Michael Cochran

Members-

Posts

1,889 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Michael Cochran

-

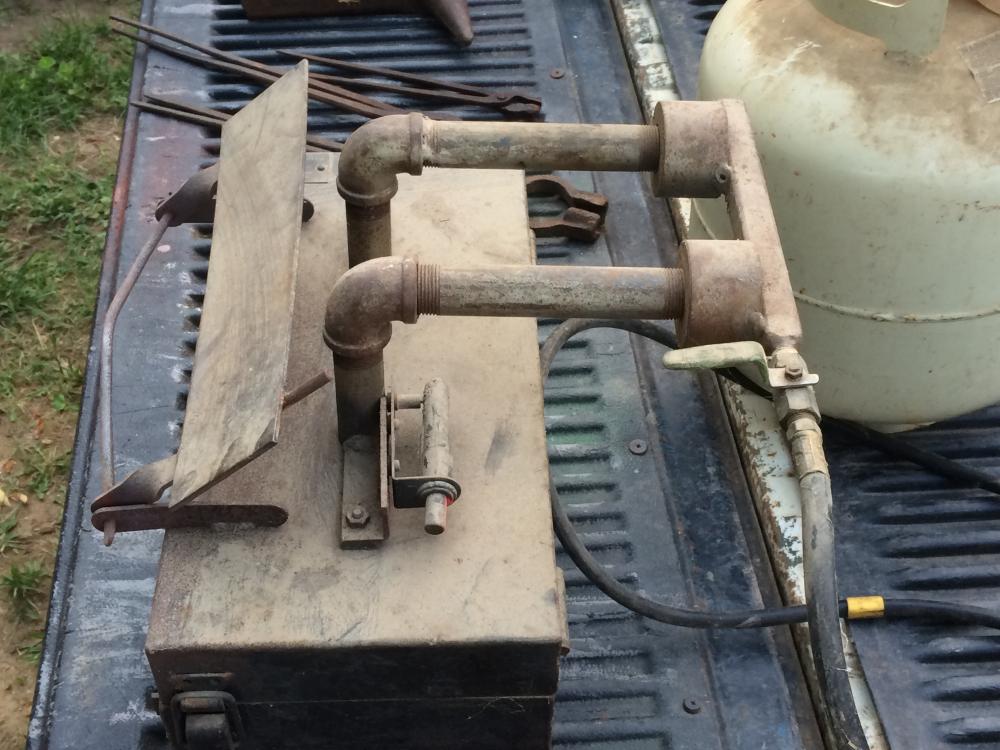

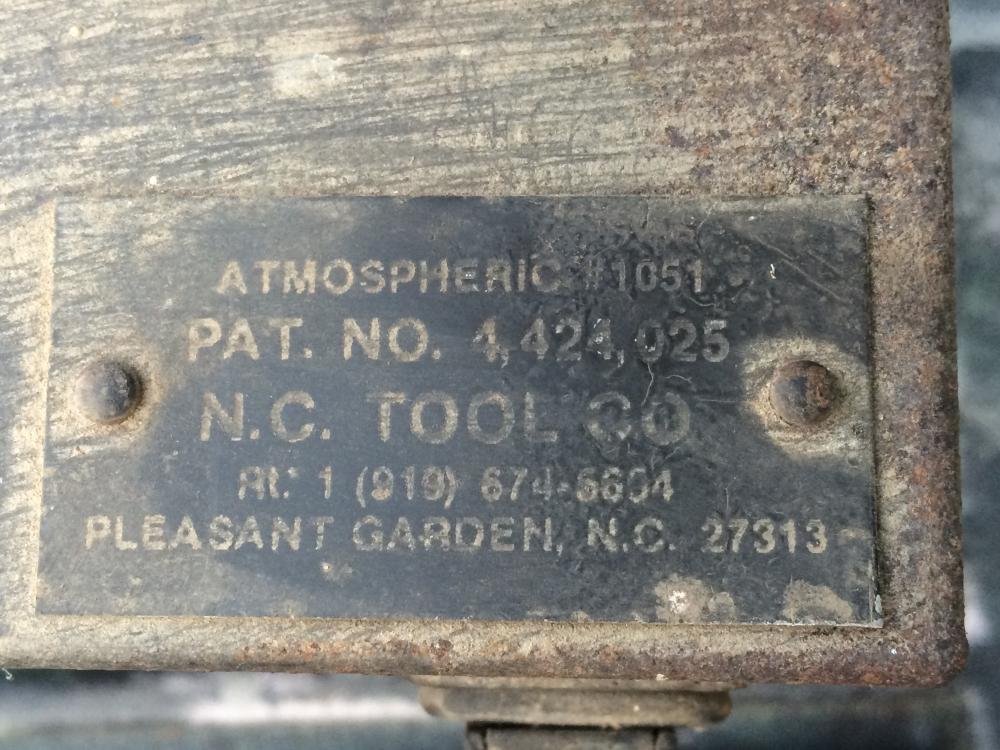

First off let me say when I got up I didn't feel like gettin out of bed much less goin to work but I went anyway. As a result of gettin out of bed and goin to work I found a 1939 Mercury head dime and was given a load of tile worth a couple hundred $. Then my lovely wife told me I could pay off early the gas forge I've been making payments on. When I go to pick up my new forge the woman still had some of the tools her late husband used while shoeing horses. I looked through and picked up 3 tongs and and hot cut hardie and what looks like a broken cast iron stake anvil. I was sworn to secrecy of the price I paid for it all so I'll say it was under $500 and leave it there. I have included pictures and would like any input anyone might have about any of these new wonderful tools. The tongs are 20 1/2 inches long and looks to comfortably hold up to 2 inches, 18 long holding 1, and 12 long holding 1/2. The hot cut is about 3 inches tall and 1 1/2 inches square with a 3/4 inch shank. The anvil ins about 10 inches tall with a 4 inch horn, it is about 4 square inches on the upright. The forge is a nctool atmospheric #1051 and looks to have a 12x6x21/2 fire chamber. The regulator that came with it is set at 10psi. I can't wait to fire it up

-

Trouble with Charcol retort

Michael Cochran replied to compboy's topic in Solid Fuels: Coal, Coke, Charcoal, Wood, etc

I've got you now, Frosty. Your input is greatly appreciated, as always. Mike -

Trouble with Charcol retort

Michael Cochran replied to compboy's topic in Solid Fuels: Coal, Coke, Charcoal, Wood, etc

