-

Posts

622 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Shainarue

-

Got them all out tonight! Freed up two before my appointment and the other 3 after. Tap tap tap, heat, cool, tap tap tap, try. Repeat. Finally got a look at what the inside had in store. I'll need to fabricate a few fan blades. Otherwise there's not much to it since basically the gears are on the outside in the form of those humongous wheels, lol Next up, the tightening pegs that hold the crank wheels in place. Tapped and sprayed them tonight before I packed up for the evening. Tomorrow I'll give them a try with the wrench and move straight to heat if they don't budge. They don't look like they have as much build up though so fingers crossed. I know, slow is fast. But my wife's patience is running out regarding the "pile of junk taking up almost all the patio". She exaggerates. It's only taking up a quarter of the patio. But I promised I'd have it moved off as soon as I got it apart.

-

I do have some fuel line wrenches like you pictured. Came in a Dremel tool bag I bought at an auction. They didn't fit the nuts though. I also have an electric impact wrench. It was actually one of the first things I tried. The socket doesn't have room to fit onto the nut due to the outward curve of the fan housing. I've got about 20 minutes before I need to run out for an appointment. I'm gonna go try a few taps with the hammer just for good measure.

-

Oh yes, I also have vinyl/neoprene gloves for stuff like that. I have a latex allergy so I never even tried the latex - but good to know they would have just dissolved anyway, lol

-

I was using the rubber mallet on the wrench - not that it mattered. The wrench wouldn't hold on to the nut anyway. I also used the rubber mallet to kind of just bang around on the seal/ears of the housing to see if it would jar something loose enough to help. I've also whacked on it a bit with a piece of 2x4, lol. I honestly don't care if I break the bolts or the nuts. I figure the worst ones will need replaced anyway and I'm not trying to keep this a "100% true to all original parts" restoration. I already knew I'd have to replace the original wrought iron legs with new steel pipe. And there are a few parts I already know I'll need to recreate or purchase. I have no qualms with replacing the bolts & nuts on the blower housing. That said, I'm also trying not to cause any stress on the ears of the blower housing where the bolts go through - because if those break off, I don't know that I'd be able to repair it without just recasting (and I've never casted, lol). I haven't worked on it at all since I last posted here, so I haven't tried heat yet. But if heat doesn't work, then I'll go with Frosty's suggestion to soak a rag in the ATF Acetone mixture and try that. I'll post an update when I have one.

-

I use the Hardy brand goat skin gloves from Harbor Freight. I have two pair. One pair that fits which I just use when I'm using a powered cutting blade or to keep my hands clean when I'm messing with transferring coal/charcoal or sorting metal in the buckets. Basically whenever I'm specifically NOT working with hot stuff. Then I have a pair that's one-size larger which I use only on my non-hammer hand to hold a punch or chisel if the stock bar is putting off too much heat for me to hover long enough. The one-size larger makes it easy to pull off if I start to feel the heat - but not so much bigger that it impedes in the dexterity I need to hold the tool in place. Other than that, I prefer bare handed & using tongs if the stock isn't long enough to hold a cool end.

-

The 50% Dextron II ATF and 50% acetone mix is what I've been using. Wire brush, spray, let it soak while I forge. Then when I'm putting stuff up, I try with a wrench, hit it a few times with a rubber mallet, try again, then spray the mix again and try again the next day. Been doing that for 10 days. Haven't tried heat. I'll give that a go next. What happens if there's still residual atf/acetone mix in there when I heat?

-

A middle-aged beginner from the Netherlands

Shainarue replied to pragtich's topic in Introduce Yourself

I have noticed that different regions in the Netherlands have fairly strong pronunciation variations. Like soft or hard g or w or whether the end "en" on verbs are pronounced. We have dialect differences here as well, but the Netherlands is so tiny compared to the US (like, the size of just one of our states) that it kinda blows my mind how many dialects y'all have. It's not surprising at all that pragtich as a username is always available. My sister has always used a mashup of her first name and last name from her first marriage to create meolgiga - which is also always available because it is otherwise just a nonsense word, lol Sounds like you have a pretty good start to a useful workshop! I work out of a 10x12 shed with the forge directly outside the door and the anvil directly inside the door. -

