-

Posts

689 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Fatfudd

-

Anyone Can Identify This Anvil?

Fatfudd replied to Dom's topic in Anvils, Swage Blocks, and Mandrels

It looks like an Austrian style anvil, I have one that is similar. There were a number of European makers including German and Swedish. -

North German anvil identity

Fatfudd replied to DiggerDiggs's topic in Anvils, Swage Blocks, and Mandrels

The anvil is still on the Austin Craigslist site and there aren't any better pictures of it so it could be any one of many early German makers. -

Actually there are getting to be more collectors just as there are more folks wanting to get into blacksmithing. Most collectors only have a few anvils, less than 250 as Thomas asked but they spend a lot for a special anvil like very small ones. even more so than the really big ones. There is a sort of net work among the really big collectors who help one another get rarer anvils. When I've talked to Fred he has told me of collectors in other states that he regularly contacts. I have met or talked to a few of those other collectors and they have anywhere from a few dozen really choice anvils to many hundreds. Some will spend any amount for those special anvils and they can afford to buy them. I guess its like any other collectors like rare baseball cards or coins.

-

Sorry but you need to provide a bit more info. What do the serial numbers look like on the front feet? Some pictures of the side with the logo will be helpful. What does the underside of the base look like- ie more pictures. I can show you a picture of my pick-up truck can you tell me where it was made and when?

-

I saw them at ABANA last summer and was really impressed for the price. They are hard and have a tremendous rebound. I really like the configuration .I don't think you would disappointed.

-

100lb anvil need help

Fatfudd replied to Michael Perry's topic in Anvils, Swage Blocks, and Mandrels

I bought one the same size for our blacksmithing group and paid $300 for it. It might go for a little more here in NM but probably not much more. -

Ernest Rellfinghaus anvil purchase

Fatfudd replied to Beatsy' s Forge's topic in Anvils, Swage Blocks, and Mandrels

My Refflinghaus hasn't been babied for the last year and the face still looks new. The dilemma with that thread is you don't know how the smith was using the anvil. If you miss your metal or you don't have it hot enough you will cause damage to anything even a wrecking ball. That being get a hold of Dick at http://www.blksmth.com and ask him, that way there is no speculation. -

To be honest, I'd get a big chunk of steel or a piece of rail and use that to begin with. Then use the TPAAAT to find a decent anvil or save your money for a really good anvil if you're serious about getting into this arena.

-

Anvil Indentification and help

Fatfudd replied to pushinhornz's topic in Anvils, Swage Blocks, and Mandrels

I had a beautiful Swedish Kohlswa that had been improperly heat treated and it had about a 50% rebound. I found out later that the problem occurred in the late 1980's at the factory. I paid a whole lot more for it and assumed wrongly it would be great just based on the name. That being said if I were you and could pick that one up for $1/lb I'd probably do it because I could always resell it for at least that much even if the rebound isn't great. -

I don't think your question was completely answered. C-1 did point out the best of the anvils made from the past. There are some new anvils that worthy of looking at and they range from the ductil anvils like JHM to old world anvils that are imported, the American anvils; Rathole, Rhino, Nimbas to the really high end Refflinghaus. Alny of those will work for making knives just depends on your money situation.

-

I have one and its a weight for a large tractor. I use it as a base for upsetting long pieces. There are railroad anvils that look very similar but have a pritchel hole. and usually spaces to sit over the rails in 2 directions.

-

Soderfor FORGED steel anvil or not?

