-

Posts

689 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Fatfudd

-

New Anvil, New Smith

Fatfudd replied to Clayton Hewitt's topic in Anvils, Swage Blocks, and Mandrels

Steven Prillwitz of Matchless Antiques can get more for his anvils than anyone else on ebay for several reasons; 1. he knows his anvils, 2 he knows how to market his anvils and provides great pictures,3. he has a sterling reputation and 4. he will allow a full value trade in/up on another anvil. That being said he has lately been setting the values for anvil sales based on his ebay sales. That is unfortunate because others trying to sell their anvils on ebay or anywhere else think they get the same prices for their anvils. One thing about Arm and Hammer anvils is they are somewhat rarer than Trentons and Hay Buddens and therefore also are of considerable interest to collectors if they are in decent shape as yours is. There is no question however as Postman said they are fine anvils as good as any others ever made. From what I have seen you should not be unhappy about the price you paid for your anvil, it is a fair price for a large anvil I have no doubt its value will only increase. -

If you google Vaughn's brooks anvil you can see their website.

-

Its cast steel and there isn't a way to determine the age. I recently purchased one of the same size for our ABANA affiliate for use as a demo anvil. I was told it was old belonging to an old man's father. No way to know how old it is, but its still a really nice anvil.

-

Sure - Its a Brooks anvil. weighs around 100lbs. Excellent quality and will serve you well.

-

Help with a small anvil ID

Fatfudd replied to awholelota's topic in Anvils, Swage Blocks, and Mandrels

On small anvils the ring maybe faint depending on what the material is its sitting on. If you put it on something that holds it in the air, like a couple of drill bits you can then judge the ring. It looks like a great anvil and A&H's are quite in demand by Smith's and collectors. -

Help identifying an anvil marked only with an M

Fatfudd replied to Dustin Quade's topic in Anvils, Swage Blocks, and Mandrels

Sometimes it best to NOT to offer an opinion if you really don't have any idea about what you are talking.. Dustn if you do a search on Milne anvils you may find something that looks similar. They were cast steel and quite good anvils but not very well known. -

What unknown stamps are you referring to, the numbers on the heel or the number under the horn? Both are typical HB stamps. according to Postman the one on the heel is the steel batch number and the one under the horn is the inspection number.

-

-

Help Identifying Large Anvil

Fatfudd replied to Ser Menalak's topic in Anvils, Swage Blocks, and Mandrels

101-HB is correct, a number of the American wrought iron anvil makers did overhauls on the English anvils after they developed sway and broken edges. ai would assume the y would identify the anvil by some method such as numbering them after the remanufacturing process was complete. With all those handling holes it has to be wrought, not cast.- 11 replies

-

- help

- identifying

-

(and 2 more)

Tagged with:

-

Did you buy the big anvil? I picked up a 433lb Arm and Hammer anvil today for under $3.50/lb. The big ones are rare but the show up occasionally

-

Right on Andy!

-

value of a 100 lb british anvil

Fatfudd replied to bustedknuckles's topic in Anvils, Swage Blocks, and Mandrels

Brooks are cast steel and for the most part very well made, there have been a few that were somewhat soft but mostly they compare to the very best quality anvils around. I just purchase one for our ABANA affiliate demo anvil and it has a 95% rebound. -

The difference in colors is not an indication of the thickness of the top plate. That anvil looks like either a vulcan or a badger, That being the case then the top plate is probably less thick than the chipping of the edges. If you just want something to pound on then go ahead and have it welded but realize that you won't have any more rebound than a piece of mild steel. The top plates on most anvils even very large anvils rarely exceeded 5/8" . On vulcans it was usually only 1/4" or less.

-

value of a 100 lb british anvil

Fatfudd replied to bustedknuckles's topic in Anvils, Swage Blocks, and Mandrels

Can anyone tell me how much my american car is worth, its blue and in OK not decent shape? -

The more recently constructed trenton anvil were all arc welded at the base and some have a very distinctive weld line. I had a near mint 150lb Trenton made in 1943 that showed a complete weld line around the middle with no grinding or cleanup. If I can find a picture of it I'll post it. That being said with only a 60% rebound and no ring you were smart to pass on it.

-

Many older English anvil's bases were forged in closed dies and have what appears to be a parting line, similar to cast anvils. We really need more pictures to tell what it is.

