-

Posts

622 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Shainarue

-

What did you do in the shop today?

Shainarue replied to Mark Ling's topic in Blacksmithing, General Discussion

Oh, I finished that back in June! I have a picture of all the required projects signed off on and ready for submission - but I'm not a member of ABANA so I don't get a certificate until I do that, lol. I don't need a piece of paper - I mainly did this to push myself out of my comfort zone and it was awesome! I figure if I go further and finish their Level 2 course, then I'll get the membership and submit both. Because with Level 2 certification, I can be listed as an official instructor for the Level 1 course and I think that would be pretty cool. There are a few places here locally that I might be able to get into as an instructor. For now though, I'm quite content to just keep playing, lol BillyBones, those are some beautiful torches! -

What did you do in the shop today?

Shainarue replied to Mark Ling's topic in Blacksmithing, General Discussion

Today I went to the Kansas Freestate Blacksmith Club meeting. It was held at a scrap yard! I think the owner is a member. Anyway, he gave us all a great deal if we wanted anything. We got to clamber all over the property. I found the perfect pipes to replace the legs on the Buffalo I'm restoring (two of them were even threaded!), a large pipe and thick plate to rig up some treadle hammer jigs, and a huge block to use as an anvil block. All for 20 bucks. Five members participated in the open forging time prior to the meeting. I watched and chatted with various members. I bring my tools every meeting and always chicken out, but I don't dwell too much on it since I'm also making connections with the other members. I wouldn't be doing that if I was forging. One of the members who was forging toppled backward in his chair when he sat down to rest and cracked his skull on something metal laying behind him. Thankfully, his grandson hollered fast for help, and a retired paramedic was first to assist, quickly followed by a fire chief. He was in good hands. Someone grabbed the first aid kit from their car and they got him wrapped up tight to stop the bleeding, then someone drove him to the hospital where he got 5 stitches and came right back to finish up his trade item These guys are hardcore, lol The trade item was "anything made with scrap". I had some railroad spikes and we had a demo at our last meeting for making nails so I made a nail header out of the spike. Pictures: short stubby nail header was my first attempt last week. Long heat painted one was the trade item. Hook was my warmup and nails I've been working on in between heats of larger stock. -

What did you do in the shop today?

Shainarue replied to Mark Ling's topic in Blacksmithing, General Discussion

I haven't checked in in quite some time - so I'm gonna quote for some of the earlier posts. Hope that's okay. John, that's a really sweet welding cart you've got going on! A place for every thing and every thing in its place Also love the shelving you added to the post vise stand for punches. Pipe wrench and butter knives - awesome. I love seeing what you come up with Das! That's a slick lookin sword. I love the hilt design. Duckwalk, I like leaf you added to the traveling trivet you made. I'm gonna add that note to my traveling trivet page. I may have been absent from here but I have continued regularly forging. We're supposed to get some rain this weekend so maybe I'll take the time to get a post together of what I've worked on. Just reading through this one thread has already eaten through my lunch break though, lol -

My stand was originally filled with sand and anvil sitting on top - but the anvil kept creeping to a slant as I hammered over time. So I removed the sand, added two 2x4s on end at the right height for the anvil to sit on, then poured the sand back in. Worked well but then I killed the ringing even further by adding a piece of angle iron over the end of each foot - wedged between the box & the foot. Now the only ringing I get is on the horn - and it's not nearly as bad as it would be without all the other stuff. I keep thinking I'm gonna bring a magnet out and try that theory - but I keep forgetting, lol

-

Nice! So did you get lucky with the blower blades all being intact or did you fabricate those?

-

I don't understand what you mean by this. There wasn't anyone leading us. We were typically in a horizontal line with no one in front. What lead would I have been following? I'm not at all implying I was truly dyslexic. That's why I put it in quotes. Intended to be read as air quotes. My mother is a retired early childhood special education teacher and I worked as Administrative Assistant at United Cerebral Palsy for 8 years. Mental disabilities are more than just a few quirks. I fully recognize that dyslexia is more than just turning the wrong direction or doing actions backwards.

-

I knew other methods would flash rust (vinegar, grinding) but wasn't sure if the black oxide from electrolysis would prevent it. Thanks for clearing that up. I'll make sure to account for time needed to brush & coat when I get started.

