-

Posts

123 -

Joined

-

Last visited

Profile Information

-

Location

Springfield, Missouri

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

Москва Россия Senior smarty pants Just about moved to Moscow Idaho once upon a time.

-

Howdy fellas. Been a while. Been a really long year, all around. Had the rona back in March. Was down with that for a couple months & really sucked. Got feeling better & was getting back to normal. Then I took a bullet to the knee. Which doesn't tickle much. Down for a couple months with that too. Got back to work for a couple weeks and wham! Injured the same knee again & there goes another month. Finally getting back to a new day job tomorrow, my little fab shop is starting to recover from the inside shutdown & I'm thankfully getting to swing a hammer again. Gots a friend in Moscow who's wanting a chef's knife. Something like a deba or Usuba. Different purposes but single bevel is the goal. Made the billet a year ago & it's been just sitting, waiting for a reason. Anywho, it's nice to be working on things again & talking to folks.

-

Jeep & Willy's & Lovers of old vehicles

fleur de lis replied to Irondragon Forge ClayWorks's topic in Everything Else

I really am a glutton for punishment. Bought another one. But I got pretty lucky with it. This is gonna be for "Poject 83 Abomination". 1970 Jeep cj5. Dauntless 225 v6, T-14 trans, dana 18 t-case, dana 27 up front, offset flanged dana 44 (no two piece shafts on this one) out back, has 3:73 gears & maybe a track lock in the rear. Runs & scoots under its own power, sorta. The carb is in need of some attention. Clutch is toast. Needs new rings & valves. Good oil pressure. A rebuild is in order. The drive train is going into the 83 cj5. I'm hoping to shoehorn the T-176 in place of the T-14, or go with a Saturn overdrive unit. Going to keep the 4" lift & 33"s on it currently. New skid plates & some other small changes. The a bunch of the left overs will be going to the 69. Which is missing a ton of small parts as it turns out. Doing this as I kinda put a rod through the 258 in the 83 & this on was cheap & has no title. -

Jeep & Willy's & Lovers of old vehicles

fleur de lis replied to Irondragon Forge ClayWorks's topic in Everything Else

Likewise. Thinking hard about finding one for the 83 cj as well. Maybe the whole drive train. As I really dont care for the AMC 20 that's in it. -

Jeep & Willy's & Lovers of old vehicles

fleur de lis replied to Irondragon Forge ClayWorks's topic in Everything Else

Got a new one added to the family not to long ago. 1969 cj5. Dauntless 225 v6. T14 trans. Dana 18 t-case. Dana 27 front axle. Offset Dana 44 rear axle. Hadn't run in 30 years or so, but I managed to get it going again. Still gonna need a full tear down. And a ton of body work, but it's a good start. Would be happening sooner, but the wife decided that we needed a pair of 59 ford f100's to work on as well. -

Time for the winter project shenanigans to begin. To hopefully be completed by late spring (as the scrapyard treasures permits). No idea of the stroke or speed. There's some writing in it, but I can stumble along in russian. Definitely not Italian. I can post a picture is anyone speaks Italian. This will be similar in design to the one blacksmith-450 made , but turned 90° with a pass through in the main beam probably 6" x 6" for those longer jobs. The main beam is a probably excessively stout. 12" x 14" x 12" & 7/8" thick x 5' long. Found it years ago at a job for just a few bucks. The cylinder and anvil are to be mounted in the channel of the beam with the legs acting as guides. The tank / pump / motor will be mounted to one side with the controls to the other side with some type of protective cover over the flammable bits. Red hot metal & pressurized oil could be fun. Just not right in front of my face. In case it's not apparent, I'm winging most of this & using as much scrapyard finds & reclaimed materials as I can dig up (not the hoses though. Those'll be new). This is mostly a fun project for me & if I end up with a press to do canister & billets with, super. I'm at a early point with this & still have to answer most of my own questions.

-

Jeep & Willy's & Lovers of old vehicles

fleur de lis replied to Irondragon Forge ClayWorks's topic in Everything Else

yep. Been calling it chocolate milk & mustard pudding. The transfer case was like rancid poached eggs in a peanut butter cream sauce. Front axle looked good though. -

Jeep & Willy's & Lovers of old vehicles

fleur de lis replied to Irondragon Forge ClayWorks's topic in Everything Else

I parted ways with the army truck. It was a maintenance hog & everything was huge, heavy, & generally expensive. So I got this little diamond in the rough. 1983 cj5 258 inline 6 T-176 Dana 300 (short tail shaft) Dana 30 (wide track) Amc 20 with a lunch box locker It wasnt running (well sorta running barely), or moving. In the last few weeks I've fixed most the mechanical issues. The clutch material was rusted to both the flywheel and pressure plate. So new clutch assembly. Carb was flat wore out. Replaced with a new Weber 32/36. Plugs & wires. New accel coil (DUI distributor coming later). New magnaflow underneath. New rubber (off the bronco which is dead for now). New besttop super top. Fresh gear oil all the way around (the pictures should explain why). Some other odds & ins. Gots to do a rear wheel bearing & seal tonight. Also thinking & talking to a buddy about doing a 4.0l stroker to drop in it. -

Scrap bucket chopper.

fleur de lis replied to fleur de lis's topic in Axes, Hatchets, Hawks, Choppers, etc

Good idea! Hadn't thought of it before. Thank you. -

Scrap bucket chopper.

fleur de lis replied to fleur de lis's topic in Axes, Hatchets, Hawks, Choppers, etc

Thank you. My wife's laid claim to it. Shes one of those hippie vegan people. So she's in need of a veggie killer. -

Scrap bucket chopper.

fleur de lis replied to fleur de lis's topic in Axes, Hatchets, Hawks, Choppers, etc

-

No worries mate. Lots & lots of info & opinions around here. Fleabay is very very subjective price wise. If ya get down to Springfield, give me a shout. I'd be happy to hammer so metal with ya. And watch out for Frosty. That guys shifty....

