376. is metal wireways: 376.56 Splices, taps, and power distribution blocks: (A) Splices and taps. Splices and taps shall be permitted within a wreway, provided they are accessible. The conductors including splices and taps, shall not fill the wireway to more than 75% of it's area at that point. 378.Non metallic wireways. 378.56 Splices and taps: Splices and taps shall be permitted within a nonmetallic wireway, provided they are accessible. The conductors, including the splices and taps, shall not fill the nonmetallic wireway to more than 75% of it's area at that point. The rest of the codes from 384.56 etc just involve different types of wireways. 390 is under floor.. N/A So there it is.. Minimum standards of what should not be done.. 75%.. NO problem.. Space them out so the splices are staggered. Access?? Remove the non metallic raceway?? 388.56 I think is the one that is most appropriate. Surface Non metallic raceways" 388.56: Splices and taps" Splices and taps shall be permitted in Surface nonmetallic raceways having a cover capable of being opened in placed that is accessible after installation. The fill can not be more than 75% at that point. Spries and taps in surface nonmetallic raceways without covers capable of being opened in place shall be made only in boxes. All splices and taps shall be made my approved methods. -

Show me your anvil stands

jlpservicesinc replied to pkrankow's topic in Stands for Anvils, Swage Blocks, etc

Plenty heavy.. Thatall work a treat. -

Show me your anvil stands

jlpservicesinc replied to pkrankow's topic in Stands for Anvils, Swage Blocks, etc

Them is mighty nice stands. Will you put some pads on the bottom for working on softer terrain? What I should say is " larger pads"? perhaps removable. -

JLP Blacksmith Teaching Center.

jlpservicesinc replied to jlpservicesinc's topic in Building, Designing a Shop

-

JLP Blacksmith Teaching Center.

jlpservicesinc replied to jlpservicesinc's topic in Building, Designing a Shop

So the inspection went well. The electrical inspector said:" He couldn't have done any better himself". The inside bonding screws I was told need to be removed.. He pointed out that the cables at the pole were short, but everyone I have talked to said that National grid should connect them. Since then the National grid site manager has come and looked and he said, they are marginal. Not sure what can be done since it's such a long drop he said. They can't infringe on the cable nor telephone lines. I have since looked into compression splices.. My original wire length was correct but 2 of the lines were short by 12ft. 15ft of the 3rd line was cut off for installation into the meter socket. So technically I only need to buy 30ft of 500mcm copper.. After talking to my electrical buddy he suggested compression splices vs swage splices as well and so is the direction going in.. So 3 splices and 30ft of 500mcm should have it complete. -

Frazer's Corner of the Internet [photo heavy]

jlpservicesinc replied to Frazer's topic in Member Projects

Sure has been great watching you grow as a smith.. Super nice too that you take an interest in an aspect and then explore it. Most will take an interest in a facet and then let it pass by.. I have some pieces of wood I'd like to send for stabilizing.. Not ready on my end yet, but just wanted to throw that out there. -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

Chad your work has come a long ways since you first started visiting here.. Very nicely done. -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

X2, same here on my hand tools, chisels, punches, etc, etc. 4140 I will usually run 2x heat cycles on struck ends sometimes 1x still seems a little to hard. -

Nice one Yves.

- 9 replies

-

- coil spring

- tooling

-

(and 1 more)

Tagged with:

-

JLP Blacksmith Teaching Center.

jlpservicesinc replied to jlpservicesinc's topic in Building, Designing a Shop

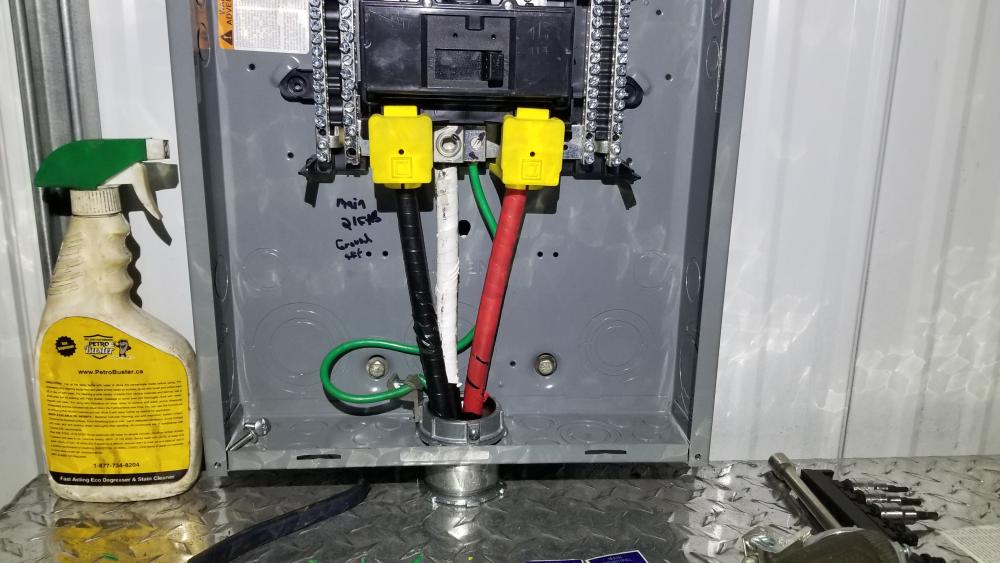

So the last Saturday my electrician buddy came over and inspected my work. the 3 things that needed to be done were the 2 bonding screws for the load centers to be installed.. ( my understanding was/is only the first disconnect required to be bonded everything after that need not be bonded) he explained that though the outside is technically the first disconnects the inside was the first load centers with accessible disconnect means. OK.. And the ground conductor needed to be in PVC conduit vs metal. I had planned on such contingencies so had the extra conductor inside the panel. The inspector was called and an appointment was setup for Thursday morning. -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

Alex the stand looks great. Looks like you also got a few years out of the last one. How old is the old one? -

Because of the long body.. You need to make the hold fast tight to the hole. it needs to be about 7/8" IIRC.. At least that is the size on my 460lbs Refflinghaus. there is a slight taper to the hole.. Make it with a heavier boss on top with a thin arm. The weight is used instead of the canting angle.

-

JLP Blacksmith Teaching Center.

jlpservicesinc replied to jlpservicesinc's topic in Building, Designing a Shop

Thomas, I am so sorry to hear you have been going thru all this health stuff over the last few years. Glad it was found for sure. -

JLP Blacksmith Teaching Center.

jlpservicesinc replied to jlpservicesinc's topic in Building, Designing a Shop

Ok, will do. Anything else? -

JLP Blacksmith Teaching Center.

jlpservicesinc replied to jlpservicesinc's topic in Building, Designing a Shop

Steve, straps on the conduit, You mean grounding bushings? (edit) never mind, you meant the hanger straps for the conduit. I had to bend it a little more to get that just right fit. The ground conductor and ground rods are below grade.. I have them exposed for inspection. I have not seen the conduit for grounds go down below ground level.. The ground conductor conduit has a grounding bushing on the end and will be pushed back against the building. I did some clean up.. Or should say some reorganizing inside both the metersocket/service disconnect and the wireway/load centers. I couldn't handle it little too cluttered and didn't like the way the cover fit on the disconnect. The wires were sticking out to far and pushing against the cover.