-

Posts

5,758 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by jlpservicesinc

-

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

David. I have double pickup tongs.. Was the 2nd set of tongs I made 47 yrs ago.. I used them rarely back then. What I use them for now is upsetting 2" stock and over when under 6" long. The hoop tongs (I believe you are calling lip) will be your best friend if you are doing hawks.. If you wanna get really special make the inside jaw rounded and the outside hollowed some.. You will get a lot of mileage out of the hoop tongs if your doing hawks.. Your skill set though is good enough you should have both. Always set your welds at the eye first. Your best bet is to do an old fashioned hawk.. The modern designs are more based on axes vs tomahawks.. Trade tomahawks were very thin and used the least amount of low quality steel they could.. Forged crudely and designed to only last about 1 yr since the steel was so lacking. Somewhere along the way in the last 8 yrs the designs have morphed between axes, Viking axes and now you see a lot of combination type deals. Start small.. the starting stock can be as small as 1/8"X 3/4".. No need to pull the socket out of the eye.. Bend it over the mandrel and weld it.. Drift back to size. Shaina.. Love, love, love the drawings.. Great seeing your layout and follow thru.. Great skill builder.. Thanks.. Thanks.. Been trying to bring about my artisticness with the wrought and patterns.. Lotta fun. Les, no reason why yours can't even look better than mine. Handle is finished.. split out with froe, aged cherry. Draw to size with draw knife. scrapped then sanded then steel wool. -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

Thanks Larry.. I've been having fun manipulating the wrought iron to create patterns.. -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

-

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

Rojo, that is some amazing work.. Super hard to get the corners to be sharp on the bottom.. How did the inside come out? Any cold shuts or folds? Das, super nice design.. Looks like you flattened the nose and eye sockets back in to gain the shadow and look of depth. past Saturday was NeB fall meet. I was able with assistance from young Mr Yaggy get the eye punched into the steeled wrought iron. No proper sized punch nor drift so made a proper drft on Sunday at the Sterling Fair demo.. I also started work on the fancy Tomahawk I was going to enter into the Northeast Blacksmiths Associations Fall meet at Ashokan NY.. Stacked wrought iron and drawn against the weak side of the welds. Sadly over the past weekend I came down with Covid and have been incapacitated since Monday. I'm feeling about 75% today thursday with only a slight sore throat.. The hammer will need to be drifted and upset more around the eye.. Drift is 3/4" sq back to back and 3/8" X 1" upset, stacked and welded onto the side. by the way.. I do not like doing large forge welding jobs in public like fairs.. At blacksmithing demos or events its a free for all.. -

