Chad J.

Members-

Posts

569 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Chad J.

-

It does, not much though. Goes from a heavy 3/16ths to an 1/8th inch 3 inches shy of the tip. I'm going off eyeball on that, my tape is in the shop. I'm going to finish everything off and give the vitals after that. I just rode the wave to actually forge the pommel and get it assembled Saturday.

-

Right at 36 ounces. I'm going to make the filters a bit wider to loose some weight

-

I ground the fuller. The guards were inspired by a messer I saw but it's not too late to play with the curves, and I actually dulled and rounded the knuckle guard with safety in mind. Thank you for the kind words and advice George, when I started this I has no plan and minimal experience. That it came out as well as it did is thrilling for me.

-

I have some cleanup work to do on it but I have finally assembled my short sword. RR Spike guard and knuckle bow, rr bolt pommel peened on, deer antler handle with epoxy for a good measure. Nothing is moving. It isn't the prettiest sword but it's my first competed.

-

What did you do in the shop today?

Chad J. replied to Mark Ling's topic in Blacksmithing, General Discussion

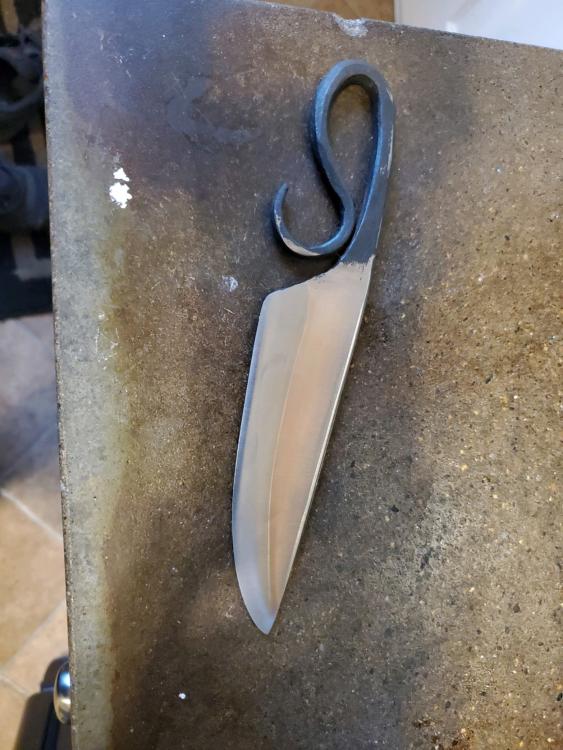

I'm going for a wakazashi, it's around 18 inch blade but I need to throw a tape on it. The coffee hasn't kicked in so I can't remember. Forged it from a rail anchor that showed up in my shop mysteriously. -

What did you do in the shop today?

Chad J. replied to Mark Ling's topic in Blacksmithing, General Discussion

-

What's your latest blade look like? Post em and let us see.

Chad J. replied to HondoWalker's topic in Knife Making

-

What did you do in the shop today?

Chad J. replied to Mark Ling's topic in Blacksmithing, General Discussion

It's not pretty but it works (too) well. I now know what it's like to burn up a project in a coal forge, several times over. On the other hand I (kinda) got my first successful forge weld... and then promptly overheated the piece. The blower is off of an exhaust fan from a kitchen and it is hooked up to an adjustable switch. Nearly perfect amount of air. -

Nicely done, what did you use for the handle?

- 74 replies

-

- spring steel

- bowie knife

-

(and 2 more)

Tagged with:

-

This was a used piece so it could very well have had micro fractures. I wouldn't put it past a bad hammer blow or me working too cold, I'd been pushing that envelope a bit. I think this is great for me learning, either way. Other than the crack, any issues on grain size?

-

Thomas, the top right is where the original crack was. That is what made me decide to finish it off. I'll get the other half

-

Quenched it in canola oil. Frosty, I'll get both pieces side by side for a picture.

-

So I broke it. It didn't look bad. I think it was while I was forging it. I may have worked it too cold. Any other opinions? 5160, I'll quenched with 2 cycles of 90 minutes at 425 for tempering. I tried breaking it further up on the knife with no luck, just moved my leg vice across the floor.

-

What did you do in the shop today?

Chad J. replied to Mark Ling's topic in Blacksmithing, General Discussion

I, personally, am always cautious about having something sticking out in an unexpected direction when it sits about waist level, let alone if it has a point on it. -

What's your latest blade look like? Post em and let us see.

Chad J. replied to HondoWalker's topic in Knife Making

5160 rat tail knife. I took it to 400 brit and then a surface conditioning belt. I made the handle a little short but it is comfortable. Not sure why, the handle ends just before the pinky. -

What did you do in the shop today?

Chad J. replied to Mark Ling's topic in Blacksmithing, General Discussion

-

Ok, so the grinder got here and the belts finally came yesterday. Ameribrade fast back with 1.5 hp vfd and 7 inch drive wheel. How long did it take you to get used to your grinder? I fully expect to wreck a bunch of spike knives learning to grind out the bevels and finishes, but they're quick and easy to replace.

-

What did you do in the shop today?

Chad J. replied to Mark Ling's topic in Blacksmithing, General Discussion

As a kids we had a sandbox in the back yard and plenty of free time and green army men. I had the bright idea to grind sparklers into a powder, mix them with gas and make a firy volcano battle scene. The sandbox disappeared shortly after. -

What did you do in the shop today?

Chad J. replied to Mark Ling's topic in Blacksmithing, General Discussion

Started learning my grinder tonight, turned a nicely shaped spike knife into a letter opener, the second one ground out a bit better and then put on the high grit belts and worked on finishing a cleaver I had started last year. Think I'm going to be making and destroying several spike knives before I mess with any of my better designs. -

What did you do in the shop today?

Chad J. replied to Mark Ling's topic in Blacksmithing, General Discussion

And along the lines of Pat's question, does it need to be a high carbon steel? I hadn't ever thought about that before now. -

You might be addicted to blacksmithing if you...

Chad J. replied to divermike's topic in Blacksmithing, General Discussion

Unfortunately I have to work, but I have a company smart phone so here I am. -

What did you do in the shop today?

Chad J. replied to Mark Ling's topic in Blacksmithing, General Discussion

My girlfriend is a bad influence, she keeps trying to get me to spend money, though usually she wants me to spend it on her. -

I actually like the counterpoint of the hard edges against the curves.

-

What did you do in the shop today?

Chad J. replied to Mark Ling's topic in Blacksmithing, General Discussion

It turned out great Das -

What did you do in the shop today?

Chad J. replied to Mark Ling's topic in Blacksmithing, General Discussion

Got my work table finished and assembled my new grinder. Now to figure out where to put it... Anyway the table legs are treated 4x4 that I cleaned up and roughly plumbed up on my jointer and the frame and table to are treated 2x6 that I did the same. Now more sparks can fly...after I clean up all the saw dust.