-

Those are some great looking hooks for someone just starting out. Great work! Also, your pigtails aren't going the "wrong" way unless you intended them to go the other way Like Irondragon, I'm also dyslexic when it comes to bends. It's my most common mistake. My mother tells me I was also 'dyslexic' with dance. Everyone else would go right, I'd go left. LOL! The blueprint Glenn posted for EZ Tongs are the first tongs I made and they were indeed VERY easy. I had only been blacksmithing for a few weeks at that point. Only had a bench vise and pliers and used a piece of railroad rail for an anvil. And I made them. They worked great for small stuff like hooks. I have since accumulated more tongs and I still use that first pair. Used them just last night actually! They're currently the only pair I have that will hold stock less than 1/4" in diameter. I agree with Irondragon, don't drop more than $5 on nippers. Or anything you're buying with intention of reforming into tongs. I've also used the kits from Kens Custom Iron and it's super easy as well - and about the same price you found your barn sale. My local blacksmithing club has a member that makes tongs and sells them for $30/pair. I can't beat that price so I've bought about 4 pair over the past year. So check your local club and reach out to see if anyone does that! I'm also still working on my own tong making skills. Figure I always seem to need a style I don't have already, lol - so it'd be cheaper & faster to just be able to make my own rather than wait to buy a set.

-

What did you do in the shop today?

Shainarue replied to Mark Ling's topic in Blacksmithing, General Discussion

I don't participate but there are regular pop up car shows at the Big Boy near my house. I assume pop up anyway. Definitely more than once a month and no extras like food trucks and banners and such. My first boyfriend had a '77 Chevy Nova. My first girlfriend had a 60s Ford Falcon. I love looking at the pretty cars but never caught the bug of having them myself. Used to have someone in our neighborhood that did dune buggies. Had them all lit up along the cage and the tall flag pole. It was fun watching them cruise around at night. -

With electrolysis - it leaves the black outer crust - the black oxide. Do I want to keep that or should I wire brush to get it off? My gut tells me to keep it but I keep seeing other people brushing it off to get the bare metal.

-

You paid using a credit card over the internet in 1968? Erm...

-

You can. It'll last longer if you coat the fire facing side with firing clay. I used uncoated fire brick in my rivet forge to get a deeper fire, and after a few months the brick started melting and cracking.

-

Anvil can correct me if I'm wrong, but I'm pretty sure internet commerce is in reference to accepting currency, not databases of inventory stock information.

-

I have the blower exactly where it works for me. I didn't realize there was a wrong side, lol This is the same way my rivet was oriented and I never had an issue in the past year of regular use. Crank with left hand, piddle with fire with right hand when needed. I rarely had to do both at the same time anyway other than when forge welding. Also, I don't stand next to the handle while cranking. I can reach it and easily crank while still standing at the corner of the table. And the counterweight on the handle will keep it going at least a full rotation after I let go.

-

Had a nice visit with a friend in Peavine Oklahoma and came home with this perfect blower for my newly built forge table. Also not pictured: a treadle hammer which I need to pour some concrete for and reassemble, and a bunch of scrap steel good for tools.

-

Obituary for Ken from Ken's Custom Iron https://wjon.com/kenneth-jon-zitur-69-avon/

-

What did you do in the shop today?

Shainarue replied to Mark Ling's topic in Blacksmithing, General Discussion

BillyBones, I like how you incorporated the plant identifier as the stake decoration. MJ, congrats! Alexandr, trash is unworthy of those trash bins. Beautiful. -

I took vacation time from work today to drive across Missouri (4hrs one way, 5hrs with traffic jams) to pick up another Buffalo Silent blower which I'll be trading TwistedWillow for a different already functional blower. The guy I was buying the blower from had a huge machine shed piled to the rafters with all sorts of blacksmithing and machining equipment and wares. Needed good balance to navigate the path through. He said he used to do a lot of blacksmithing, mostly gates and fixtures, but hasn't done much lately. As I could see, there wasn't room for any blacksmithing until he offloaded some of his accoutrement, lol Anyway, he told me to poke around and while I was gawking around, he was showing me the pieces he was most proud of. Some really cool stuff honestly. He had a whole row of just old forge tables, one of them looking like a "newer" model of the Buffalo forges. I mentioned I'm currently restoring a Buffalo 0 forge and asked if he had any forge hoods like they used on those tables up on the top shelf. He went scrounging around and found this! It's gonna look great on the Buffalo 0 forge once it's all up and ready. And now I don't have to fabricate one myself.

