We had some bad luck 3/31 - 4/1/2023! The fire took out the forge in Madison, Wisconsin.

The Bradley, 100#, Upright Strap Hammer has seen better days, as you can see. However,

I have been working on it since the fire, and the good news is that all the parts that move

still do! The paint job is toast, but the bearings etc., did not get hot enough to melt the babbit

metal so we can save it. All the rubber burned up totally and I need dimensions and a source

to replace the two round cushions that sat atop one another at the rear of the arms which lifted

the straps and the top 100# die. This hammer served us well for over 20 years and deserves to

be resurrected.

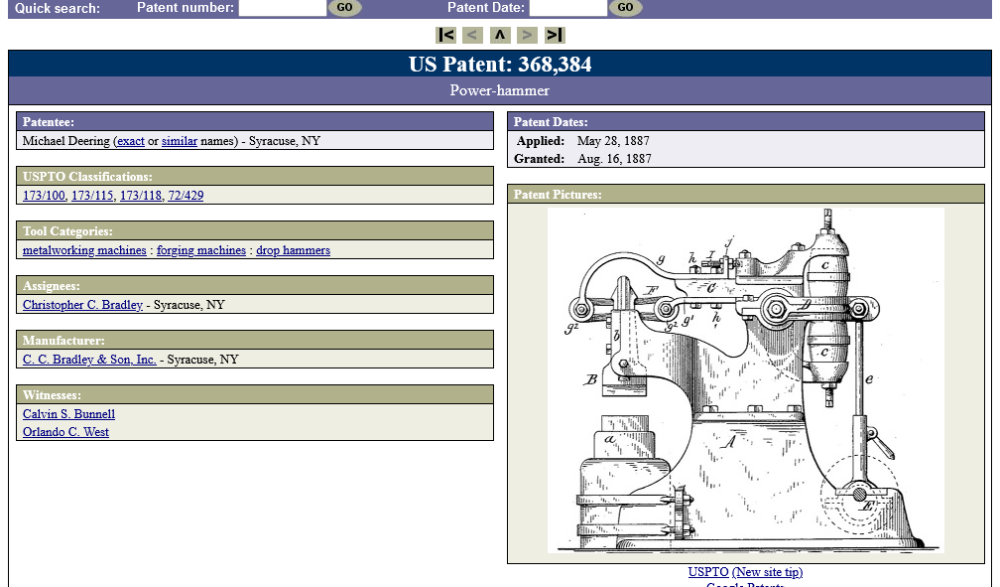

The patent was issued in 1896 and the illustration shows the rubber cushions, or shock

absorbers, at the rear of the hammer. The gray hammer is not ours but is basically the same

and shows the missing rubber cushions, just two.

As we all know, moving things like this on the spur of the moment is NOT easy. I was lucky to

save it from the scrap yard and get it to a safe location in the same day. The shop it's in now

has been sold and I have about a month to get it up and running, and moved,before the new

owner takes possession and scraps it. Any ideas, information, sources etc. will be greatly

appreciated. Help if you can.

Thanks & Stay Well,

Magister

William L. Howard (Bill)

headmaster

Howard Academy Metal Arts

howardacademy168@gmail.com