-

Posts

1,056 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Gergely

-

What did you do in the shop today?

Gergely replied to Mark Ling's topic in Blacksmithing, General Discussion

Thank you, Mark! I cannot complain grinding is not my favorite thing... The guard was a piece of scrap 20x10m flat stock. Plain MS. Textured with the same hammer used on the "curly bark" candle holders. The customer saw those on my FB page and told me he likes them. Also he asked would it be possible to texture the blade surface with the same pattern. That was a no-no blade heat treated already and all plus I think edged tools don't supposed to have that sort of deep texture in them. - Long story short I made the guard with this surface, and he liked it very much. Win-win. Bests: Gergely -

What did you do in the shop today?

Gergely replied to Mark Ling's topic in Blacksmithing, General Discussion

Finished this comission knife and handed it to the customer. (Pfuh, right on time... was a bit tight schedule.) I call this the Brutality Dagger it's a nice little beast. Overall length is around 13", blade length: 8", width: 2,5", max thickness: 1/4". It weighs 890g / ~2 lbs. The handle is composed of brass, hide, black walnut and copper. All upcycled materials. (And the customer demanded the surface style as it seems. No grinding except on the last 3mm of the edge. And heavily hammered texture. Was fun ) Bests: Gergely -

Ideas for putting a finish on multiple small items?

Gergely replied to Derek Melton's topic in Finishes for Metal

I'm sorry, Thomas, you mean the picture I posted or something else? -

Ideas for putting a finish on multiple small items?

Gergely replied to Derek Melton's topic in Finishes for Metal

-

Cool! Way to go on the bus! Nevermind the small details, you've become a star now Bests: Gergely

-

Nazel 4b finally made it.

Gergely replied to DanielC's topic in Power Hammers, Treadle Hammers, Olivers

Yum! High ceiling it is! And what Beaver said. Bests: Gergely -

Show me your Bottle Openers!

Gergely replied to Arbalist's topic in Blacksmithing, General Discussion

Nice first pieces! I like the bottom one. Keep up the good work! Bests: Gergely -

What did you do in the shop today?

Gergely replied to Mark Ling's topic in Blacksmithing, General Discussion

Dear Jim and All, I have pretty much the same tools for the task - weird, huh? Only the ring part is applied to the bottom die of the power hammer. So it sits on a plate. The upper part is a plain cylinder, because my original tool was too big dia. Today I did my demo allright - no problems. But before that I managed to struck out six more tea light holders. (Not sold any one of them, it's the end of the month...) Bests: Gergely -

Nazel 4b finally made it.

Gergely replied to DanielC's topic in Power Hammers, Treadle Hammers, Olivers

I saw this hammer on the FB Power hammer page, didn't I? I liked it very much then, but I must tell you, I like it even better when I see it here in the family Great, great hammer! good luck with it. Wanna tell us what do you plan to use it for? I'm guessing not for "the lucky horseshoe" making... Bests: Gergely -

What did you do in the shop today?

