-

Posts

469 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by jason0012

-

I would tack with nickel rod in a few places. Drill and pin in a few places, then grind deep and wide channels around the break. The pins holding alignment. Preheat as much as possible and peen your weld at each pass. Weld all the way around. Wrap in refractory wool and wire it up tight when done welding- to let it cool slow ( nickel rod isn’t terribly sensitive but it doesn’t hurt)then the hard part, grind, file and scrape the sliding surfaces level. I am sure someone here will sugest something better than nickel rod, but it is what I have the most experience with on castings.

-

Beaudry power hammer

jason0012 replied to Simm367's topic in Power Hammers, Treadle Hammers, Olivers

For a 100 pound hammer a three hp is typical. Some older machines might have a smaller motor, and it really doesn’t hurt to go up to 5hp. -

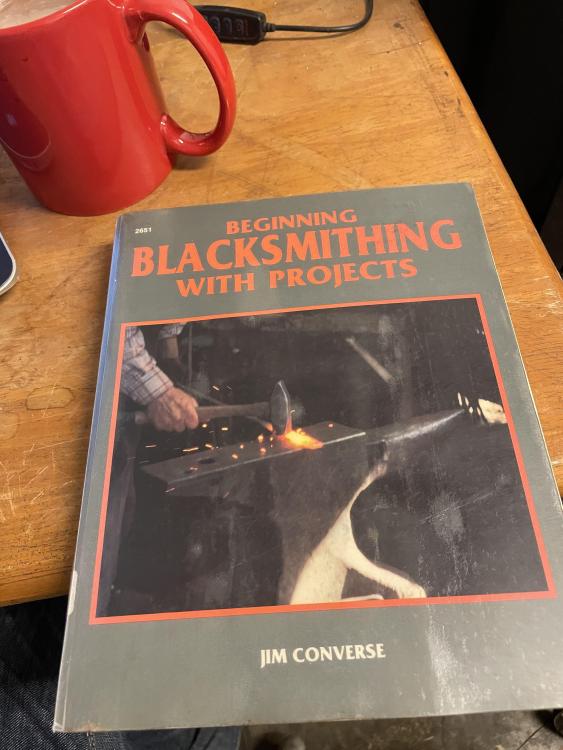

Finally found it. My memory was not the most precise it turns out. It is “beginning blacksmithing with projects” by Jim Converse. It goes into depth on chimney design, ventilation, fire maintenance, and anvil dressing.

-

Casting a Gingery Lathe

jason0012 replied to Nobody Special's topic in Smelting, Melting, Foundry, and Casting

I built a gingery lathe in high school, started the shaper, then happened upon a big commercial shaper for really cheap. I decided I needed to redo the lathe in iron, built a cupola furnace, fired it once and my parents ( and the fire marshal) shut the project down. That was more than 30 years ago so my memory is a bit iffy. I still have half the patterns ( just pulled them out last week) the big thing I recall from the lathe was what a huge pain the bed was. That takes a lot of sand, the flask is unpleasantly huge and it takes a lot of aluminum to fill. The pattern was the worst of the lot to make too. I wish I still had that one… -

Back in the 90s a lot of work I did came from interior designers and decorators. There was a year in the mid 90s where I don’t think I made much in between drapery rods and hardware. It seemed a lot different then. I have been away for a while but returning, all the folks in that field seem to be just painting homes shades of grey, filling them with cheap big box store furniture and not using any ironwork. Have things really changed that much?

-

Antique screw threading strap.

jason0012 replied to 4575wcf's topic in Gunsmithing, Muskets, Flintlocks etc

You will have to make a tap first. Might as well cut the thread on the plug the same way. While you can lay out 16 marks per inch on a 11/16 plain, wrap in string to connect the marks, scribe the string then file a thread to follow the scribed line, it is way easier and less frustrating to use a lathe… -

What's your latest blade look like? Post em and let us see.

jason0012 replied to HondoWalker's topic in Knife Making

-

I have been thinking about this. I would like to find some good input but haven’t heard many suggestions about size. Dust collection and air supply is a given. I have a collection of various grinders but plenty of floor space. My original plan was to use a room in the shop that is 8x14, but with 4-6 grinders I think it might get cramped. I am sure someone here has already gone down this path.

-

That looks very weld able. Keeping everything square might be tough, but Nickle rod should do the job. As mentioned though, it will likely break again. This looks like the effect of combo dies side loading the ram. Whatever your solution, work to get all the slop out. The more wobble in the guides the more those dies will impact the casting.

-

The guides can be fabricated from angle and plate. Use a thick piece of angle for the V and cut paper templates from the old guide for side pieces. Burn those from 3/8” (?) plate and hot bend to match the old guide. Clamp all three to the hammer frame and tack together. Remove the assembly and clamp well for welding. Skip around with lots of short beads to control distortion. After welding it won’t hurt to put it on a mill and skim the bolt up surfaces as well as the V.

