Exo313

Members-

Posts

224 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Exo313

-

I completely agree. To be honest, that's always come across as a power trip; the "old master" that can size you up by the way you walk into the room has always seemed like so much processed bull feed. I'm willing to concede that it might be possible, after a few minutes of one-on-one forging, to assess a level of natural inclination. But "never gonna go pro" is a pretty harsh assessment for a pretty broad skillset. Not to mention, the student's local market may not require high levels of finish. Rustic may be the ticket, and a smith who can deliver "good enough" for his local market might do very well ..

-

I'm guessing most smiths these days aren't production nail makers. There are historical examples of dedicated tooling. I like this idea, things that stay put are a +1 in my book.

-

Um. I'm sure you're not meaning using propane as a shielding gas...? Kaboom. Unless there is a special new inert propane nobody's told me about? GMAW and GTAW don't "use" propane. Preheating often uses propane!

- 16 replies

-

You might say you were in the jaws of envy.

-

Jim, Thanks for the feedback! I will definitely keep them in mind; their website was super informative.

-

Was looking at India presses and noticed one manufacturer using mild steel for their screws. Rationale? I'm thinking liability. So it wears out? At least it's not gonna explode? Cheaper for company to produce too, no doubt. Thoughts? Or is this a perfectly normal way of making these and I'm just uninitiated?

-

Aha. This explains my confusion perfectly. I should have expected the trade standard of "there is no standard"! Thanks guys. Now, if anyone has one they want to trade for a case of beer, just name the place and I'll start drivin'. I hear they're awful dust collectors and I'd be happy to unburden you!

-

Maybe I missed it. Can anyone explain what the press numbers mean?

-

I'm not certain. Does the cracking look like it starts near the places that look welded? If so it's possible that's the source of the cracks. And as far as will they spread? Maybe. Maybe not. You might get a full life or three out of it with no issues. Or maybe they'll get worse. I don't think anyone can give you a definitive answer due to the nature of cracks behaving unpredictably. Watch for spreading but use as normal is what I'd do.

-

-

If you could post a picture of your setup, we all love photos here. And you'll probably get some pointers as to what to improve or ways you can use existing things differently. As far as a better lump of steel, anything heavy and with a face bigger than the face of your hammer will work. Hardened steel works better than mild.

-

The issue is wearing down a hardened plate of unknown thickness. The cracks weren't caused by sanding. I'd have left it at a knotted wire wheel for cleaning up if it were me. But the cracks might be a sign of a bad repair in a past life, so at least you've uncovered them.

-

I think that's a bit dramatic.

-

Frosty clearly hasn't seen this yet. Maybe it's for the best. Against him in a pun battle I'd probably lose my chert. Metamorphically speaking.

-

I don't think I'd like to armwrestle any of them. Maybe the kid in the back, but with the hours of charcoal carrying he was probably doing I'm not sure about that either..

-

Love it. I need a print of that.

-

I can't speak to the design duration issue specifically. But I find a human tendency to hold "hostage" the effective deployment of their skills or knowledge in an effort to exert control. What is organized striking, after all? Really what you have there, rockstar, is a mini strike situation. No different than a walkout or a production slowdown.

-

So a situation where taking it for granite would be a good thing!

-

Question about Powder Metallurgy

Exo313 replied to Meridianfrost's topic in Blacksmithing, General Discussion

Asking good questions is a learned skill. And specifics are important. Non-specific questions lead to more questions, which is what happened here. OP could have taken another approach and simply answered the questions and problems being posed with the original post. Instead, offense was taken. "Knives" and "tools" alone are huge categories. It's why a specific project helps. e.g. "I'm making a skinning knife, and I want it to hold an edge under field conditions, but the blade needs to hold up generally under rough use so edge retention isn't the only factor I'm keeping in mind." Knives plus tools plus powdered metallurgy equals confusion. OP started on the right track by clarifying desired characteristics. Then it all fell apart. It's frustrating, no doubt, to hear that you still need to dial in the specifics. But I'm restating what's already been said. -

http://www.bioenergylists.org/stovesdoc/Boyt/pyrolysis/pyrolysis.html

-

Frosty, you made me laugh out loud. Not because you were being funny, but because due to your comments l was able to see the humor in my own actions. You're dead right. I'm without a workspace right now so I'm armchairing at the moment. I'd done just enough tinkering at the in-laws to get bitten by the bug, but that situation is unavailable now. So I spend a lot of time reading and thinking about smithing. Or overthinking..

-

So if I was told in a pm over kijiji that asking was $300 CAD... This is what I'm talking about exactly.

-

I think there's a cynicism that comes with exposure to strangers in short bursts. I was in retail for over ten years before I decided to go work in metal fabrication. I'm still amazed at how pompous or thick people can -seem- when your only interaction with them lasts seconds to minutes. It's cutting through the initial aloofness and making a human connection that takes a good performer. The ones that are most difficult were my favorite challenges when I was in retail. They're people underneath the attitudes. It's getting them to engage that's the trick. Some will always walk away. But the best is the ones that start out as opponents and get won over.

-

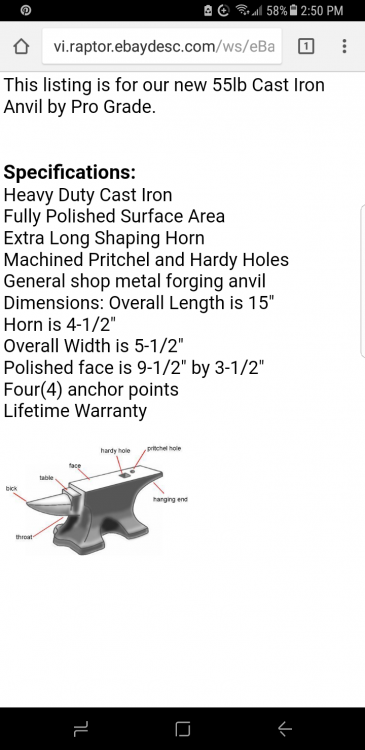

It's not just old anvils. Taken from fleabay. I've been hanging my anvils up from the wrong end all this time...

-

I think the trench vs. bowl is what was messing me up.