-

Posts

2,024 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Marc1

-

Anvil ID assistance Please

Marc1 replied to cooperstock's topic in Anvils, Swage Blocks, and Mandrels

I just noticed the word wrought on the side, and sice PW is the one that crows about using wrought iron (to it's detriment) it is most likely a PW. It is a common brand, and a good workhorse that no one would turn away. What else do you have to sell? -

Anvil ID assistance Please

Marc1 replied to cooperstock's topic in Anvils, Swage Blocks, and Mandrels

Rub all the places that seem to have letters or numbers with chalk. That will reveal a bit more. It looks like Peter Wright to me, but from those photos I am not sure. Price will depend from location. That would fetch 3000 + in Australia -

It's just a commercial name since 'mutatis mutandis' fulfills the same role as a fuse in an electric circuit. You may call it a "propane sudden loss of pressure valve" or less words to the same effect If your hose bursts the drop of pressure will shut the gas off at the bottle. Not sure what the legislation is in your corner of the woods, but here in our beautifully over regulated country we can not build DIY gas contraptions to use on either LPG or natural gas. They need to be approved and usually have a sort of badge or metal label hanging from them.

-

Get the one you posted in the second picture and hang a spanner from a chain next to the bottles. if you can add two LPG fuses to the bottles, that would be a plus.

-

Take the Hay Budden and the post vice without a doubt. Lately I believe the prices for anvils have started to soften a bit. Try $300 for the anvil and $80 for the post vice. Remember that if you are not ashamed at your own offer, your offer is too high Those prices are cheap for Australia.

-

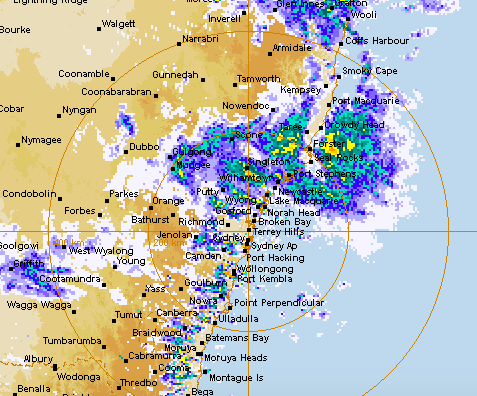

Well ... we got way more than we bargained for. Fires are all out ... It never rain but it pours.

-

Wire wheel the lot including the base feet and under side. Oil it and use it. Patina ( read rust ) does not help forging. In my opinion only.

-

Sure ... or you can walk around the anvil ... Just saying because chiselling a square hole in steel is not fun. You can ofcourse sleeve a hardy on a stump away from the anvil. Many different ways are possible. I must say that if I had an anvil with no hardy i wouldn't even consider drilling a hole. Better use of my time. However everything is possible to the determined man ... or woman

-

Since I had no idea what chinking is ... sounds like something to do with shooting ... I looked it up and this is what I came up with I see now. (sort of) it's like caulking between the logs. The groove should keep the caulking in place (?) And what is it with the last sentence ... portland cement ? Hard to obtain when you are up a mountain and a few days ride from the nearest town. I thought that lime or mud would have been more the thing ... or tar. If the use of the mystery thing is to carve a groove along a log for purpose of sealing with ... whatever they used ... the fact that you need to swing it sideways, shouldn't be a problem. After all it is not like the groove needs to be perfectly straight. It should work on soft wood. Good luck using it on our timber. As for the argy bargy above ... may I say that it is the tone that makes the music, and also that the intentions of the author are irrelevant and only the potential effect words have on the reader are important. That is why when you write what you may think is funny or clever, you have to think that may be, just may be someone else is not in the mood for jokes and may be over sensitive to something due to personal issues or events. Yes, it is different from having a conversation because the body language is missing, and the words stay on the screen. Just saying.

-

Why does it need to be square? Drill a 1" hole or other size of your choice, then enlarge the hole sideways both ways and you have an oval hole. The tool will not turn, and that is the only purpose of a square hardy. Then forge your tool to your oval hardy.

-

We are getting the rain from the last 3 month all at once. I expect some minor flooding, but water is better than fire.

