-

Posts

622 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Shainarue

-

What did you do in the shop today?

Shainarue replied to Mark Ling's topic in Blacksmithing, General Discussion

Thank you for the compliment on the snail Larry. Haha about the pens Billy. Thanks Frosty & BlueRooster. Frosty, I have a few ideas if I were to do it again - I'm sure you'd come up with something even better! I would like to do another one but not a a 150mm challenge, lol. I've also been wanting to do a mancala game for a few months now. Just haven't gotten around to it. I have another club meeting this coming Saturday. Because of where I live, I can go to all of the Kansas meetings so I joined their club last year. I'm able to go to about half of the Missouri meetings. Anyway, the trade item this Saturday is yard art. I have an idea but I haven't even started it yet so we'll see. Today I welded up a coat tree for my best friend. It's not finished. I still need to get it level, grind a nice dome shape to the end of the branches, and paint. None of the decorative work is mine. I had picked up a bunch of solid metal railing balusters for free from someone on FB Marketplace. I figured I could grind off the coating and use them as stock. When my friend mentioned needing a coat tree, I told her I had just the thing! I only used 4 pieces for this. I still have 50 or so left, lol I also worked on the Buffalo 0 forge I've been restoring. I learned how to lace a flat belt using cord and got that done. It's super loud because I still need to work on the fan but this is huge progress! (In case you can't watch the video: it's just me cranking the lever, making the wheels spin which turns the fan pulley and blows the air.) 401388169_24031428269837949_6806182915641071939_n.mp4 Dabbersterrin, that's a lot of progress for 6 hours! Or at least, it would be for me, lol! I like the punchline. I've been thinking I need to get something made for my punches. I've gotten to the point that the cups I keep them in currently aren't as convenient as I'd prefer. I just have to decide what I want and where I want it. Nice setup John. I see you also have tools in cups - but keep them all together in a toolbox. That's a great start at least. I think I'll do just that when I'm out in the shed tomorrow evening! -

What did you do in the shop today?

Shainarue replied to Mark Ling's topic in Blacksmithing, General Discussion

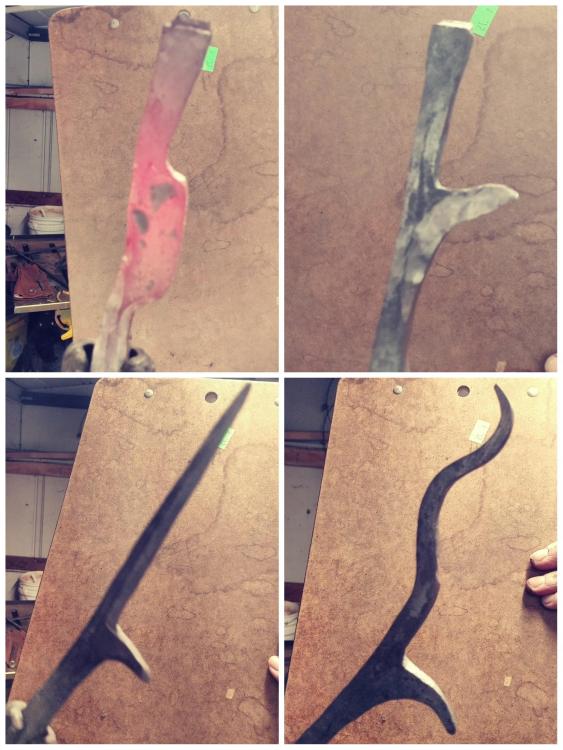

In early October, I started working toward the ABANA National Curriculum Level 2. I finished the scrolling tongs, scrolling wrench, and basket handled fire poker with 3 different welds (faggot x 2, scarf x 2, collar) I also went to a class. We worked on square corners with a radiused inside and with a 90° inside. We also worked on scrolls. After that class, I decided to take a step back from learning and just have fun for awhile. Maybe through winter, maybe longer, lol. So here's some of the fun stuff I've done: Snail from rebar for a scrap challenge A thin fuller out of one of the H13 slugs gifted to me. A "Dinglehopper" from The Little Mermaid, which my wife wanted as a back scratcher and very specifically made certain I knew she didn't want it to be longer than the dinner fork she currently uses, lol And most recent is my first time participating in a 150mm challenge. It was the trade item for today's BAM meeting. 6" of 3/4" square. I decided to make a Tic Tac Toe game. Here's the table showing everyone else's entries. Since really impressive stuff! -

What did you do in the shop today?

