Chad J.

Members-

Posts

567 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Chad J.

-

What did you do in the shop today?

Chad J. replied to Mark Ling's topic in Blacksmithing, General Discussion

It's not just spiders that like dark places. In Okinawa I was on an airforce base for rapid runway repair school. We were moving some corrugated steel when I turned and froze because there was a Habu napping on the piece we were about to move. We ended up tossing it over a fence but until we were ready to do that we moved really slowly. -

British bladesmith recycling nitrous oxide containers -- article

Chad J. replied to JHCC's topic in Knife Making

After it's done taking the edge off, he's putting it back on. -

What's your latest blade look like? Post em and let us see.

Chad J. replied to HondoWalker's topic in Knife Making

Great tip Thomas. Thanks! I'll look into that. And texturing the handle would be easy enough with my dremel. -

What's your latest blade look like? Post em and let us see.

Chad J. replied to HondoWalker's topic in Knife Making

That's great Doc! I'll get the hang of forge welding and Damascus soon I hope. This is the solution I came up with for a one handed fleshing knife for my boss. It isn't 100% finished, just needs some sanding and polishing, but I wanted him to put it to use. I want to make sure it works and then I'll remake a finished version. Blade is from a lawnmower blade and not hardened. It's rounded over from a 45° bevel that goes all the way around the blade. The handle is designed to be gripped in multiple directions and still be comfortable. This is more functional than finished right now but if it works I'll be making this one again. He's rather happy with the design. Handle is maple with brass pin and lanyard hole. -

What did you do in the shop today?

Chad J. replied to Mark Ling's topic in Blacksmithing, General Discussion

As I was an Engineer in the Marines I can say we lead the way, if course is you obverse to that you can find the landmines and IEDs the hard way. No shop time. Went out to enjoy the weekend in Eagle River, WI except I developed a scratchy throat on the drive up and the gf got a nasty cough for our second go round with the 'Rona. We still went out on the snowmobile because how are we going to spread it at 45 mph with helmets on in sub zero wind chills? The plus side is I'll be spending the next couple days of isolation in the basement shop trying to finish projects. I'm fine BTW, I had minimal symptoms. -

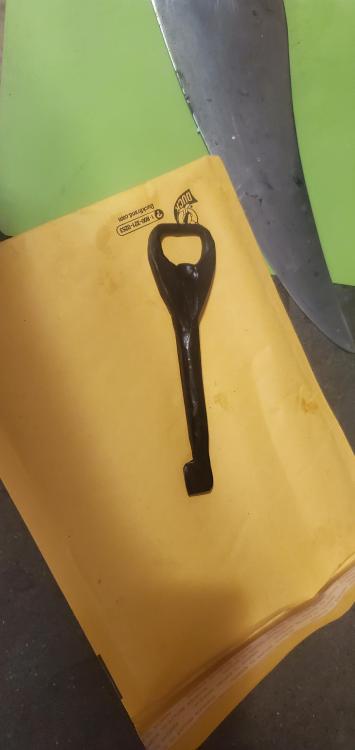

I couldn't resist adding the church key. Enjoy

-

What did you do in the shop today?

Chad J. replied to Mark Ling's topic in Blacksmithing, General Discussion

I've been working in the basement due to cold. I guess I'll call it my finishing station. Saturday it was skinning deer shins, harvested the skin and sinew along with the bones and a catching up on housework after the holidays. Spent a good chunk of Sunday working on the fuller on the oakeshott 12 project and sanding on a couple knife handles. I set up a 3 x 18 belt sander in a vice and it actually worked extremely well for the sanding I did on the sword blade. Slower removal and less heat. Between that and the hand filing I managed to straighten a warp I had ground in. I'll have to make a better handle clamp for it so it doesn't keep falling out though. I'd hate to get road rash if it falls into my lap while running. -

What did you do in the shop today?

Chad J. replied to Mark Ling's topic in Blacksmithing, General Discussion

Set up a work station in my basement Monday night and started finishing knives and the sword. Much warmer inside than the shop right now. -

Knife Making Class Log 112: Guards and Metals

Chad J. replied to Dodge's topic in Knife Making Class 101

I'm curious a to where you're heading with that design. I would slit a piece of brass and solder it in place, but I'm a keep it simple type of guy. How rough are you planning on being with this blade? -

Nope. I'll let you know when I get one skinned and I'll send it your way.

-

4 deer shins followed me home yesterday, my boss got a pair of does and cut them off for me. I need to skin them and set them out so nature can clean up the rest. Who was it that was looking for Canon bones for a bowie handle last year?