Gergely replied to Mark Ling's topic in Blacksmithing, General Discussion

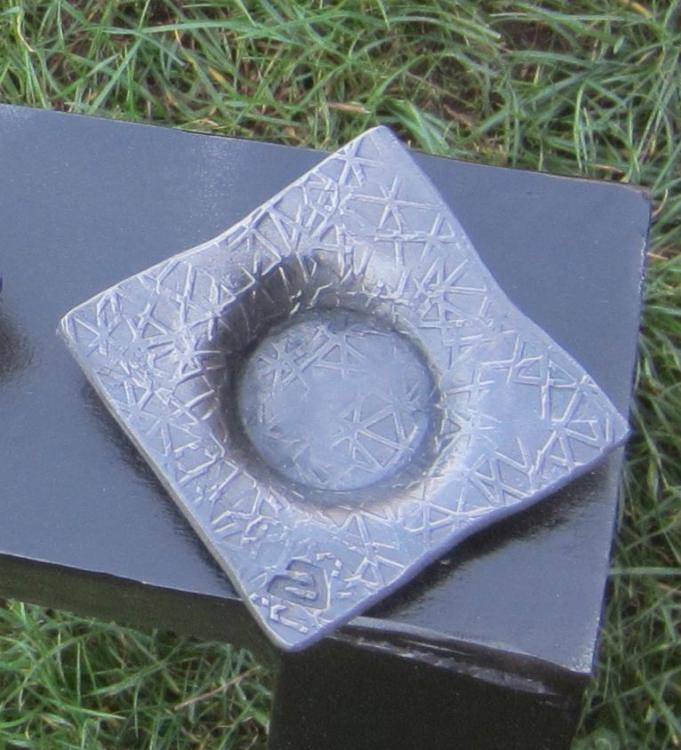

Tooling tested, I'm pretty happy with it, although I had to change the upper part of the tool. The result comes in two heats: 1. Texturing and hitting the logo in. 2. Sinking the hole under the power hammer. Surface cleaning and carnauba finish applied. Want to try this with different textures. Bests: Gergely -

What did you do in the shop today?

Gergely replied to Mark Ling's topic in Blacksmithing, General Discussion

Thank you Guys and Gals for the nice words and for the help naming that thing The hand is all right, thank God, it's not the best, but hammering doesn't cause any pain. And overall it heals quickly. Yesterday after resting the whole morning I quickly hammered out 40 half done S-hooks for the kids to finish today at the demo. And a new set of PH tooling was made for tea light holder making. Today I'm testing it. Daswulf: for the weight of the stand - my mobile anvil stand has very sturdy construction (60x40mm heavy wall tubing and 3/4" plate) and it still weighs half of the stump I used to carry to demos. The stump was ~50kg/110lbs, the stand is around 25kg. Bests: Gergely -

What did you do in the shop today?

Gergely replied to Mark Ling's topic in Blacksmithing, General Discussion

Thank you, Guys, for the nice words! My original idea was the incense holder, I just thought it wouldn't be that popular around here. (But I'll give it a shot anyway from thinner stock.) Language related question: curly bark sounds amazing for identifying it, but I actually wanted to picture some pine shavings that curl at the thin end. Do you have any word in English for the thicker pieces of shavings? And as for today shop work: proceed with some knives, but the bigger half of the day went to restoring tractor parts for my father-in-law. I badly damaged my hammer hand with a piece of wood which was struck by my brother-in-law with a sledge. The wood kicked back and injured the hand part where the thumb gets its strength. (Can't find better words, sorry. The lowest region of the thumb.) No wound but the inner tissues suffered nicely. I really hope I can hold a hammer tomorrow because at Friday I have demo to do... Bests: Gergely -

What did you do in the shop today?

Gergely replied to Mark Ling's topic in Blacksmithing, General Discussion

Got done a new design for candle holders. (At least I think it's new - please, if you've seen this shape before, let me know!) Bests: Gergely -

What did you do in the shop today?

Gergely replied to Mark Ling's topic in Blacksmithing, General Discussion

Working on two big knives. Blade length is 8", width 2,5". Spring steel (56Si7). Also made earlier a karambit from a Trabant leafspring - "Trabambit". went with the folded loop instead of punching it. Bests: Gergely -

This 4lbs sledge head followed me homne from the local scrapyard. How a Mexican hammer wandered here? I guess it's the wonders of globalization. Bests: Gergely

-

Hi lyuv, - what alloy did you use? common structural mild steel, or something else? - did you use borax or any flux? - did you somehow fix the two plate faces together so they stick together while in the fire? - have you welded smaller pieces (ie. rods) together with success and then tried this bigger and more difficult thing? I'm not sure about the size of the workpiece. Is it around 4" long and 2" wide. If so you need a quite effective fire to take it to an even welding heat (but not burn it). Bests: Gergely

-

What did you do in the shop today?

Gergely replied to Mark Ling's topic in Blacksmithing, General Discussion

Some new tooling for the PH. Bearing balls and rollers and two texturing tool in the style of beammeupscotty. (The biggest ball is 20mm/3/4" dia) Bests Gergely -

Minimum effective time to spend at the forge

Gergely replied to Meadowgrove's topic in Blacksmithing, General Discussion

I think Vaughn hit the nail right in the head. My experience shows that if you want to learn something in this trade it's best to start and make a 100 of it. And as for the time: as a beginner I scheduled 3 hours of workshop time at once. (Now it has changed into half to 10 hours as the circumstances dictate ) Bests: Gergely -

Hi MG, It's very useful to have 10mm plate around in the shop. Maybe not for a portable hole though. (Unless you weld together 2-3 pieces.) But you can build a guillotine tool. I think 10mm is enough for the structural wall thickness. You can find some 10-12mm thick leafsprings for dies, and as soon as you get the sizes of the die stock you can start the build... (I think you also can buy new springsteel, most likely 56Si7 as flat stock. That way once you have the first set of dies and built the frame around them you can buy exactly as much steel as you need. That's the time when new stock is cheaper then scrap ) Of course this is just one way to go, that plate is very good for other stuff, too. Bests: Gergely

-

What can you make from a spanner?