A middle-aged beginner from the Netherlands

Shainarue replied to pragtich's topic in Introduce Yourself

Welcome from Northwest Missouri in USA, pragtich! (also, is there a story behind the letter flip in your username or just because it was fun?) Like you, I'm also forty-something (but a gal, not a guy) and just started out about a year ago. This has been by far my most dedicated and most loved hobby in my life. I hope it becomes the same for you. I looked into The Green Circle and it looks like a wonderful group of tradespeople. There is a similar organization near me that specializes in demonstrating & teaching the historic arts. I'm glad to see you've already invested in a workshop, as that's the fastest and most painless method to learn this craft! -

I've been soaking & tapping on the bolts holding the blower cover on for over a week now and they are not even close to budging. I'm thinking I'll just use a dremel to cut them off since they'll likely need replaced anyway. Keeping my eye out for a used air compressor with 1HP or higher, and then purchasing a cheap hand-held sand blaster. I plan to set a table over this and drape a tarp over the table - creating a make-shift spray cabinet - so I can reuse the blast medium.

-

What did you do in the shop today?

Shainarue replied to Mark Ling's topic in Blacksmithing, General Discussion

That's a lovely penny scroll John. It's one of my favorites also. -

Here's what it looked like before I turned it upside down and removed the legs for easier access to the blower.

-

What did you do in the shop today?

Shainarue replied to Mark Ling's topic in Blacksmithing, General Discussion

That's a nice steak flipper David! I like the ball end. -

What did you do in the shop today?

Shainarue replied to Mark Ling's topic in Blacksmithing, General Discussion

The railing is looking great John. Alexandr, those candlesticks are beautiful. Sharp looking knives Duckwalk. Rich, I'm also working through the ABANA Level 1 Curriculum. I'm currently hung up on the hook of the gate latch assembly. I've made 3 so far. Just struggling to get the correct dimensions. Perfectly functional gate hooks otherwise, lol I decided to take a break from class work this week and just play a bit. Made these coins for Mother's Day out of 1/4" thick slices of 3/4" round bar. The one with the skull is a memento mori coin for my sister in law. The one with the cross was for my mother. The thumb spot is on the reverse. I'm calling it a "reminder coin". They both loved their gifts. I still need to make one more for my sister. I'm waffling between a cat face or the Avatar "Earth" written character (she's a massive Avatar fan - the series, not the blue people). And since I have an extra disc, I might make another memento mori and give it to my nephew along with his graduation gift. -

What did you do in the shop today?

Shainarue replied to Mark Ling's topic in Blacksmithing, General Discussion

What a lovely design John! -

Whoa. I was also coincidentally looking at this thread the other day because I am ALSO looking to restore an old buffalo forge! Mine isn't exactly like Martin's. However, it does have the lever-operated blower which is what I needed more info on. Mine's a Buffalo No. 0 (zero) which is also shown in that ad above. I was going to post pictures once I actually started working on it. So far I've only just removed the legs & the lever mounting piece. Lots of soaking & waiting to get the blower cover off and see what all I've got going on in there (or not going on, lol).

-

April 2023 BAM's 31st Ozark Conference

Shainarue replied to Shainarue's topic in BAM Blacksmiths Association of Missouri

I did indeed. Jumped in with both feet. All or nothing! It truly was one of the best experiences I've ever had. -

What did you do in the shop today?

Shainarue replied to Mark Ling's topic in Blacksmithing, General Discussion

That works! -

Welcome to the active membership. I wholeheartedly agree with the sentiment to learn with other smiths. Check out the BAM site, I think the next few meetings are only a few hours from your neck of the woods. There are quite a few members who get together outside of meetings just to forge together and gab. I'm in the KCMO area. Looking forward to seeing what you work on!