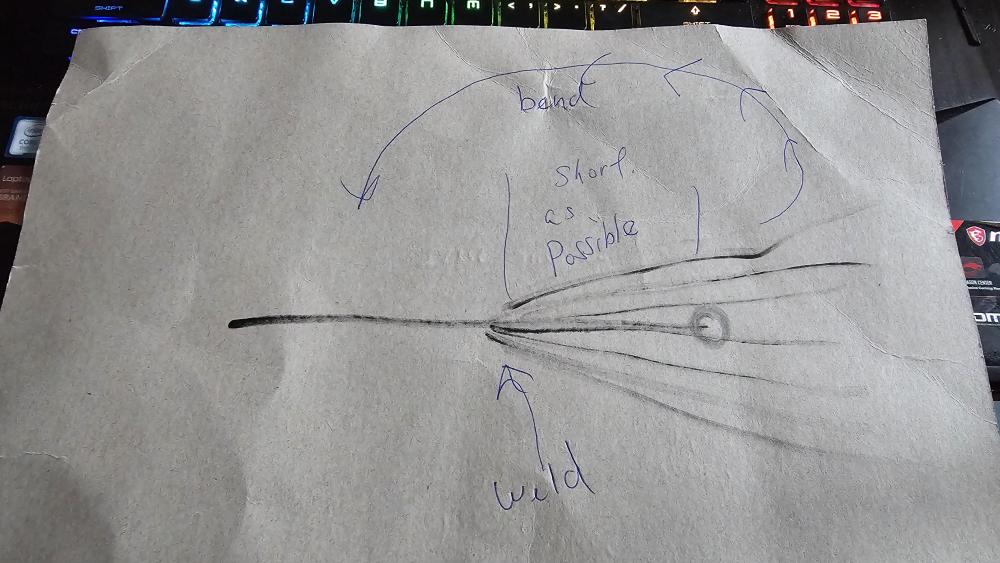

If you use 1/4" you will have a terrible time bending them once welded. On projects of this magnitude it's best to follow the recipe as closely as possible.. Once you get comfortable making additions to a recipe changes can add flavor and depth.. If all you have is 1/4" you could forge the bars to size.. You can use square vs round.. The same principles apply for any multi bar twisted handle.. the count is based on shaft material circumference. If you flatten the ends you can change the bar count but will also increase the difficulty in holding them. Since the weld is on the inside you have to scarft the ends of the rods before welding if you want it to be finished nicely.. I left the ends less tapered so people could see what was being done.. Ideally everything should be smoothed and blended well. Scarf both ends to the rods before welding..

-

The single inverted twist is easy.. Just run the bars along the finial and weld them.. Then pull them back gracefully back over and reweld. Then twist.. It's good for people to use their forging brain power to help establish complex thought processes.. I highly recommend taking a drawing class or just doodling.. There is a great tablet app called Concepts.. Has lessons and everything. The double inverted twist I did as a joke or complex puzzle for other smiths to oogle over and speculate on how it was done. NO one has figured it out. So, that one will go to my grave unless someone does figure it out.. That and the hard way flat basket twist.. Of course, if the demand is high enough once the school is open I'll show it. But that's a ways off. All the videos I've produced have been designed to be watched 3-5 times.. Watch it Once or twice then go and try it a time or 2 or until one gets stuck.. Then watch it again. By the 3rd watching more or less the skills should be on the way to being understood and the little nuances should be seen. Then the videos will make more sense as does the process. All the footage from those early examples are missing. I believe it was on my NAS that crashed. Put the finial on first.

-

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

Still looks like coral though vs hive.. The depth is lacking in between.. I'd suggest drawing it before trying to apply it to the metal. It's the same eye/hand thing.. -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

Frosty, Handle blanks or staves are the reason for the froe.. The wood we have here is so knotty that is does not take kindly to a froe. But with that being said, I drive a froe in and then using the second one insert it into the gap created and leverage them away from each other. Works a treat.. Since dislocating my elbow i cannot push on anything. I can pull but can't really push.. So using 2 froes will suit me well. I can swing a hammer like a mad dog but any kind of pushing on an object including a rasp is painful. -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

Frosty, it works by holding the handle up and driving the edge of the froe into the.... Just kidding. worked well when I split out the handle stave for my old forging hammer. Have not tried it with the new handle. I like to use froes in pairs on knotty wood. Have a second one in the works. Les, thanks for the feedback on the video. Glad it's getting used. very Nice hawk. -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

-

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

Billy the smithing community though worldwide is still a fairly small environment. Often times meeting and seeing the same people over and over again though from miles away via social media and events. Also what I consider to be top-tier smiths are highly accessible so always make a point to introduce myself and let them know I appreciate what they made or shared. So many talented people out there willing to share. Smithing unites us all. -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

Savlaka I love it. The design is retro.. very nice. -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

Ghost town, looks good. That will work wonderfully. Jhcc, holding out for the climatic build. I love it. -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

Looks like a great time.. Who was the smith demonstrating? -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

Those are the days we learn the most from. -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

David, it's the reason why flat basket twist handles are not done.. The flat stock turns to bend the easy way vs the hardway. Your results would be the norm.. So a very good trial.. Does it feel good in your hand? I often find the upright sides to be not so comfortable. By the way.. I love your pokey part.. Great design. So, yesterday I wanted to put a new handle on my 45yr old 2.5lbs Truevalue cross peen hammer. I noticed that every tool I used were ones I have made for processing the wood into staves and then into handles. This hammer was my go to hammer for nearly all my career and then some.. Well until I made my hammers too. So, I make a hammer, to make an axe, to make a froe, to make a draw knife to make a handle.. -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

