-

Posts

159 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by NoGoodWithUsernames

-

Where on Earth kind I find this fence bracket!?

NoGoodWithUsernames replied to Phillip-SC's topic in Problem Solving

Those are quite a bit larger than I had initially thought! The test pieces look like they turned out well. -

Where on Earth kind I find this fence bracket!?

NoGoodWithUsernames replied to Phillip-SC's topic in Problem Solving

Hopefully this doesn't get cut for being a commercial site. Actually I just won't post the link. But go to open builds parts store and search for "Cast corner bracket" it isn't exactly what you're looking for but might be easier to modify those to make them work than fabricating a bunch from scratch. Edit: apparently after modifying the link it still takes you there somehow, if the mods can fix it but still keep the web name for the OP so he can find them that's fine. -

Oak chest project (picture heavy)

NoGoodWithUsernames replied to Jobtiel1's topic in Member Projects

Great tips everyone, and thanks for the inspiration Jobtiel. I'll post up a thread with some photos once I've got it completed. -

Oak chest project (picture heavy)

NoGoodWithUsernames replied to Jobtiel1's topic in Member Projects

Thank you for the correct terminology, that is always helpful. Any tips on clenching nails? -

Oak chest project (picture heavy)

NoGoodWithUsernames replied to Jobtiel1's topic in Member Projects

How did you attach the handles? I am working on a small chest like this, and I was thinking of nailing the handles on where the ends pierce through and folding them over into a staple on the inside like you see on really old door hinges. I assume you used screws on yours? How have they held up to being picked up and moved around? Any issues with them pulling out when the box is loaded up pretty heavy? -

If you're making anything like that you'll more than likely be using bolts and a welder. What type of metal you use depends on what you are wanting to make. You don't build your floor out of 2x4s, you put a sheet of plywood down. The same goes for metal, pick a shape that works for what you are doing. Your question is too broad, there is no general "this is the right way" answer to what you are asking. If I was making a bed frame I would use angle iron to hold the mattress just like a commercial bed frame with maybe square tubing for the legs. For an all metal box I would start with thin sheet material use a combination of cutting and bending and probably welding. The only time I've ever seen an all metal "desk" is a welding table. Most of the time you'll combine materials. Ex you'll make some legs with brackets that you can screw to the bottom of a wooden desk top. Anything can of course be done with hand tools, electricity is a relatively recent thing. Of course by hand takes longer but hand drills and files and wrenches can make a lot of stuff. Add a welder and you can make almost anything with some creativity.

-

George, I was looking at the photo earlier and noticed on the more pristine swage block on the right you can clearly see wear around some of the more commonly used holes. So obviously they were used for something, like you say perhaps holding bottoms tools or the like. But clearly there were are few that were used quite a bit and some that don't look used at all.

-

Help with a messed up Heat Treat

NoGoodWithUsernames replied to RobertMorman's topic in Heat Treating Knives, Blades etc

From what I've read grain growth comes from being at heat without being worked. Heat soaking basically. I don't know how that plays with the quenching and tempering but my first though would be it was sitting in the forge too long while you were doing the normalizing cycles, or possibly while forging if you were doing other things at the same time. -

Coming up With a Touchmark Design

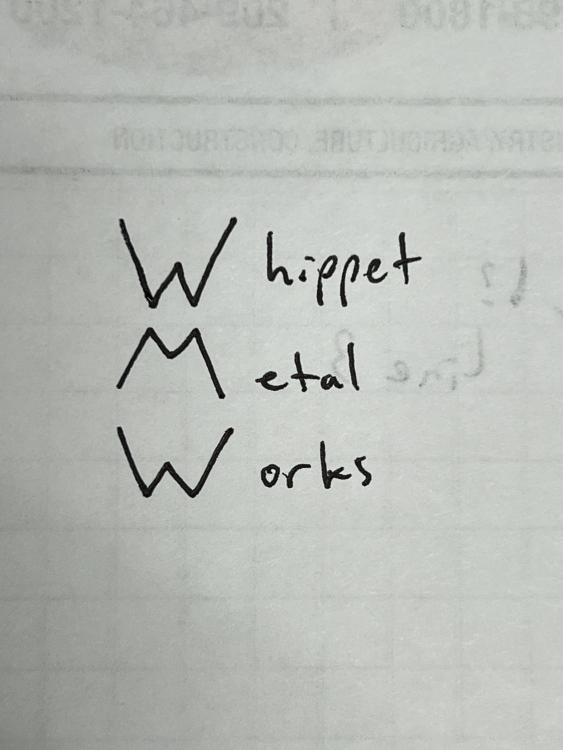

NoGoodWithUsernames replied to NoGoodWithUsernames's topic in Tools, general discussion

