All Activity

- Past hour

-

The animated roll eyes, Oy Vei emoticon wasn't enough clue that I was joking? You're pretty easy to sneak up on when you're concentrating aren't you? Frosty The Lucky.

- Today

-

JLP Blacksmith Teaching Center.

jlpservicesinc replied to jlpservicesinc's topic in Building, Designing a Shop

Well like all this, it's a journey. After a talk with 2 different peeps the stock shelving is on the way out the door and Pallet racking on the way in. Another section of interior siding installed and a 16ft pallet racking self moved into position. These were supposed to be 14ft tall which I did not measure on arrival.. Anyhow, still not in the home position was it was a long day of removing the old full shelves, moving all the metal and installing it, then bringing in the pallet racking. This racking is 4ft wide by 9ft long. This means all the current contents from all the shelves will fit on this rack. This also means that the surface grinder will live under the first shelf.. This will open some floor space. Sadly all the metal working machines use coolant and that stuff makes a mess. That is to be sorted at a future date. But another large step in the right direction. -

No buttons there; that’s just screenshots of the app from my phone.

-

shiggy joined the community

-

I bought the rebel 215i about 2 years ago and was very happy with the features. Smart mig is great.....when it works. This is my home project and side job machine not being used harshly or a lot even. Probably put 25 lbs of wire through it. First 3 months the main board fried. It was under warranty so I wasn't too upset. Now the display board went out over night and it will be 600 to repair. I feel like the rumors they worked out the bugs was started by esab. I talked to them and no mercy. I won't repair it again. I bought a titanium from harbor frieght to use while the esab was down and for 450 it does a great job for 1/3 the cost. My sentinel hood does weird stuff all the time too. Speedglas never failed. Buyer beware.

- Yesterday

-

The buttons don't work for me John. Seriously, it looks like you're coming up with a good system to organize your library. You're beginning to scare me buddy! Frosty The Lucky.

-

Ahhh, another dangerous book for my library! It's turning out to be a great Saturday! Frosty The Lucky.

-

Just like Dad said to us when we were kids and after that "lecture" my Grandmother, Mom chuckled and said that's almost exactly what Guy, her husband told their kids and what her Father told her and her sisters. Things change, it's the only thing that remains the same and having to learn to deal with new ways is always a stressor so it feels like things are going to pot in a hand basket. "do as poorly as is tolerated" There's another way to put that and my experience says it works. "People and heck animals will live up to expectations. Frosty The Lucky.

-

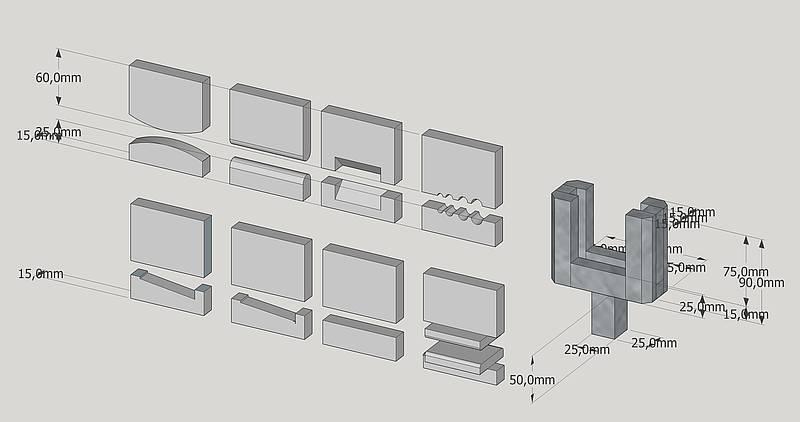

Die size/thickness for Guillotines/Smithing magicians

Frosty replied to KYBOY's topic in Tools, general discussion

I wish I remembered Will, when I built mine I started with the piece of leaf spring I figured I could get the most dies out of and built out from there. I also wanted to be able to work across or lengthways on the stock so my guillotine doesn't look like "normal." Sooooo, I made an open throat frame with the dies on a 45* angle so I can pass stock across or along the dies. Say I want to fuller a piece down or put a fuller in a blade. Rotate the guillotine to suit how I want to address the anvil depending on what I'm doing. The last pic is a detail WIP to show the open throat support and the upper die guides. At first I welded a piece of 1/2" square across the top of the top tie as a striking surface but they didn't survive long so I chamfered the striking surface SLIGHTLY and made sure the temper wwas drawn to dark straw. Version two will have a socket to receive the hardy shank so I can use the guillotine over the center of the anvil rather than on the heel. Frosty The Lucky. -

What did you do in the shop today?