Ah, see the flat bars are not flat.. Great first try. Those days happen for sure.. Great first try for sure. -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

Billybones.. I think what you have done is good.. With this said I often wonder why people pick modern hardware to copy.. For 15-20.00 one can go and buy that very hardware all painted and ready to install. Since blacksmithing and forging are what blacksmithing is about.. More traditional design would seem to warrant making. The reasons are this.. The traditional designs were perfected over a very long time to their best useable form. The modern items are not designed to last nor really offer any durability. Coming from a hardware background myself jades me some as seeing the real performance from old hardware is amazing. If you can forge a leaf then one can forge a cusp.. There are videos on my YT channel showing the whole process. If I can do it, anybody can do it. I learned how on my own.. Now with education and videos no one has to go it alone. For just a few more minutes of time that flat bar could be a contour and figured thumblatch or handle. -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

Nice job. I'm a farrier so hold my tools in accordance which is backwards to how regular people hold them. I like to have a scoop on the hoof end like a long spoon. Ideally the bend of the shoe should rest in your palm and the scoop part is facing away or pointing away from you.. A wrist flick away or down in the commissures of the frog will clean out one side and same on the other. This one is pointed toward the person.. You can see the scoop in the blade. it makes a world of difference. Started doing the spoon blade many years ago and works better then any other design. I don't have any photos handy of the blade facing the way I like.. But it's opposite of this one. -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

I do not have any videos on the channel. After showing one of the videos to my buddy, he said youtube would be a waste of time and a DVD or bluray would be the way.. So, I shelved the videos on forging most of these. here are some sample flat twists, the legit one is photo 3, I scrapped the first 2, and then an assortment. If you do try a flat twist hardway handle be sure and show the photos.. You are in for a glorious ride.. Billybones.. Nice job.. Wow. Congrats.. Commendable work.. -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

Frosty finding a commercially made loop knife here in the 90's was tough.. You could order them, but no one carried them as stock items. They made loop knives which were much smaller for doing abscess removal.. Different items though. This loop knife is standard sized for trimming feet so it's loop would be oversized compared to convention.. I'm not sure what was used in other parts of the world but from everything I have seen or read in my early career the loop knife was a special item for abscess removal.. Of interest they also had special drills used based on spoon bits.. I call them cherry pitters as they resemble that type of spoon bit. Anyhow, be nice if you could find an old photo or draw a picture with the scale of size to see the difference. I'm not saying shoeing is not required.. But I am saying shoeing is required because of.. The because of was even pointed out in your comment about Imbalance.. "needed a special shoe because it was crooked by the farrier".. LOL.. Yes.. It's all semantics and after 35 years I see the same things all the time.. Barefoot hoof care is a totally different science applied totally differently. I use some of the same tools but understanding the hoof and growth takes on a whole other worldliness. I've given up explaining the differences.. It's got to be seen in action to see the differences.. Like anything there is unlimited possibilities to forging an S hook.. Yet some are better than others.. It's a matter of the person seeing the difference for themselves before they even try to understand why it works or is better. -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

David nice work. Flat twist handles are super tough going at them hardway bend . You are the only other person I know that's done it. Kudos. Coming from the welding trades. I hope he's a huge guy or the photos are not showing a true scale of size. While called chipping hammers, they are really more used like scratching hammers. I prefer light and small. Beautiful work just the same. -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

IFCW, Truth!!!!!!! -

660 downdraft Buffalo forge with a # 200 blower.

jlpservicesinc replied to Miami 13's topic in Solid Fuel Forges

Twistedwillow, You have some pretty nice stuff.. I've seen your stash of items and if you were closer I'd be over every other week to pilfer and riffle thru your goodness.. You have some pretty amazing items.. I have no money in the pot either.. Just feel sorry for the old equipment.. The stories they could tell.. IFCW me too.. Now though I get plum tired and sit down.. LOL..