-

I paid a third of what your asking. For my 6-1/2" iron city that was in immaculate condition. This was late last year or early this year. Either way, not long ago & I'm not but an hour from you. Not trying to be critical either. If you can get your asking price, more power to ya. But you may have that vise a while.

-

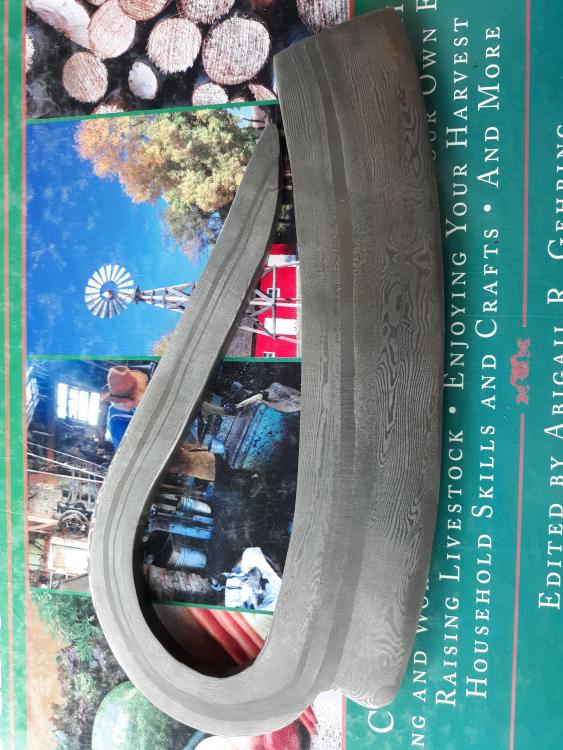

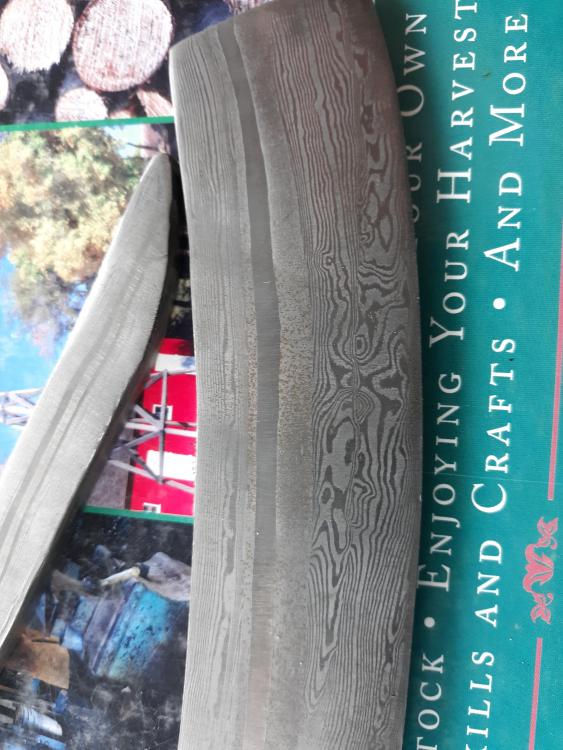

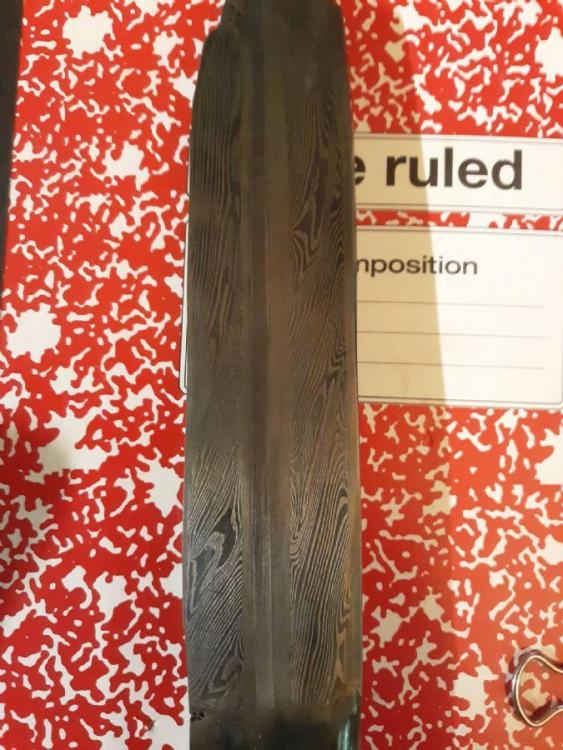

Had some scrap damascus cut offs I didnt want to waste. Put them in a can with some 1084 powder. Didnt have anything in mind for this, just let it go it's own direction and ended up with a big kitchen chopper. Almost ground & ready for heat treat, except for one wee little bad weld I'm chasing near the edge. So we shall see.

-

Здравствуйте!