-

Posts

168 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by M3F

-

I believe they traded their secret blood quench and human ash flux techniques for the capped bottles but one can't be sure.

-

Something from the Mastermyr find hopefully. Haha. At least my take on what a bottle opener in there would have looked like.

-

Nice trade!

-

As tactically as I could represent for my taste

M3F replied to templehound's topic in Folding Knives

Very nice! -

-

What did you do in the shop today?

M3F replied to Mark Ling's topic in Blacksmithing, General Discussion

Thanks guys yes I could have been more descriptive. The table is the exact size the customer wanted it to be, I wasn't impressed with the design (which is also per the cutomer) so I shot it down which I really shouldn't have done. The last pic like I said was from the customer and they loved it, I need to learn to not be so hard on myself. After all they did comission me to make it, when they could have bought something at a big box store. Scott build away good sir. -

Nice score on the press! I went 4 years without a vice and now that I have one, I don't know why I waited so long.

-

What did you do in the shop today?

M3F replied to Mark Ling's topic in Blacksmithing, General Discussion

Maybe I need to look at it differently. The customer sent this so they must be happy and that's all that really matters. -

xxxxxx you guys beat me to the runes idea. Nice openers by all so far. All the submissions look great. I'm going to have to go with plan B.

-

What did you do in the shop today?

M3F replied to Mark Ling's topic in Blacksmithing, General Discussion

Those railings are something! The architectural work you guys do blows my mind. As far as the pendant and arrow head go I'd like to know what the "contaminant" was so I can accidentally contaminate my acid with it! Clean, sharp work. Table done. To me it's nothing to write home about, but the customer is always right. Right? -

Really neat, thanks for sharing.

-

Trying to get back into smithing

M3F replied to Jason L's topic in Blacksmithing, General Discussion

My thought is I wouldn't think softer steel would hinder your progress. Progress is progress. In fact, it may build your hammer control faster as you won't be striking so hard to move the steel. As far as holding the material more securely two thoughts come to mind. Tong clips for sure and a bike chain hold down. With those you could lower your anvil back down. The bike chain is just a chain secured to the far side of your anvil stand. Then drape the chain perpendicular toward you over the piece your working on, you make a stirrup shape and attach it to the end of the chain and use your foot to tighten the chain down while hammering. Not the best explanation, I can take a pic of mine later on and post it if needed. -