Gergely replied to ausfire's topic in Blacksmithing, General Discussion

Those cats are excellent, Aus! Thank you for sharing! Bests: Gergely -

All the bests to you! Congratulation! Gergely

-

Did a minor clean up job on a cast iron relief for a friend. As a thank you I was gifted a 5lbs/2,5kg piece of bronze. Its dia and size is perfect for a big soft hammer. I give it a go, just grinding it a bit and drilling hole for the shaft. Bests: Gergely

-

What did you do in the shop today?

Gergely replied to Mark Ling's topic in Blacksmithing, General Discussion

Nice work, Mark. Very nicely textured hanger. And I like the ball peen, too. Hopefully I get my half of the job done in this month Bests: Gergely -

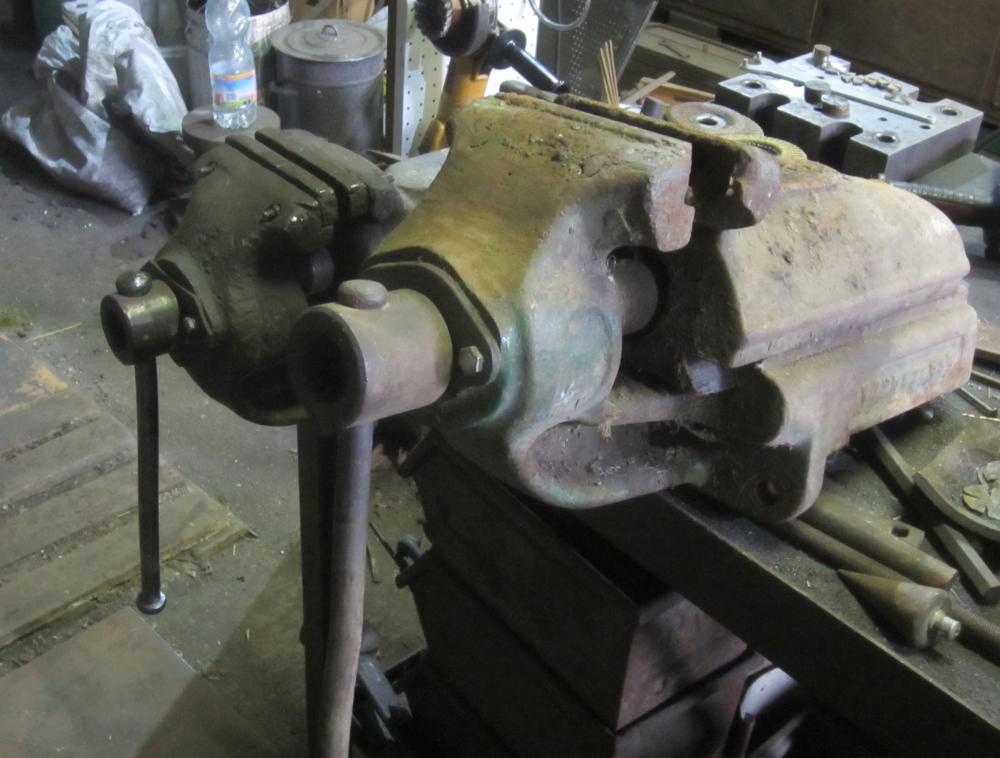

My car drove me to the scrapyard, I really not intended to go there While I was there I thought it worth a look around. I need nothing anyways so only a quick screening... Well, almost like that... I came out with 240 lbs/110kg scrap steel and 114lbs/52kg machinist vise. The vise is the big brother of my actual heavy duty machinist vise - and it is taking its place when the jaws are restored. I was very happy to find these ball shaped items, as I need some more texturing tools for the PH and couldn't find any big sphere shapes. The biggest is around 4" dia. Bests: Gergely

-

I like it very much! Very elegant. Bests: Gergely