Shainarue replied to Mark Ling's topic in Blacksmithing, General Discussion

Back again after another long hiatus. I'm gonna have to get better at checking in here more regularly because the activity in this thread alone took me a few hours to get through! Forgive me for not using the Quotes feature, but the forum platform doesn't seem to like me jumping back and forth between pages while creating a new post. A lot of beautiful work being shown lately! So I'll start with a big "great job!" all around White Fox Forge - I think I just read on the BAM forum that you'll be a demonstrator at the 2024 BAM Conference doing your pipe tomahawks? That's awesome! I was already looking forward to it but now I'm gonna have to make sure to say hello! Jim86 - that little armoury made from nails is SUPER cool And finally, regarding the blower repair - someone mentioned Billy aka TwistedWillow using c-clamps to take care of the lateral movement and that is correct. He suggested the same to me when he was talking me through my own blower repair and it worked wonders! I've been staying busy in the forge - still trying to get out there at least a few hours every day. I just haven't been online much other than to check IG/FB notifications and email. My wife got a promotion and now works days - same hours as me - so we're home together a lot now, lol. She's super cool about me still doing my thing - as I am for her. But she would like to eat dinner together (I never ate dinner when she worked evenings - just a snack while forging, lol). I'll try to get some pics & an update together sometime this weekend. -

What did you do in the shop today?

Shainarue replied to Mark Ling's topic in Blacksmithing, General Discussion

Nice work Chad. I've also been working on basket twists and crazy enough, I had also made a paper towel holder this week, lol The coil in the middle is to add a bit a resistance when a square is being pulled off. Previous paper towel holders I've made required the person to hold the roll still while tearing, otherwise you'd end up with 6 ft of towels! I had quite a few hiccups during the making of this... just have those days sometimes where nothing seems to go right ... this was one of those weeks, lol But Ashley (the wife) is happy with it so that's all that matters this time around. -

I love that design Frosty! I adjusted my tool tongs to fit the punch I was using and made sure they still also fit the tool set they came with (which I have yet to forge to the shapes I want, lol). That worked well for the indexed punch. I'm saving Frosty's design though. Irondragon, oddly enough I have yet to ever miss when using a handle but for some reason I do miss when it's my hand. I don't get it. Anyhoo, thanks y'all for the input!

-

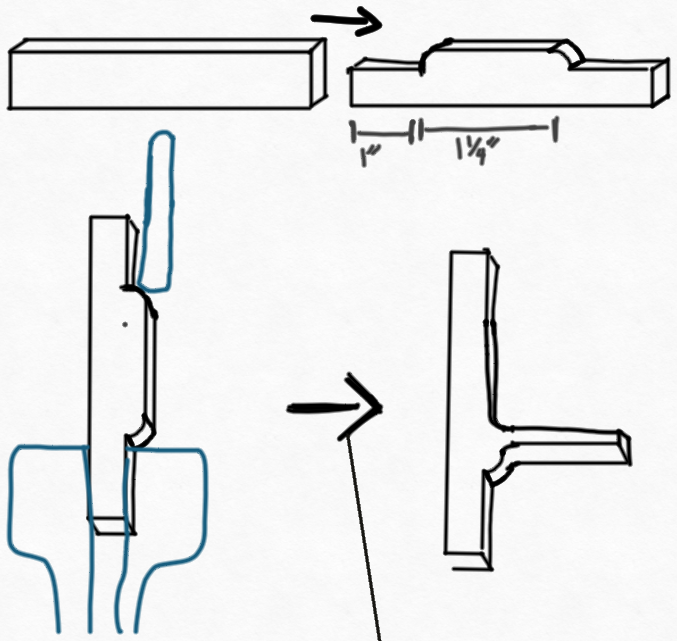

Your second idea is exactly what I was trying to sketch up but was just going at it way too hard, lol I have a pair of tool tongs that are designed to fit in a groove around a tool body - I'll try those tonight to see if they'll grip. I'm embarrassed to say I hadn't even tried.