-

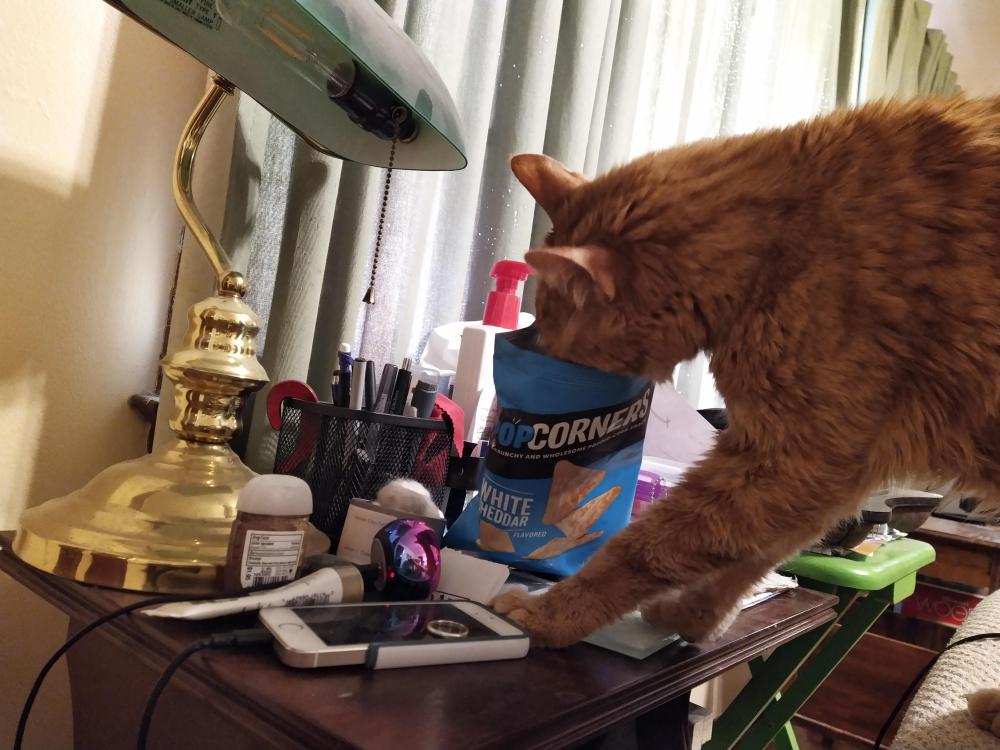

Show me your blacksmith pets

Shainarue replied to Glenn's topic in Blacksmithing, General Discussion

Charlie LOVES chips. He hears that bag and comes running! The only way I can eat my own chips is to put a single chip nearby just for him. This time I intentionally set the empty bag down so he could lick up all the dust, lol He's old and spoiled. 18yrs old on May 8th! -

April 2023 BAM's 31st Ozark Conference

Shainarue replied to Shainarue's topic in BAM Blacksmiths Association of Missouri