I've done a little more browsing around looking at retorts (4th time since I started smithing) and found this page. http://islandblacksmith.ca/2012/03/charcoal-retort-v-2-0/ Frosty, i think what you're describing is something similar to what he has here isnt it? Next to last image shows a cut away. -

Trouble with Charcol retort

Michael Cochran replied to compboy's topic in Solid Fuels: Coal, Coke, Charcoal, Wood, etc

Frosty, if you have time could you show a sketch of what you're describing. I think I understand but I'm one of those people I do better with visuals. I'm gonna reread what you said though since I've been thinking about trying to build one of these. Charles, I've never heard of the setup you describe but it sounds like a good way to cook charcoal and heat the shop in the winter. :) -

Planning on attending my first meeting

Michael Cochran replied to Michael Cochran's topic in Alabama Forge Council

I was plannin on trying to make it this month but things came up that prevented it. Hopefully next month I'll be able. You can add my email to the list too, nightwolf1284@gmail.com -

Makeshift stump anvil

Michael Cochran replied to clrobert60's topic in Anvils, Swage Blocks, and Mandrels

You can find rail on eBay all the time. Not the best way to get it but that's an option. -

local (AK, ANCHORAGE) steel

Michael Cochran replied to Steve Anderson's topic in Alaska Blacksmith Association

I know this isn't an answer to your question but look up njsteelbaron.com the guy that owns it (Aldo) is on here and I've bought from him. I've heard several people here and on another forum dedicated to bladesmithing have used his steel, never have I seen any complaints. -

ball hitch tools

Michael Cochran replied to Ethan the blacksmith's topic in Tools, general discussion

They definitely look good. I'm gonna have to give it a go one day. -

ball hitch tools

Michael Cochran replied to Ethan the blacksmith's topic in Tools, general discussion

Are you plannin on rounding off the edges a little? -

round or flat hammer face to hit punches?