Goods replied to Mark Ling's topic in Blacksmithing, General Discussion

That’s kind of funny. I tend to make a fair number of blacksmith knives from salvaged 52100 and 5160 forged down to 1’ x 1/4”. Every time I’m making them I tell myself I need to make box jaw tongs to simplify some of my stress in the starting process… Keep it fun, David -

What did you do in the shop today?

TommyVee replied to Mark Ling's topic in Blacksmithing, General Discussion

The butcher dies are made from ordinary 1" mild steel square bar that I will harden somewhat with superquench. The person who showed me the design does exactly that and has a good dozen sets of dies superquenched that way, and says they have served him well for years. -

My friend Miriam wrote the Girls version.

-

What did you do in the shop today?

GhostTownForge replied to Mark Ling's topic in Blacksmithing, General Discussion

It looks nice. I still need to make one of those for my anvil. What steel did you use? -

What did you do in the shop today?

TommyVee replied to Mark Ling's topic in Blacksmithing, General Discussion

I haven't done much forging on my new anvil yet, I'm still making tools to go with it. Today I cut and welded up a Mark Aspery style "smoosh-o-matic" guillotine tool and a set of butcher dies for it. (the cut-and-pasted image looks stretched, but if you click on it it expands to the right aspect ratio) -

See also "The Dangerous Book for Boys" by Conn and Hal Igguldnen. There are also modified editions for girls and men. G

-

Die size/thickness for Guillotines/Smithing magicians

wicon replied to KYBOY's topic in Tools, general discussion

-

Okay, I tried updating with exporting, editing, and importing, and it worked pretty well. This involved exporting everything into a comma-separated-value (CSV) file, opening that file in MS Excel, deleting the rows for the items I didn’t want to change, typing the article titles into the Notes field, saving the CSV file, and importing it back into the app. Here’s a sample of the result: Now, this actually created duplicate entries for each issue, so I had to delete the original entries and then add photos of the covers to the new entries. I have to see if there’s some way to duplicates together rather than delete the extras. The next step is to try creating new entries by importing a CSV file. I’ll give that a try with my old copies of the Blacksmith’s Journal. More to come….

-

Die size/thickness for Guillotines/Smithing magicians

Will Brouwers replied to KYBOY's topic in Tools, general discussion

Resurrecting this thread with the same question as the original post. What size dies does everyone have? Thickness and width please! -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

Thanks David, I try to keep it interesting.. I love, love, love your tongs. On smaller sizes it's a good idea to leave a relief section just in front of the jaw boss vs upturned lip. If I'm doing knife work or the like then this design of full jaw is my preference. But for general work, having that relief in front of the jaw pivot allows to hold stock 90 to the tongs for upsetting and such. I prefer full jaw side lips if I"m only drawing and want maximum control. The full side lip tongs are also much harder to forge cleanly. -

As we age, it is natural to think everything is going to pot, and it is; that the following generations don't measure up, and they don't. It is also natural for us to secretly resent how easy "this generation" has got it, but they certainly do not! The only thing that's changed is the level of intolerance. The majority will do as poorly as is tolerated, and a small minority will do the best that they can. Solomon said that there was nothing new under the sun, about 3000 years back, and human nature has not changed since.

-

Frosty----really depends on the kid, ive started with a few easy projects with a coupla real youngsters-----lucky to have 3 nephews , young men now, had all 3 eager to keep going with the adventures-----all 3 still love doing these kinds of things-------with their kids !

-

Okay, I downloaded a free copy and am finally through the preface and started on the table of contents. Lots of cool sounding stuff, I remember seeing a couple of the illustrations in Boy's Life back when. I may not do this stuff . . . again but it'll be a good thing to look through. What age do you think is right to give a copy to a boy? Frosty The Lucky.

-

What did you do in the shop today?

Daswulf replied to Mark Ling's topic in Blacksmithing, General Discussion

Billy O that turned out great. -

Having a clue would make most cloners above average. . . well above. Have you seen how many have to put chokes on a T burner? A too small jet stuck well into the mixing tube and chokes is like pollinating a daisy with a politician. I expected bad builds when I published the T burner plans WITH how directions but holy MACKEREL! I'd just like to see the bad builds being sold without MY name attached. I guess following directions isn't a realistic expectation. Frosty The Lucky.

-

all things i lived through---and sadly--too few today-------i have given countless copies of one of my favorite books to nephews/nieces kids of friends and family----THE AMERICAN BOYS HANDY BOOK----alot of it dated ,most of it pretty fun-------gotta give it to them old enough to handle some easy tasks and have fun doing it.......and young enough they dont give it a 10 second look, a toss in a pile and on to the next video game....