-

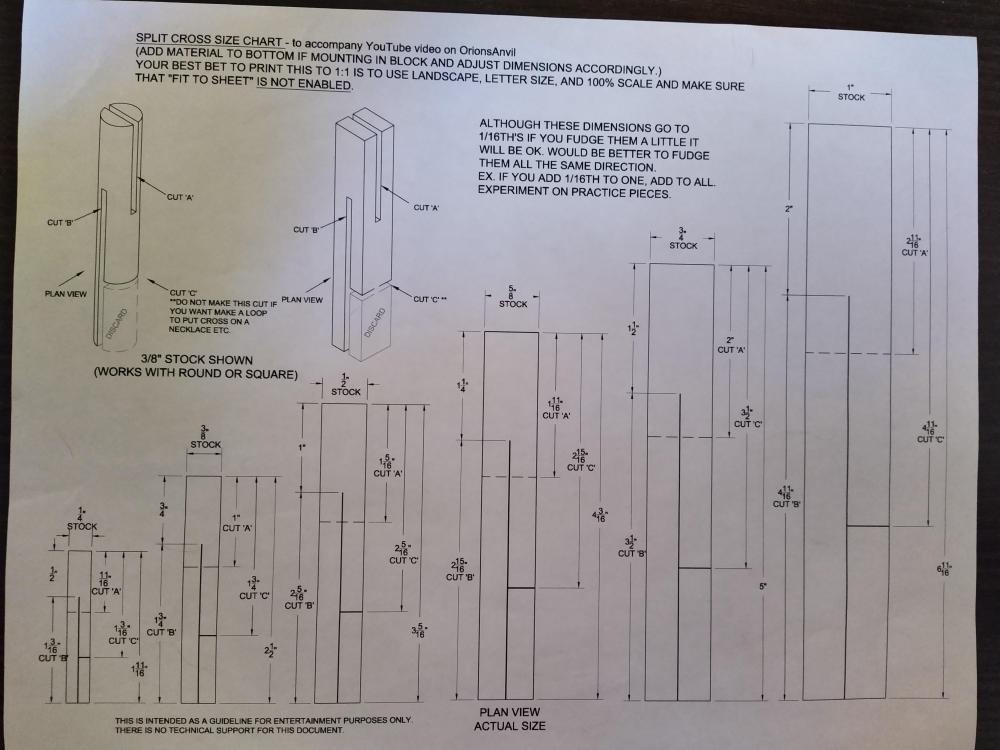

I have this printout. I don't recall what site it came from but the note at the top indicates a YouTube channel. I can't find a file or bookmark anywhere so I just took a picture of the printout for you.

-

Yeah, America is a bit new for legit castles, lol. We do have a few castle ruins sprinkled throughout the country. One of them near me. But the fact they are ruins attests to the quality of their construction in comparison to the European castles, lol This sounds like a super awesome event gewoon. Like Frosty, I'm also looking forward to the pictures of the process & finished project. I know how I am with remembering to capture pictures while I'm involved in something though - so I'll settle for just the finished project if that's all you get, lol

-

What did you do in the shop today?

Shainarue replied to Mark Ling's topic in Blacksmithing, General Discussion

Love the anglerfish lamp Macleod. I'm in a group on FB called "Scrap Metal Art" and some of my favorite shared projects on there are the sculptures patched together with sheet metal. -

Good tip on the garlic oil. I'll keep that in mind when I start using a bigger slack tub. I currently just empty after each session bit it's just a standard galvanized bucket. Maybe use a gallon of water each time. I didn't like all that was required safety wise for the acid so I'm going with a standard pH plus bath even though it will take considerably longer. Naval jelly was also on my list if for whatever reason the electrolysis didn't work out. I was worried it might take iron with it, and knew I needed to preserve the gear teeth as close as possible. It's that a legit concern? Because if that's not a concern with the jelly, I might just save myself some time and use that.

-

What did you do in the shop today?

Shainarue replied to Mark Ling's topic in Blacksmithing, General Discussion

Nice looking hammer Jono! -

Yup, I planned on having many electrodes and also planned on skimming the water of sludge & cleaning the electrodes daily. I also read in a research article (in regards to using electrolysis for restoring artifacts) to file away the rust in at least two areas to give the reaction somewhere to begin more easily. One where the clip attaches and one on the opposite end. So I'll be doing that on each piece I put in as well. I do have a power source that will not auto-shutoff. Just need to get it all hooked up & set up. But I have a few other forges to work on before I start that. I'm also still pondering where I can put the baby pool where it's not more of an eyesore than the existing pile of rusty forge parts. Maybe I'll just surround the perimeter with beautiful potted plants, lol Oh - serious question I hadn't thought of until just now - anyone know if mosquitos will still be able to breed in this electrolysis bath? Because if so, then I need to get some mosquito netting to cover the pool.

-

I have last season's baby pool to use for the derusting process. I am going to use electrolysis. Pool just needs a few patches and it's ready. PNW_Sparky, it's model 0 (zero) from the late 1800s. I've been following your thread as well and already had the POR15 paint bookmarked. Though I'm kinda leaning toward BLO. Just depends on what it looks like after rust removal. I shiny metal, it will get painted. If dark metal, then blo