Fatfudd replied to a topic in Anvils, Swage Blocks, and Mandrels

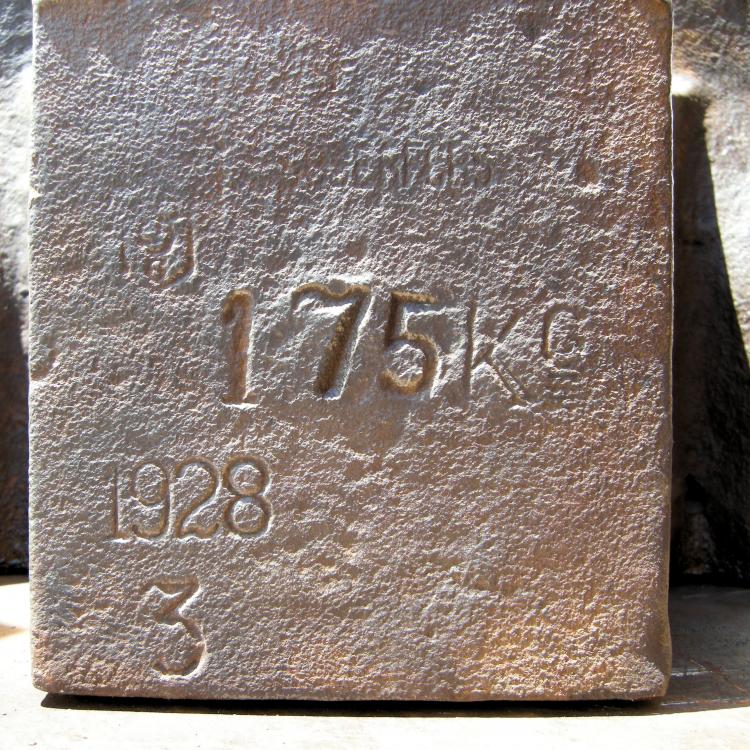

I appreciate this thread being brought back to life. It is possible that they could have forged anvils at some point but every Soderfors I have seen appeared to be cast.That being said I have seen Soderfors anvils with both raised and stamped lettering. My little 175KG Soderfors is clearly cast with the lettering stamped on both sides. -

Welding an anvil down?

Fatfudd replied to jpfabricator's topic in Anvils, Swage Blocks, and Mandrels

I've cut a few anvils off of a welded onto a base. It seems sort of silly to weld an anvil on to something because it becomes a fairly permanent attachment which may be ok for the person that is doing the weld at that time but things change. I wouldn't recommend it because every anvil I have had to cut off of a base wouldn't be of much value for anyone else because of height, style, or some some other use issue. -

Mule- Peter Wright anvils did not have serial numbers but you can get an approximate era that it was made in if you do a little research. At a point in the early 20th century England required that any exports be labeled with "England" . that isn't on your anvil that I can see. Very early anvils, called colonial were of a specific design and yours dosen't look that early. Hope that helps?

-

Trenton Phoenix ACME anvil

Fatfudd replied to Joel Castro's topic in Anvils, Swage Blocks, and Mandrels

I had a Phoenix marked Hay Budden that I traded to Fred Moore a few years ago. (you can see it on one of the videos of his stash). One could assume that manufacturers like Trenton and Hay Budden were happy to stamp whatever the customer desired. It's conceivable that Trenton made a run of Acme anvils for Sears and with a few left over marked one of the remainder for Phoenix. I guess we will never know what actually happened but its a very cool anvil none the less. -

Hey Chris- Are you looking to give Fred Moore a run for his money as to who is the biggest anvil collector?

-

Nice little anvil Chris. Actually Blackfrog is building the database on Trenton and Arm and Hammer anvils. I am amused tho about folks claiming that they can tell that an anvil is an Arm and Hammer because ot the heavy forging marks under the tail. I have a number of A&H anvils and have had many more Trenton's with similar forging marks. Yours is a perfect example of what I'm talking about. Thanks for sharing your anvil pictures with us and nice score!

-

Probably it seemed expensive at the time but with the current prices it is a steal. How much does it weigh?

-

Well it was made after 1908 because the numbers on the heel were only on the anvils with a top half made of tool steel which started around that date. The serial numbers on the front foot aren't much help since its not possible to tell where in the serial number 437 is located. Other than that it looks to be a nice anvil.

-

Help Identifying this ~300lb beast

Fatfudd replied to jdawgnc's topic in Anvils, Swage Blocks, and Mandrels

I'm not talking about the serial numbers which would be found on the front foot. I'm asking if there is a number or remnants of one right under the horn next to the handling hole just under the horn? -

Help Identifying this ~300lb beast

Fatfudd replied to jdawgnc's topic in Anvils, Swage Blocks, and Mandrels

Is there a number under the horn? It sort of looks like I can see one in your pictures? -

Anyone ever reface a fisher anvil?

Fatfudd replied to Callmecrazy's topic in Anvils, Swage Blocks, and Mandrels

Rob Gunter has repaired a few fishers but he admits it is difficult. If you weld into the cast iron you'll need a special nickel welding rod. -

Interesting question Glenn- I'm not sure size of stock is the determining factor or even an issue so long as the stock remains really hot and you use the appropriate size of hammer. I have easily worked 1" thick stock on anvils weighing under 100lbs using a 2lb hammer. Obviously, its easier to work thick stock on larger anvils because the mass of the anvil provides a more suitable rebound surface. Again so long as you maintain a high enough heat on the stock it will remain soft enough to be easily worked on any size of anvil. Where you get into more of an issue is the size of the working surface. For example if you want draw out a piece of 2" thick stock on an anvil with only a 3" face, you can still do it but the working surface limits the amount of work you can perform. You would wind up laying the piece long wise on the face rather than perpendicular across the face.

-

Ernest Rellfinghaus anvil purchase

Fatfudd replied to Beatsy' s Forge's topic in Anvils, Swage Blocks, and Mandrels

mine is on a tripod stand and I move it by just walking it around but normally you really don't need to move a shop anvil that much. The 400lb fisher gets moved a little more frequently.