I think I have finally settled on a design. I really liked the mirrored look that Hefty was playing around with but wasn't happy with a name yet. This is just a quick sketch of what I am 95% sure I am set on, the touch mark would just the the WMW portion and on things like business cards and such I would probably make those three letters either slightly larger or bold to emphasize them. It will need some refining to see if I like it better with letters touching, or with some space, and fonts etc but this is the general idea. Also for those wondering, I do in fact have a Whippet, his name is Kirby and he is an absolutely fantastic dog. Great breed if anyone is looking for a new pet! Few health issues and as long as they can get some zoomies out for a few minutes a day they make good couch potatoes the rest of the day. Kirby hangs out at work with me all day and spends most of it napping and the rest of the time trying to get attention from FedEx and UPS drivers that are dropping stuff off. As always I appreciate the tips and feedback that everyone has given! -

Having learned on GMAW I bought a Lincoln unit from Home Depot ages back. Still on the same tank of 100% CO2, have a backup of 75%/25% to try out for when I run out of the CO2. It came with a spool of flux core wire but I've never bothered to try it out, only time I could see it being useful is when welding somewhere besides your welding table. But the tank of CO2 weighs next to nothing compared to the welder so again, I've never felt the need to try the flux core. I've never had an issue with spatter, I'm using some .030 wire now and it gives a little more to clean up than I had running .025 wire but most of it pops right off with a screwdriver swipe. Not as clean as my TIG at work but still pretty clean. My $0.02 is give the gas setup a shot. Can always sell the setup off if you don't find yourself using it much and recoup some of the money. Keep it in good condition and it shouldn't lose too much value.

-

Looks good, I like it. The only thing I would change personally is taking off the sharp corners on the base. Though going from that sharp edge raw stock transferring to the smoother forged look may well have been an intentional design choice. Looks good either way. I like that you used a piece of oak with those small cracks, gives the piece some nice character.

-

What did you do in the shop today?

NoGoodWithUsernames replied to Mark Ling's topic in Blacksmithing, General Discussion

Thanks for all the kind words folks. I am sure both will be well received come Christmas but nice to get some feedback from fellow smiths. Goods; what are you working on? As it stands that looks like a cross guard for a smallsword or epee in the works. Thomas; speaking of a brave man, do they have mirrors in the hospital? Glad to have you back on the forum. Been praying for you and your family, though I've never met you, the more the merrier in that regard. Have lost several folks I know to different types of cancer, but also know several who have beaten it too, so keep on out stubborning the darn stuff. Fighting with a gamma ray knife sounds positively sci-fi though. -

What did you do in the shop today?

NoGoodWithUsernames replied to Mark Ling's topic in Blacksmithing, General Discussion

Not "Today" per-se but over the last several weekends have gotten two Christmas presents done. One for my mom and one for my MIL. A potted plant hanger after the style of the one Joey VDS made a while back from railroad spikes, and a set of dragons to hang on the wall and hold a sword in the MIL's library. Hopefully the photos are all small enough, I tried to keep them all under 2mb. (For some scale the back plate on the hanger is about 9" tall, and the hook is 1/2" square bar. The placques the dragons mount to are 8" tall pieces of 1"x4" {so 3/4"x3-1/2" for any not familiar with our weird lumber measurements}) I think I most enjoyed the hanger as it is all traditional blacksmithing and was very fun to put together. This was my first tenon joint, not that it's much different than doing a rivet really. I did tack weld the collar on the top with the MIG gun just to make sure it doesn't open up over time. It is finished with beeswax applied hot. And I'm supplying two pyramid head lag screws with it to attach it to a wall or pillar or whatever it ends up on. The dragons were a lot of welding and filing and carbide burring to get all the fingers and arms and tails attached. There was plenty of forging shaping the fingers and tails and arms and such but I am not good enough at this point to do some of these parts out of one piece, but I think they turned out looking nice. Used parts and stuff all laying around so didn't have to purchase any material which is always a plus. The dragons and mounting plaques are gloss clear coated, sorry that makes some of the photos kinda hard to make out. Feel free to give thoughts and criticisms, I am still learning a lot so none of it is perfect and I could find details I wished were better all day long. -

A day that will live in infamy.

