-

Posts

33 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Lac la Biche, Alberta Canada

Recent Profile Visitors

1,273 profile views

-

What did you do in the shop today?

Camerican replied to Mark Ling's topic in Blacksmithing, General Discussion

Made a little pipe holder out of some c channel I had kicking about. Nice little project while I was warming up the forge to forge weld some finials... -

I would love to do a bigger one with collars at all the touch points. My wife has been asking me for a driveway gate. Maybe I go with this look for it...

-

Coming back to the Community

Camerican replied to Camerican's topic in Blacksmithing, General Discussion

Thank you arkie -

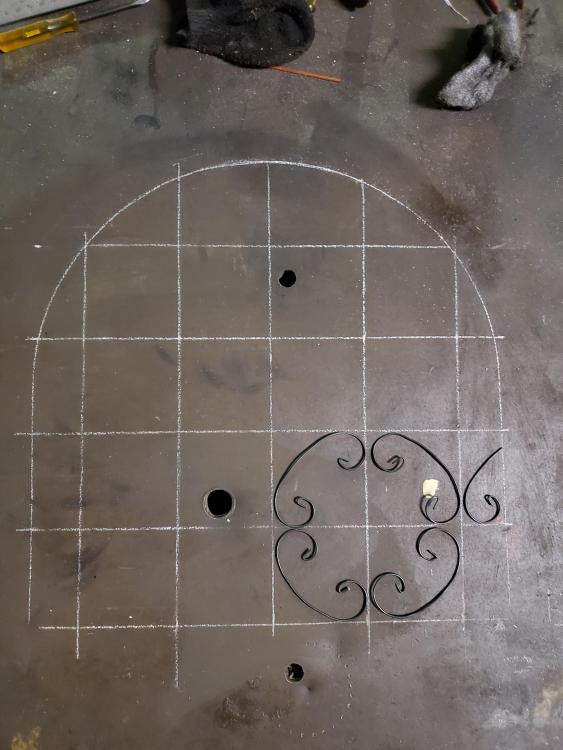

Hey all here is a fireplace collab I did in 2021 with a local metal fabricator. She did all the flat steel stuff with her plasma table. I did the forging parts and she welded it all together. Comments and questions are always welcome. First 2 pics were prototyping. I realized quickly that consistency was key and came up with a process to get repeatable results using a 4" radius swage and then a scrolling jig. Also ended up using 1/4" square whereas the prototypes were 3/8 square because that's what I had on hand. Next 2 photos were to figure out proportions. I scrolled some mechanics wire by hand. Next pic is the layout before welding and the final results last. The fireplace was actually double sided. The rear door was in the garage which let the client keep the firewood out of the house.

-

Coming back to the Community

Camerican replied to Camerican's topic in Blacksmithing, General Discussion

Thanks Frosty and George! I have progress pics from all my projects. I will get the last couple projects posted individually in the coming days/weeks. The fireplace grill was welded on the backside indeed. I also forged the hinges and the handle to open the door. It was actually a collab with a local metal fabricator. The door was powder coated before install. -

Hey all, took a bit of a break from the community but back now. I have been forging through the passed 6 years of silence but have decided to come back as I don't have any smithing friends to troubleshoot with or bounce ideas around. I feel like I have come a long way in the past 6 years. The first is a pic of one of my first projects, the 2nd I did in 2018, a cowboy cook set. The 3rd is a commission from 2021 and my most recent work (2023) last. Comments and critics welcome all.

-

Well first of all, I am really flattered that you want to build a forge like mine! Here is an update after using this forge for 4 months or so... Still have the blower on the right. It is nice to give the left arm a break while I am cranking with the right. I use sub-bitumous coal so it stays well lit even without the air going. Have about 1200 lbs of it so i am not needing to buy coal for a long while. Klinkers are annoying but a fact of life and I have learned to deal with them. The only thing I plan on doing with this forge is to upgrade the firepot. 1/4 inch is a little thin for my liking and at 3.5 inches deep I find it a little too deep. Will be replacing it this winter probably with either 3/8" or 1/2" and make it only 2.5 inches deep. I find the 8"x8" geometry about perfect for the work I do which is tool making. I only need to hear 4-6 inches at a time with being all manual on the hammer anyhow. The 6" pipe for the chimney has not been a problem. Even at 85F in the summer it draws fairly well. I will remind you that I have an ideal situation though. 15ft straight up and no buildings in the area to cause turbulence. When I build my new smithy it will be upgraded to a 10" flue. Other than that I am happier than a pig in s#!t with this set-up. Hope to see your build in the near future. I am really looking forward to it! Thanks for the interest!

- 44 replies

-

What did you do in the shop today?

Camerican replied to Mark Ling's topic in Blacksmithing, General Discussion

I use mild steel only. Save the coil springs for punches! -

What did you do in the shop today?

Camerican replied to Mark Ling's topic in Blacksmithing, General Discussion

Made a set of box jaw bolt tongs with welded reins. No forge welding yet. Just flux core it. Ugly but functional. Only the 2nd set of tongs I ever made. Will work for now. Trying to get the curves symmetrical is hard!!! All in the learning process. -

Met a fellow today. Had an anvil sitting out in the rain. It's used frequently but kinda sad to see it all rusty. Gave it a good look over. Can't tell the make outright. Maybe you fellers can help. No other markings on it but what's on the pic. Bottom is flat. And I mean almost machined type flat. One handling hole in the bottom. Handling holes in the waist. No markings about the feet. Any ideas gents? 125lbs. Verified by picking it up. Not a Trenton. The diamond has a W in it

-

Point taken! Looks like I'll be moving the blower to the other side! Always glad to have you curmudgeons around. Your small notes and observations are worth their weight in gold.

- 44 replies

-

That was my thinking as well. The blower isn't attached. The bracket can be moved to the other side, but I was concerned with the lopsidedness as most of the work would be on the left side. The more you know...

- 44 replies

-

Do you also bolt it down? Or is the Silicon caulk enough to hold it by itself?? And do you just put it on the bottom? Or run a bead all around the outside as well? It is an interesting idea indeed.

- 44 replies

-

I have been tossing around ideas for holding down the anvil. I am thinking just some flat bar with a couple holes punched and lag bolts. Pics don't show it but I have magnets on the front side of the anvil which deaden the ring quite well. Those buckworth anvils ring like a bell. It really is a nice sound but probably not good for the ears all day. This was just an impulse day. Couldn't well fire up the forge without hitting any hot metal. Thanks for all of the positive feedback gents!

- 44 replies

-

Darn bad habit! I constantly remind myself to keep that darn thumb down. Have a proper weight hammer now so I am hoping it will improve . Sigh. I'm such a rookie.

- 44 replies