I had an absolute blast at my first ever blacksmithing conference. Long post ahead! I took part in a 1-day ABANA National Curriculum Level 1 class they offered on the Thursday before the conference officially started. It was led by instructor Bud Harvey and there were three other certified instructors also there to lend guidance and observe. There were only seven of us in class so we had a lot of individualized attention, which was great. We did most of the work in propane forges as that is what they keep in their mobile training station set up. However, when we got to the forge welding portion of class they pulled out a coal forge to increase the chance of success. I've used propane before in a few project classes I took a few years ago before I really got into blacksmithing as a main hobby, but this was my first time forging for real in an all-day situation using a propane forge and I gotta say, I really enjoyed the propane forge! I wouldn't mind having one of those to use in addition to my coal forge, lol! My original plan going into this was that I would take the class on Thursday and then spend all day Friday watching demonstrations and checking out the tailgates and just getting a good feel all around for the conference because it was my first time. However, I really really really wanted to just keep on working on my projects and they told us on Thursday after class that they were leaving the coal forges available for us to use while they had a beginners class on Friday and Saturday using the propane forges. So with the exception of about half an hour at the beginning of the morning (where I checked out the tailgating and bought a few supplies from vendors that I knew I didn't want to miss out on) and about half an hour around lunch time on Friday I forged using the coal forge pretty much the entire day! I wandered over to check out the raffle items just before they closed everything down. I noticed there was also a sign up sheet for a forging contest that evening. One sheet for beginners and one sheet for intermediate. On a whim, completely out of my comfort zone but riding on a high from the last few days, I signed up for the beginners forging challenge. They held the contest after dinner. Contestants in the beginners group were a given a 6" length of 3/8" round bar. Our challenge was to draw it out square as long as possible, even throughout and no tapers. In 4 heats. There were 12 contestants and I came in 2nd! Unfortunately, in all the excitement I forgot to get my finished piece back from the judges so I don't know the exact measurements but I'm guessing it doubled at least. I received quite a few compliments on my technique and a few on my hammer grip and swing. On Saturday, I decided to leave all of my tools in the car so that I could really focus my time and attention on experiencing the conference in means OTHER THAN hammer in hand, lol I immediately checked out the tailgating to see what was left and see if the price had gone down on anything or if more things had been added that I didn't notice on Friday. There were a few forges, but I decided I didn't really need another forge that my rivet forge was just fine... there were a few good sized blowers, but if I'm not getting another forge I don't really need another blower either, LOL and besides I have TwistedWillow for that, LOL! I had picked up a pair of lightweight and springy Tom's Tongs on Friday but on Saturday I noticed a table of tongs handmade by somebody in our local blacksmithing group. This person is also at every meeting, so I've always had the opportunity to buy these tongs and I've never had the extra cash. Well I saved a lot of money just for this conference and I was not going to pass it up. I bought three pair of tongs from this guy and they are all made from mild steel so they can be reshaped to fit as needed if necessary. Holland Anvil was there and they of course had all of their wares. But the one that got everyone excited were these little swage blocks that had slight imperfections so they were selling them for only $40! Of course, I ran over there and grabbed one for me before they ran out! I also picked up a few tshirts. One for winter which has a cross stitch screenprint. And one that says "Get it hot. Hit it hard." which I found out was an innuendo when I showed my wife. I truly did not know that when I bought it and was mortified when she told me. It will be relegated to a forging shirt, lol I had signed up to volunteer working in the art gallery for the 1:00 to 5:00 shift so I didn't spend too much more time perusing the tailgating section once I decided there wasn't much else I really needed. Instead, I went and checked out some of the demonstrators. They had three demonstrators. One was Lisa Elias, who did very delicate forms using mostly localized torch work and welding. She was making lamps and wall sconces during the demonstration. They were very beautiful and I really loved the look of it, but there really wasn't much technique to it that I needed to sit around and watch. So I went and checked out Glenn Horr, who was carving animal heads using an air hammer. That was exciting! I stayed over there for about an hour watching him and chatting it up with a few other people sitting nearby. The only demonstrator I did not go and check out was Nick Rossi. I had saved that one for last knowing that of everything, knives was the one that I had the least interest in. I'm sure future conferences will also have a knife demonstrator so I'm sure I'll eventually see one, LOL When the demonstrators started putting up their things for the lunch break, I knew I only had about an hour left before I had to report in for my shift. I grabbed a quick lunch from the food truck then went back inside to peruse the tailgating again and make sure that there wasn't anything I really just had to have. I noticed an old forge next to the auction items so I went to check it out. It was a fixer upper Buffalo 0 from the 1800s complete with original belt driven blower. It was a silent auction and the high bid was $65 so I jotted my name down for $70. I also kept walking by this big fire pot that was being sold for, if I recall correctly, $150? With a note that any offers would be entertained. I also knew the guy that was sitting at the table, so I started talking to him about it. He said he would be there until after the banquet. So I decided to test fate, and see if it was still there after I finished my shift at the art gallery. Well, as I'm walking away Bud Harvey comes up and says, "I saw you were looking at that fire pot. Are you thinking you want one?" and I told him yes, that I was considering it. He asked me to follow him. He proceeded to lead me to his car and show me the fire pot that he had gotten a great deal on that same day. And then he wanted to pass that deal on to me. So a very long story coming to an end, lol, I came home with a big fire pot that I bought from Bud Harvey for only $40! Now I just need to make the table and stand to go with it, and buy (and possibly refurbish) a blower from TwistedWillow! Oh, but wait, what about that Buffalo I bid on? I thought surely someone would bid again but just in case, I took measurements. Should have done that BEFORE putting my name down. It won't fit in my wife's hatchback opening so I was really hoping someone would outbid me. I checked in at the art gallery and I must say, talk about inspiration! There were so many beautiful things and some of them were marked for the auction! After the banquet, they had the auction. Another first for me and whoa. Very exciting. Maybe a little too exciting, lol. My anxiety was spiraling so I edged my way over to stand in the doorway away from the crowd. They announced the winner of the Buffalo before the live auction started. It was me. Uh oh. I started talking to a guy I knew from a few of the Kansas meetings about my dilemma and he offered to haul it home for me as long as I could wait a week or so for him to bring it over. Problem solved! Sort of. Now I have a full on restoration project on my hands, lol But seriously, it'll be fun and I'm looking forward to it. Here's a pic of A Buffalo 0, but not mine: I also won one of the lamps made by the demonstrator, Lisa Elias! -

What did you do in the shop today?

Shainarue replied to Mark Ling's topic in Blacksmithing, General Discussion

Beautiful stuff everyone! -

Show me your blacksmith pets

Shainarue replied to Glenn's topic in Blacksmithing, General Discussion

-

Crazy how well some things manage to stay preserved! Very cool find.

-

JLP Blacksmith Teaching Center.

Shainarue replied to jlpservicesinc's topic in Building, Designing a Shop

Lookin' great! -

A6EEE445-8431-4777-969B-EA01871454EE.jpeg

Shainarue commented on prof's gallery image in Member Galleries