-

I've been sketching out ideas but I've only managed to fill up two pages with crossed out ideas. I also did a search online but not finding what I'm thinking of. I have a variety of hand-held top tools (punches, chisels, fullers). Some are made with an index, some have a hex body, some have a round body. I apparently can't manage to use hand-held tools without eventually missing & wacking my hand. Usually one of the knuckles of my pointer finger. Last night it was the metacarpal of my pointer finger and I legit thought I finally bungled up everything and broke my hand. I had to call it quits early because I couldn't hold anything with that hand anymore. Today it only hurts when I press on it so thankfully it's just bruised. But that was a scare. I've tried using vice grips to hold the tool but they aren't optimal. The vibrations from the hits is wears down the spring (I'm guessing) and they come unclamped, sending the top tool skittering off. Obviously, I'll go back to using the vice grips until I have something better. Because a skittering tool is better than a broken hand. Of course I *could* re-make all my hand-held tools so they can be handled, and that's a consideration (just adding a neck of sorts which a pair of tool tongs can grip). And then of course I'd have to heat treat & temper the tools again. Or I *could* make a handle for each individual tool - and then build a tool rack to hold them all since they'd no longer fit in their tidy cups. But I'd rather make one handle that could be adjusted to tighten around any of these existing tools without modification to the tools. Anyone feel like helping me brainstorm some ideas?

-

What did you do in the shop today?

Shainarue replied to Mark Ling's topic in Blacksmithing, General Discussion

JD, I like the towel racks. Michael, I just recently started following Caitlyn on IG. She's posted some great tips in the few videos I've seen. That's a nice looking leaf. -

I'd never seen one like this until you mentioned it but now I'm intrigued. I'm looking through YT video reviews. Going by price, I assume you're referring to the yellow on one Temu. I haven't found a review specific to the yellow one but have watched a few on others with the same model name. Just add 'reviews' to your search and then click Videos to look for video reviews.

-

What did you do in the shop today?

Shainarue replied to Mark Ling's topic in Blacksmithing, General Discussion

John those are beautiful lookin' tools! Almost look like they were made from obsidian! -

What did you do in the shop today?

Shainarue replied to Mark Ling's topic in Blacksmithing, General Discussion

Kal, I'm not sure if you're giving this info in response to my comment regarding my poker end or just as information. But in case it's in response to me, yes I know the final project must be done exact to shape and size as indicated on the provided drawings. There are also projects that lead up to the final project which don't have as rigid of specifications but rather just to show you understand the concept and can demonstrate the skill. Basket poker only specified length and diameter of rods for basket and handle to attach to. Scrolling wrench only specified width of jaws and length of tines, and diameter of hanging circle. No specs at all on scrolling tongs. Etc. -

What did you do in the shop today?

Shainarue replied to Mark Ling's topic in Blacksmithing, General Discussion

That's such a well thought out portable setup. Pretty slick. I did another basket handle with collar finial tonight. Forged a bit thin while trying to blend the scarf a bit more. But otherwise everything went off without a hitch. I think I've finally got it. I even remembered to clean out my fire after an hour before I started the collar weld. I think tomorrow I might work on something not welding related. I'm not ready to attach any tips to these handles yet. At least not for assessment. I might attach something to them at some point just because, lol. -

What did you do in the shop today?

Shainarue replied to Mark Ling's topic in Blacksmithing, General Discussion

I'm going through the curriculum for the same reasons as Goods. I'm very goal oriented and without a goal, I tend to get stuck in a rut of just doing what I'm comfortable with and not growing. I'm not actually even a member of abana (yet) so I didn't even get a certificate from the Level 1 I completed. I would have just used it as kindling in the next fire anyway, lol As for the length of that flame bit, mine's definitely longer than what they demonstrated in the videos. I don't think it matters for the assessment though. It's not indicated in the assessment guidelines anyway. Pretty sure that project is just to demonstrate an understanding of the various welds (and the stock ratios for those) and the upsetting of the second tine. I will likely use this fire poker in my own firepit after it's assessed in October and adjust the end as necessary based on my usage. My wife loves the pictures she's seen online with the marble inside the basket - and she's been asking me for a paper towel holder - so I'm thinking I'll make her a holder with a shallow basket twist on the end and maybe I'll pop a marble in there! -

What did you do in the shop today?

Shainarue replied to Mark Ling's topic in Blacksmithing, General Discussion

Jennifer, "The Feather Duster". Seriously, that's what I see, lol Das, there's a lot of great work on those tables. Sounds like it was a good experience for you. I worked on redoing the poker end today. I like it better. I might still do another one though. I also started prepping some 1/4" bar to do another basket twist. I'll finish that tomorrow. Tried something different this time. Instead of two bars bent on half and then slipped over each other, I bent the bar in half and then in half again. -

What did you do in the shop today?

