-

Posts

229 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Silverton, OR. USA

-

Interests

making and building, art, music.

Recent Profile Visitors

1,117 profile views

-

Got it, Frosty. I'll get those, maybe on Wednesday. I promised my wife that we could go in to the city and do a run around of things tomorrow. Catch ya later.

-

Thanks Irondragon, great point. I overlooked that in the first few heats of this attempt, the one that failed. But at that time I took a moment to think about what I was doing, and started cleaning scale and excess flux off that second round. I neglected to mention that in the write up. Good catch. I made a few adjustments toy process on the re weld, I'm looking forward to firing it up again and getting another few goes at it.

-

Awesome! Thanks Frosty. Will do. Although, I may try running it without the choke. And see how it does, I can't say I've attempted to run it like this before. So I'll run it unrestricted and let you know how it goes. Also thanks, M3F I hope to have more progress to share in the coming weeks and months. Now that the weather is keeping me out of the forest as much I'll be spending more of my free time in the workshop again.

-

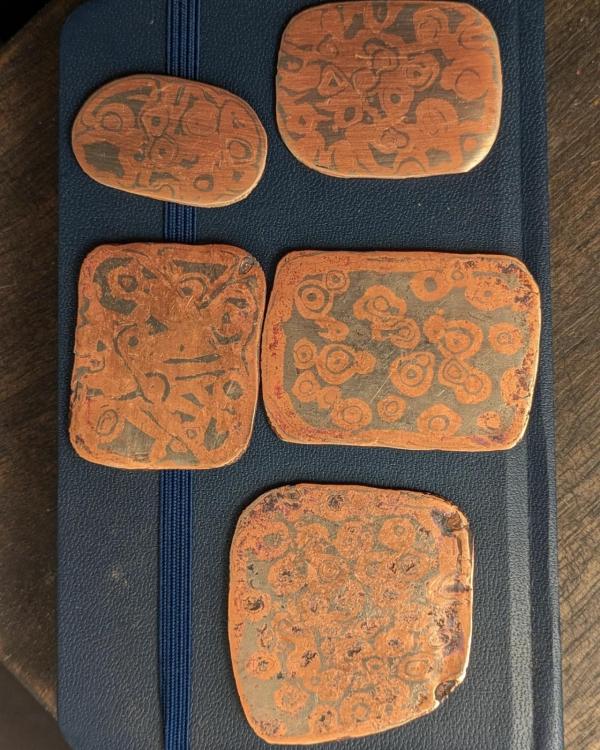

Hey guys, I know it's been a while but I figure it's about time for an update. I know it's a bit of reading, but I promise a load of photos as well. I'm sure a few of you have seen some of the projects I've gotten up to in this forge over the last 6 months or so. So we know it does it's basic job just fine. But one of two of my main concerns with this build from real early on in the all the way back to the planning and design stages was "will it forge weld !?!?!" Also "can I forge weld?" The other being the question of fuel efficiency. At this point, all I can really say is at general forging temps I can get about 12 to 14 hours of forging off of a 5gal lpg tank running the pressure around 7-12psi. Not really sure what that looks like up in the higher psi ranges (15-25psi), so I'm sure at forge welding temps it could for seeably be double the usage. Now back to the important question, the one I have been dancing around as a blacksmith for the last couple years, can I forge weld? After a few failed attempts early on, working in my first forge, charcoal, modified JABOD style, with a hand crank champion blower. I shyd away from it in hopes that I could connect with someone in person who could show me the "magic" firsthand. Alas, I got sidetracked, by a local tool maker, and ran down the road of hammer making. But always in the back of my mind that burning question, am I really a blacksmith, if I can't......? (And, yes, I know some may say, "that's not what makes you a blacksmith", but I know it sure helps, big time.) So this morning I decided to make sure my forge could weld. And in turn making sure I can forge weld. I started by tossing a full sized firebrick on the floor of the forge, to protect the cast floor from the mess I was about to make. As well as reduce the overall volume of my forge, by about half. Then I cut a quick n dirty baffle system for my T burner, from some scrap sheet. And slowly started heating up the forge. While the forge was heating up I took a scrap piece of mold flat bar, cleaned up one side of the flat and ground a quick bevel on the opposite side to form a scarf. once the forge hit about 1000°c I tossed in the flat bar brought it up to heat and folded it over so the clean faces were nearly touching, fluxed it with some borax tossed it in and turned up the propane to about 17psi. At first the forge was just teetering back and fourth around 900-1000°c, but I figured I'd pull it out close the gap and give it some more flux and try and get it hotter. I closed up the doors a bit more, and got my Lazer to say it was around 1160°c. So I got the piece back up to heat and pulled it out gave it a few quick blows, tickled it with borax and back in the forge. Well, that felt pretty good I guess. When it was back up I pulled it out and gave it a few more good hits with my bigger hammer. Re fluxed, then back in. I'm not so sure I felt as good about that last heat but, I can only really look at the next right now. This heat I worked the sides perpendicular to the plane of the weld, then flipped it back flat to straighten it up and knock the wrapped eye that had been created with the fold, over to one side of center as if it was going to be a wrapped eye hinge of some sort. As I knocked the eye off center line the weld popped almost wide open. Bummer....but forward we go. I fluxed it up. Then brought it back up, and closed the weld nice and tight. More magic powder then back in the heat. While I was doing this I was checking the temp of the forge with my laser thermometer and was seeing it riding just below 1200°c so I bumped up the gas a little more closed down the baffle as much as I could kicked the back doors nearly closed, and went in for a re weld. This time it felt good. And so did the following welding heats, I then moved back to the sides and re aligning the eye. At this point I felt like it had stuck but I needed to be sure, so I grabbed a hinge eye drift and ran it through the eye a couple times. Now I know it stuck. After working down the weld a bit I decided to test the weld again, by punching a hole through the weld, and being pretty unforgiving about it. It was pretty cool buy the time I sheared out the plug. But it was still stuck. I'm the end I'm pretty pleased, although I feel like my scarf is still a bit too visible and could have been welded a bit better in one corner. Next time I will make sure to thin it out just a bit more, and focus on the scarf of the weld a bit more. All that said, I hereby present to you, my first forge weld and a home made forge with a diy Frosty T burner , that can in fact forge weld! Couldn't have done it without you guys here on IFI, thanks. And as a bonus, I have some pictures of a couple experiments in making copper and nickel Mokume Gane. Made from coins in my forge, I was using my 13lb sledge to get em stuck together. I know I still have a long way to go with this before I am getting the results I am looking for. I also have a pretty good collection of failures from this run of experimentation. And a double bonus, because you made it this far in the thread. The real motivating factor in today's adventure. I decided that I need to make myself quite proficient at forge welding, before taking on a couple of really special projects. Two days ago I was gifted a very special bloom of authentic Tamahagane. Roughly 3lbs. At that moment, I realized that I have a lot to learn before I accept that challenge. Any way I hope you guys are well.