-

The sub board in the workshop is the best idea. In your case you have two workshop so you could have one sub board for both. Get 3 separate quotes and chose the one you like the best, may be not necessarily the cheapest. i don't know how it is in the US where you are allowed to do your own electrical work, we have a ban for DIY electrical here. However we usually can reduce the bill by doing the wiring first and then get the sparky to do the connections and oversee what was done. Not every electrician likes to do that, but if there is conduits involved you can certainly do the digging and the laying of the conduit, or clipping them to the wall, if you know the outlay and the sizes required.

-

I agree. 10 AWG is 6mm2 and can carry 32 amp. In a conduit heat is your enemy. Go 8, that is 10 mm2 for the welder. If you have extra load, I am afraid you need to go thicker. Best still, consult an electrician, not a blacksmith,

-

Shabumi. Get an old buzz box, you can get them for $50. Make sure you have enough juice in the powerpoint. Rivets are very good looking and very strong if you choose the right size. Drill or drift, does not matter. It's not a religion, no sins to be committed. Just do what you like and share your results without fear.

-

Yes, the Italians issued them to their troops because it was in their words a "humanitarian" round that is intended to wound and not kill. They also issued them with grandes made out of sheet metal that exploded but did not throw any shrapnel ... but that's another story How did we get from hearing protection to historic ammunition? To the OP, please don't turn up to your blacksmith demonstration with ammunition plugged in your ears ...

-

There is a lot of that in the hobby blacksmithing folklore. How far do you go? Must search for wrought iron in the scrap metal yard? iron ore? heat with wood that you collected in the forest by hand? Cut the wood with an axe and not a chainsaw? Some think that using a jig for hot bending is cheating and must make the scrolls by hand. A bending machine of course is anathema! It is your project and the only "exam" you need to pass is your own appreciation of your work. If others appreciate it too ... well that is a bonus. If you want to sell your product, the 'exam' is the customer that buys it When it comes to the professional side of things, how many times have I heard from experts in a field that they want to "educate" their customers via their product, be it a craft, a meal or a drink. The artist does not educate, he offers, and the customer choses. To say "I want to educate the public" is an extremely patronising and arrogant posture to take in relation to a customer, and one to be avoided at all cost.

-

Yes that works too. 7.62 pistol ammo fits my ear duct perfectly ha ha.

-

Peening the weld as it cools down relieves stresses in the weld, if done properly. It will also change it's appearance. If I have an inevitable weld that needs to look forged, I take to it with the ball peen hammer and if necessary reheat with the oxy and have another go. Reheating the whole piece in the forge and forging it, can have mixed results for the weld. It all depends of who welded it and with what. Doesn't take much to experiment. Weld a flat bar on end from both sides with a rod and full penetration. chuck in the forge hot, reheat and have a go with the hammer.

-

Mm ... the metaphysics of identity, isn't there another one about the axe of someone who is on his fifth handle and third head but still going strong?

-

Wax impregnated cotton wool would work a treat of course. I had to resort to improvisation when required to shoot in a pinch, in circumstances that will remain untold, and used to make a plug with masticated paper. Worked rather well. I don't think the OP is interested in such last resort measure though. His proposed musician ACN plugs look the part.

-

I use the "active noise cancelling" headphones from KOVE. At $200 they are not cheap, but cheaper than those custom made ear canal plugs used by shooters. As a bonus they have a bluetooth connection and so you can listen to music, radio or audiobook and still make a racket and hear the music over the noise. Much lighter and comfortable than ordinary earmuffs, and way more effective. However ... anything is better than nothing, even cotton wool.

-

I looked those up and they are certainly discrete compared to my sound cancelling earmuffs. Those plugs say they work with noise up to 110 db. 110 is not very high. If you have a power hammer they will probably not be enough. Another choice would be to look at what hunters use to cancel the noise and still be able to hear and talk. All of these gadgets are not cheap, but your hearing is worth it. Do stop the anvil ring. You can have a ringing anvil to attract the crowd and then work on a silent one. And explain the difference and mention that Blacksmiths of old were all deaf and you want to keep your hearing, or words to that effect.

-

Are you mocking me now Jennifer? That is disappointing, and so is the chorus of pseudo adults that followed.