-

old style 250 pound little giant

jason0012 replied to jason0012's topic in Power Hammers, Treadle Hammers, Olivers

These were some heavy chunks…the 2 3/4” round knocked down to 3 1/4x1 1/2, then drawn to 1 1/2”square, rounded, straightened and cooling. Turning and threading these is going to be a trick, my small lathe isn’t up to it and I still haven’t worked out the thread gears for my 1880s lathe…but that adventure is for another day -

old style 250 pound little giant

jason0012 replied to jason0012's topic in Power Hammers, Treadle Hammers, Olivers

Two pieces of 8640 cut to forge new arms. The old arm straightened v’d deep into the crack into sound metal, then a bit deeper) and filled with 7018. I don’t really trust it but the 2 3/4” round will forge better under the 250 than the 100. An odd aside, I measured the spring, and compared it to factory spec. It is a full coil shorter, and 1/2” by length as well as 1/2” smaller diameter than little giant spec. Probably the original. I ought to replace that as well… I wish I could find my notes on Clifton’s springs. He went oversize on his and had a place that custom wound them for him. Anybody have that info? -

old style 250 pound little giant

jason0012 replied to jason0012's topic in Power Hammers, Treadle Hammers, Olivers

The adjustable arm developed a serious bend. It seems to be smacking the guides occasionally and perhaps this is what happens when it hits stuff that is way too tall. I took it off to straighten it only to find a crack. The link arms are both shop made, and the t bolt is quite a creative part. The t end was a steel bit cleft welded into the wrought body. I can’t quite tell but it looks like the threads are steel also, but I haven’t identified a seam or weld. The wear on the t end was pretty extreme so I welded a 4140 pin in its place (7018, with heat treat) the wrought body shows a bad crack. Looks like I will be making new arms next week… -

Burnt Bradley needs rubber parts1

jason0012 replied to Magister's topic in Power Hammers, Treadle Hammers, Olivers

That is terrible! The good news is that Bradley’s are pretty bomb proof. Scrub the soot off, replace the belts, motor and rubber and it should be ready to oil up and run. Rubber seems tough to come by. Mine were cast by a gentleman in Michigan many years ago ( Jeff Stark was his name but I haven’t heard anything from him in quite some time) Bob Bergman had a place that made them, and I know that Stuart has a pile of rubber cushions from a 200 ( be prepared to remortgage your house though) the ones I had cast were from an ether urethane and apparently rather inexpensive to produce. The molds were duct taped together from aluminum flashing, and the rubber is mixed as a two part material. ( I have not tried this personally)- 3 replies

-

- need help

- need dimensions

- (and 3 more)

-

Oil on Bradley brake

jason0012 replied to edennis's topic in Power Hammers, Treadle Hammers, Olivers

Wipe it off from time to time. That’s really all you can do. My 75 does this, and a wipe down usually does the trick. The alternative is to not oil the hammer and destroy the bearings. More than a little bad advice about Babbitt here. These bearings require an oil film to function. If you aren’t feeding them oil they will run dry and then it’s game over. These are meant to be total loss bearings, they gush oil. Little giants do too and any other Babbitt type bearing. Some prefer grease to reduce the mess, but I never trusted grease to give a proper flotation. There are no seals in these bearings. I am not sure how you would add one. Perhaps a leather washer on either side of the bearing to act as a wiper? A rag and a can of wd40/ break cleaner and the oil wipes clean pretty easily. I have considered trying some more aggressive break lining. My hammer had belting nailed to the maple break shoe when it came to me. I removed this and have run on the wood block for nearly 30 years now. -

The book states that it will. I have it powered from a 240v 60 amp 3 phase line. The line is good, it is running my big miller mig welder.

-

I have a plasma cutter I got cheap (really cheap) because it is three phase. ( it will run on single phase, but the guy who sold it too me did not realize that) it powers on and starts. I can even get the pilot to fire from the panel, but the gun won’t do anything. I put new consumables in it ( cost more than the machine) but I can’t get fire? Any idea what I should look at ( possibly a less questionable machine, yes it has occurred to me) This is one of the newer “rounded” chassis models and is by all appearances and reviews a fine machine, when it works…

-

Kuhn Reiter K0, help needed

jason0012 replied to janosch's topic in Power Hammers, Treadle Hammers, Olivers

I have had a kb1 and a k24 apart before, but it was quite a long time ago. I seem to recall that seal being either leather or some sort of felt packing (?) that was kind of a pain to get to seal right when replaced. I may be confusing it with one of the Turkish hammers we had at the time. I know we had issues with the hoses between the compressor and power cylinders rupturing. The Kuhn is still being made I believe (?) though not these models. There is a chance that they would have helpful literature. -

None have speed control at the moment, but it avoids switching wheels/ platten. Truthfully it is the result of years of collecting bits and pieces

-

Perhaps this belongs in the “building a shop area” but it is knife related so I am putting it here and prepared for scolding later… Any of us that do much grinding have fought the dust thrown everywhere. Abrasive tools in my shop are pretty numerous and this work is dirty by its very nature. I have accumulated more than a few abrasive belt and disc machines, and am rather impressed by the idea of getting them all in the same location, and isolating the dust from everything else. I have a fairly large space to work with, and my shop had a dust collection system in place when I bought it. Thinking these arrangements looked overly expensive I had not considered it until I realized that I already have everything. I have an unused room (previous owner did painting in it) that is 7x14. The dust collector is just on the other side of the wall. I am trying to get 3 2x72 grinders and 2 12” disc sanders as well as a 12” buffer. I am not sure if this is enough space. I am currently hunting through various articles for suggestions on what should be included. Upgrading the two fluorescent fixtures to six LEDs is certainly on the list, and I already have it air conditioned and heated.

-

What is its nickle content? Some of these alloys have enough nickle to make them good for high contrast damascus

-

Power hammer technique

jason0012 replied to Momatt's topic in Power Hammers, Treadle Hammers, Olivers

It has a handle and can be used either top or bottom. I find roughing with the taper block on the bottom to work best with heavy initial blows, but for smoothing it works best as a top tool