NoGoodWithUsernames replied to Irondragon Forge ClayWorks's topic in Everything Else

Don't watch much news but it still is on our calendar at work. The wife and myself tried to go to Hawaii early last year and one of our major stops was to visit the memorial but Covid tests came back late and we had to cancel the trip sadly. -

What in nature are y’all thankful for?

NoGoodWithUsernames replied to TWISTEDWILLOW's topic in Everything Else

Geez! Not too long ago I had a whole clan of widows living under the bottom side of my VW. I think I went out a couple nights a week after dark with a flashlight and can of spider spray and kept spraying any I could find until no more popped up anymore. Had to have killed a dozen of them or so all told. -

My little cable friend

NoGoodWithUsernames replied to Pigsticker's topic in Blacksmithing, General Discussion

Pigsticker, I don't have a ton of experience with forge welding everything I have read and seen seems to indicate that light blows are better for setting the weld. Also a 4lb hammer must be a beast to swing! -

I've never met the man but he is a great resource on here always offering help. Glad to hear he is on the mend, and hopefully he will be able to be home with family for Thanksgiving.

-

Coming up With a Touchmark Design

NoGoodWithUsernames replied to NoGoodWithUsernames's topic in Tools, general discussion

Dang it George, you just had to go and make that connection huh? I doubt that I'll ever get big enough doing this as a hobby to make it over to the far side of the pond, so it may not be a huge deal... Reminds me of all the times big companies go to release something in a different country only to have a huge flop because of a name connotation or translation oversight. I have noticed that John Switzer has two touchmarks, one a small bear and one with the initials of either his name or his shop. I may do something like that where you can have both pieces when space permits but aren't constrained trying to fit everything into one touch mark. Thanks again to everyone who participated, have a very happy Thanksgiving! -

Coming up With a Touchmark Design

NoGoodWithUsernames replied to NoGoodWithUsernames's topic in Tools, general discussion

This is fantastic so far, thanks to everyone who has thrown ideas out there. I kinda like the mirrored WC, simple but looks good. Will have to do some pondering still and maybe sketch out a couple of these other ideas. If anyone else has anything to add feel free! Cheers to all and have a great weekend! -

Coming up With a Touchmark Design

NoGoodWithUsernames replied to NoGoodWithUsernames's topic in Tools, general discussion

That is a very fair point and one I didn’t realize until after I had printed out some cards of course! I like making anything though mostly ornamental or useful. Pokers, roasting sticks, coat racks. Thinks like that. One knife has been made by yours truly to date. We've got wild chickens in town a number of which roam our neighborhood. I enjoy building things. Machining, welding, woodworking, obviously Blacksmithing. I do a bit of sewing on occasion with my $20 thrift store vintage singer. I have an old VW Squareback and a Porsche (VW) 914. Nothing distinctive about the shop, just a tin roof lean-to next to the garage so that may be the least interesting part of the whole shebang ha! I can easily change the name and print some new business cards as well. Also thank you to the mods for moving this, I wasn’t sure if this should go in general, the business side or tooling since it’s a bit of a broad question. -

So I am generally a fairly artistic and creative person able to sketch design ideas and such. However, for the life of me I cannot seem to come up with a touch mark design, or even any ideas. Obviously it should not be too complex or you'll lose details or need an obnoxiously large mark. Nor do you want it to be too simple, you do want it to be recognizable. I have some business cards printed up and I called the forge "Backyard Blacksmith" since the forge is quite literally setup in my backyard. Anyone have any tips to get the design juices flowing or criteria to watch out for?

-

It followed me home

NoGoodWithUsernames replied to Glenn's topic in Blacksmithing, General Discussion

I can confirm a spring is not entirely necessary, I have still not gotten around to putting one on my post vise. However the way it is mounted it leans just enough that the jaw opens on it's own most of the time without any help. Occasionally I'll need to wiggle the piece in it to open the jaws and pull the piece out, but not usually. -

What did you do in the shop today?

NoGoodWithUsernames replied to Mark Ling's topic in Blacksmithing, General Discussion

Bring it in the house and give it a hot drink, seems to help things that are froze in the movies. -