-

Posts

1,056 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Gergely

-

Industrial Ajax Spring hammer HP?

Gergely replied to Krush's topic in Power Hammers, Treadle Hammers, Olivers

Sounds good. Both the rpm and the being busy part Bests and patience: Gergely -

What did you do in the shop today?

Gergely replied to Mark Ling's topic in Blacksmithing, General Discussion

Thank you, Guys! I did give it some thought The first two goes to the grandmas of our children. Then if I can somehow fasten the making procedure I try to sell a couple. I really like the Cobra, too! Real cool shape! Bests: Gergely -

What did you do in the shop today?

Gergely replied to Mark Ling's topic in Blacksmithing, General Discussion

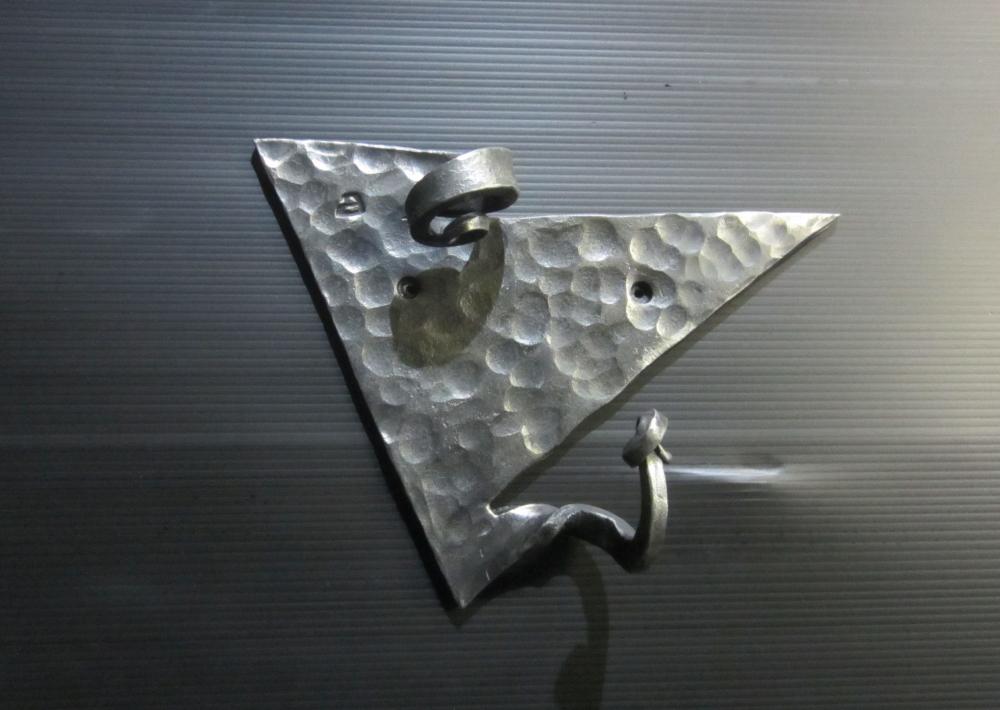

Wow, that's nice drilling exercise! Lately I've been playing around with picture frame ideas. This came out of it (the frame, not the baby!) Angle iron starting stock for the two parts of the frame, and 10x5mm MS for the small parts. The leg is fixed, works in both vertical and horizontal positions. Bests: Gergely -

What did you do in the shop today?

Gergely replied to Mark Ling's topic in Blacksmithing, General Discussion

Nice feathers! Keep them coming! Bests: Gergely -

Well, I'm not a conservative on the anvil subject, but I can't consider this piece of art as an anvil. No fat at all under the face. Definately not understand the square pipe part. Maybe a rough dog sculpture... But it still needs ears and the tail is kind of misplaced. As far as the question you asked: when there is no ability for rebound I think the anvil concept is lost. Bests: Gergely

-

John, that story made my day. Sometimes it just makes you feel good hearing about other's "not-best-day". Having one myself, this really helped today. Bests: Gergely

-

Yeah, in the new age the best flux has been the Nazgul dust. I still have a little from my great grandpa. It's the only way I can forge weld elvish stuff I found in the troll caves. A bit on-topic: around here the most common anvils are the Hungarian made cast steel austrian pattern anvils from the 50's-80's. The most typical weight is 70-80kg / 150-180lbs. Also some Austrian JEB's appear quite often mostly in the same weight. So I was pretty happy when found my German two horn pattern 450lbs. Bests: Gergely

-

I really loved the power hammer pictures of yours and I'm amazed by these, too! Very nicely planned shop, and helpful topics to think about my own workspace. Thank you for sharing! The tool holding solutions around the shop are brilliant - simple, functioning and space-friendly Is the red machine on the second picture an iron-worker? Bests: Gergely

-

What did you do in the shop today?

Gergely replied to Mark Ling's topic in Blacksmithing, General Discussion

When you heat SS above 900 C grade it losts its stainless-ness. So you can hot forge it on your anvil with your regular hammer. After the forging you need to reestablish the stainless surface by passivation. (Or surface grinding, or electro polishing.) After you've made the new stainless surface you must be handle it like in a meat packing plant When you hammer your SS cold that's when the stainless hammer and "anvil" may come into the picture. Bests: Gergely -

What did you do in the shop today?

