-

Posts

2,679 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by arkie

-

Nice work. The dragon fly is kool !!!!

-

Blacksmith Organization of Arkansas March 2107

arkie replied to arkie's topic in Blacksmith Organization of Arkansas

Update/Confirmation: NE Chapter meeting on March 4th will be held about 10 miles north of Jonesboro, AR. PM me for details. -

That's normal.......

-

Blacksmith Organization of Arkansas March 2107

arkie replied to arkie's topic in Blacksmith Organization of Arkansas

BOA Meetings scheduled for March 2017: NW Chapter: Mar. 11, Siloam Springs, AR NE Chapter: Mar. 4, Correction:...Jonesboro, AR (There have been two locations posted recently for the NE meeting on Mar. 4. Please PM one of the NE Chapter members here on IFI for the correct one. The contact here is "EJRailRoadTrack". Central Chapter: Mar. 18, Roland, AR River Valley Chapter: Mar. 4, Witcherville, AR PM me for details if interested in attending a chapter meeting. Visitors always welcome. -

Very informative video. Easy to follow steps. Thanks for posting. I'm about to start a touchmark myself and this really helped a lot.

-

Things to do with wrought iron

arkie replied to Bill in Oregon's topic in Blacksmithing, General Discussion

I'm afraid those are a bit above my skill level...would be neat to do, though. -

Nice thing about using the WD-40 is that it doesn't leave a thick, oily residue like regular oil and it's cheap. Easy to wipe clean off the face. A can lasts me several weeks. I've never tried the ATF...might have to give it a test run.

-

Things to do with wrought iron

arkie replied to Bill in Oregon's topic in Blacksmithing, General Discussion

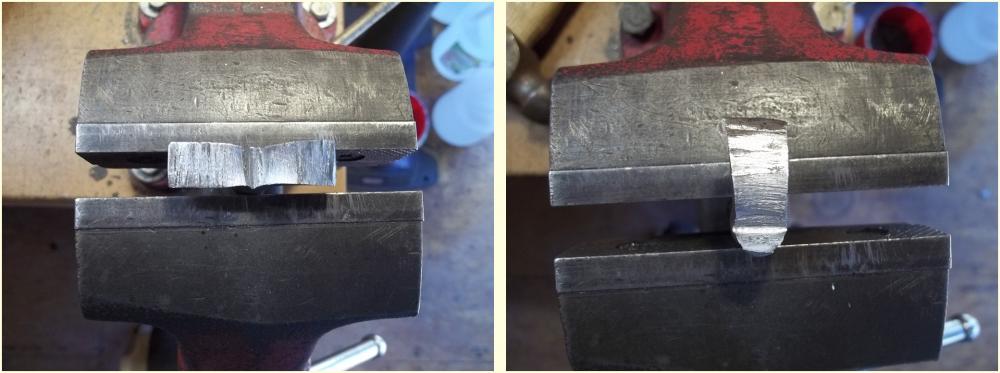

I imagine that photos showing the difference between wrought iron and "steel" such as mild steel have been posted here on IFI, but from my searches it appears that earlier photos are no longer available on the site. So, in that regard, here are some that I took recently. My digital camera doesn't take close-ups very well, but here are some comparisons. The photos include a comparison of two 1/2" round rods, one wrought iron and one mild steel. Each was cut part way down with a hacksaw then split apart. You can see the fibrous structure on the wrought iron and the microcrystalline appearance on the mild steel (the shiny one with one ear broken off). Also included is a large bar, probably from a piece of old farm equipment that was folded over forming an eye. I cut through part of one end on the eye and bent it back to show the fibrous structure (you may have to zoom in on that one). The clue to the bar probably being wrought iron was the linear weathering along the bar. It's about 3" wide and 1/2" thick. Must have been fun bending that piece over. Now, I'd like to figure out what to make from the large piece, or maybe just cut it up for several projects. -

My anvil is outside under a metal shed. When I finish working, I wipe it off with a rag, give the face and horn a light spray of WD-40 and cover it with a large plastic storage container. It can sit as long as a couple of weeks if I'm on vacation and when I remove the top, no rust. Wipe it off again, and go to work! It's been outside like that for 4 years using the WD-40 and the face has no rust.

-

Excellent advice, Frosty!!

-

If you grind a hammer face to change the shape, be sure to keep it cool!!! If the hammer is heat treated, hard grinding can remove the temper resulting in a softer face. I never grind more than what is comfortable to the hand touch and move around the face, stopping when it gets too warm and let it cool down.

