Chad J.

Members-

Posts

569 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Chad J.

-

What did you do in the shop today?

Chad J. replied to Mark Ling's topic in Blacksmithing, General Discussion

Started in on a set of hinges for the shop door I'm building. My barn has no good way to be secured currently and I have a bunch of tools to put in it. The site is going to be 2 x 6 dowel pinned together and sealed. These hinges, a handle I'm forging then riveted steel straps going across the door. The swinging garage doors are going to be another challenge but one at a time. -

Several of my tools finally came home from my family cabin. A couple routers, sawzall, drill, 12 inch disk sander, and a could small work tables. Also found a pressure vessel for a pump system. But sure what I'll do with it yet.

-

What did you do in the shop today?

Chad J. replied to Mark Ling's topic in Blacksmithing, General Discussion

Think I'll leave it. Rarely do I get entertaining changes. -

What did you do in the shop today?

Chad J. replied to Mark Ling's topic in Blacksmithing, General Discussion

I was looking at doing 2 old propane tanks welded end to end and then I know there are some fuel sipping burners in the forge section. I was also considering a JABOD using charcoal. But you're right, a simple Brock like fudge would be quickest. -

What did you do in the shop today?

Chad J. replied to Mark Ling's topic in Blacksmithing, General Discussion

I'm gonna have to build a bigger heat treatment oven. My little forge took forever to get my shirt sword up to critical. Gonna have to roll up my sleeves and start researching ideas. -

I didn't harden the tang. I did successfully harden and get the first tempering in. I had a warp about 3/4 of the way up the blade after the quench. I have a gas oven and I know it can vary greatly in temperature. I put the sword in the oven on my pizza stone with my cast iron wok, which is heavy, on top of the warp. Wouldn't you know it, the warp came out. I tempered it at 425 fire an hour and a half, second will be tomorrow after work.

-

You don't get any better your not trying. I like the shape on that top one. Look at the weight banner you're using as well. I started by using a 2 pound drilling hammer with a really short handle. It gave me a bit better control, though it still took me forever to get the hammer marks out. What were you thinking of doing for the handle?

-

What did you do in the shop today?

Chad J. replied to Mark Ling's topic in Blacksmithing, General Discussion

JHCC, what was the original piece? Bar stock square sock? I made a new quench tank for longer blades. It's 4 x 4 x 36 inches tall so I don't think I'll have to make another unless I start making sabers. -

What did you do in the shop today?

Chad J. replied to Mark Ling's topic in Blacksmithing, General Discussion

Chimera, my youngest daughter is into the goth scene and asked for a coffin shaped bookshelf, she wanted it stained completely black though I preferred the natural accents. Also thank you, I'm getting excited about finally finishing that blade though now I have to figure out a pommel. Frosty, thanks! I've toyed with the idea of making and selling those. It seems like there are a lot of people who just want Halloween all the time now and it was a fairly simple build. But that'll be when I get the shop set up completely. -

What did you do in the shop today?