Shainarue replied to Mark Ling's topic in Blacksmithing, General Discussion

Jennifer, that tomahawk is beautiful! Glad you're feeling better and hope you're back to normal soon. Das, looking forward to your update on how the demo goes. I worked on a poker end this evening using a technique from the ABANA level 2 curriculum. I'll try again soon. Not happy with the bottom tine. I think I just need to shoulder in the pillow deeper. -

Blacksmith Twist Handles (AKA Basket handle)

Shainarue replied to jlpservicesinc's topic in Blacksmithing, General Discussion

I'm excited. I have a pretty good idea but I'll need a few days to play with a piece. I don't have any 1/8" rods, but I do have 1/4" so mine will have to have fewer pieces in the basket but the concept should still play out okay. -

Blacksmith Twist Handles (AKA Basket handle)

Shainarue replied to jlpservicesinc's topic in Blacksmithing, General Discussion

hahaha - challenge accepted on figuring out those other two! I'll text you if I figure it out, lol I'll check out the app. I love to sketch, so maybe it'll actually get used. I just went through a purged a bunch of apps I haven't used in the past year. -

Welcome to the active membership Steel Serpent Smithy! I can relate to SO much of what you and Frosty have said - and it feels good to see someone else make sense of it in writing, lol As for the executive dysfunction - here's what I've done which helps me (everyone is different): I use my Google Calendar for freaking EVERYTHING in my life. Friends have teased me (in kindness) because I even have my daily meds and my daily 8-5 work days and my daily 'feed the dog' set up as events. They're like - seriously? You won't remember to do that?! But yeah, seriously, executive dysfunction is dumb, lol So anyway, I've started adding "Forging: pick a project" to my calendar on days when I know I'll have time to go out there. Then in the description, I list out all the stuff I want to work on. Sometimes, I'll be thinking about it during the day and I'll go in and change the title to read the actual project I want to do. Example: "Forging: basket twist". Then my event reminder goes off, I look at my phone, and I know exactly what I'm going to do. I don't get all overwhelmed and shut down from indecision. Before my calendar, I used a cup with slips of paper in it. I'd pull out a slip of paper to see what I'd be working on that evening. And if I already knew what I wanted to work on, then I just wouldn't pull a paper from the cup! I'm sure you'll find something that works for you!

-

What did you do in the shop today?

Shainarue replied to Mark Ling's topic in Blacksmithing, General Discussion

If you hadn't pointed out your "mistakes", I wouldn't have known, lol -

What did you do in the shop today?

Shainarue replied to Mark Ling's topic in Blacksmithing, General Discussion

100% Also, that's a really cool skull. Tommy, that booth setup is pretty slick! -

What did you do in the shop today?