-

Back From My Alec Steele Class!

arkie replied to mutant's topic in Blacksmithing, General Discussion

mutant might want to go back and edit (non G-rated language) his video so that it can be posted..... -

Either face will work...personal preference. If you want to do some top fullering by tilting the hammer head on the stock, then obviously the square face is what you need to use, otherwise you'll leave round hammer marks that don't spread the stock uniformly. Look at some of Brian's videos to see how he uses the square hammer head to fuller his work.

-

Railroad spike "tomahatchet"

arkie replied to lanternnate's topic in Axes, Hatchets, Hawks, Choppers, etc

I had heard that the superquench could "harden" to some extent mild or low carbon steel. Being bored one day, I mixed up a batch to see if it worked. I did the non-magnetic quench on a piece of A-36 mild steel (man, that stuff really screams at you when it hits the water!!!!). End result with the file skate test was a *little* apparent hardening, more like thin case hardening, not anything that probably would hold an edge for long. The quench is still in the bucket, never have used it since that first time. "HC" railroad spikes are not higher carbon in the sense that you would use it for cutting tools, chisels, axes, punches, knives, etc. It is merely a slightly higher carbon than low carbon spikes. It is my understanding that they were supposedly a slightly tougher steel used on curves and such where the trains and rails might exert a higher stress on the spike's holding power. I'm sure some spike experts will jump in here and expound on the subject. I don't use spikes but once in a blue moon, don't really like them. -

Also, try to keep your work out of the bottom of your fire where the oxidizing zone is...contributes to scale. Get further up in the fire, the neutral zone...less or very little scale. Glenn has posted a diagram several times here on IFI of the "layers" in the firepot. See if you can locate it.

-

Jeep leafsprings and a pair of coils

arkie replied to missourikid's topic in Blacksmithing, General Discussion

Great, welcome to IFI. -

I hope you have fun and enjoy building your forges. Be sure to post back here on IFI to show us your forges. We like pictures!!

-

Jeep leafsprings and a pair of coils

arkie replied to missourikid's topic in Blacksmithing, General Discussion

missourikid, if you post your location on your avatar, as Frosty often says, you might find someone in your area who can help you out with sourcing material and smithing as well. -

Either should work. Lots of folks start out like that. Cheap and easy. You might line the horizontal drum with firebrick or clay to keep from burning it out. I'm sure some here who have made forges like that will chime in real soon. There are lots of designs you can build. Here's an example of one that one of our members made recently. This had a hair dryer, which I don't like...to darn noisy. Other blowers can be found. Have fun!

-

Jeep leafsprings and a pair of coils

arkie replied to missourikid's topic in Blacksmithing, General Discussion

For your leaf springs, try a spring or suspension shop in your area. Once they replace a leaf spring set, the old ones are useless to them. I found a great source for coil springs, leaf springs, and suspension bars (torsion bars, tie rods, etc.) being the aftermarket off-road conversion shops. They sometimes even have brand new take-offs when a customer brings in a Jeep, big 4x4, Hummer or something like that straight from the dealership and has a lift kit, new heavy duty suspension parts, etc. put on it. My son and I went to a shop near Atlanta once, and the counter guys told me to go check out the bin in the shop. We found a 6' x 6' square bin that was about 4' deep of brand new, bar code sticker still on them, coils, tie rods, anti-sway bars, no dirt, nothing etc. spotless clean! They let me take a few coils and rods; I didn't take more so as not to appear greedy and maybe get more later. -

Better to use a weak baking soda solution...some Windex is ammonia-free if that is what might be doing the neutralizing with Windex. I use Windex on the windows Vinegar is great...kinda like aspirin...seems to be good for just about anything!

-

What did you do in the shop today?

arkie replied to Mark Ling's topic in Blacksmithing, General Discussion

X2 on the aloe....I use it frequently!!!!!!!!!!! I recall that in the old "Rawhide" western TV series (I believe it was), the chuck wagon cook, Wishbone, used to say that "it don't take me long to turn loose of a hot skillet handle!!), being cast iron of course. Smithing, I tend to grab hot stuff other than skillet handles. -

Jeep leafsprings and a pair of coils

arkie replied to missourikid's topic in Blacksmithing, General Discussion

As a manner of "paying it forward", I would rather donate them to a local smith than try to sell them...most smiths can get them for free one way or another. My local mechanic will give me any discarded springs or leafs for free if I just ask...they don't put a price on them...they just want the junk out of their shop. If you might need them in the future, just keep them. That way you won't have to go scrounging some from a scrap pile or a smith who has an abundance and would be happy to give you some of his. I know that I have been given springs like that for free and if I had enough to work with, gladly shared with other smiths.