-

Knives seem to be the gateway right now. Odds are a combination of hammer and heat. How is your hammer dressed? Sharp edges are very bad. What are you using for an anvil? Are the edges crisp or rounded? If you're getting cold shuts and your working temp is good this is possibly the reason. As a bit of advice; make S hooks. Make them until you're sick of them and then make 50 more. They are great for learning hammer control, how to use the anvil,'s work face, and they're handy around the shop. I've got them everywhere with anything I can hung upp on them.

-

What did you do in the shop today?

Chad J. replied to Mark Ling's topic in Blacksmithing, General Discussion

Been focusing more on my tool making and smithing small items. The other day I made a fork and spoon, made the fully finished fork last night. and spoon. Today I knocked out the knife, a pair of forks, and a scribe. My current goal is to make a set of 8 place settings including the knives. Maybe I'll pull it off, maybe the sub zero temps coming will sidetrack me. -

What did you do in the shop today?

Chad J. replied to Mark Ling's topic in Blacksmithing, General Discussion

Last couple of days I made a set of chopsticks, a couple s hooks, parts of a new set of fire pit tongs, a spoon for a utensil set I've wanted to make, started on the fork, the first of several dishing forms from old bearings, a chef's knife I just need to clean up some hammer marks, and cleaned up the hot shop a bit. I don't have ADD and focus issues at all... Anyway here are some pictures. I still haven't managed a forge weld, so the baskets are chisel cut. -

What tools do you use the most?

Chad J. replied to Glenn's topic in Blacksmithing, General Discussion

Along the lines of this thread, what sizes of stock do you find yourself using the most? I use mainly 1/2 round and 5/8 square stock now. -

Scrap Yard Won't Sell Scrap Metal!!!!

Chad J. replied to CurlyGeorge's topic in Blacksmithing, General Discussion

When I worked for the scrap company, which will remain nameless but rhymes with faulter, we weren't allowed to officially sell scrap, though I allowed it occasionally. It was said it is because of the payment systems we used. Liability also kept me from letting people dig through the scrap. State laws require ID for any copper and for ease and uniformity we required ID for all sales, plus I hate scrap theives and that helps catch them. We also scanned in every ID and had cameras at the counter and on the ATM. -

What did you do in the shop today?

Chad J. replied to Mark Ling's topic in Blacksmithing, General Discussion

Did you vary the twist pattern on the pieces? Edit: This was meant for JLP on her basket handle -

When you go to a craft fair and such what is generally the breakdown between large medium and small items you take? I'm trying to build my inventory to get to my first craft show this spring but am not sure on what to focus on. Obviously the small quick items, like the leaf Keychain, decorative hooks, and such are easy to stock large numbers. I guess I'm looking at items like fire pit tools and pricier items. I'm looking for a general starting point and modify from there.

-

What did you do in the shop today?

Chad J. replied to Mark Ling's topic in Blacksmithing, General Discussion

Gah! All those spelling mistakes and auto corrects! I need to quit posting late. I meant a small fullering tool not filet tool. -

What did you do in the shop today?

Chad J. replied to Mark Ling's topic in Blacksmithing, General Discussion

I pulled this off this evening. Single piece 5/8 inch square sock at 24 inches in starting length. Made a smaller fileting punch to get the rope twist handle and used my hot cut for the twist and the hook. It needs a bit of dressing up but I was extremely excited as I felt this was the most technically changeling piece I've done since I started smithing. -

A friend dropped off a 100 pound propane tank. It's older and needs to be tested before I fill it but if it fails I have a future long tempering oven or extra long propane forge body.

-

What did you do in the shop today?

Chad J. replied to Mark Ling's topic in Blacksmithing, General Discussion

JHCC if you get near Madison, Wi you're welcome in my shop. It's a disaster, but I know where everything isn't. -

I'm not sure where I saw it but there is a nice series of drawings on how to make a rail spike tomahawk. Maybe it was on a bladesmithing site. It was a very simple set of instructions, but at the time it was beyond my skill at lost interest. I have focused since then on knife blades, bottle openers, leaves, s hooks with a more complex build occasionally to test myself. My bick out of 1 1/8th inch hex stock was a huge smile on my face when I was able to complete it.

-

What did you do in the shop today?

Chad J. replied to Mark Ling's topic in Blacksmithing, General Discussion

Thanks Frazer, when I had them in my hands I noticed how sharp the corners felt. A couple passes with a good file will clean that up and my next set will be that much better.