Gergely replied to Mark Ling's topic in Blacksmithing, General Discussion

As far as I know SS is very sensitive to surface contamination. It means that if got your workpiece passivated all right but then apply ie. a Scotch Brite flap disc you used earlier on carbon steel - the stainless probably will rust later where the flap disc hit it. Or you take a freshly bought totally nice SS piece and hammer it cold on the anvil with your normal carbon steel hammer and the surface contamination causes it to rust later. Hope this helped. Bests: Gergely -

What did you do in the shop today?

Gergely replied to Mark Ling's topic in Blacksmithing, General Discussion

Hi Mark, There are different colors of the Scotch Brite flap discs. Mainly red and blue. I use the red but as far as I know there isn't that much of difference. Stainless finishing #1 rule applies here too: if you want to use something on SS use it only on SS. I very much like your trivet - it's nicely composed and clean looking. And the black walnut handle does look good with the PW hammer! Bests: Gergely -

What did you do in the shop today?

Gergely replied to Mark Ling's topic in Blacksmithing, General Discussion

I often use Scotch Brite angle grinder discs on SS. It cleanes the surface more aggressively than a wirebrush but doesn't effect as abrasively as a flap grinding disc. Bests: Gergely -

Hi Lyuv, I'm not a knife guy but I do make knives time to time. So here it is what I think/know about your questions: 1.Yes the blade will move/bend. That's why I don't do the hammered finish at the end but while I do the major shaping. Actually I don't DO the hammered finish I just leave it uncorrected. 2. If you forge the blade at correct heat you don't damage the steel. And stress relieving HT is something I don't want to forget when the forging is done. 3. You don't want to hit tool steels cold. It damages the material, and if you're not lucky flying pieces of broken steel may damage you. I made this knife for a costumer who wanted very rough hammered texture with minimal grinding: Hope I could help you but if you have any further questions I try my best to answer them (Not to mention the folks here actually knowing things about knife making ) Bests: Gergely

-

Nice going! Don't compare yourself to others - this was your first, you learned a lot and it seems that it really went well. Maybe a lighter colour sheet could have enhanced your stuff on the table. If I were you I made a bunch more feathers as requested - it may come handy at the next fair. (And when you get the feeling of making something it's easier to make more at once than continue it later.) Bests: Gergely

-

Good luck! Bests: Gergely

-

What did you do in the shop today?

Gergely replied to Mark Ling's topic in Blacksmithing, General Discussion

Beautiful pair of tongs you made there! Very stylish and functional - I like it very much. Bests: Gergely -

What did you do in the shop today?

Gergely replied to Mark Ling's topic in Blacksmithing, General Discussion

Thanks, Aus! Those are real nice works of yours, too! The longhorn had me think about its adaptation for the Hungarian Grey cattle. Those are pretty popular and iconic creatures nowadays around here, being revived ancient cattle Hungarians used to have in the shiny past. Bests to you! Gergely -

What did you do in the shop today?

Gergely replied to Mark Ling's topic in Blacksmithing, General Discussion

Thanks, Das! People tend to like these hooks The poker made me think of something unusual for the hanger. Unfortunately I realized only when it was forged ready that my original thought was to cut the hook part from the opposite direction. There went almost a year between the thought and the realisation of this project so that's why I forgot it Anyway the costumer seems to like it, so all okay... Bests: Gergely -

What did you do in the shop today?

Gergely replied to Mark Ling's topic in Blacksmithing, General Discussion

Finished the wall hanger part for an old fire place tool. (Not old-old, I just made it couple years ago.) Also the owner wanted the tool shaft drawn out a bit longer. Also made two of these Aus' nail hooks: Bests: Gergely -

Well, that's a valid idea And you made me laugh very loudly... G

-

That's a good idea, and probably very right about the burning of chains I try and look around a bit myself over here.

-

Nazel 3B 97 year service.

Gergely replied to upsetter's topic in Power Hammers, Treadle Hammers, Olivers

Wow! Cool work there! You did posted a video file, I just had to download it to my computer and open it to watch. It shows the open cylinders while the compressor works and blows air to the work cylinder. - Fun stuff, I've never seen that before. Bests: Gergely -

My experience also says that it's not suitable for any kind of hammer handle. I love black walnut, it's beautiful wood but its structure is weak. My first idea was osage orange too for an exclusive handle with the exclusive hammer head. Bests: Gergely

-

Nazel 3B 97 year service.

Gergely replied to upsetter's topic in Power Hammers, Treadle Hammers, Olivers

Hi Upsetter, It's a magnificent hammer, congrats! I hope everything will be repaired soon and you can use it on full throttle. Bests and thanks for sharing! Gergely -

Industrial Ajax Spring hammer HP?

Gergely replied to Krush's topic in Power Hammers, Treadle Hammers, Olivers

Glad to help! That's a nice old lady! The ram seems to be in perfect shape. Don't forget to drown her in grease (not as you wouldn't know that, I'm just saying). Bests: Gergely