Shainarue replied to Mark Ling's topic in Blacksmithing, General Discussion

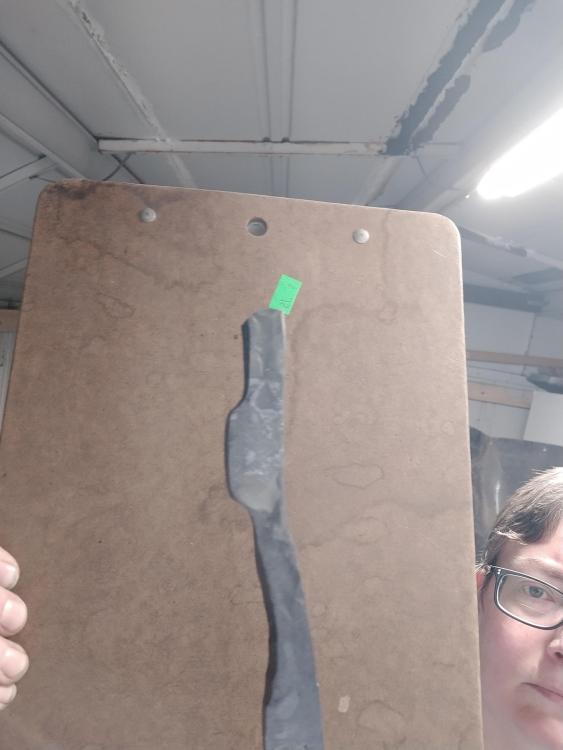

I haven't been active on the forum in awhile. Still keeping busy with blacksmithing though! I try to get out there at least a few hours every evening after work. And if we don't have plans on weekends then I'm usually out there all day. My stubborn self even tried to forge when we were in the midst of severe heat advisories! I waited until the sun went down and set a timer for 30 minutes. But the 2nd night, I ignored the timer thinking I was so close to done. I ended up making a bunch of stupid mistakes, threw in the towel and went inside only to discover I was sick from dehydration even though I had finished an entire 40oz tumbler of water in that 45 minutes. Ugh. Anyway, here's a few pics of stuff I've been working on: The garden candle holder thingy was made as a donation to my local blacksmithing club to sell at a fair last weekend. If I'd have had more steel, I would have made a set. I underestimated how much it would take to make one, lol. Basically about a 40% loss from original length once all the coils/curls/corkscrew elements are added. This one stands at 39" once it's in ground. Future ones I'll make shorter so I can use a 4ft piece of bar and they'll end up more of a seated-height at 28" in ground. It was my first time doing one of these and got the idea from the Lorelei Simms book Backyard Blacksmith. Overall it's fairly straightforward and easy. It was tricky getting the circumference just right so that the glass vessel fit inside just at the base of its lip. Probably spent the most time on that. If I decide to make these more often, I'll need to make a jig. I volunteered as a silent demonstrator at the fair - the more talkative members were up front. I made my first meat flippers. I was already starting on the second one before the first one was finished cooling - and then the first one sold as soon as it was cool enough to put on the table! The second one (a left-handed one) was still on the table when I left a few hours later. The two S-hooks were the last items I made. I had burned the tips multiple times and then turned the hook in the wrong direction. Just dumb mistakes. I decided I should be done for the day. The horseshoe heart was not mine - it's just there as a paperweight for the club's pamphlets. I'm also working on the ABANA National Curriculum Level 2. I've been practicing forge welds lately. Their first project is a fire poker with a basket twist handle & collar finial. A few examples of my practice (newest=left, oldest=right). Far right 3: over the span of a few weeks and troubleshooting with a local smith via pictures of my in-process. 4th from right: first fully blended and welded 3/8" bars using drop-tong on Friday evening. You can just make out the edge of the scarf - it lines up with the end of the scarf of the bar next to it. 2nd from the left was my first collar weld on Sunday which I did on the 1/2" bars from my first successful drop-tong weld (not blended). So technically, that one is a combination of the oldest & newest. The one on the far left is what I did this Sunday and will likely become an actual fire poker - just not one that I will submit for review, lol. But a good faggot weld for the basket, a fairly well blended drop-tong weld and a decent collar weld. -

Prayers and condolences Glenn, family and friends

Shainarue replied to Frosty's topic in Prayer List

I never met Glenn in person, nor talked to him on the phone - but we did have many conversations via messages and exchanged a few cards via snail mail. He imparted many words of wisdom and I'm sure he'll be in my thoughts regularly as I often think of him whenever I'm doing something which he's guided me on. -

That turned out beautifully!

-

Back in my 20s, my gf at the time and I fancied ourselves a kind of band. Drums, electric guitar, vocals - just the basics. But we lived on the second floor of an apartment building. One evening, a knock on our door from the older tenant downstairs. Crap, we thought we were done for. Nope - they were just coming up to let us know that we were sounding better and to keep up the great work! [fist pump] We got lucky having such awesome neighbors.

-

Blacksmith Twist Handles (AKA Basket handle)

Shainarue replied to jlpservicesinc's topic in Blacksmithing, General Discussion

Hi Jennifer! I know this is an old post but I'm wondering, were you able to get a video done on the inverted twists? I really love it and if I work at it, I think it would make a lovely feature on things I make for my wife's fiber room. If no video, can you try to give an explanation? And in case I haven't said so lately, thank you so much for all the time and effort you put into these videos. The search bar on your channel is one of the first places I go to look for something I'm struggling with! In fact, just yesterday I was watching your video on the collar weld because I remembered you had a different method for measuring which was WAY easier than trying to math it all out! And now that I've done a few, I need to re-watch your video to see if I can glean any other pointers. Sometimes I miss stuff when I don't know what to watch for yet!