-

Oh yeah, that's a good thought. Would of saved me like 90+lbs of weight. But I really wanted the straps visible. The doors are 2x4 framed with 1/2"OSB and 1/2" T111 siding then 1/2" trim board. Lots of weight.

-

Yeah, no day but Billy. I hope none got injured. And happy independence day everybody!

-

Hey, if they function. I think that's the important part. And having a reminder of the progress you are making is totally a bonus.

-

Thanks Anvil. It's always nice when a project comes together.these were my first hinges I have attempted.

-

Thanks Frosty! It feels pretty good getting the shop closer to setup and running full swing.

-

Thanks George. My wife helped me a bit, when it came to shimming to level and helped guide all of my blocking and the door while trying to get them to line up well enough. I did the lifting. I also built a "door jack(??not sure what to call it)" type of tool out of some leftover OSB and 2x4s. To help hold the door in an upright position. but it's basically a fixture that the door sits down in and it supports the door from front and back so it wouldn't fall over and flatten me or the wife. Which was nice because we were able to set it up and move around it and move it around without having to always have hands on the door.

-

M.G. started following Smithy door Strap Hinges

-

Hey guys, sorry I've been out of the loop again broke my phone a few weeks back and finally got a new one. Unfortunately, that means I have lost all of my photos from the last few years, as well as a bunch of progress shots of a bunch of my projects, this one included. So you will just have to use your imagination a little. Well... Just to catch you up, I have slowly been working on building out my smithy. It started as an attached carport adjoining my detached garage. Over the last year or so I have been working on different aspects of the shop build in-between other home renovations. Started out by framing in and enclosing 2 of the open walls. Leaving the front wide open. I then built out my new (and first) gass forge. And a new anvil stand. Once I had those I couldn't help but move a few tools into the space and start working. After a handful of projects made in a half a** and half built half of a space, I decided it was time to make it a full a** space. But before I could move the rest of my tools into the smithy and out of the domestic garage, I needed to make the space secure. It needed a set of barn doors. And a set of hand forged strap hinges to hold em up. So I set out on making a big old set of hinges. The doors are about 4 and a quarter feet wide and 8 feet tall, weighing just about 180lbs. each if not more. So I needed the hinges to be sturdy. I decided to make them out of 1/4 inch plate of mild steel for the straps and the jam plates. I started out by cutting the stock plate down to size for the jam plates, and straps. I then forged bevels up n the jam plates and rolled the hinges barrels and drifted them to size. Next I fullered down the material for the spade finial using a spring fuller I made a little while back. Then chased that taper back to about the midway point of the strap. Followed by bevels to knock off the corners. Then to rolling and drifting the barrel, followed by straightening and tinkering for a while. I cut the hinges barrels with an angle grinder and and some hand files to clean them up. Next I made my hinge pins and started with an upset on one end to become rivet head. Once all the pins were cleaned up and cut to length I fitted them to straps and plates, and riveted over the ends of the pins. And tried to true everything up at the anvil. Then I got all the holes drilled and counter sunk. Now that I had the hinges put together, I dropped them all in a vat of white vinegar for about 24 hours,to eat all the forge scale off. Pulled em out and scrubbed em down with baking soda water. And hit em with a wire wheel to finish cleaning them up. I then used a bit of heat and some "blacksmiths finish paste" mostly BLO, bees wax and terp. With a bunch of charcoal dust mixed in. Then I built the doors, I'll save you the carpentry stories. But I got the doors hung today and the hinges seem to swing freely with no issues. Other than I kind of stink at hanging doors, and there are some slight fitment issues that I will need to address before they will close securely. Next I will forge/fab a simple bolt lock and forge some handles.