Michael Cochran replied to Ethan the blacksmith's topic in Hand Hammers

Because you don't wanna mess up the pretty and smooth dressing. You could mark up the hammer face and then either leave marks in your forgings or have to redress it again before you use it. -

How big are you planning on building it? I know lowes and homedepot around here sell new clean metal paint cans for pretty cheap. It'll be quite small but with a good burner and properly insulated it'll make a dandy little gas forge. You can even stack them end to end and make it longer if need be. I second Wayne Coe for insulation and lining.

- 7 replies

-

- ceramic fiber blanket

- materials

- (and 3 more)

-

Planning on attending my first meeting

Michael Cochran replied to Michael Cochran's topic in Alabama Forge Council

Jwilson, where about in hayden? I'm actually in nectar just around from the strawberries and pumpkins. id like to go to Tannehill one time for an iron pour but haven't made it yet. -

An aluminum drink camp will melt in a campfire because of how thin it is. I think if you had some steel that thin it would more easily melt too. I have melted/burned nails in fires while cleaning up construction debris so I don't thinks it's that hard to achieve.

-

The way you described it would be the first way I tried myself. I don't know if 'hard' it really the right word, maybe 'time consuming' would be better.

-

Planning on attending my first meeting

Michael Cochran replied to Michael Cochran's topic in Alabama Forge Council

I didn't even think about glasses and gloves. I'll have to stop by the store and get another pair of glasses. I've got two pairs of leather gloves in my shop but big suprise I can only find two left hands lol. Guess I should get me another pair of those too. -

If you're gonna make mini hammers you'll have to make a forge too

-

Planning on attending my first meeting

Michael Cochran replied to Michael Cochran's topic in Alabama Forge Council

Thanks for the reply, Spanky. When you go what kinds of things do you take with you? -

That's pretty cool. Just out of curiosity how much did it end up weighing?

-

Looks somewhat like a brick/stone masons hammer.

-

There is a local AFC group that meets about 25ish miles from me and I plan to attend a meeting in the next couple months. Since this is going to be my first time I have no idea what kinds of things I should bring. I would greatly appreciate any input you guys could give me. I do plan on calling the forge master listed on the AFC site but wanted some input from more experience people. If it makes a difference, I'm going to the one in Cullman, AL. If anyone's on here that goes feel free to give me a shout here so I know whom to look for when I show up. Things I plan on carrying including a new pen and a notepad so I can take notes as well as my camera (just in case). Seeing as how I'm not a member yet I don't expect to get any forge time but as I said, I've never been to one of these functions so I have no idea what to expect. Thanks in advance.

-

Beginner steel stock

Michael Cochran replied to Shamus Blargostadt's topic in Blacksmithing, General Discussion

Thomas, do you have any pictures. Not of your legs but of the dragon? -

Gotcha, I understand now.

-

May I ask what kind of forge you were using before you decided to go to a break drum? I've only been at this for a few years and going to a drum would be like going backwards in my opinion.

-

Swede, I really hope I don't sound like I'm ignoring any helpful advice. I can assure you I'm taking notes, mentally of course, so that I can better my set up. This whole project come about because Charles suggested I could use a piece off the bottom of my rail anvil I cut off when I mounted it upright (pictures are in my introduction post). I agree there are loads of useful info shared with me and whomever else is reading along with me and hope to one day be afforded the opportunity to pay it forward myself. Charles, I'm glad you reminded me of dog head hammers. It reminded me I have another (much smaller) piece of rail a guy gave me a few months ago. It would be ideal for making a small crosspein. I'll see how big it is tomorrow after work but off the top of my head I'd say it's about 2 1/2" total height. I'll have to figure out a drift and a punch before I start forging a hammer. Of course as you pointed out earlier I should be able to make them from other pieces of that smaller rail. I have a spud wrench (pictured with my hammers in my intro thread) that I though about cutting the crescent wrench head off and reforging it into a drift for smaller hammers. Thanks again for your help so far.

-

I didn't even look where it came from just did a quick google image search for something like what I'm doing. I'm thinking about cutting out the web and sitting the plate on top of the web and flange. I've seen pictures of pexto plates and that's kinda the direction I was thinking would be easiest. I'm pretty sure that's what you are referring to but I'm going back to searchin just to be sure. by the way I've spent the last couple hours reading up on rail stock projects, thanks for helping me realize there's far more use in them than I even had a clue. Photo and post removed as requested