-

I have both a new anvil, a Refflinghaus and some older anvils. My suggestion is, if you have the money, buy new. You know what you are getting and their are some very high quality anvil available. That being said you will need to do research on which are the best new anvils. My Refflinghaus is one the finest anvil currently being produced but you pay for that quality.

-

Blackjack is a fairly common Hay Budden anvil as are Lakesides and Acmes. I don't know that the retailers had "big heads" it just they had a line of products with their names they sold whether it was anvils or screw drivers. All 3 of the American wrought iron anvil manufacturers made anvils for different concerns. If you research IFI you'll find lots of examples, even more than were in Postman's book.

-

Looks like a vulcan or badger. better pictures would help.

-

It appears that the shows on TV about forging knives and making guns have stimulated the anvil buyers market. I recently led a group of NM blacksmiths down to Fred Moore's place(check out youtube largest anvil collection). Fred had indicated he is getting old and was considering selling much of his collection. In the past he had been selling his duplicate anvils for $3/lb so I figured he was still in that price range. When got to his place he showed me a check for $18,000 written to him by a buyer from Texas who had purchased "a few" of Fred's anvils. He told me that he thinks the Texas buyer is going to buy the rest of his collection. It turns out Fred's prices now start at $6 to $10 depending on make and condition and he knows he is selling to resellers. Some of the anvils you now see on ebay are from Fred's collection. You can still find reasonable deals locally on anvils but they are getting fewer and farther apart. I agree it makes more sense to buy new rather than a beater anvil for $6/b but when newbies get the bug the prices go thru the roof. I'm afraid that what we are seeing is the new norm.

-

There were quite literally hundreds of anvil manufacturers in England. They also made anvils for other concerns. As someone said on your previous post it is a pre-1830 anvil. You maybe able to glean more of the stamping on the side of the anvil by wire brushing the rust off with an angle grinder and then rub some chalk on it. also try looking at the anvil from different angles to see if the shadows help. It a cool old anvil tho and one that deserves to be used.

-

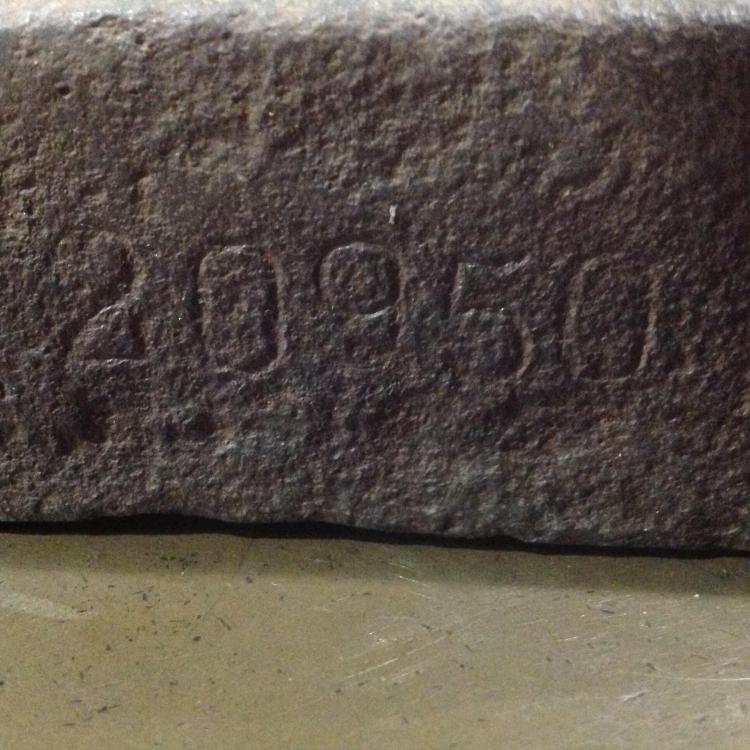

Its an Arm and Hammer for sure. I wouldn't use a flap disc on the face only a wire brush on an angle grinder to remove the paint. If you can read the serial number on the front foot we can give you an approximate age.

-

I'm sorry to tell you but its not really an honest anvil. Its a cast iron vise with an anvil shaped object on the back. It can't be used for actual forge work because it would simply break up into small pieces. It won't be worth much to this crew.

-

$450 is a good price, if it were here in NM it would last about 30 minutes on Craigslist. Denver seems to be in about the same price range. At $600 it might take a bit longer.