Chad J. replied to Mark Ling's topic in Blacksmithing, General Discussion

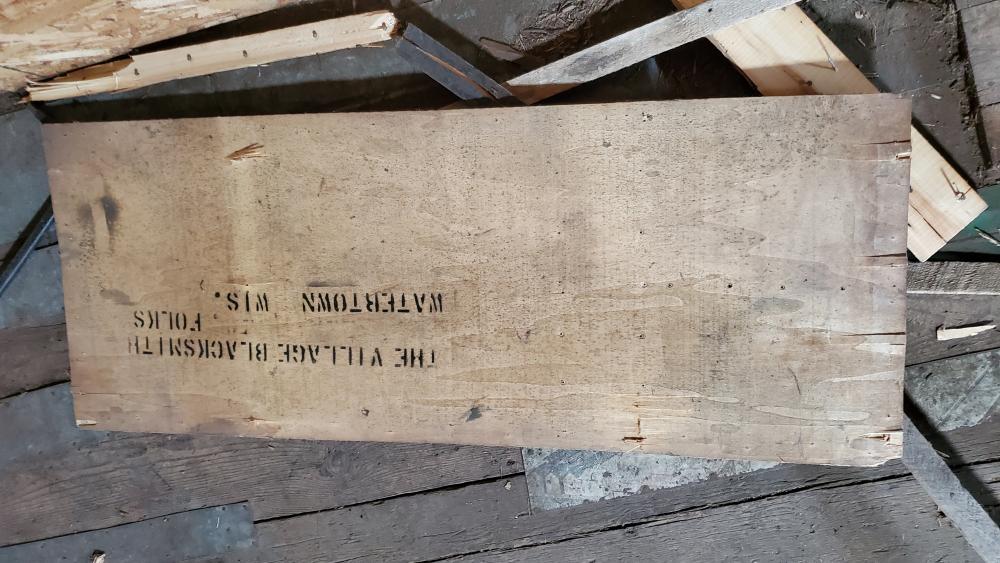

I was scrolling through Facebook today and what should come up but a reminder of a post from last year. It was my first attempt at forging anything. It had my make shift charcoal forge my railroad anvil and what I made. I was at the time attempting to make handles for a book case I made for my youngest daughter. I'll attach pictures of all. I've spent some money since then. You'll see I'm using a set of channel locks for tongs. I've come a little way since then. Oh, and what I was working on today is at the bottom. Fitting the guard and handle on my short sword. More on that in the sword thread. I don't think that's Shirley. -

I hadn't heat treated it yet because the work needed to be done on the tang. It would have wrecked it. I also have to make a longer quench tank.

-

Almost got the elk antler to fit today, though I did have to thin down my newly welded on tang and I'm going with a different pommel now that I'll have to make but there's finally progress again on this. The knuckle bow and rear guard are out of proportion but that's a simple fix. For the tang I welded it up several times then took it to critical and let it air cool. There were no signs of stress cracks or uneven heat. I'm happy.

-

What's your latest blade look like? Post em and let us see.

Chad J. replied to HondoWalker's topic in Knife Making

That looks good JPoor. I like the angle for the handle to blade. What steel did you use? -

Went and filled my propane tank yesterday and had money follow me home when the attendant bought a steak flipper from me, totally didn't expect that. A coworker gave me a piece of hex shaft. This should be good for me to learn with. It's a 5 foot long piece I'm going to test it to see how it heat treats.

-

Has anyone tried this brand out? I'm looking at a mid grade grinder, my cheap 4 x 36 grinder was not made for metal and the dust created a short in the motor. Not unexpected. I'm in my initial research phase now.

-

What did you do in the shop today?

Chad J. replied to Mark Ling's topic in Blacksmithing, General Discussion

-

Grabbed the cutting blades off the Cat loader at work. They're at end of life so they're worn almost perfectly round on one side. Since my anvil has a bad swayback to it I'm going to set one of them up as a striker/straightener for the longer blades I want to get into the other I may section and make an upsetting block and other things I don't know to make yet.

-

What did you do in the shop today?

Chad J. replied to Mark Ling's topic in Blacksmithing, General Discussion

The handle is a 2 part acrylic or epoxy. I have a friend who turns pens that showed me how to make it and we mixed a batch up. The antler hurt like crazy, it pierced the bottom of my foot. They can't stitch it for fear of infection and I walk 6 or so miles a day at work. -

Its got a convex edge right now, I'm going to have to run and get my wet grinder to get it a flat grind but I like how this shaped up. I may leave it like that and not do a folding handle.

-

What did you do in the shop today?

Chad J. replied to Mark Ling's topic in Blacksmithing, General Discussion

I was off work today due to an unfortunate injury to the bottom of my foot Sunday night that involved my girlfriend's dog's deer antler that was in a dark hallway with a tine pointing up. Anyway I went over to my shop that has power and did since finish work on a couple blades. I'm happy with them. I'm debating doing anything else with the razor or leaving it as is. Just have to sharpen them. KMD, no one judges stick welds unless you're doing them all the time. -

Found it! It slipped between the couch cushions. Finished shaping and quenched it. I'm thinking hickory for the handle.

-

You'd misplace that too?

-

Wouldn't you know it, I brought it inside set it down and now have no idea where.

-

He said mokume, but I'll direct him to JPH'S store. He may want the mokume just as a decoration piece with no iron in it.

-

Nice, can we see how the knife looks on it?