-

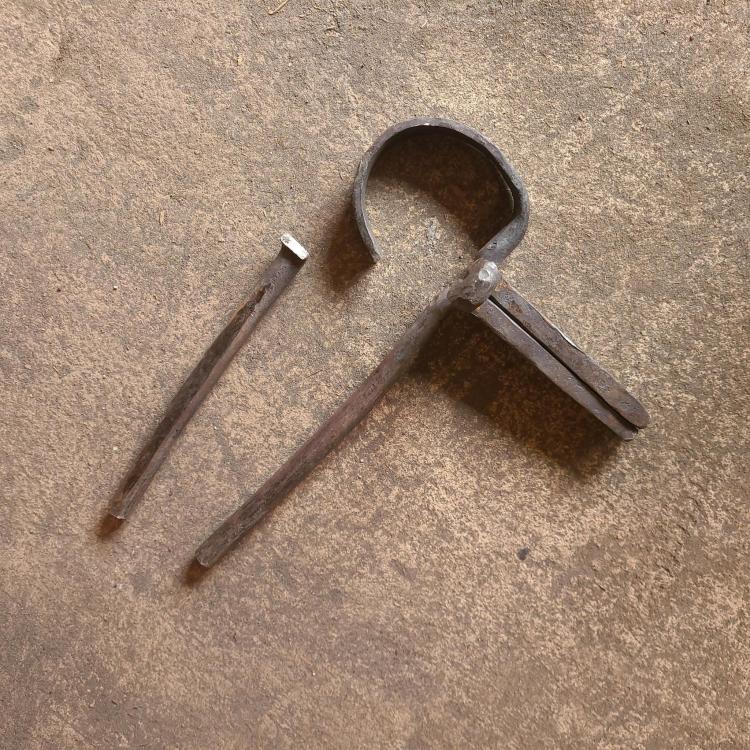

Yesterday I fired up the forge and as I was collecting myself and my tools to start working on some strap hinges for my shop doors, I reached down to pick up my spring fuller and realized that it was bent out of alignment. Mind you, this was just your run of the mill quickie spring fuller made from bent up mild round bar, with a flat spring section. It has had some pretty heavy use over its time, so it's already on its way out. but as I took a closer look I noticed a small fracture at the step between the round stock and the flat spring section. Gave it a light tap and it let loose. I guess making the straps that session wasn't in the cards. So I figured I should take the opportunity to make a more long term solution tomorrow(today). But, with the forge hot, I went ahead and rolled my hinge plate barrels. I'm making the hinges from 1/4 inch plate. And I needed a 5 inch section rolled for the barrel on the plate. Way more work than I was expecting. But it's done. I had to make a pretty long drift for to fit the long barrel, I picked up some random farm equipment springs from the scrap yard, i left it in a normalized state for use. Today I got in to the scrap yard first thing and made it home to light the forge by 9 am. I picked up some inch and a quarter round bar to make some hardie shanks from. Once the forge was hot I threw that in to heat up while I preped a couple of 3 inch pieces of coil spring and a length of 1 1/4" flat bar. I forged down each end of the flat bar to about a 3.5" section at 3/4"x3/8". Then I knocked a square taper on about 3 inches of my 1 1/4" round, and broke the corners to fit my hardie hole. Then cut it off and upset it in to the hardie hole using my 13lb sledge for the first time!!! Made real short work if it. Only took 3 heats to upset about 1 1/4" of 1 1/4" down to about a quarter of an inch. I love it! I also used the time between heats to bend up the flat bar into my spring shape. I preped all of my welds. Grinding a flat on the back of the coil spring steel, so it doesn't try to roll away and sits flat on the surfaces of mild steel spring ends, which will also be the struck portion of this tool. I gave the spring steel fuller bits a good long pre heat with a torch before burning them on to the spring section with my mig welder. I also mig welded the hardie shank to the bottom of the spring. Taking special care to orient the shank correctly with how it fits the hole in my anvil. Gave it a clean up with the grinder, and a final tweak or two for alignment. And finished up before noon. Back on with the hinges tomorrow.

-

Thanks Shainarue! I'm glad you all are enjoying it.

-

Ah, thanks IronDragon and company. I really appreciate it. I can't wait to see your version. I know this still needs a bit of refinement. So I am looking forward to making another. I hope to bring the next one in at about 3lbs. Maybe 3.25lbs. I feel it will be a really comfortable weight for this style hammer. I may try to find longer or just all around bigger handle blanks for my next few hammers.