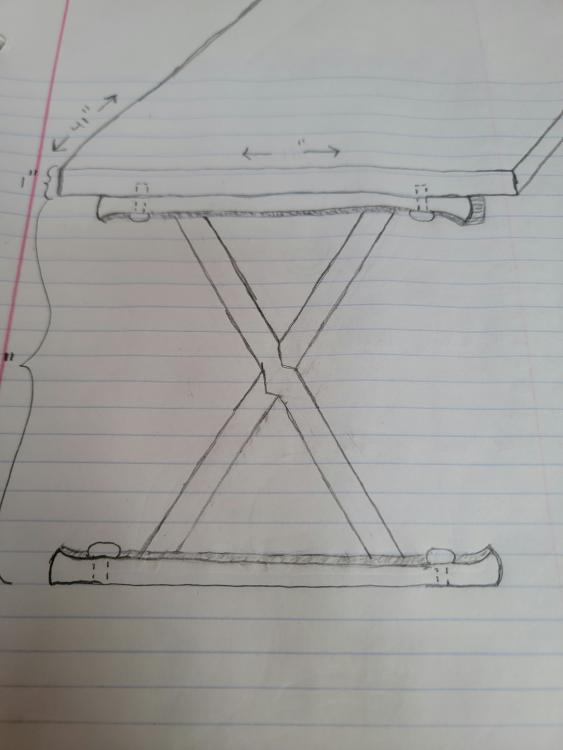

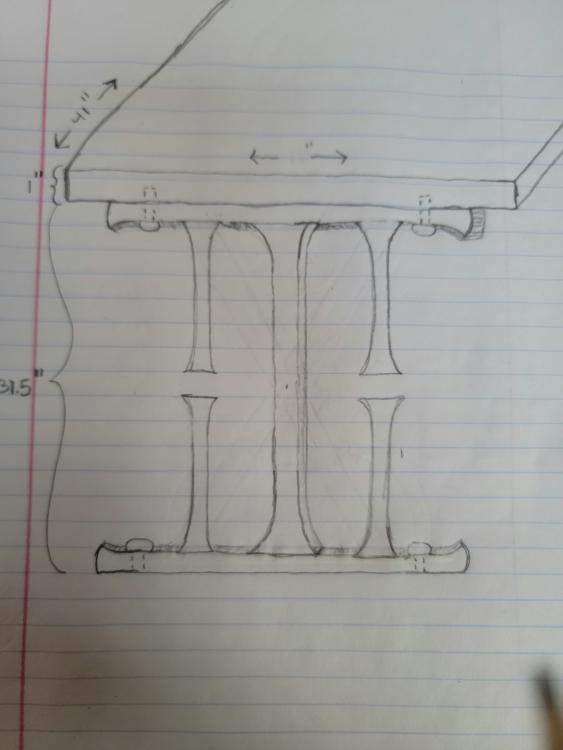

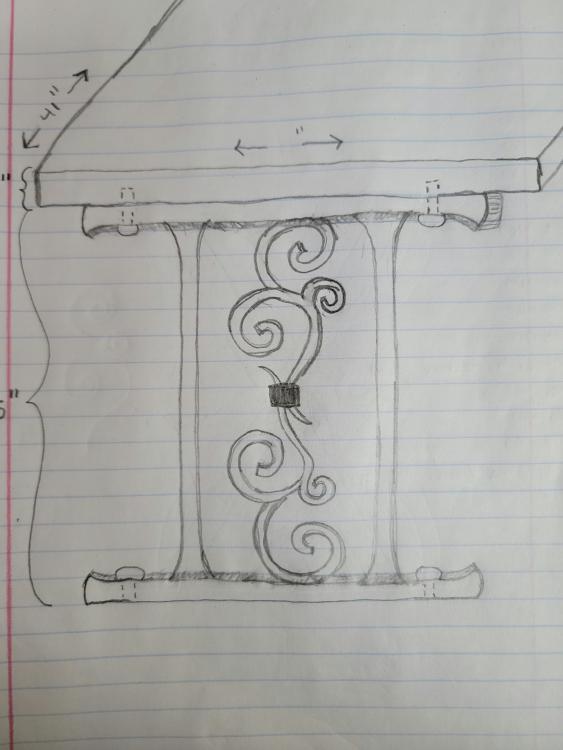

Thanks Anvil I appreciate it. The upsets are simple but elegant in my opinion also. Here's the base. I wanted to do exactly what you said with drifting the "x" but the angle is too acute. The points of the X are only going to be 9" apart as the table top is only 11" wide. I've been thinking about it for days. I don't like the way it looks if the X bars are placed on either side of the horizontal bars so my only choice is to do some fab work and cut and weld the X. I chose 3/4" sq bar instead of 1" sq. I wanted the framework a bit thinner than the table top which is an inch thick. That and 20ft of 3/4" sq vs 1" sq was over $100 less.

-

Old fire hydrant anvil stand

M3F replied to Pirateforlife's topic in Stands for Anvils, Swage Blocks, etc

I'd be concerned about a few things. If it's cast iron can it take the shock without cracking and what will it do for the ring? I don't know, maybe someone with more experience can answer that. Like Frosty pointed out with the outlets they could be a trip hazard, but you also wouldn't want to have to bend forward at an awkward angle while forging because your not close enough to the anvil. Your most definitely going to drop things down the center hole. Punches, drifts, hot steel etc. so that's something to think about. How to raise it to your level safely. Lastly, as is, that is going to walk around your shop floor while forging. I like my stands immovable unless I want to move it. I think it would be a pretty neat stand if you can figure those things out. -

Tools look great, looking forward to the rest.

-

What did you do in the shop today?

M3F replied to Mark Ling's topic in Blacksmithing, General Discussion

I'll try that technique for sure thanks again. BillyB I was able to get it pretty square on the initial set downs with die I made for my guillotine tool. They're 45 degree butchers with a 16th of an inch radius instead of a sharp edge. Suggested in a video by my hero Mark Aspery lol. After that I used squaring dies (also 16th of an inch radius) to draw out the tenon. The monkey tool really didn't do much since it was already pretty clean. I suspect if it wasn't that's where Frostys tip of a stout monkey tool would come in handy. I will admit at first I tried to "wing" it and it was BAD, after realizing there's a reason some techniques are done a certain way I made the tooling. Now it's my new favorite thing and everything is going to have a mortise and tenon joint. Kinda like how everything had a brass finish when I learned that technique. -

What did you do in the shop today?

M3F replied to Mark Ling's topic in Blacksmithing, General Discussion

The monkey tool I made is NOT stout, it was made from the same 3/4" bar I'm using in the project. I didn't think about that so I'll make another one. I've never heard of a chisel cut in the mortise. So with the tenon in place just before piening where would the cut be made? Thank you very much for the tips! -

What did you do in the shop today?

M3F replied to Mark Ling's topic in Blacksmithing, General Discussion

My first serious attempt at tenons for a table I'm working on. I made die for the guillotine tool and a monkey tool today, then finished up the base of this table. -

Ones man junk... This sucker was heavy. 6" pipe is darn expensive so I've kept an eye open. The plan was to use it as a quench tank. I cut a 4' section out with my newly aquired Oxy/Acetylene torch. I had zero experience with it and I have to say that much fun shouldn't be legal. I welded a cap inside the tube and then welded the tube to a plate to try and get it as water tight as possible but it still had a couple slow leaks.

-

Yeah I see I can't edit the topic name even though I started it. Oh well. Yeah the level 3 scrolls would have been nice and speaking of the curriculum I may start looking into level 1 classes soon, seems like there's a lot of good skill building exercises through the training.

-

Ugh I see what your saying. I knew I got the idea from somewhere. Gonna have to remedy that. I figured with how much I've been posting I should start my own instead of blowing up "What did you do in the shop today." Unfortunately his wife picked the "X" but he said he may ask for another table down the road because he preferred the scrollwork.

-

-

A repeat customer ordered a table and supplied the wood top. The wife wants a long thin table for under a windowsill. He gave me a picture of one with an "X" design so I drew my version up and gave him another couple options I thought of. I really wish I could draw! Anyway he's my best customer and usually gives me artistic freedom. Hopefully he likes my ideas more than the "X"

-

Looks like it's been machine welded, not forge welded. Maybe weld the rest of that crack? My only concern would be hammering on a piece while it's in the vise as is and opening that crack up. When you say restore what are you planning? If it's operational I would maybe clean it up and that's it. As far as what steel it is, someone else may know but all steel is carbon steel, some is high carbon, some is low carbon.